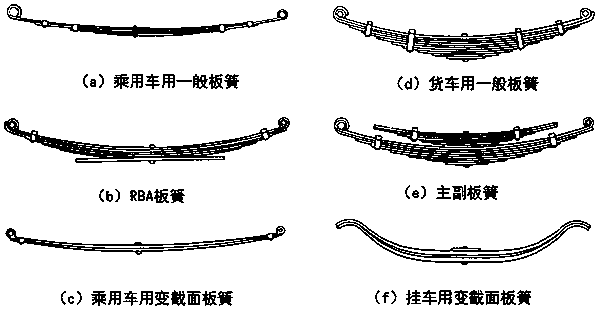

Leaf spring and manufacturing technology thereof

A leaf spring and manufacturing process technology, applied in springs, leaf springs, springs/shock absorbers, etc., can solve the problems of poor fuel efficiency, complex manufacturing process and low reliability of leaf springs, and reduce weight and use. The effect of huge cost and market value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0072] The technical solution of the present invention is described in detail below through the examples, and the following examples are only exemplary and can only be used to explain and illustrate the technical solution of the present invention, rather than being interpreted as a limitation to the technical solution of the present invention.

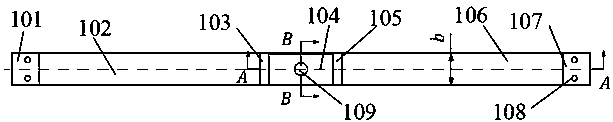

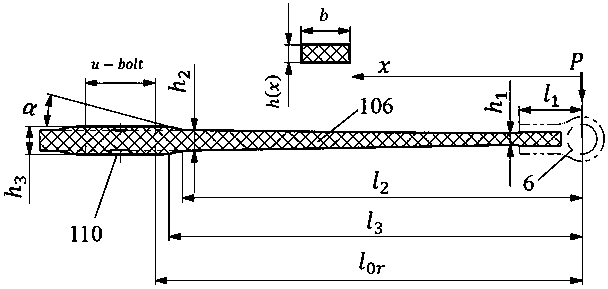

[0073] The present invention relates to the suspension component mechanism of the vehicle, specifically the elastic element of the suspension. According to the characteristics of the low allowable shear strength of the leaf spring and the force condition of the leaf spring, the present invention carries out the structural design of the FRP composite leaf spring on the premise of fully ensuring the life and safety of the suspension, and according to the leaf spring Design a set of rapid mass production process for leaf springs to meet the performance requirements, solve the design and manufacturing process problems of FRP composite leaf ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com