Fixing device for loop laying tube of loop laying head

A technology of fixing device and laying tube, which is applied in the field of laying machine equipment, can solve the problems of large vibration of laying machine and weight change of pipe clamp, etc., and achieve the effects of good fixation, reduced vibration and avoiding welding process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

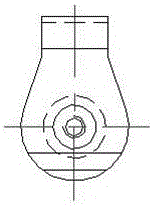

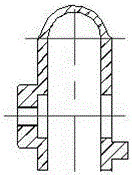

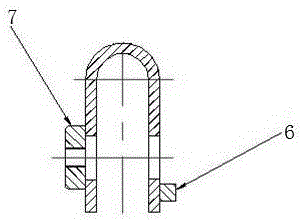

[0020] Example 1 : see Figure 1-Figure 5 , a spinning tube fixing device for a laying machine, the fixing device includes a spinning head 1, a spinning tube 2, a pipe clamp 3 and a fixing assembly, and the spinning tube is arranged on the spinning tube according to the Archimedes spiral On the head, the pipe clamp is arranged on the laying tube and the laying head, and the fixing assembly is used to fix the pipe clamp and the laying head. The fixing assembly includes a fixing pin 4 and a bolt 5, and the fixing pin 4 is arranged on In the pin holes of the pipe clamp and the spinning head, the bolts are arranged in the fixing pins. The fixing device can avoid collision between the pipe clamp of the laying machine and the protective cover, prevent the pipe clamp of the laying machine from being worn out, ensure the dynamic balance of the laying machine to be stable, and greatly reduce the vibration of the laying machine.

Embodiment 2

[0021] Example 2 : see Figure 1-Figure 5 , As an improvement of the present invention, the pipe clamp includes a weight block and a limit block 6, and the outer circle radius of the root of the pipe clamp is 30.5mm, which prevents collision with the protective cover and causes wear; the limit The position block and the pipe clamp are integrated to ensure that the weight of the original welded limit block is consistent; the bolt fixing block of the pipe clamp is integrally formed with the pipe clamp, which avoids the welding process and has good alignment with the pin hole; The number of the pipe clips is 13. The weighting block of the pipe clamp is integrated with the pipe clamp, which avoids the welding process, has high reliability, and will not cause desoldering during operation and use.

Embodiment 3

[0022] Example 3 : see Figure 1-Figure 5 , a method for installing a spinning tube fixing device for a laying machine, the installation steps are as follows: 1) first set the spinning tube on the spinning head according to the Archimedes helix; 2) set 13 tube jackets On the spinning tube and spinning head; 3) Insert the fixing pin into the pin hole of the spinning head and pipe clamp; 4) Insert the bolt into the fixing pin, and tighten the bolt to ensure the fixing between the pipe clamp and the spinning head Firm, the spinning tube is fixed by the limit between the tube clamp and the spinning head.

[0023] working principle:

[0024] see Figure 1-Figure 4 , the technical proposal proposes to remake the original pipe clamp into pipe clamp 3, and the radius of the outer circle of the root of pipe clamp 3 is reduced by 4mm to prevent collision with the protective cover and cause wear; the bolt fixing block 7 of the pipe clamp is integrated with the pipe clamp The weldin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com