Patents

Literature

40results about How to "Improve local stress" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

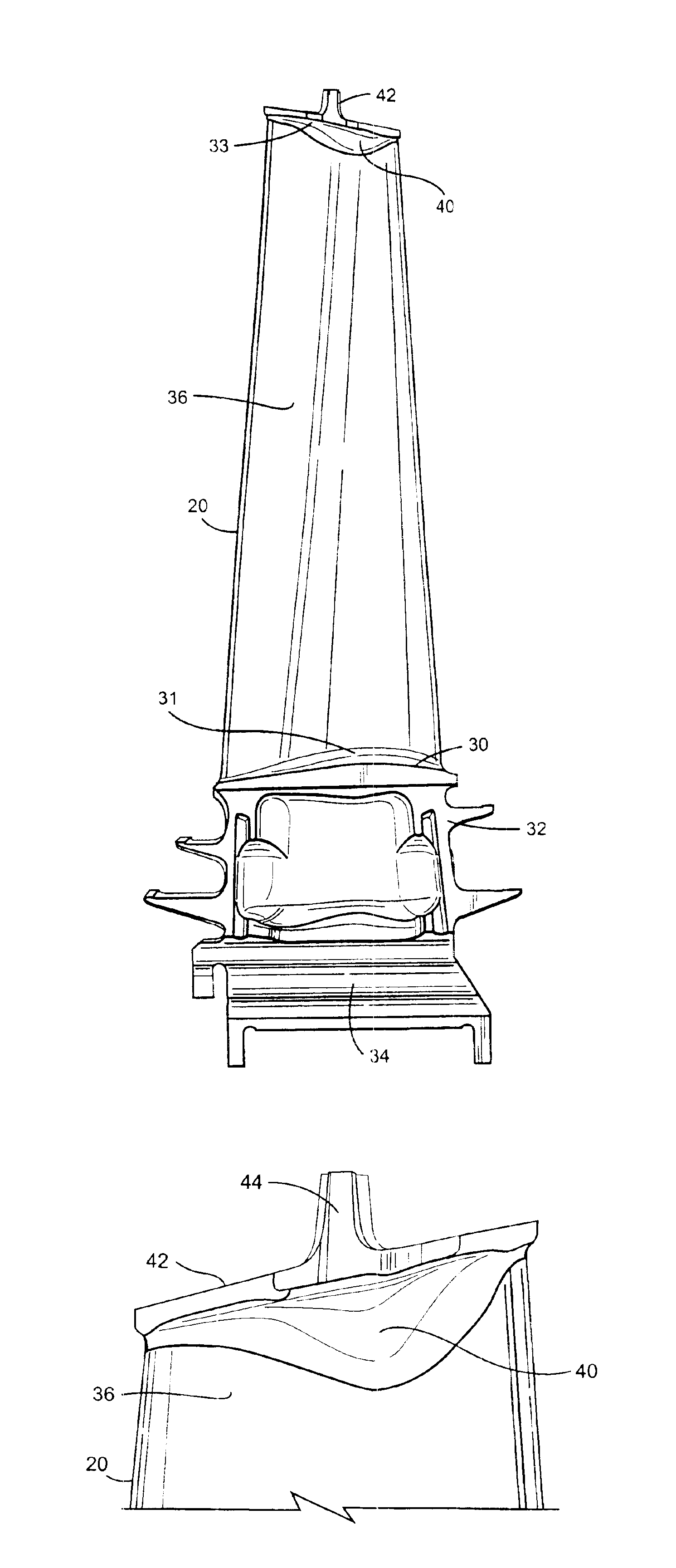

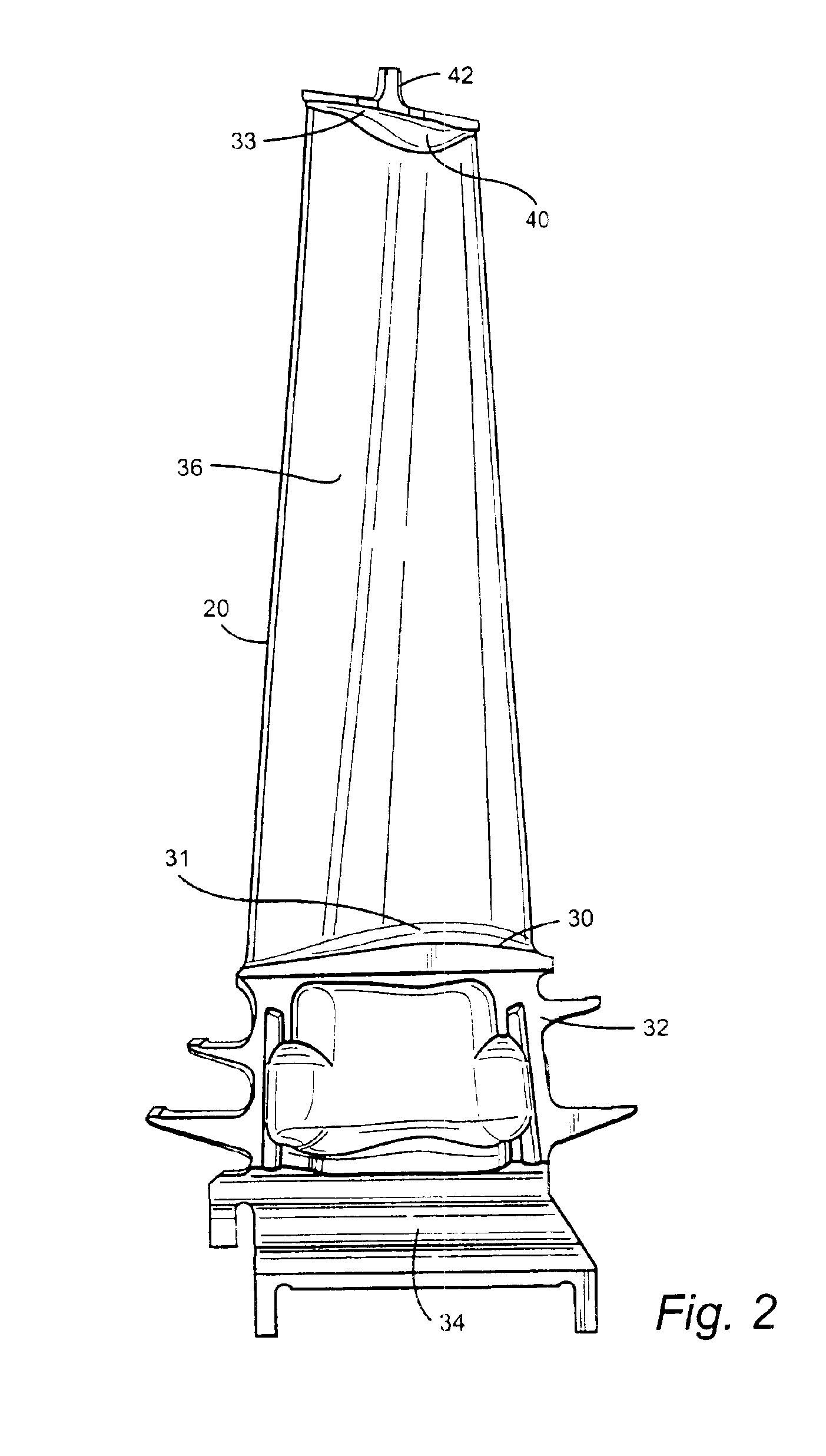

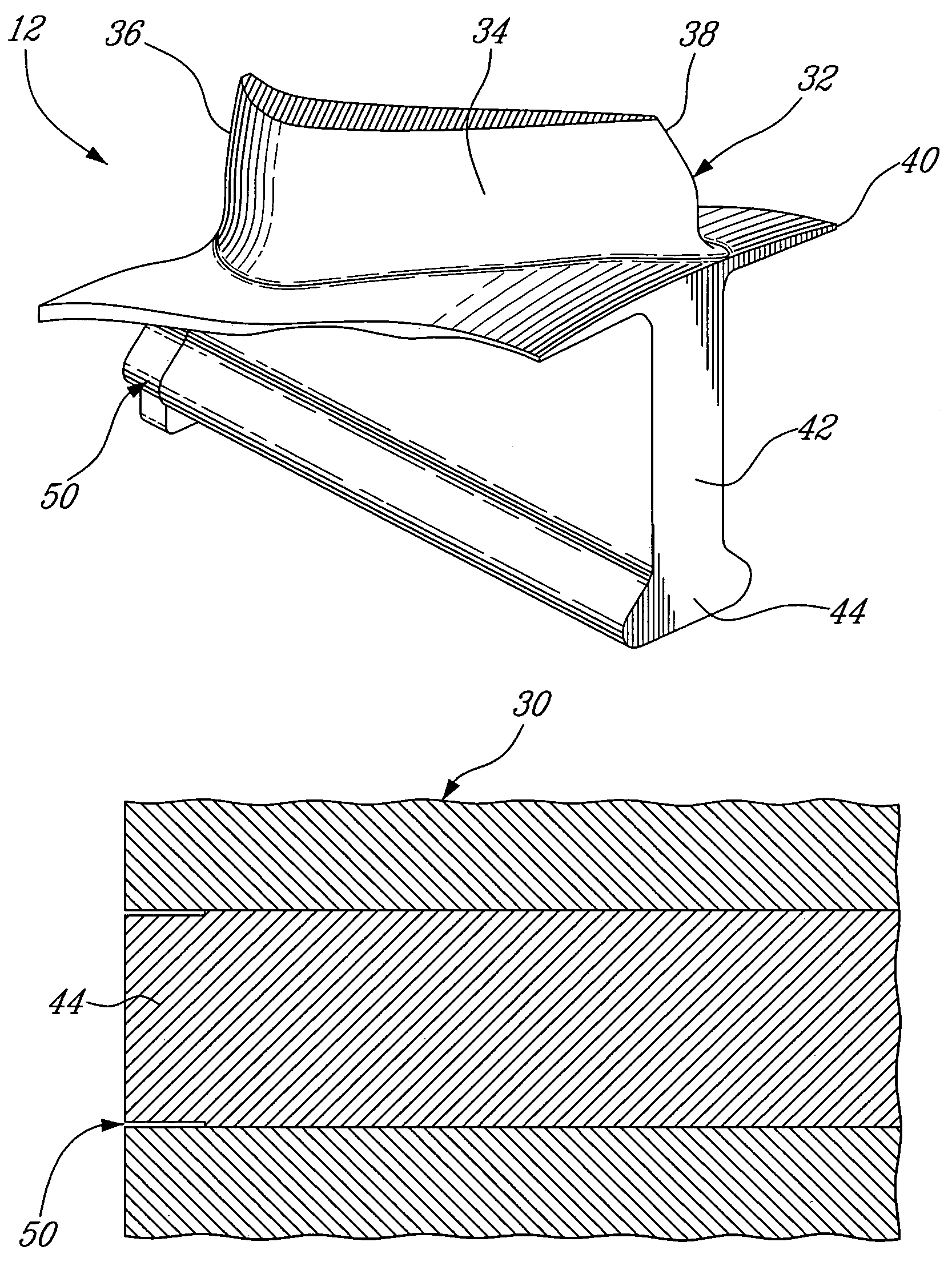

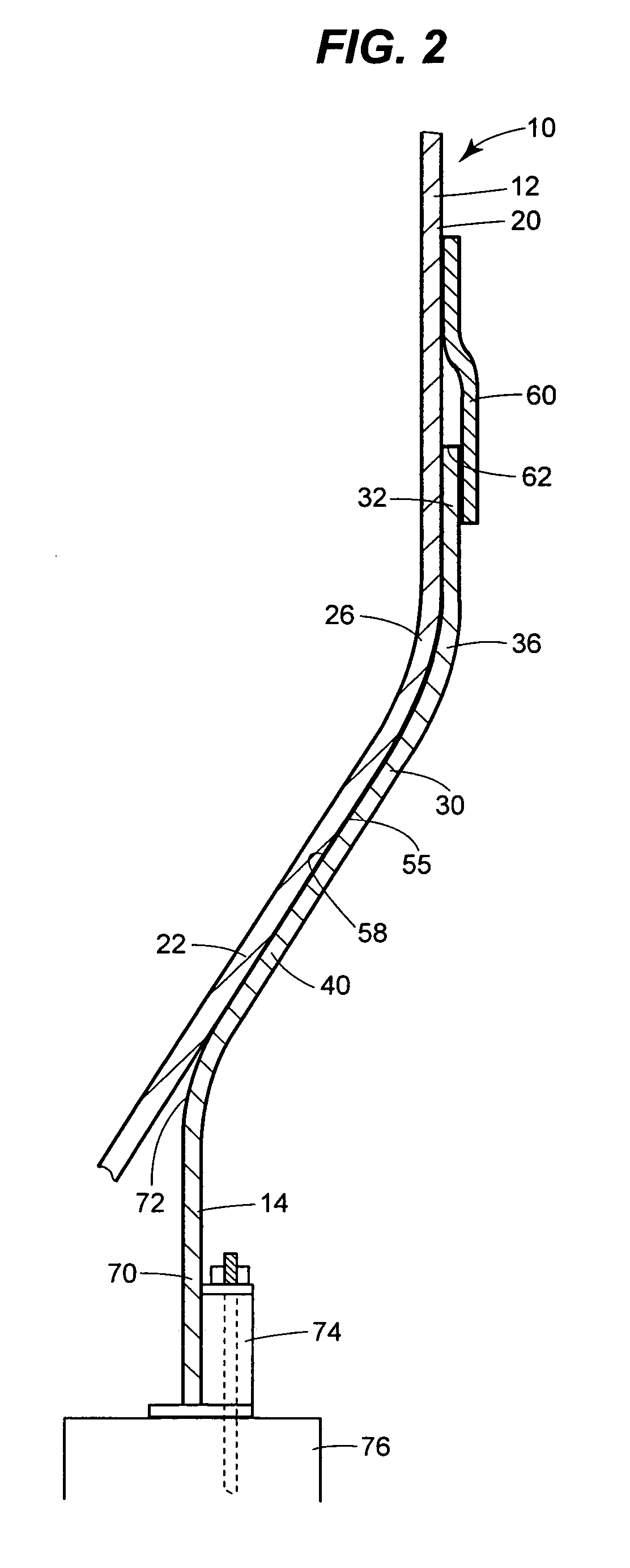

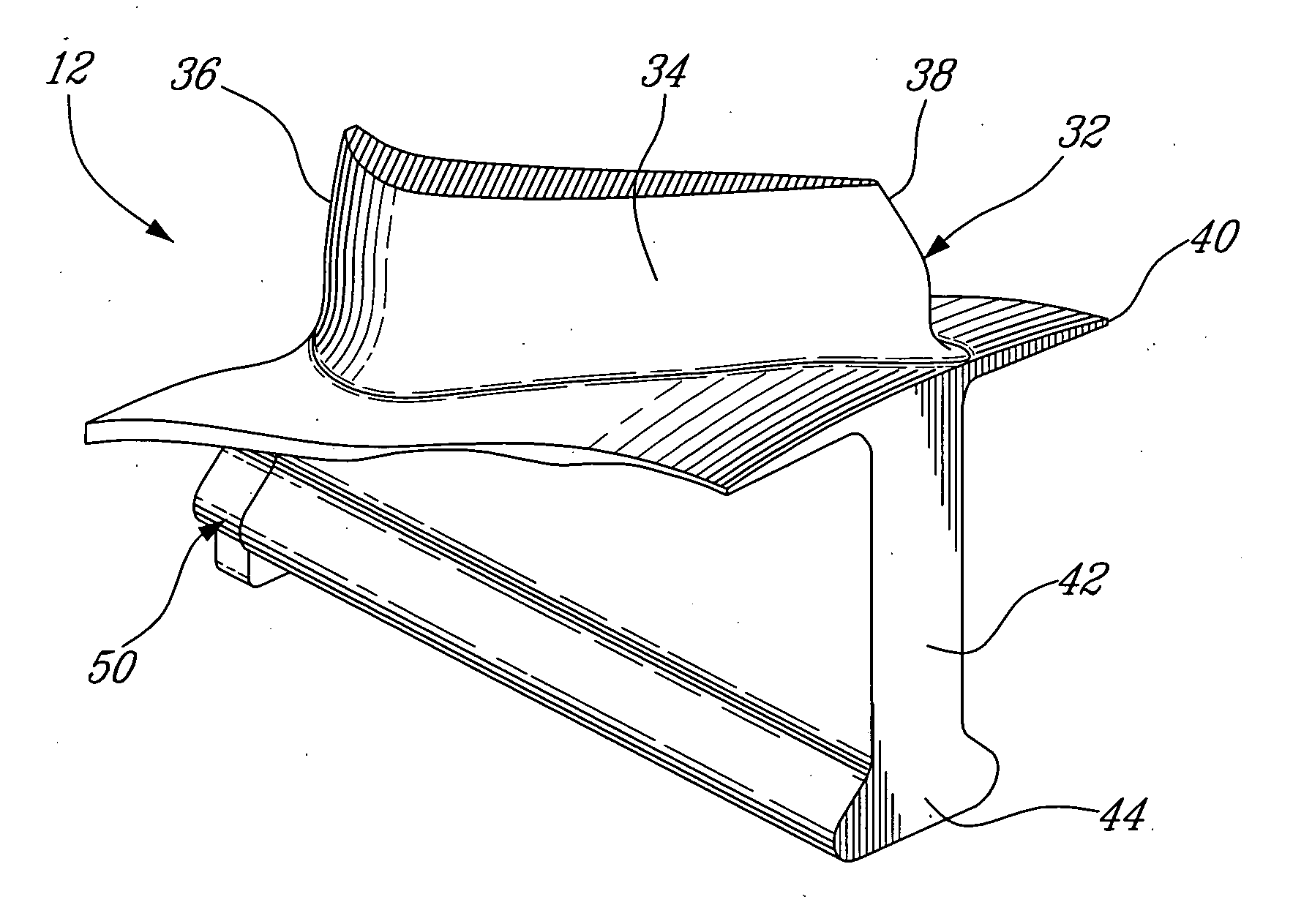

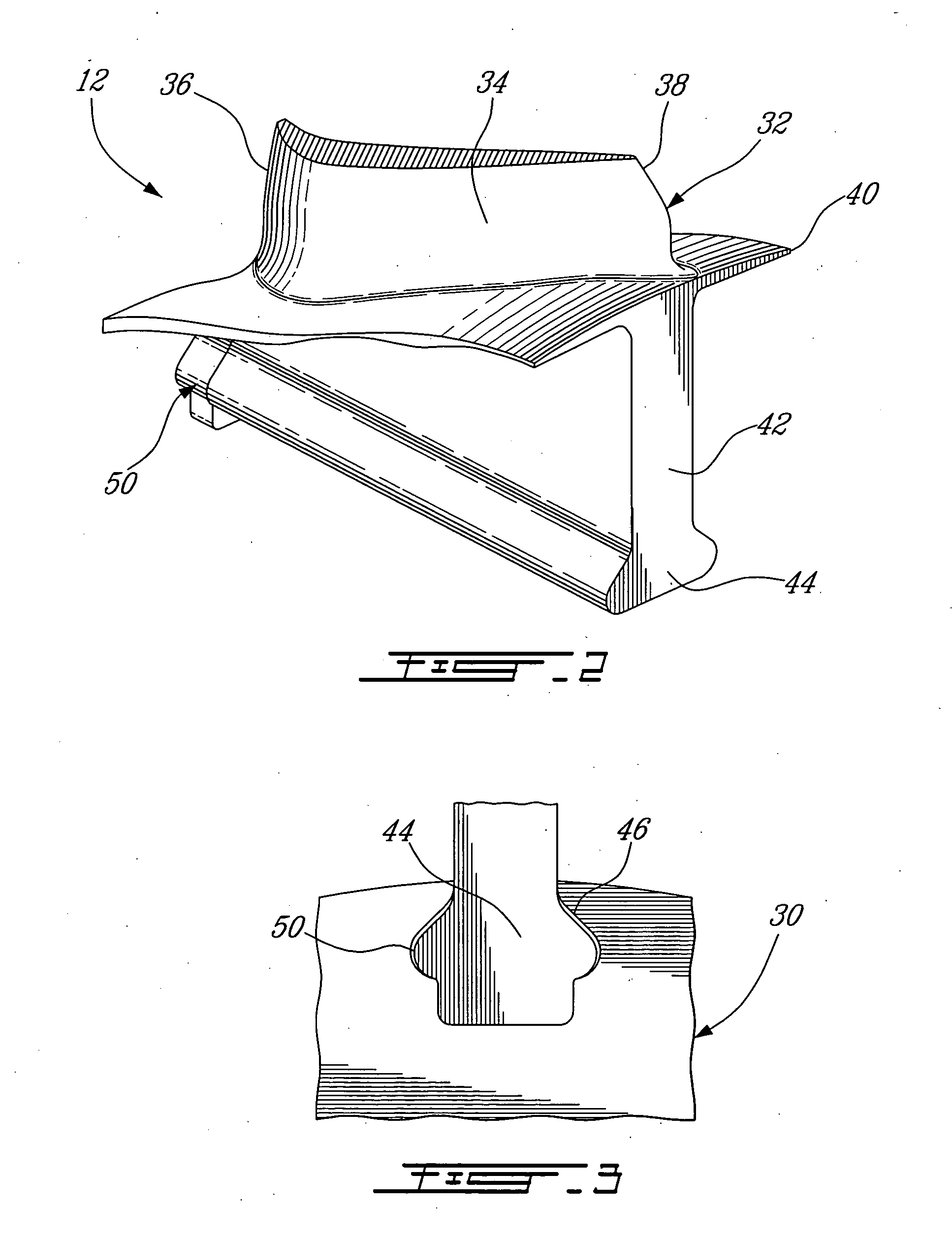

Conical tip shroud fillet for a turbine bucket

InactiveUS6857853B1Minimizes creep and massStress smoothPropellersEngine manufactureEngineeringTurbine

Owner:GENERAL ELECTRIC CO

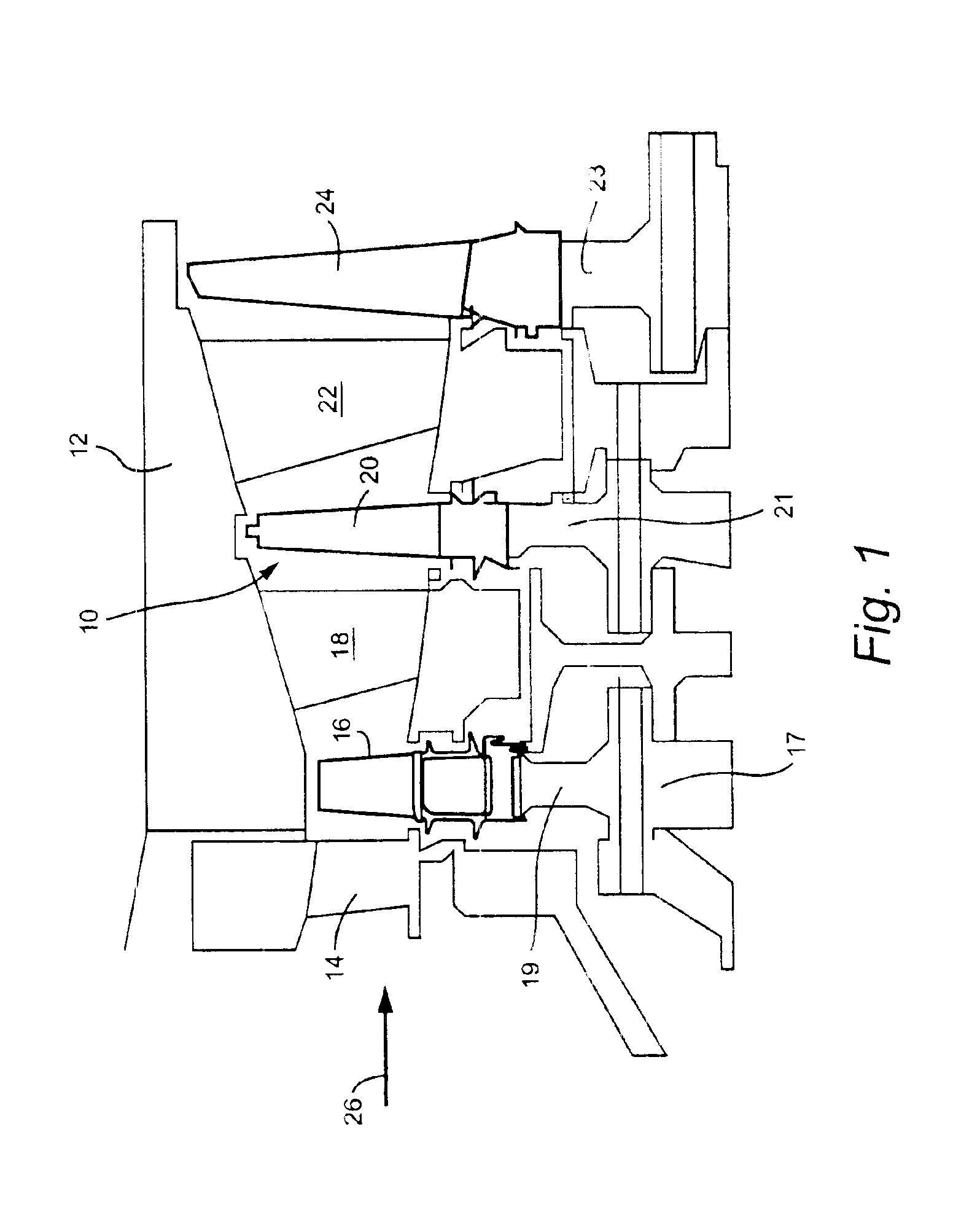

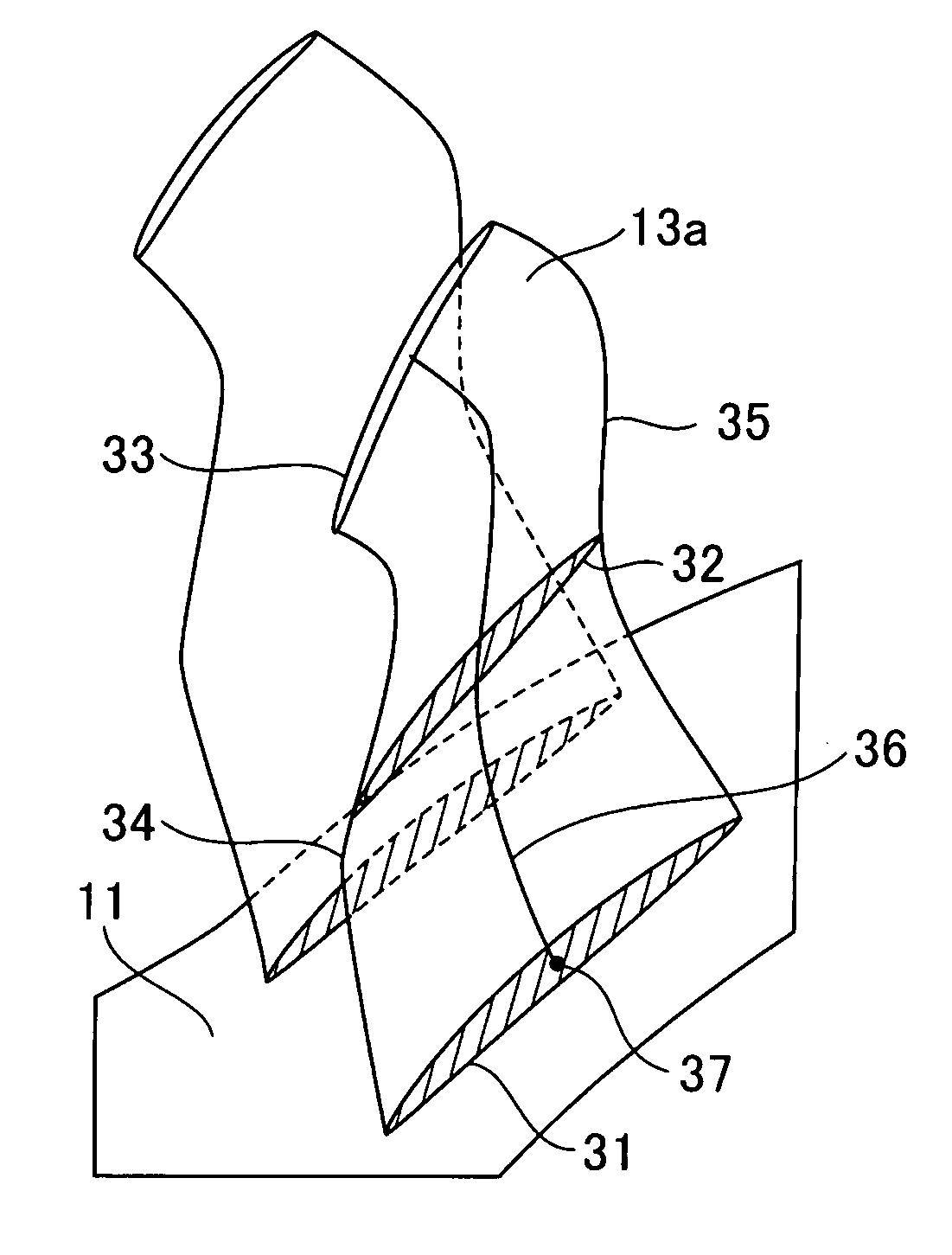

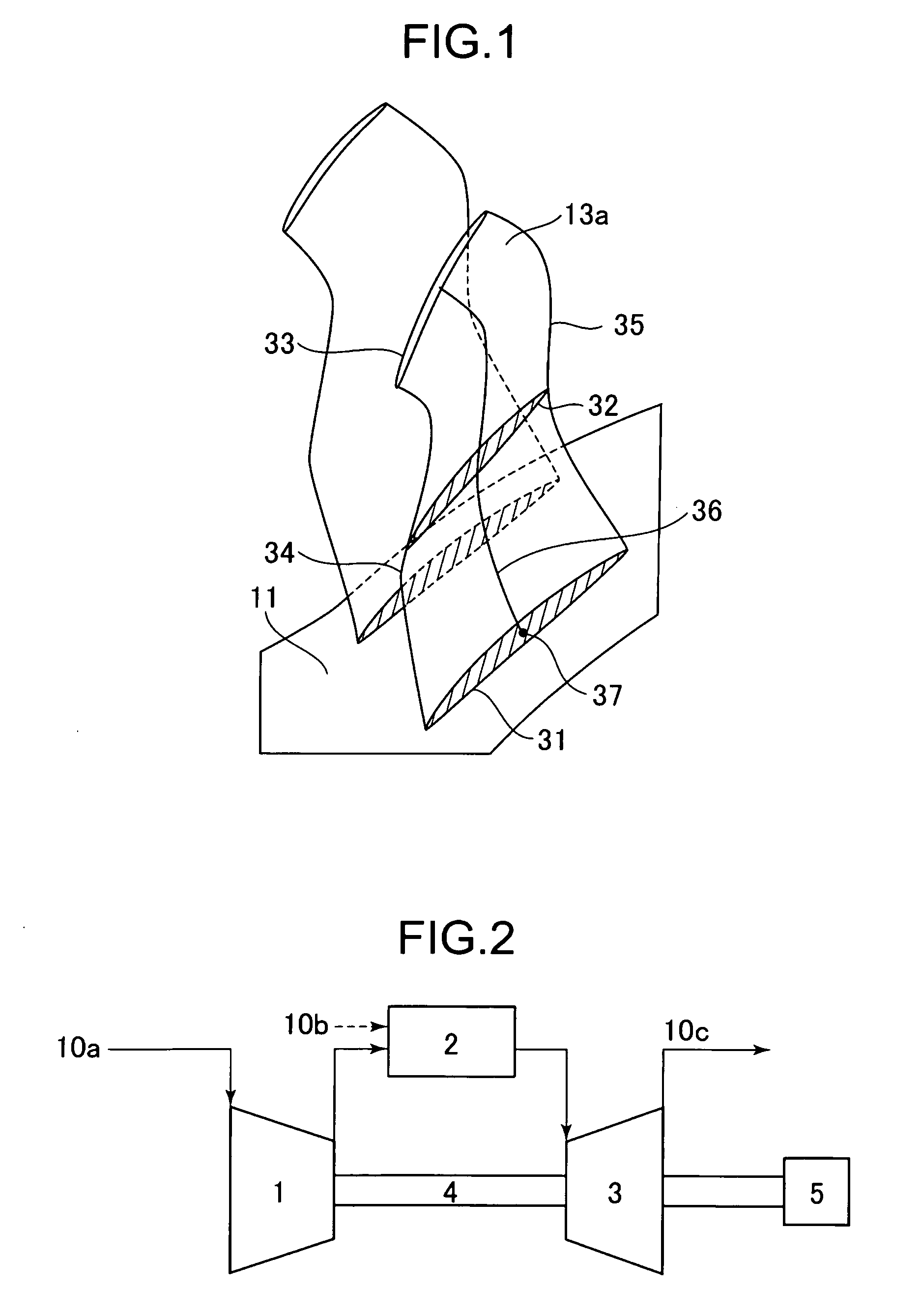

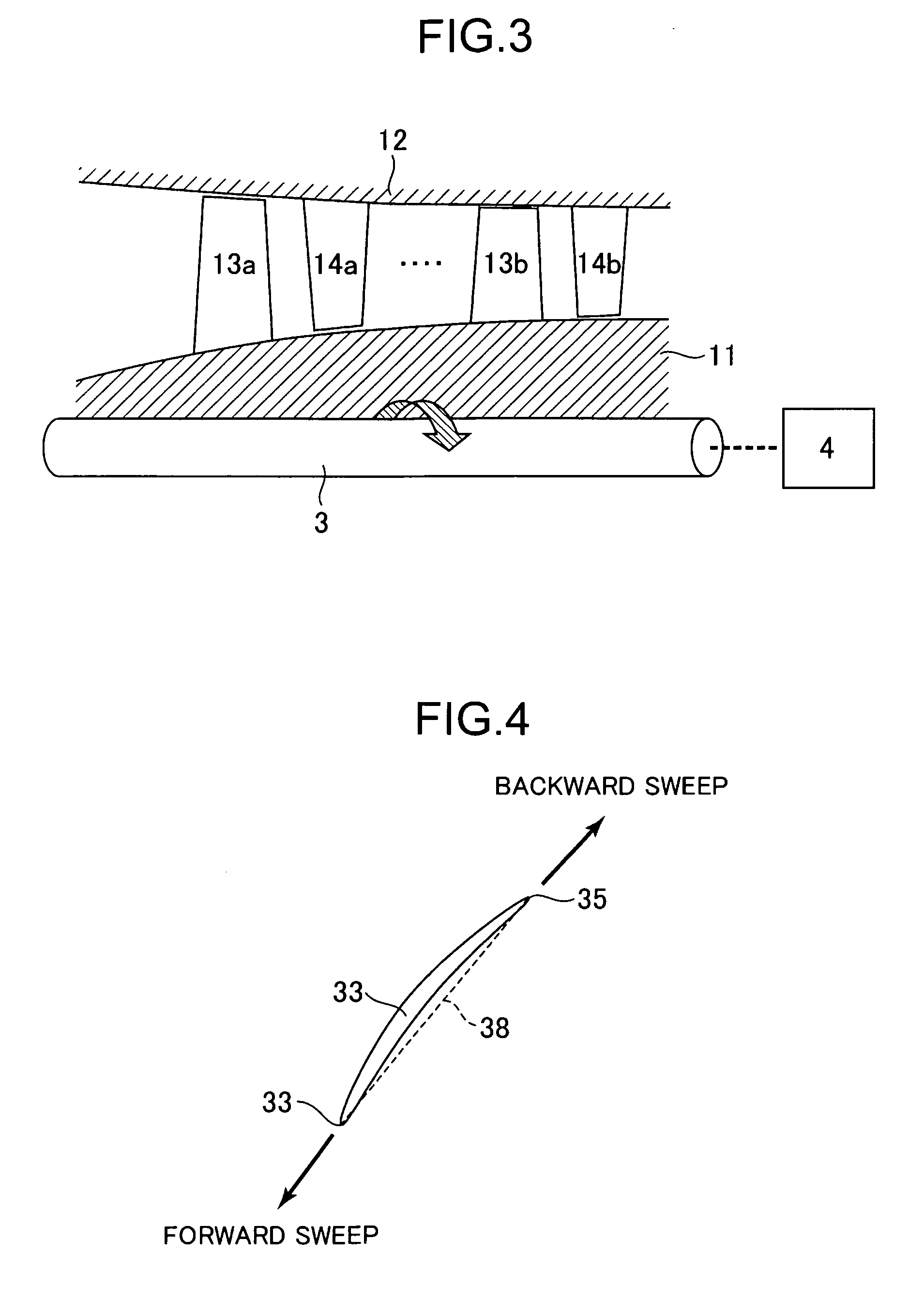

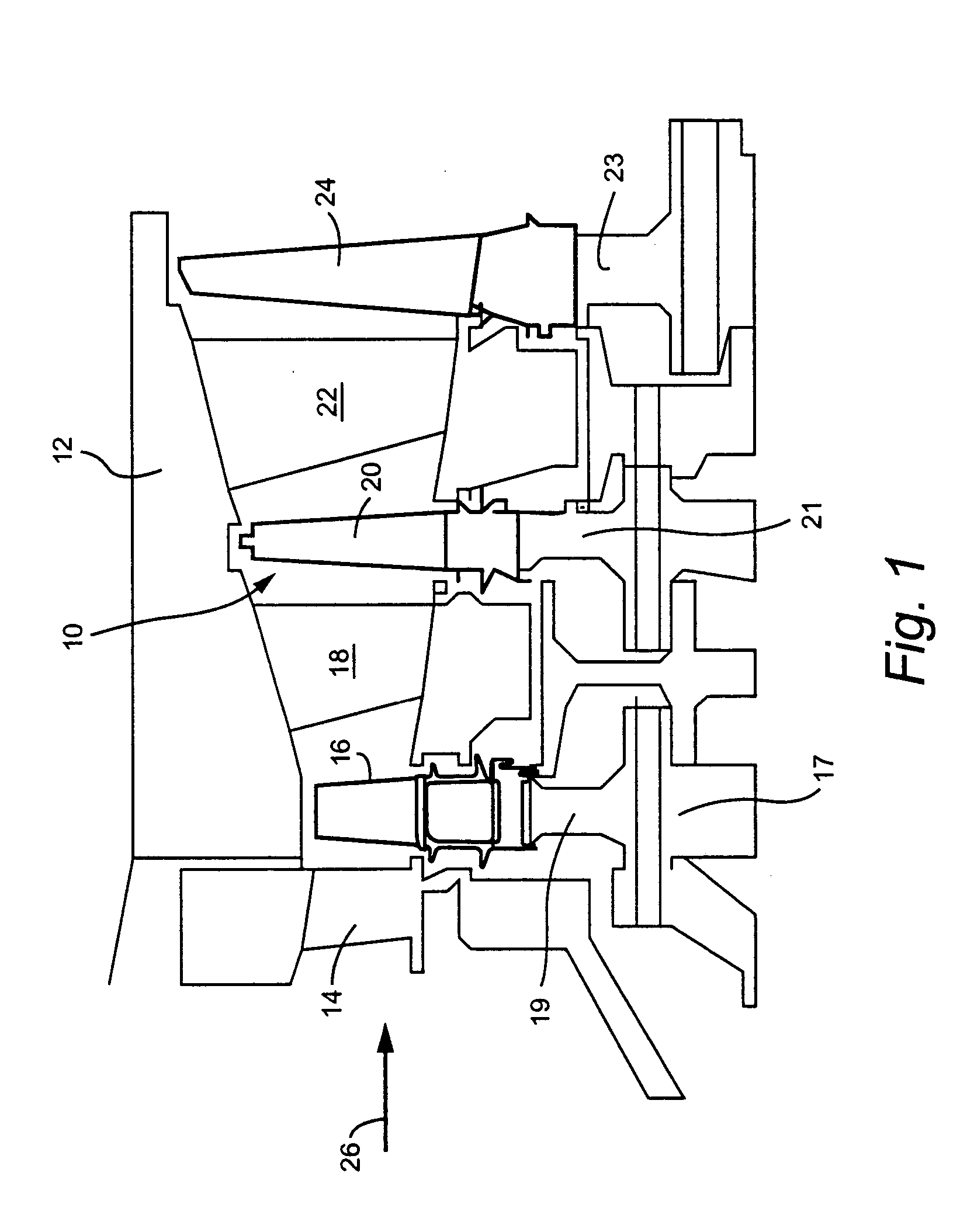

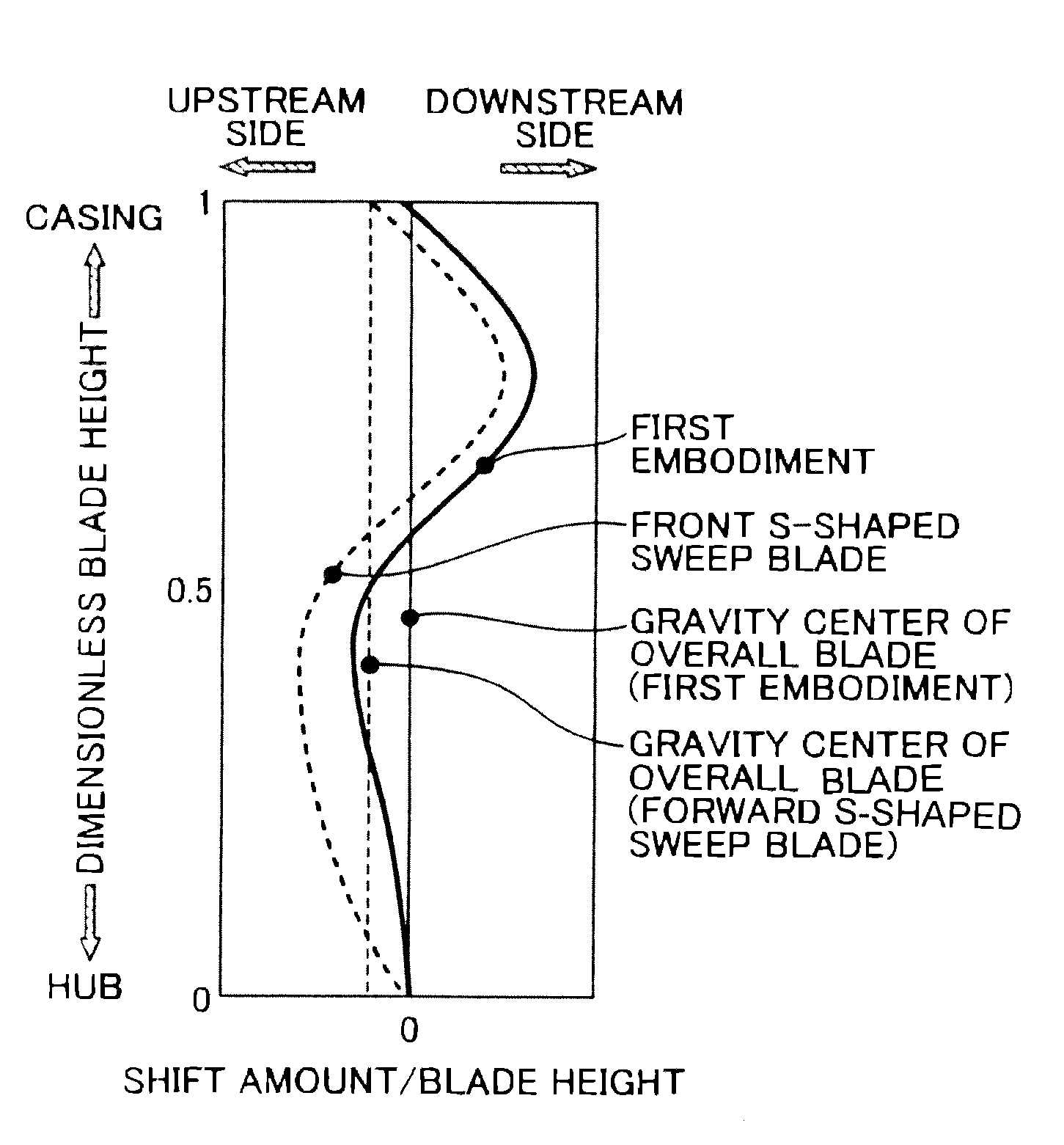

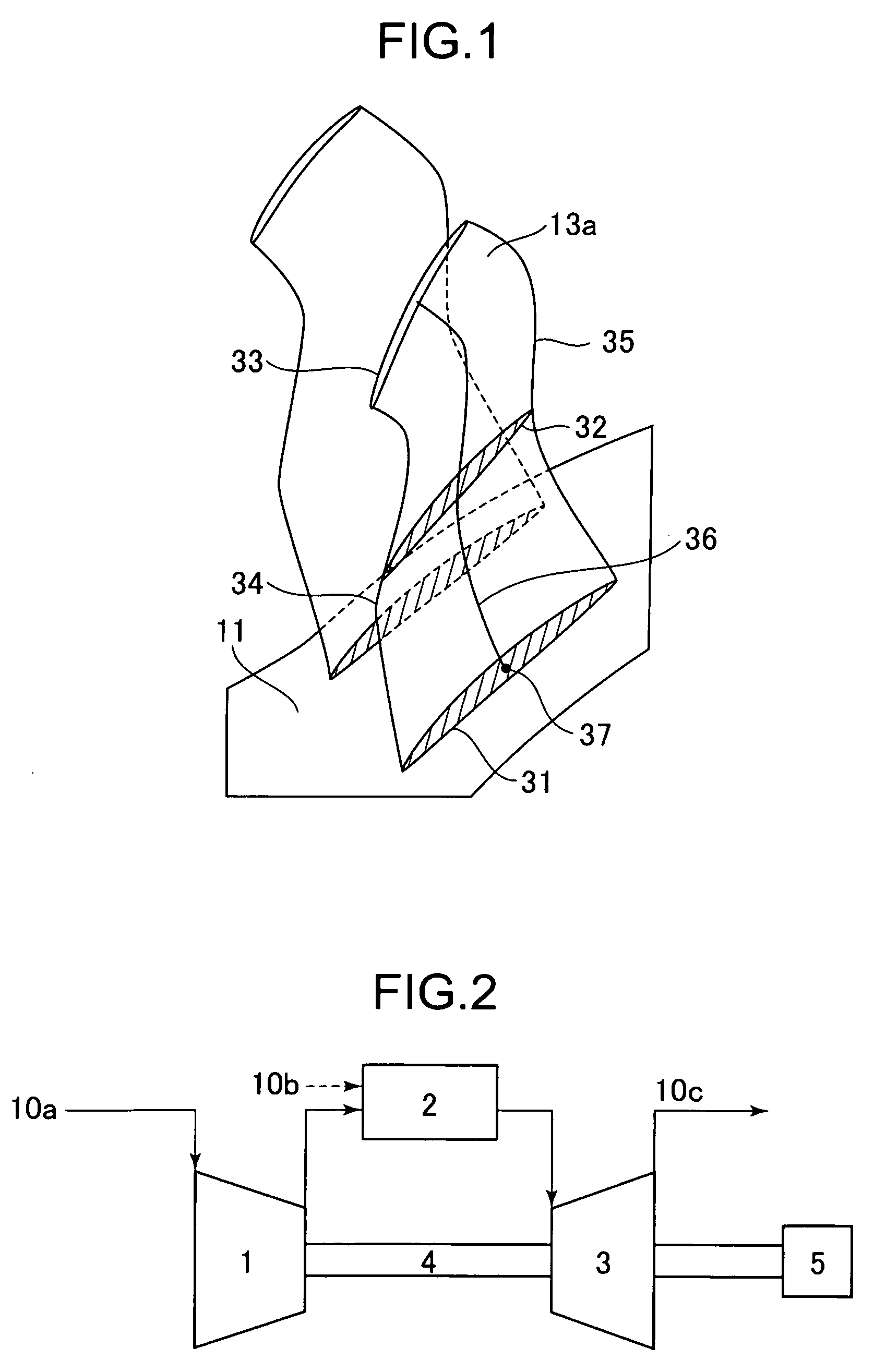

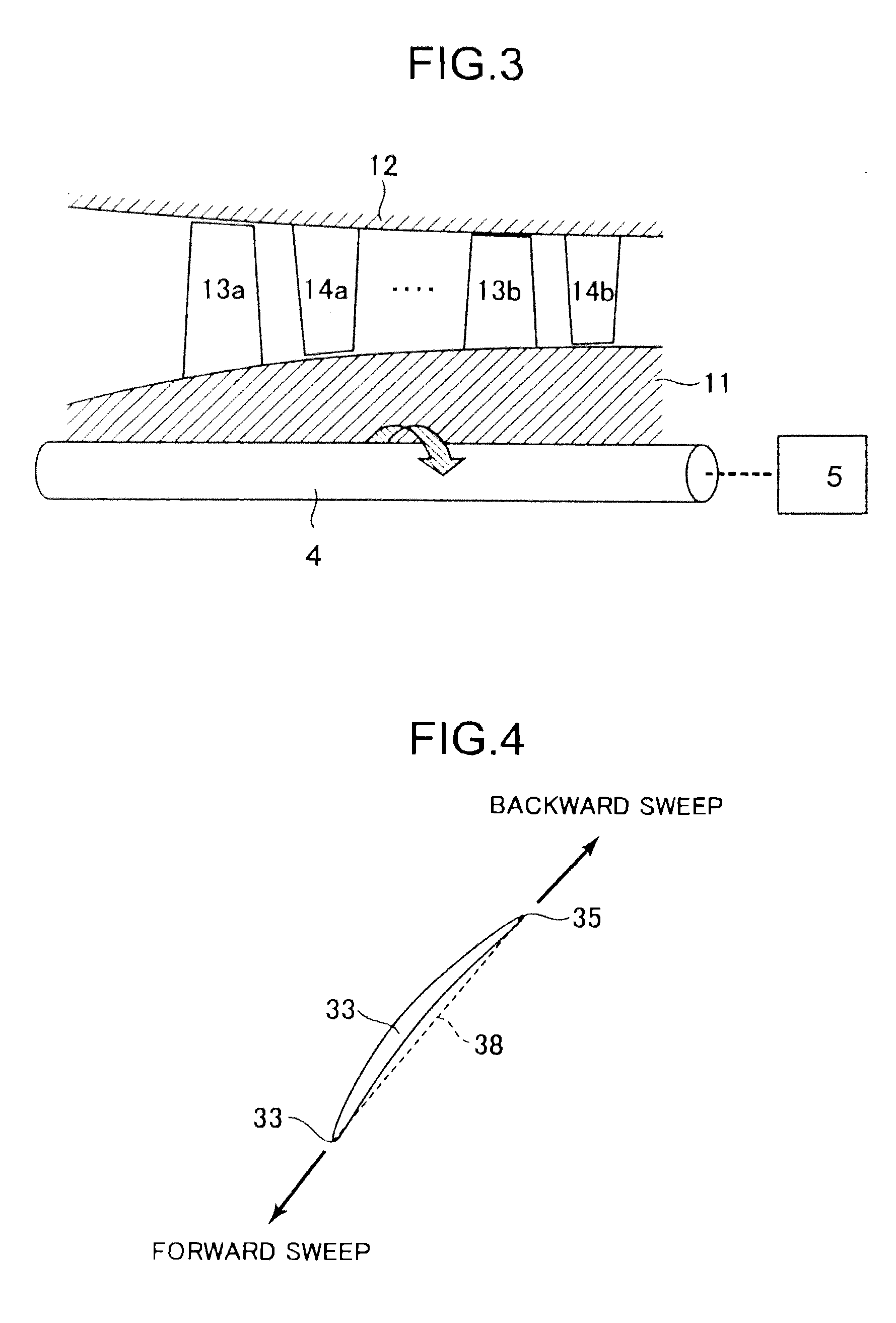

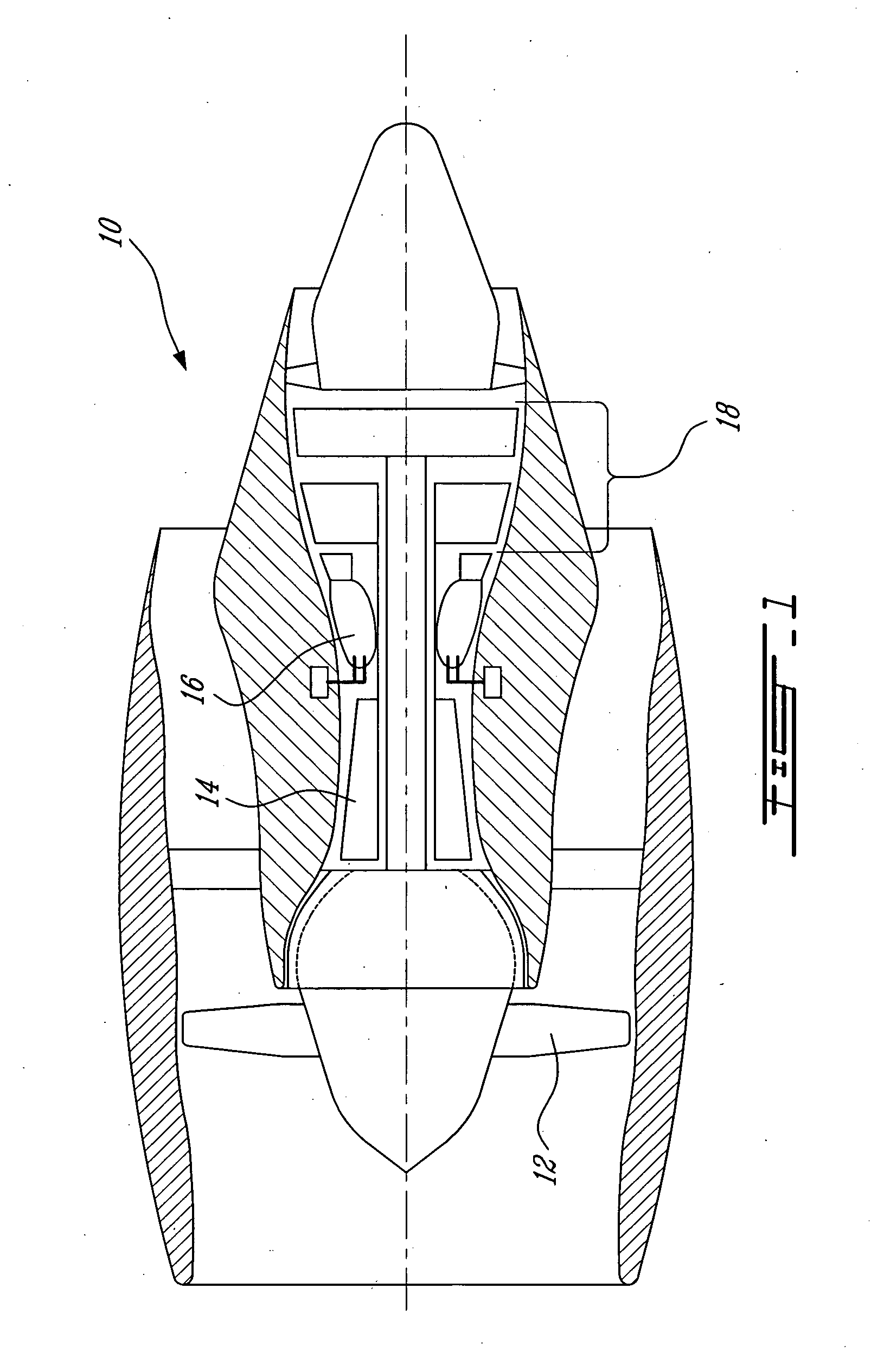

Transonic blade

ActiveUS20100215503A1Reduce various lossesImprove local stressPropellersReaction enginesLeading edgeWorking fluid

A transonic blade is provided that operates in a flow field where flow has a transonic speed or higher in an axial-flow rotating machine and that concurrently achieves a reduction in shock loss and in the local stress of the blade.The transonic blade includes a hub cross-sectional surface joined to a rotating shaft or an outer circumferential side casing of a rotating machine; a tip cross-sectional surface located furthest from the hub cross-sectional surface in a spanwise direction which is a vertical direction of the rotating shaft; a leading edge located on an upstream side; and a trailing edge located on a downstream side. At least a part of a passing working fluid flow has a transonic speed or higher. A portion of a stacking line which is a line connecting together respective gravity centers of cross-sectional surfaces located from the hub cross-sectional surface to the tip cross-sectional surface is located on a downstream side of a stacking center in a flow direction of a working fluid main flow.

Owner:MITSUBISHI POWER LTD

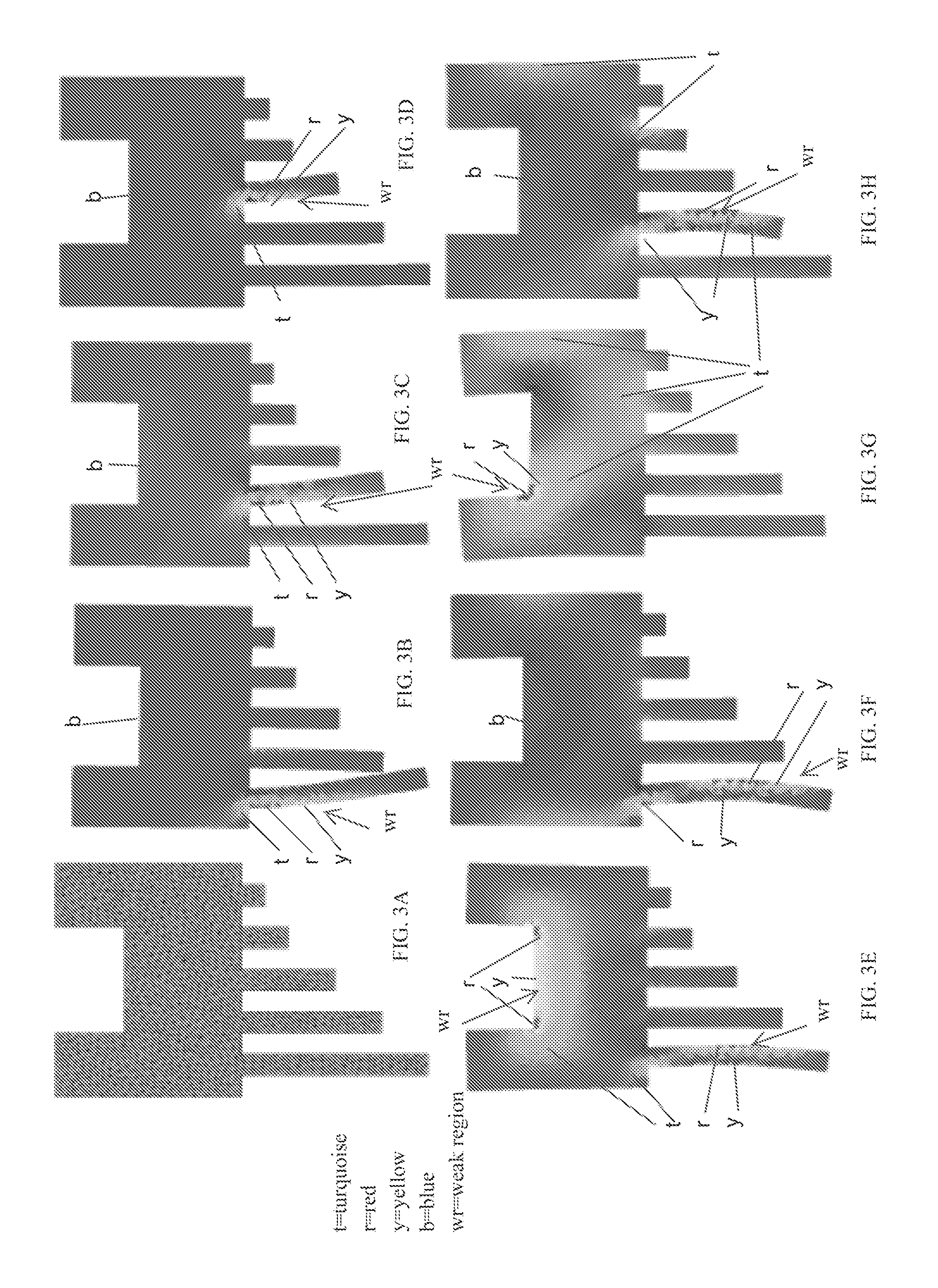

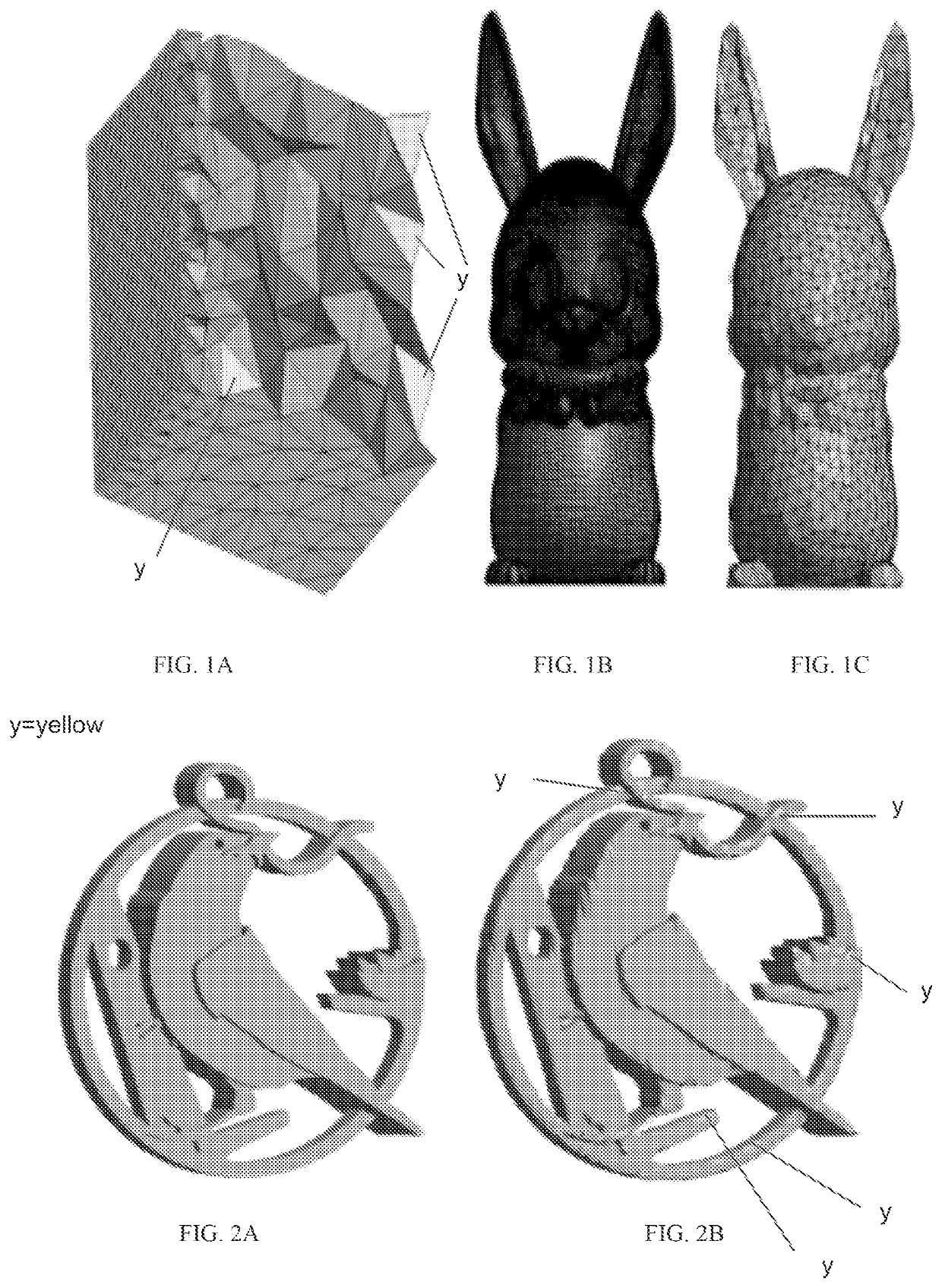

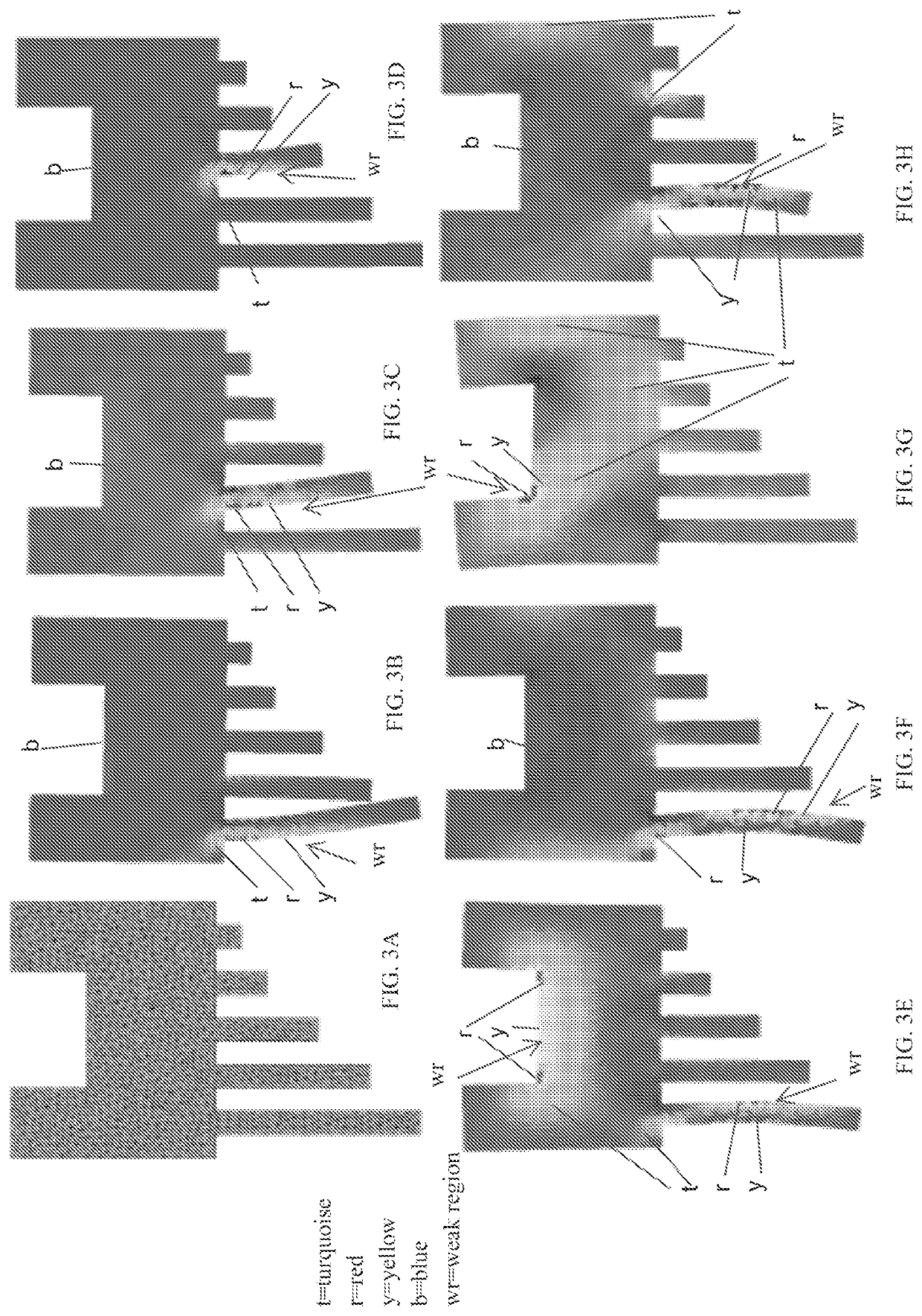

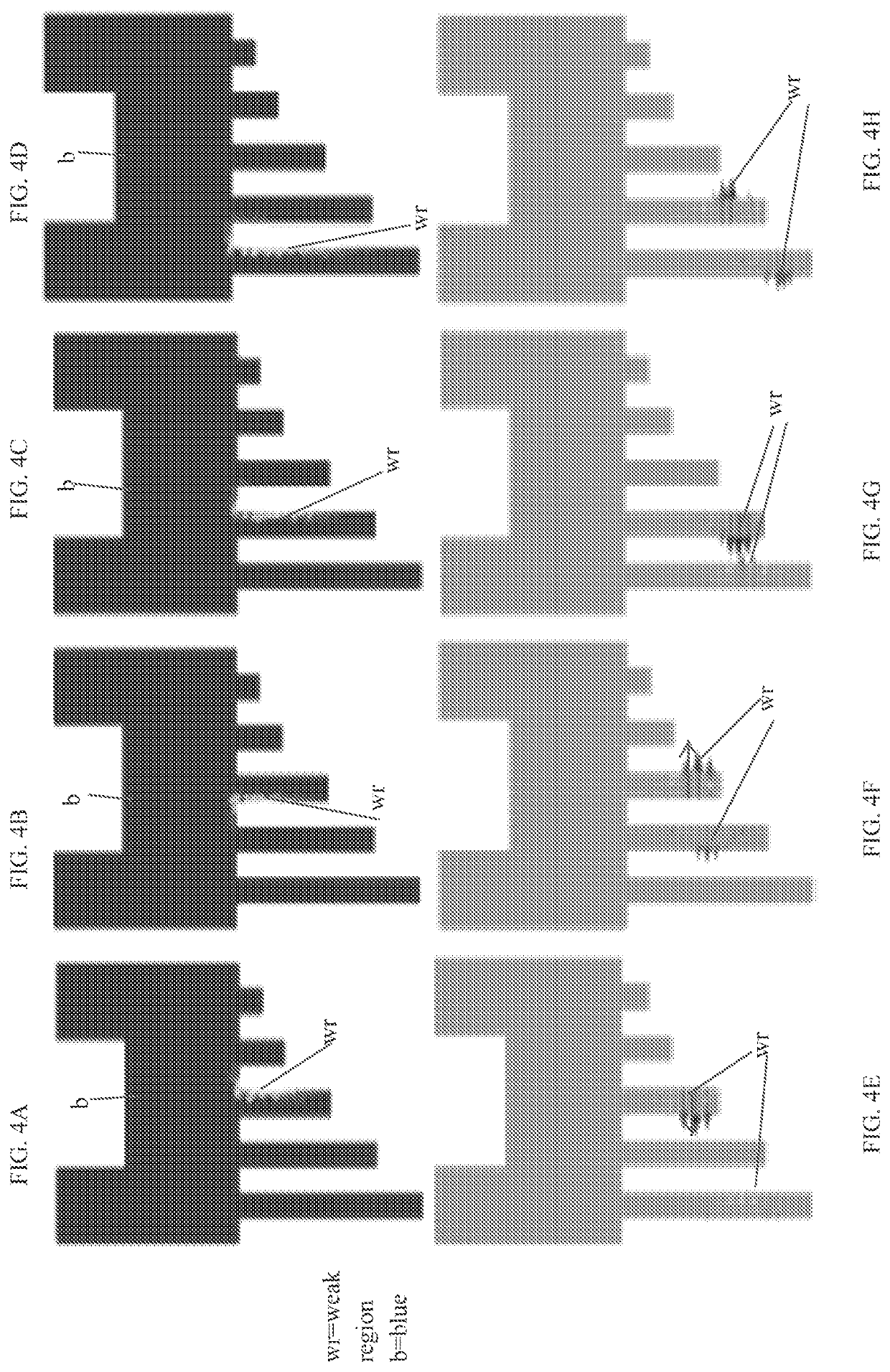

Structural weak spot analysis

ActiveUS20150278414A1High computational costSuperior predictive powerComputation using non-denominational number representationDesign optimisation/simulationOptimization problemSystem usage

A system and methods for weak spot analysis. A mesh shape is preprocessed to approximate an input model for an object. The mesh shape is analyzed with modal analysis to identify weak regions. A method and system for determining weak spots in an object. The method and system uses an optimization problem which is solved to determine a pressure distribution on the object maximizing maximal principal stress by solving a set of optimization problems maximizing stress for each point of the object.

Owner:NEW YORK UNIVERSITY

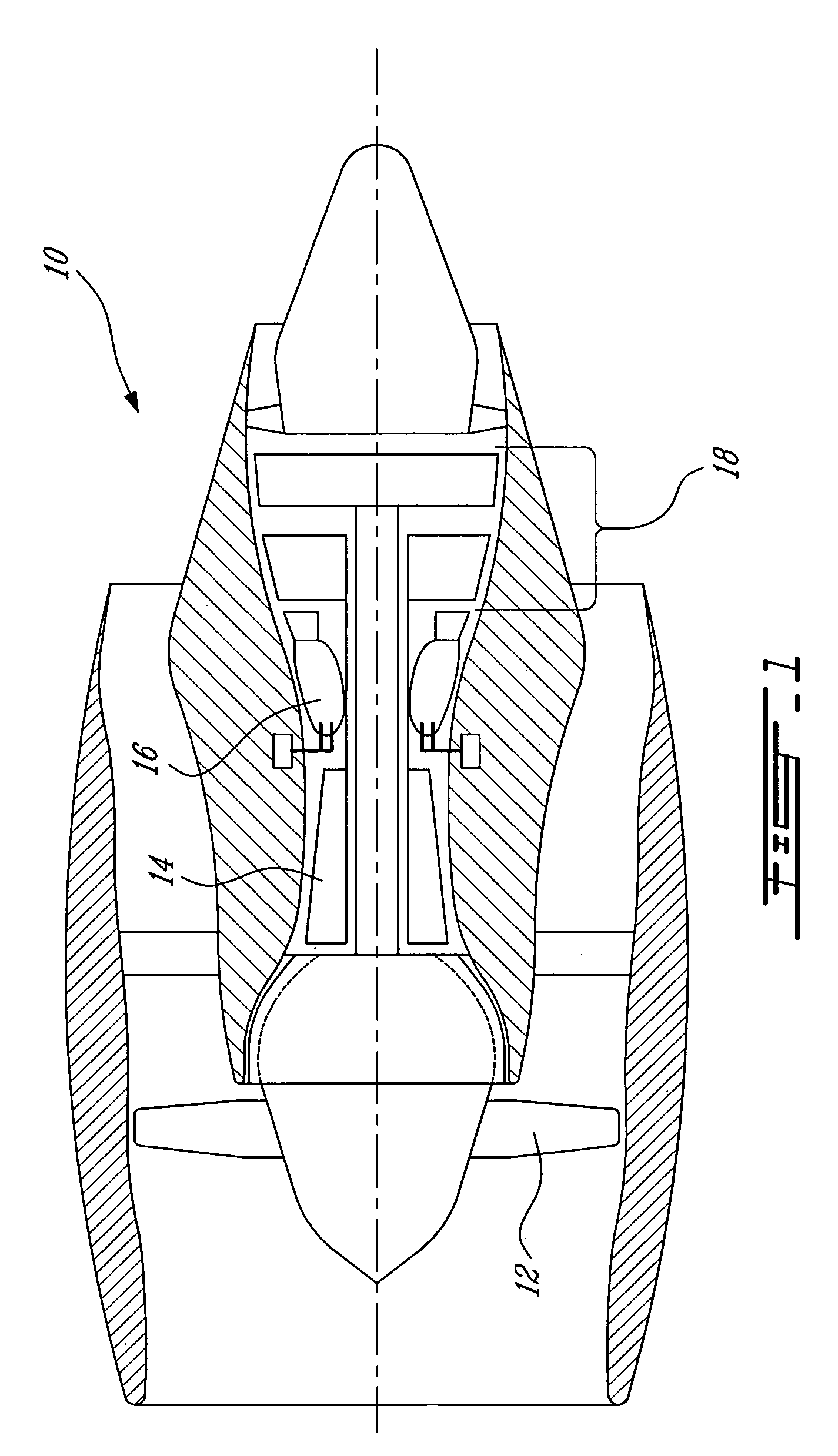

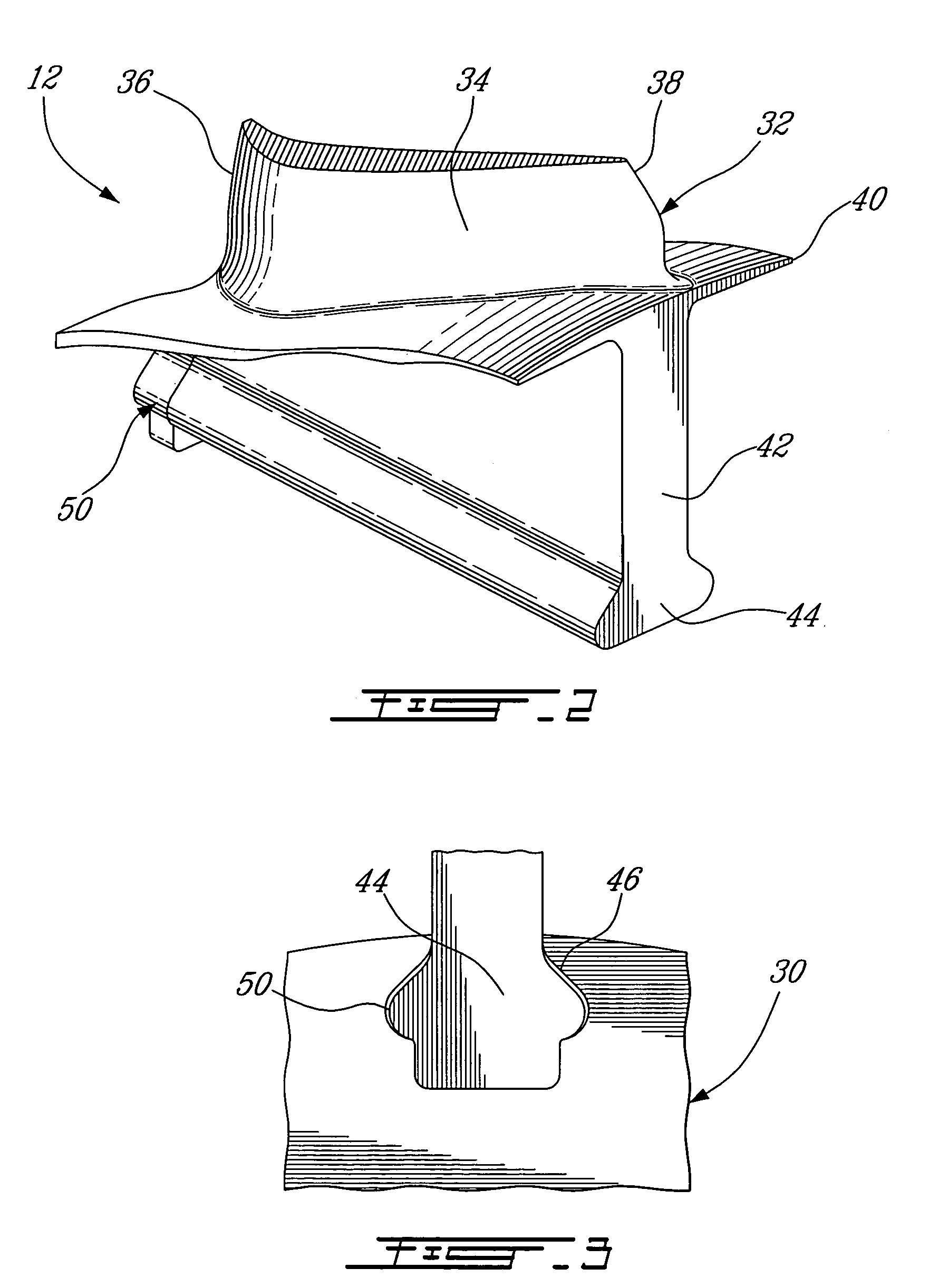

Blade fixing relief mismatch

ActiveUS7156621B2Improved blade and disk interfaceReduce local contact stressPropellersRotary propellersEngineeringGas turbines

A blade fixing and blade mounting slot arrangement for a gas turbine engine has a mismatch fit along a portion of the length of the blade fixing and slot where contact stress would otherwise be maximal.

Owner:PRATT & WHITNEY CANADA CORP

Conical tip shroud fillet for a turbine bucket

A turbine bucket airfoil has a conical fillet about the intersection of the airfoil tip and tip shroud having a nominal profile in accordance with coordinate values of X and Y, offset 1, offset 2 and Rho set forth in Table I. The shape parameters of offset 1, offset 2 and Rho define the configuration of the fillet at the specified X and Y locations about the fillet to provide a fillet configuration accommodating high localized stresses. The fillet shape may be parabolic, elliptical or hyperbolic as a function of the value of the shape parameter ratio of D1D1+D2at each X, Y location where D1 is a distance between an intermediate point along a chord between edge points determined by offsets O2 and O2 and a shoulder point on the fillet surface and D2 is a distance between the shoulder point and an apex location at the intersection of the airfoil tip and tip shroud.

Owner:GENERAL ELECTRIC CO

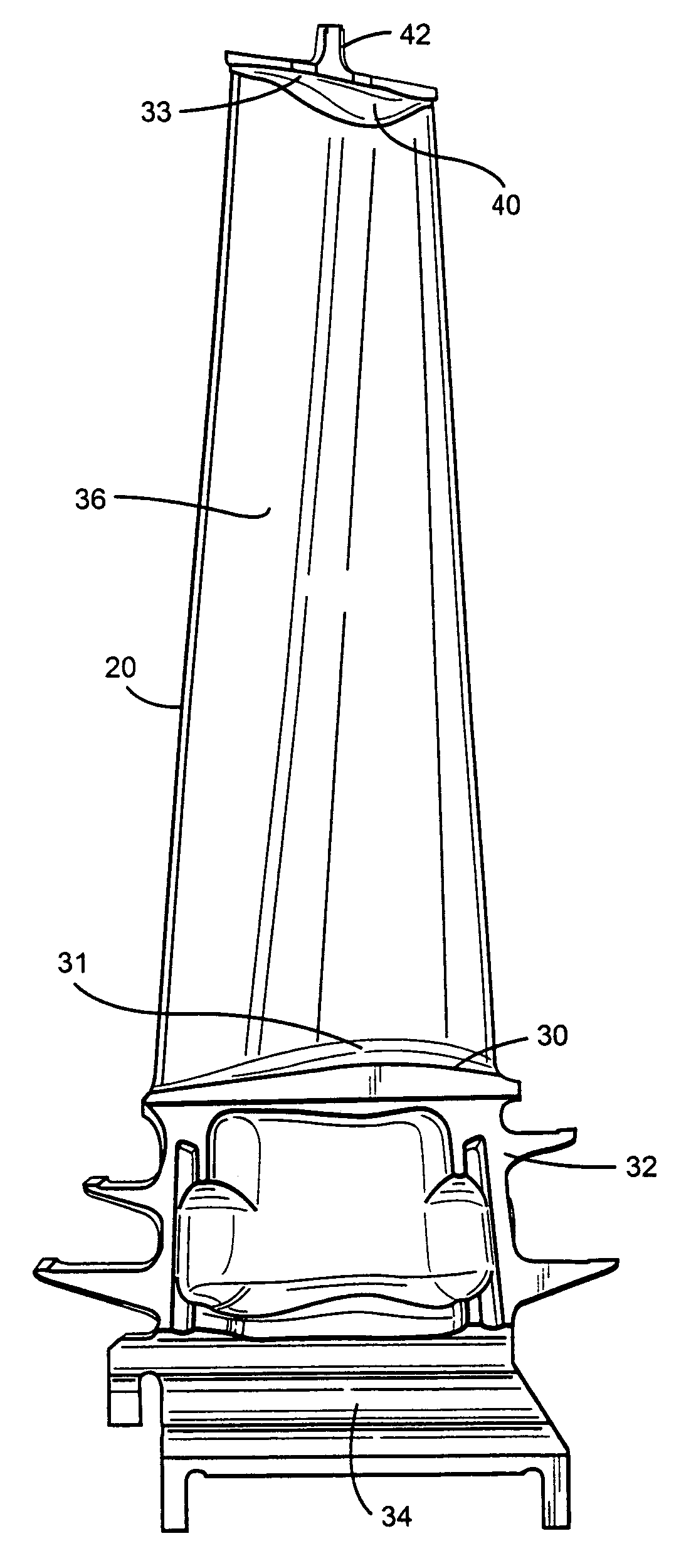

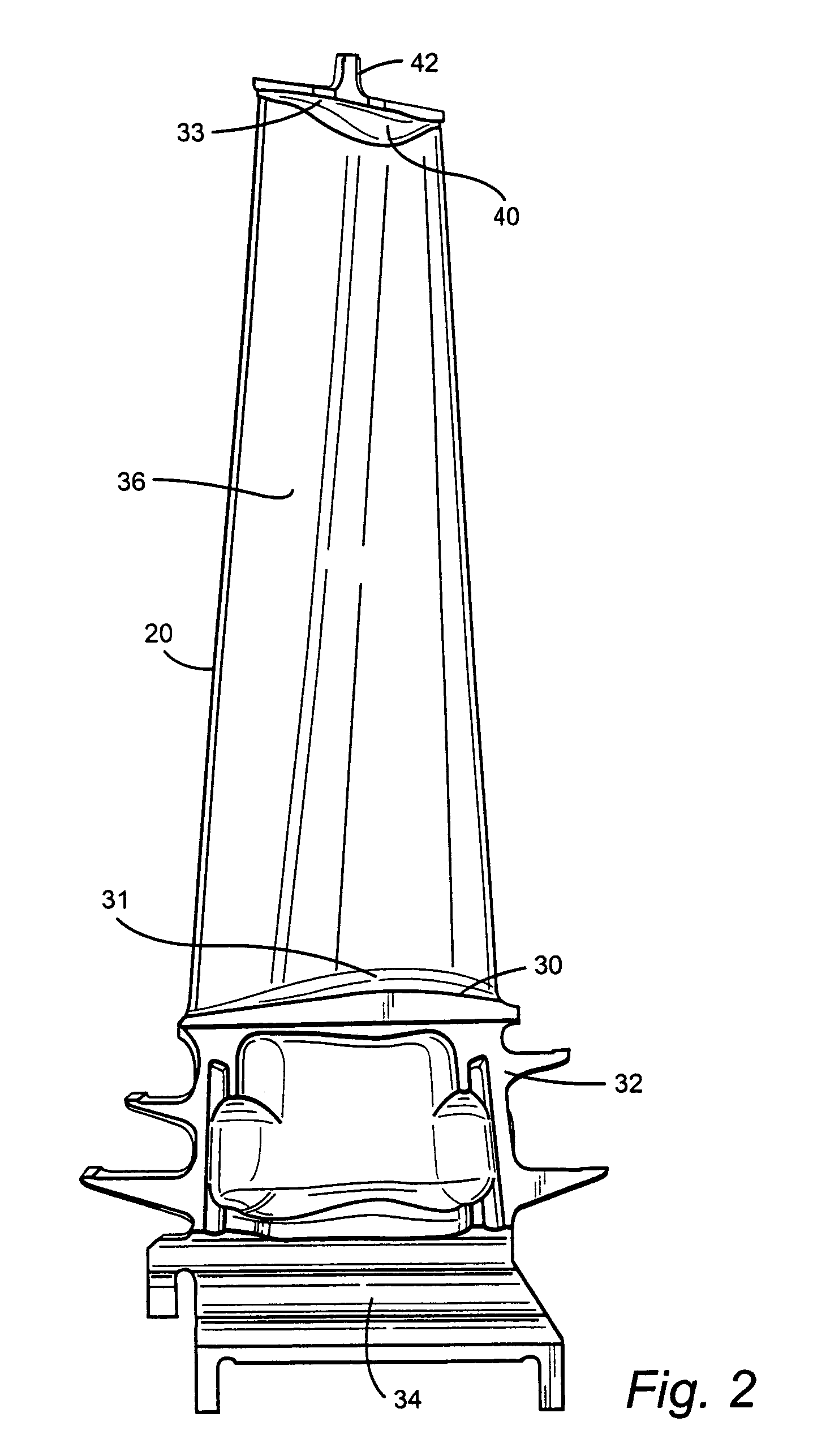

Transonic blade

ActiveUS8425185B2Reduce various lossesImprove local stressPropellersReaction enginesLeading edgeWorking fluid

A transonic blade is provided that operates in a flow field where flow has a transonic speed or higher in an axial-flow rotating machine and that concurrently achieves a reduction in shock loss and in the local stress of the blade. The transonic blade includes a hub cross-sectional surface joined to a rotating shaft or an outer circumferential side casing of a rotating machine; a tip cross-sectional surface located furthest from the hub cross-sectional surface in a spanwise direction which is a vertical direction of the rotating shaft; a leading edge located on an upstream side; and a trailing edge located on a downstream side. At least a part of a passing working fluid flow has a transonic speed or higher. A portion of a stacking line which is a line connecting together respective gravity centers of cross-sectional surfaces located from the hub cross-sectional surface to the tip cross-sectional surface is located on a downstream side of a stacking center in a flow direction of a working fluid main flow.

Owner:MITSUBISHI POWER LTD

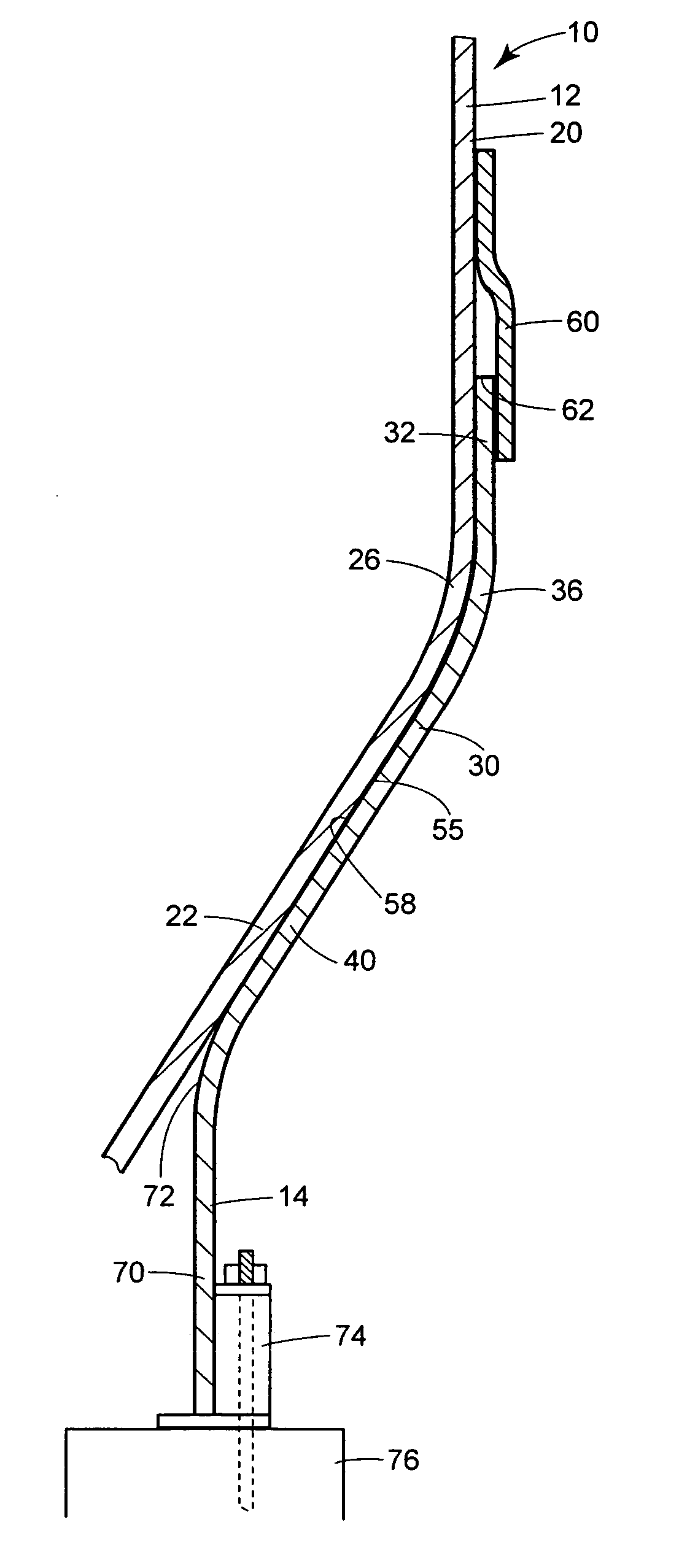

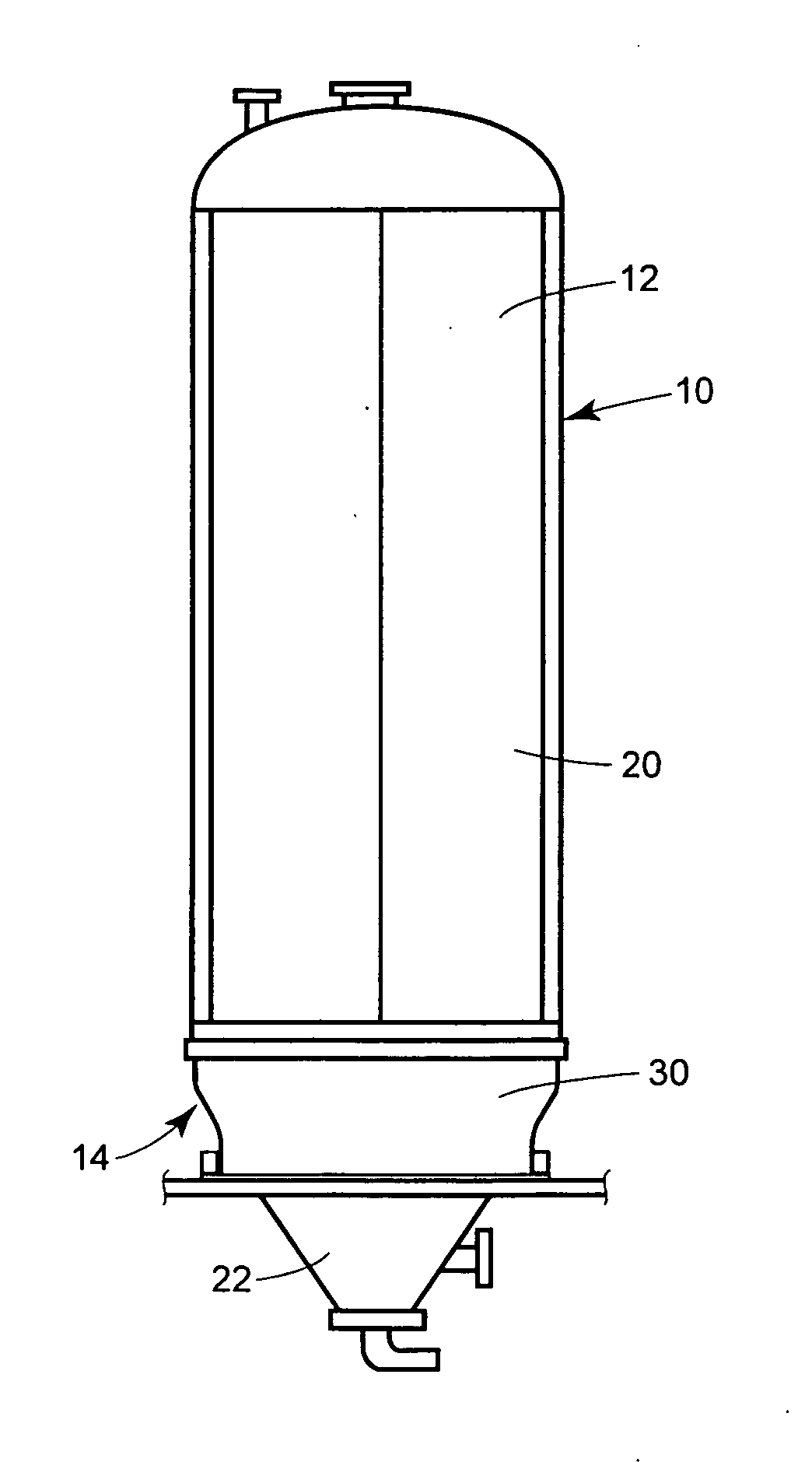

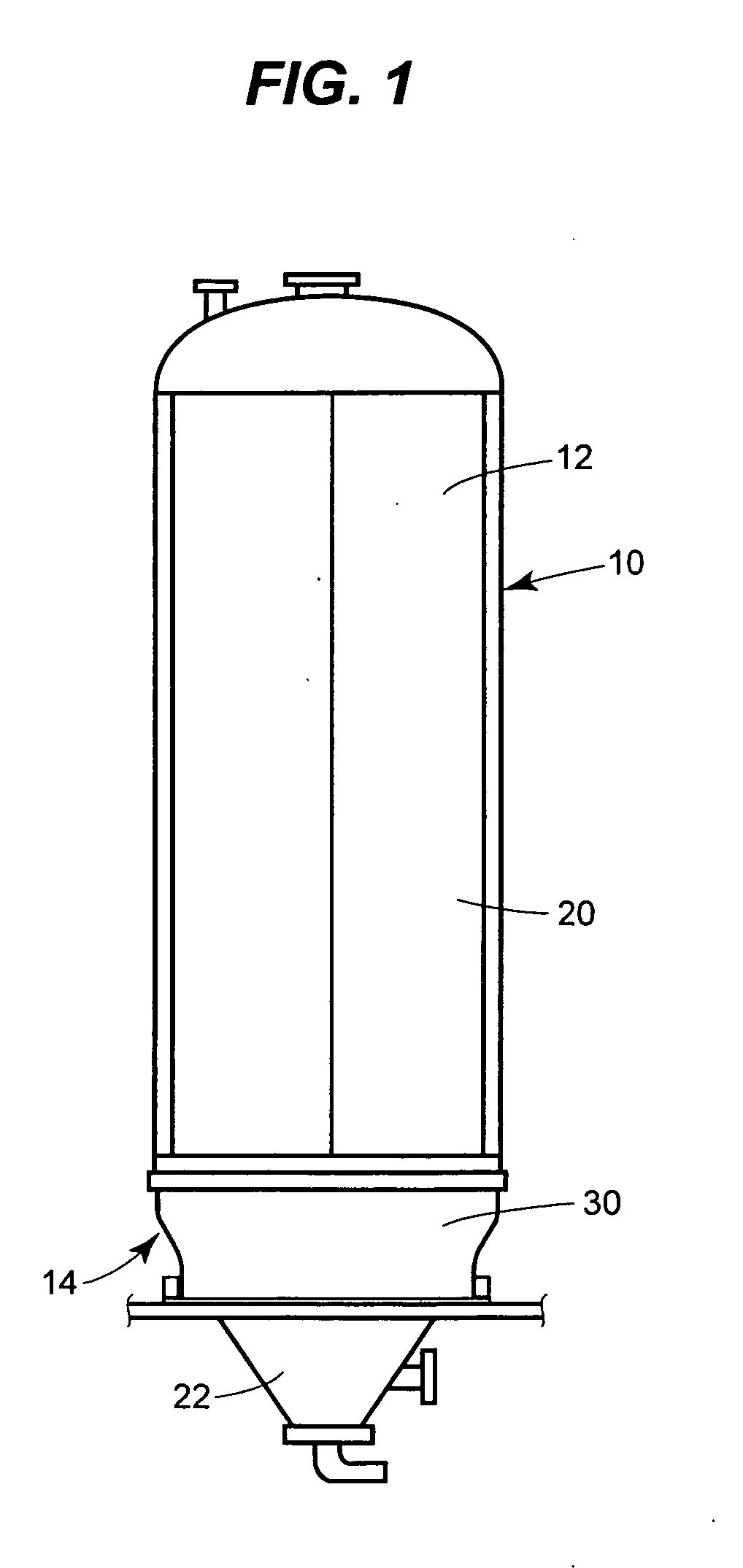

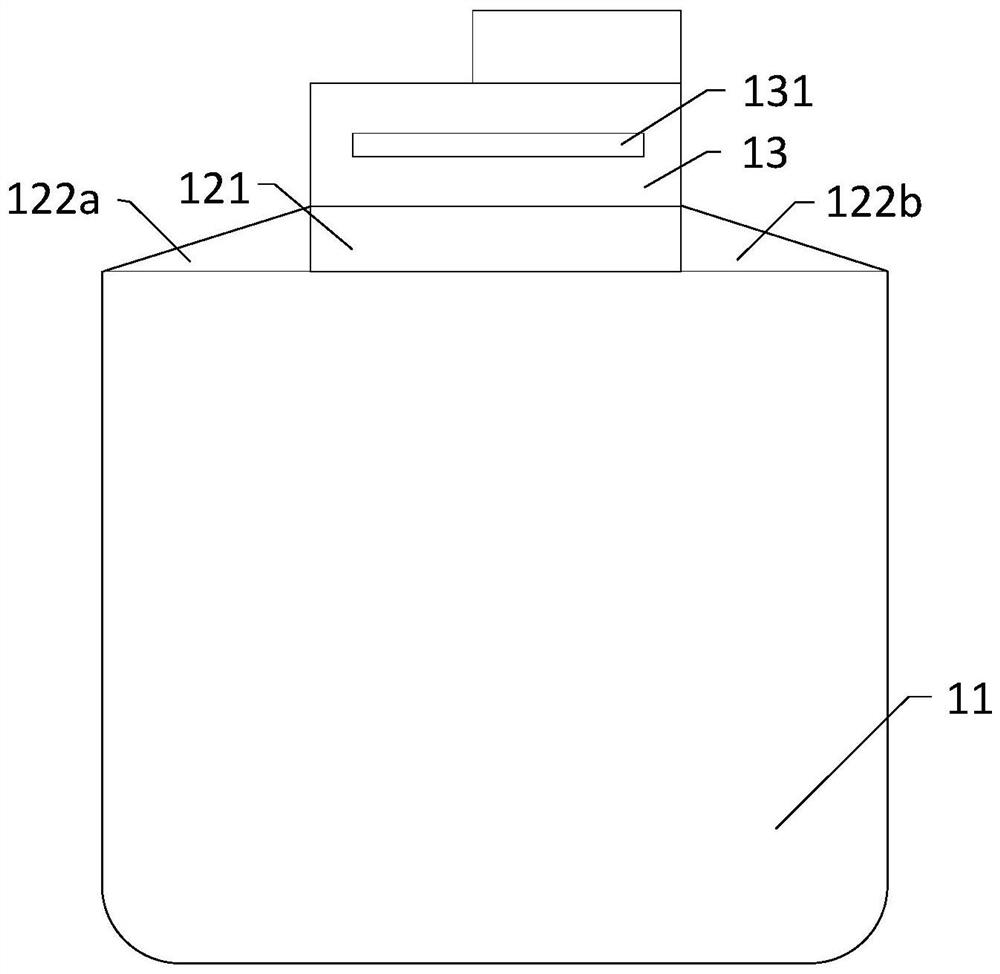

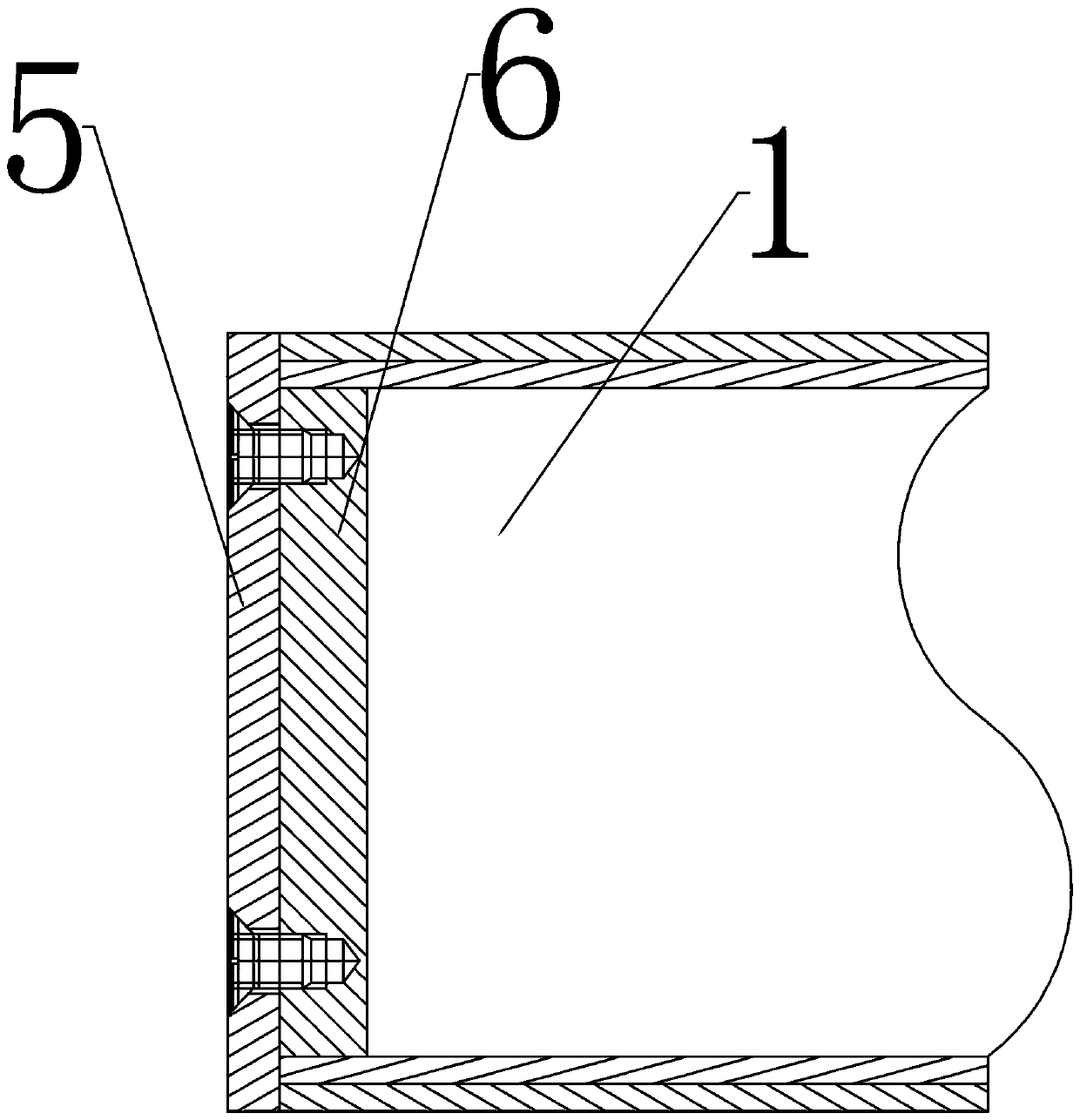

Structure for extreme thermal cycling

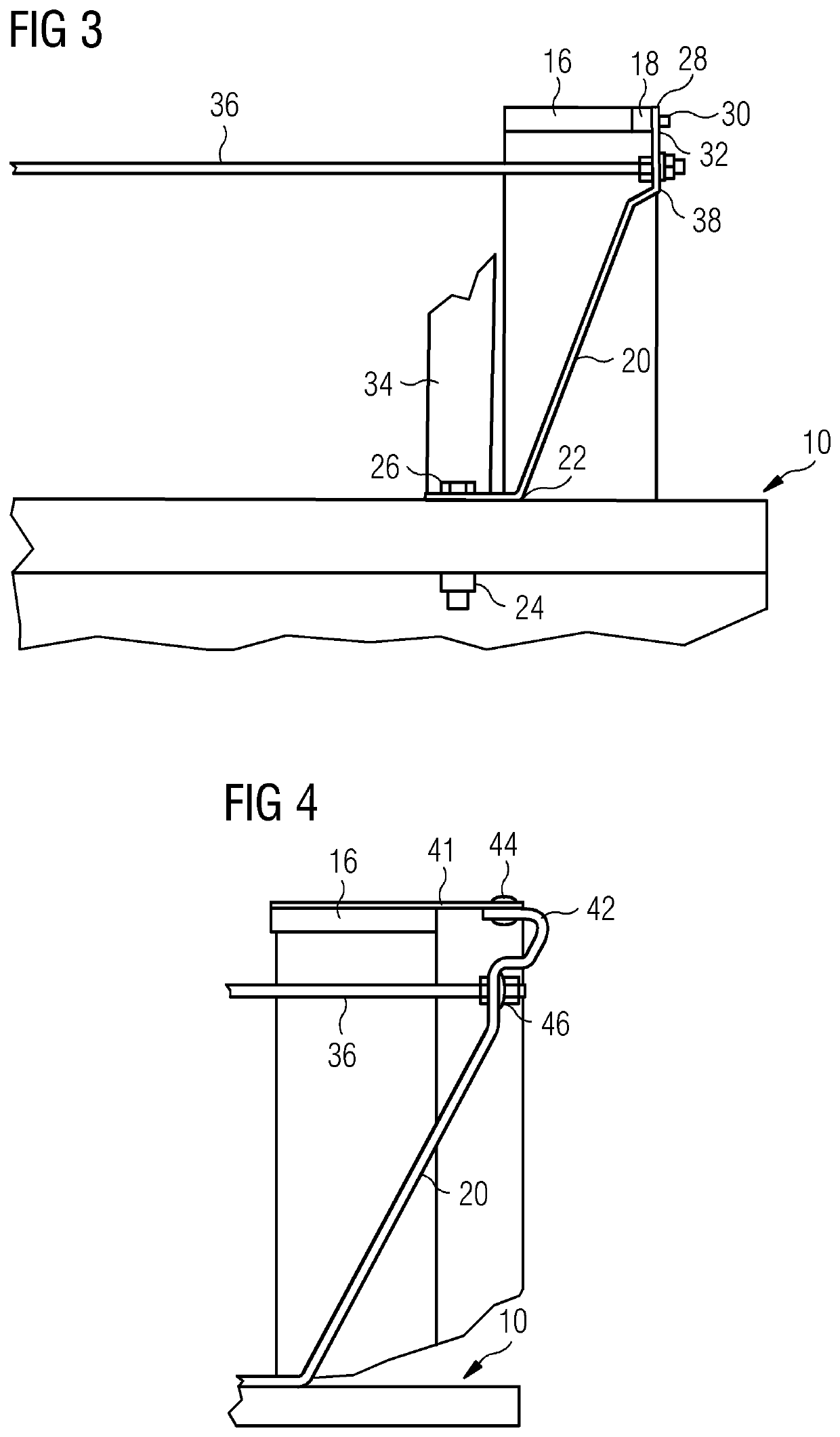

ActiveUS7666279B2Reduce the amount of weldingFlexible connectionMechanical conveying coke ovensCharging-discharging device combinationsPre stressPre stressing

A structure for extreme thermal cycling has a support element that supports a vessel primarily by bearing and frictional forces rather than by welds. The support element has a bearing portion that tapers inwardly beneath a knuckle that separates a cylindrical section of the vessel from a sloped lower section. The bearing portion of the support element follows that slope, providing an extended area of contact between the support element and the vessel. An annular section of the support element can be heated and expanded before placing it around the cylindrical section of the vessel to provide pre-stressing. If required, a strap may extend downwardly from the vessel over an upper edge of the support element.

Owner:CB&I STS DELAWARE LLC

Blade fixing relief mismatch

ActiveUS20050254953A1Improved blade and disk interfaceReduce local contact stressPropellersPump componentsEngineeringStructural engineering

A blade fixing and blade mounting slot arrangement for a gas turbine engine has a mismatch fit along a portion of the length of the blade fixing and slot where contact stress would otherwise be maximal.

Owner:PRATT & WHITNEY CANADA CORP

Structure for extreme thermal cycling

ActiveUS20070215452A1Reduce fatigueImprove fatigue resistanceMechanical conveying coke ovensCharging-discharging device combinationsPre stressPre stressing

A structure for extreme thermal cycling has a support element that supports a vessel primarily by bearing and frictional forces rather than by welds. The support element has a bearing portion that tapers inwardly beneath a knuckle that separates a cylindrical section of the vessel from a sloped lower section. The bearing portion of the support element follows that slope, providing an extended area of contact between the support element and the vessel. An annular section of the support element can be heated and expanded before placing it around the cylindrical section of the vessel to provide pre-stressing. If required, a strap may extend downwardly from the vessel over an upper edge of the support element.

Owner:CHICAGO BRIDGE & IRON CO

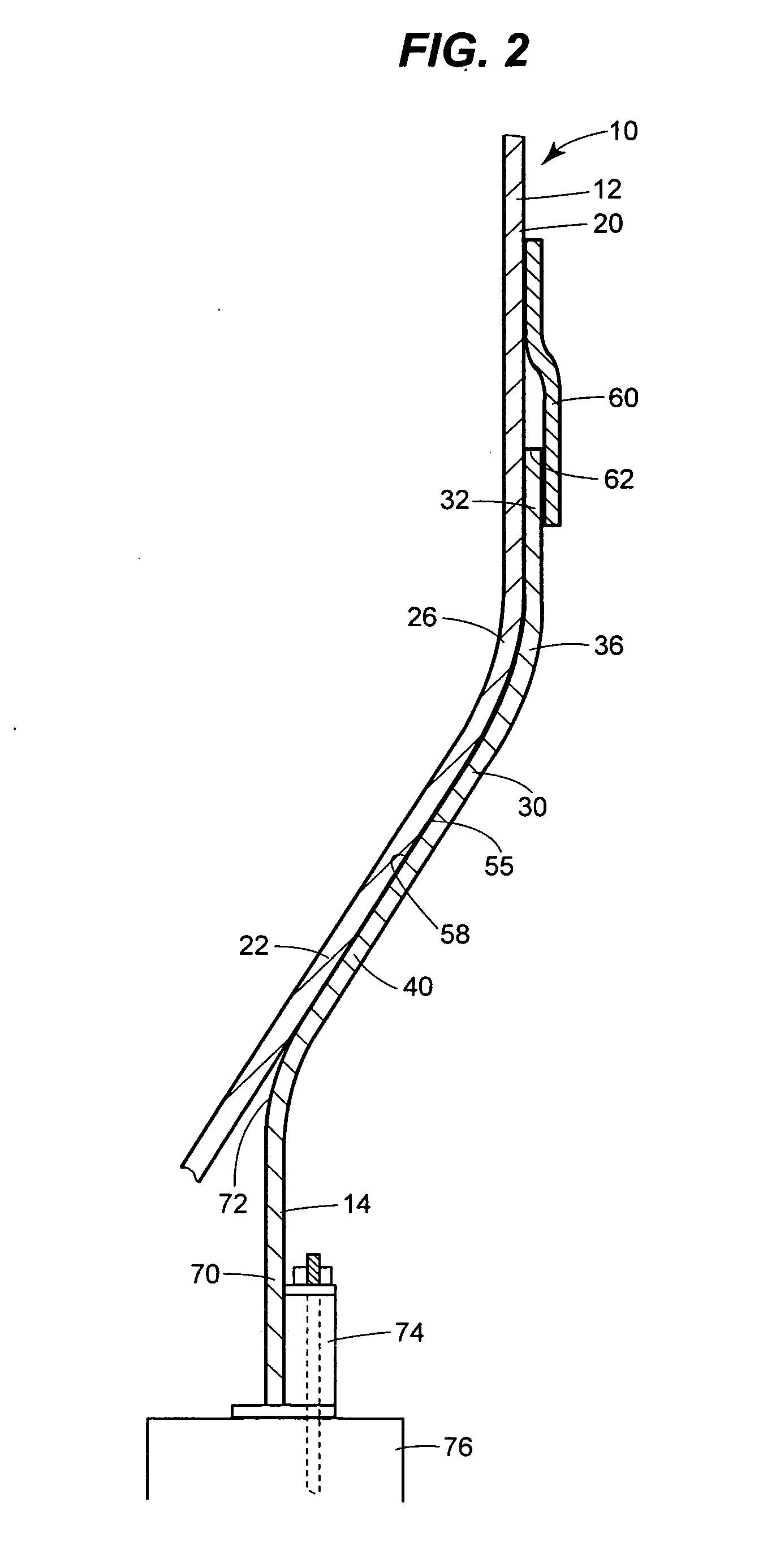

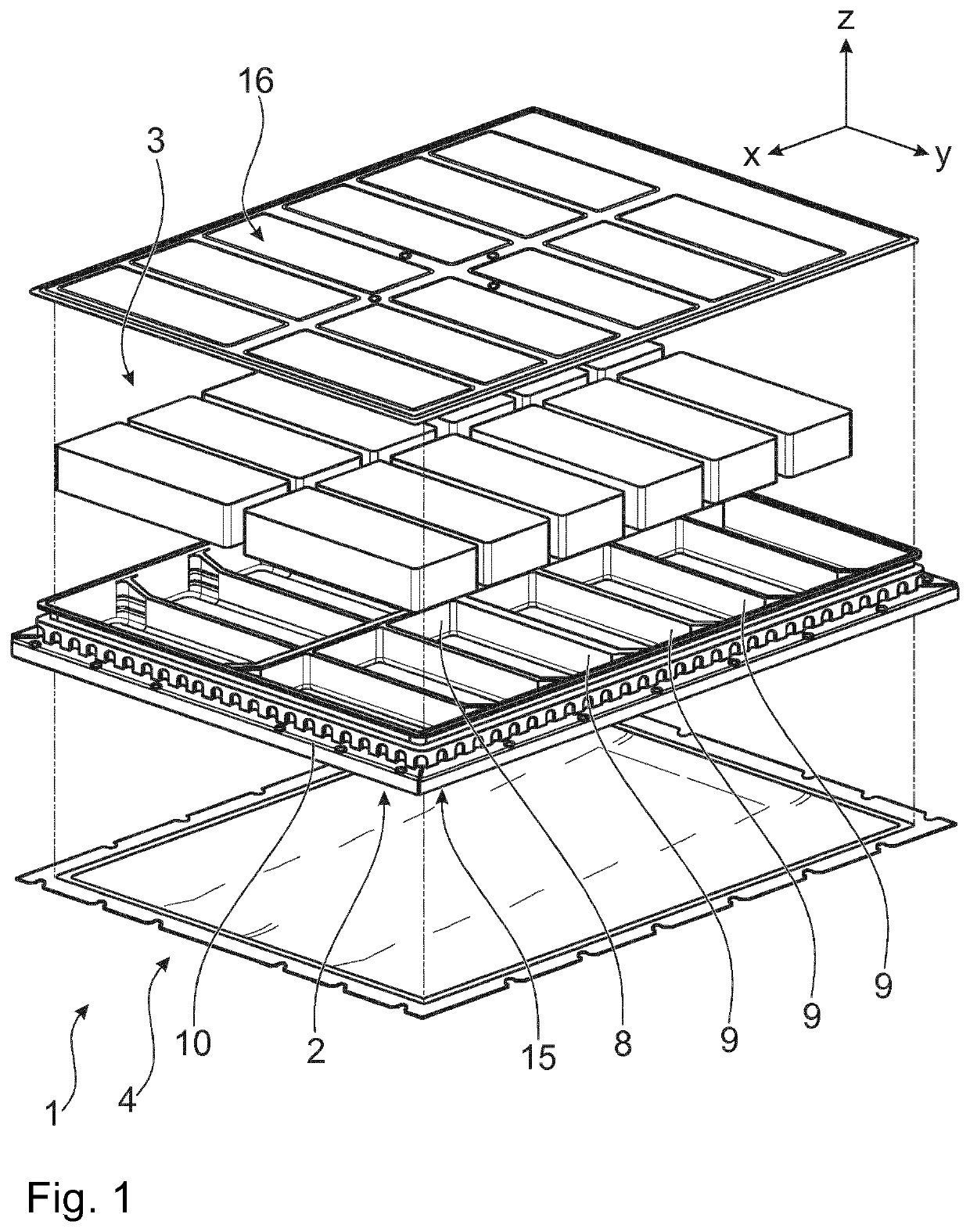

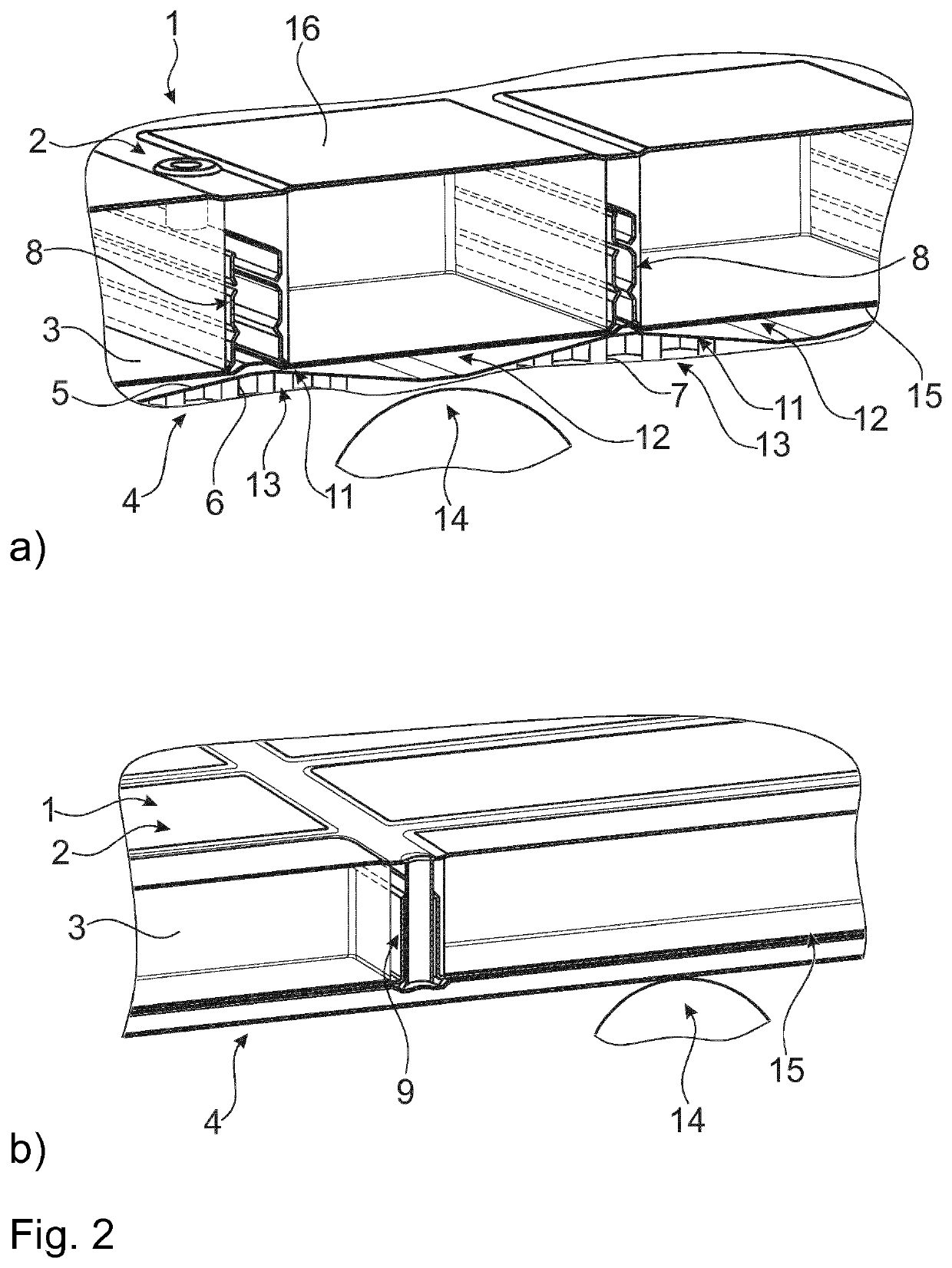

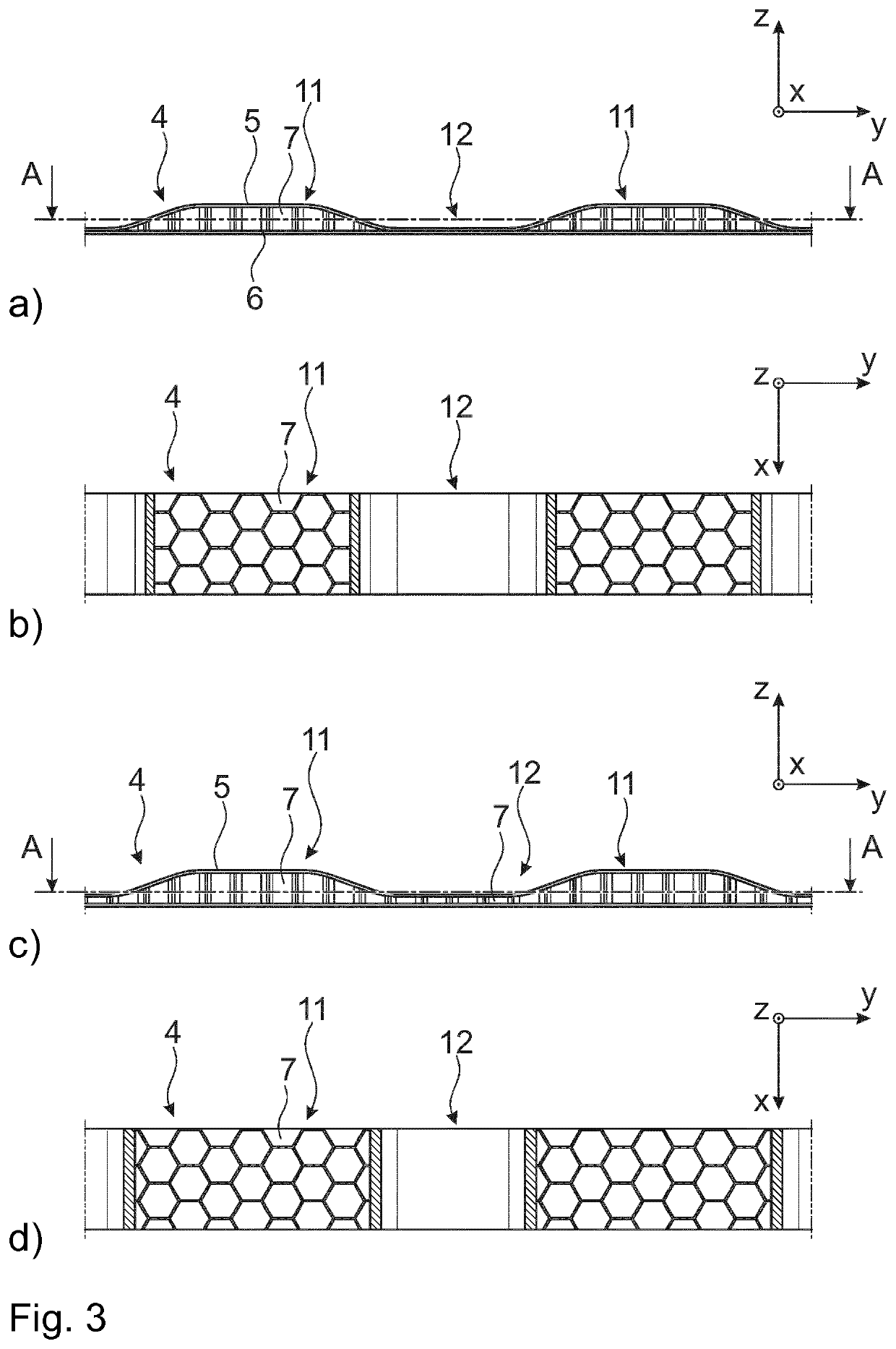

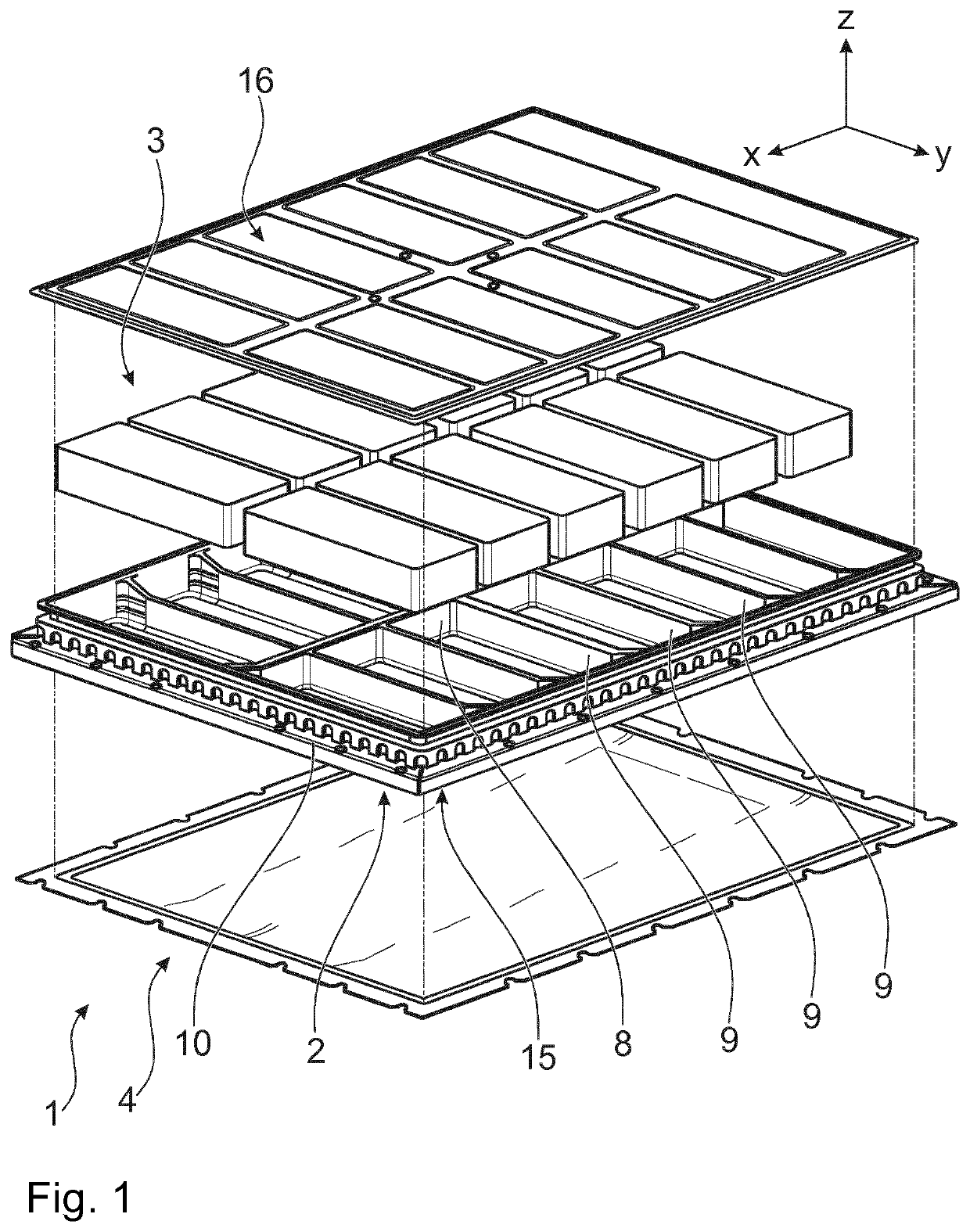

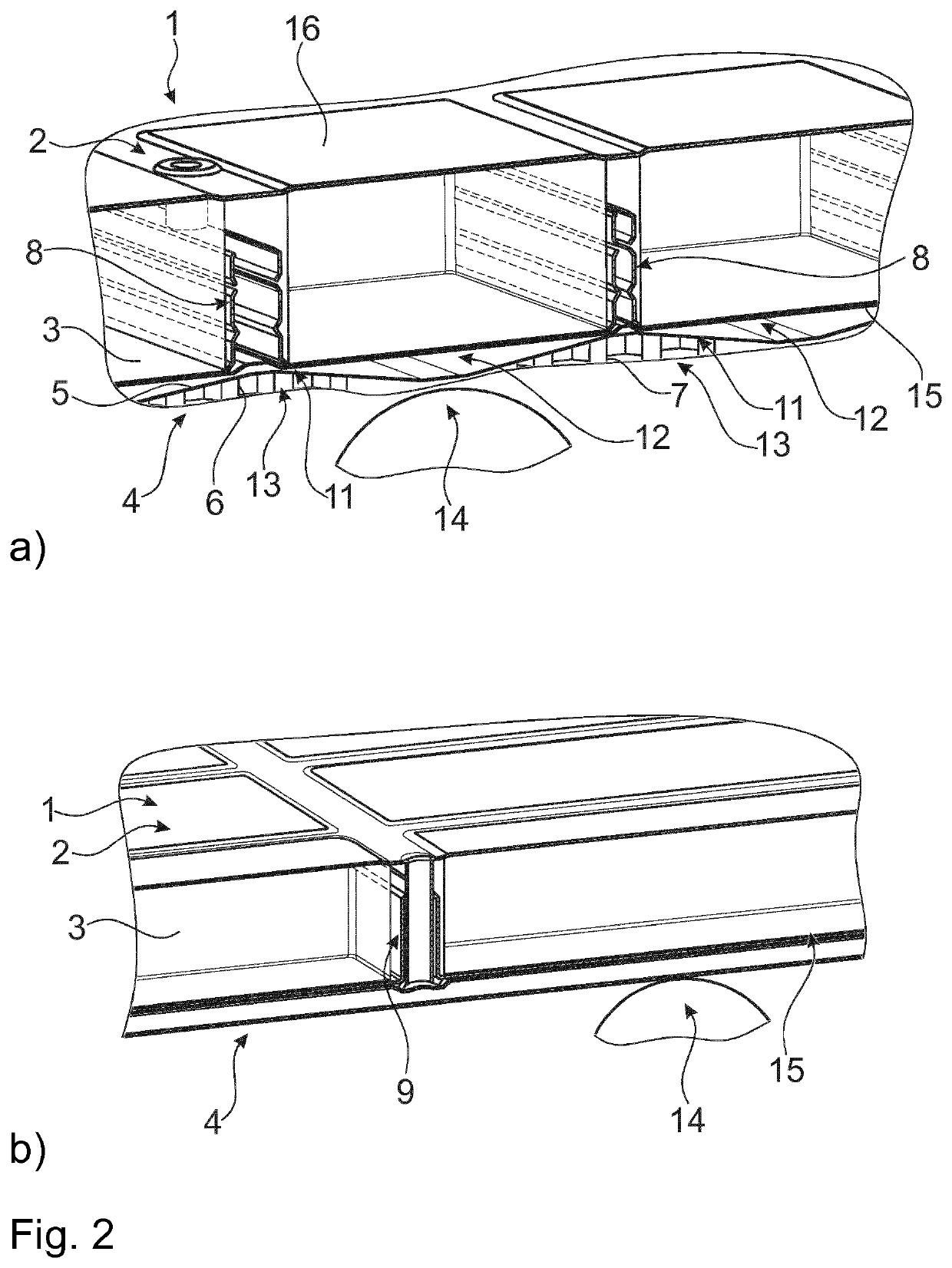

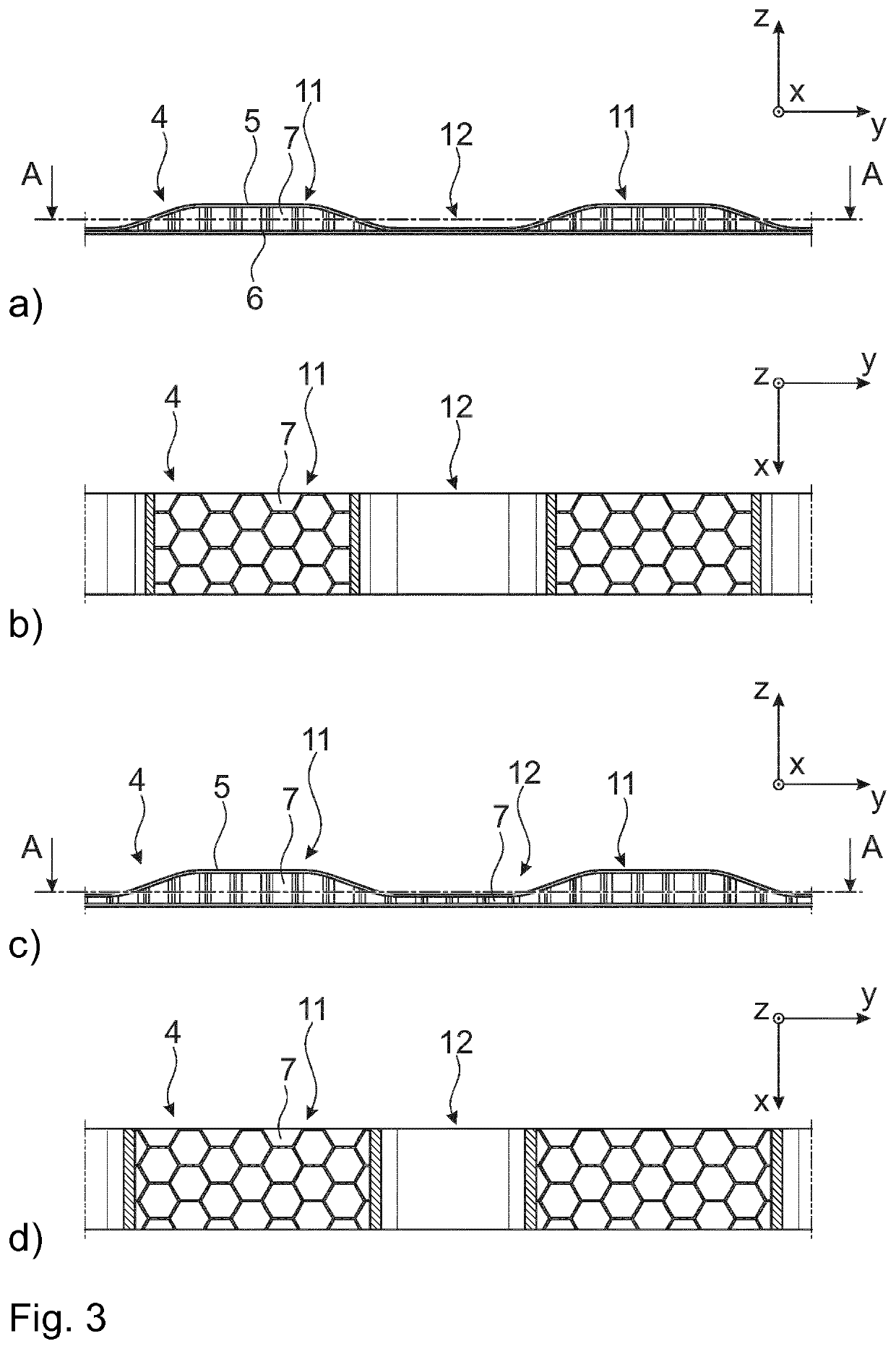

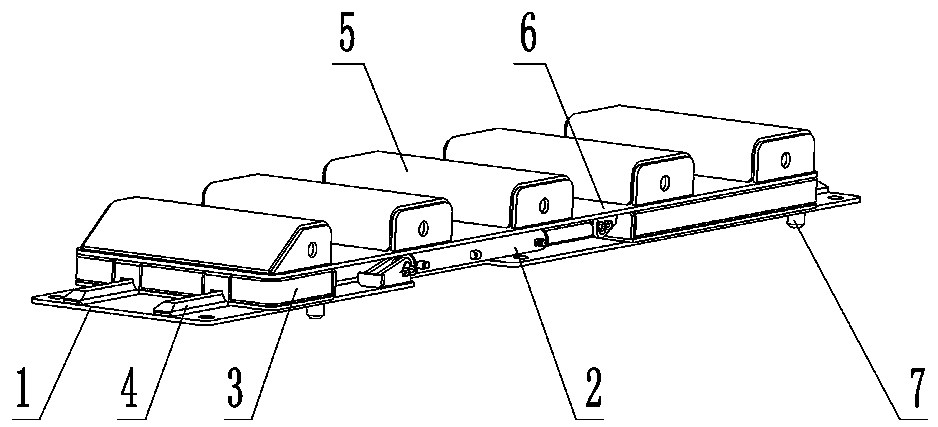

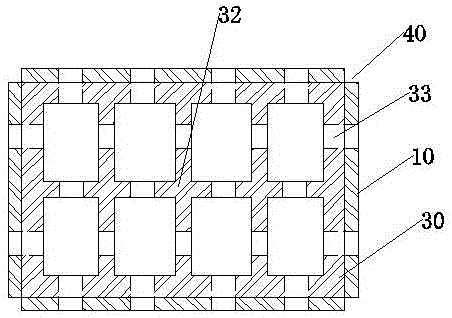

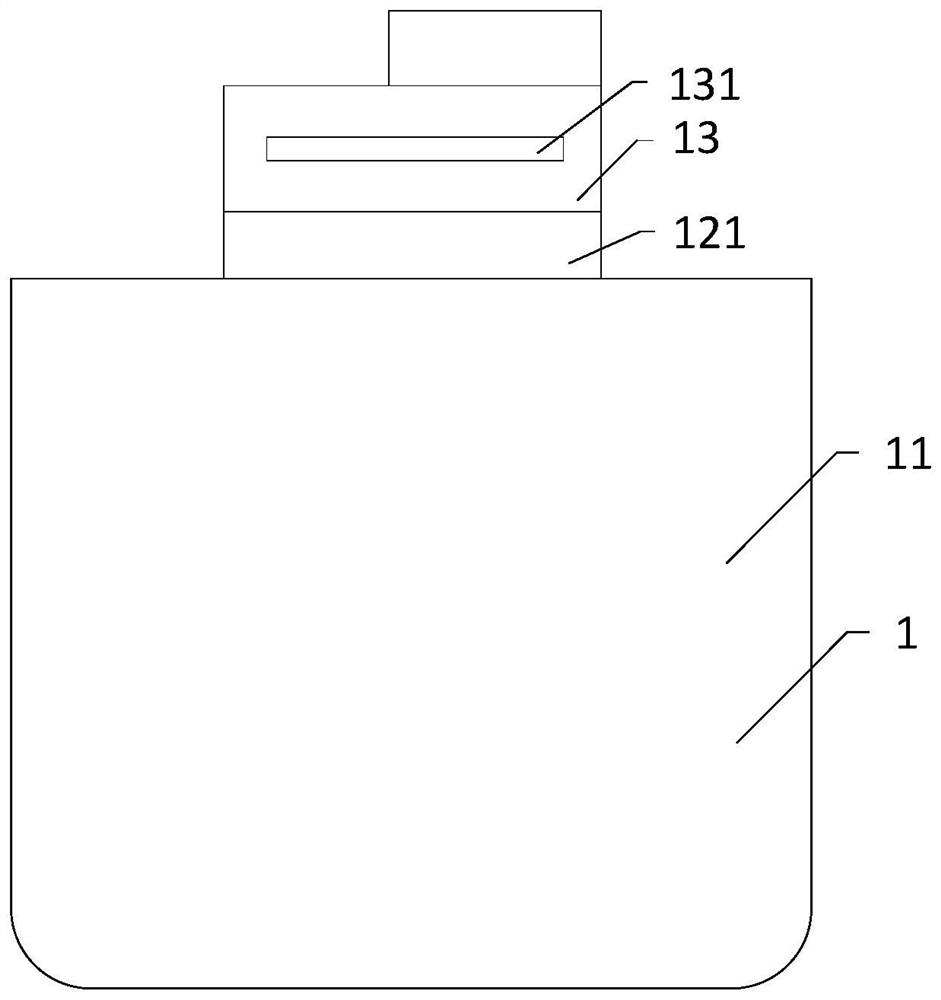

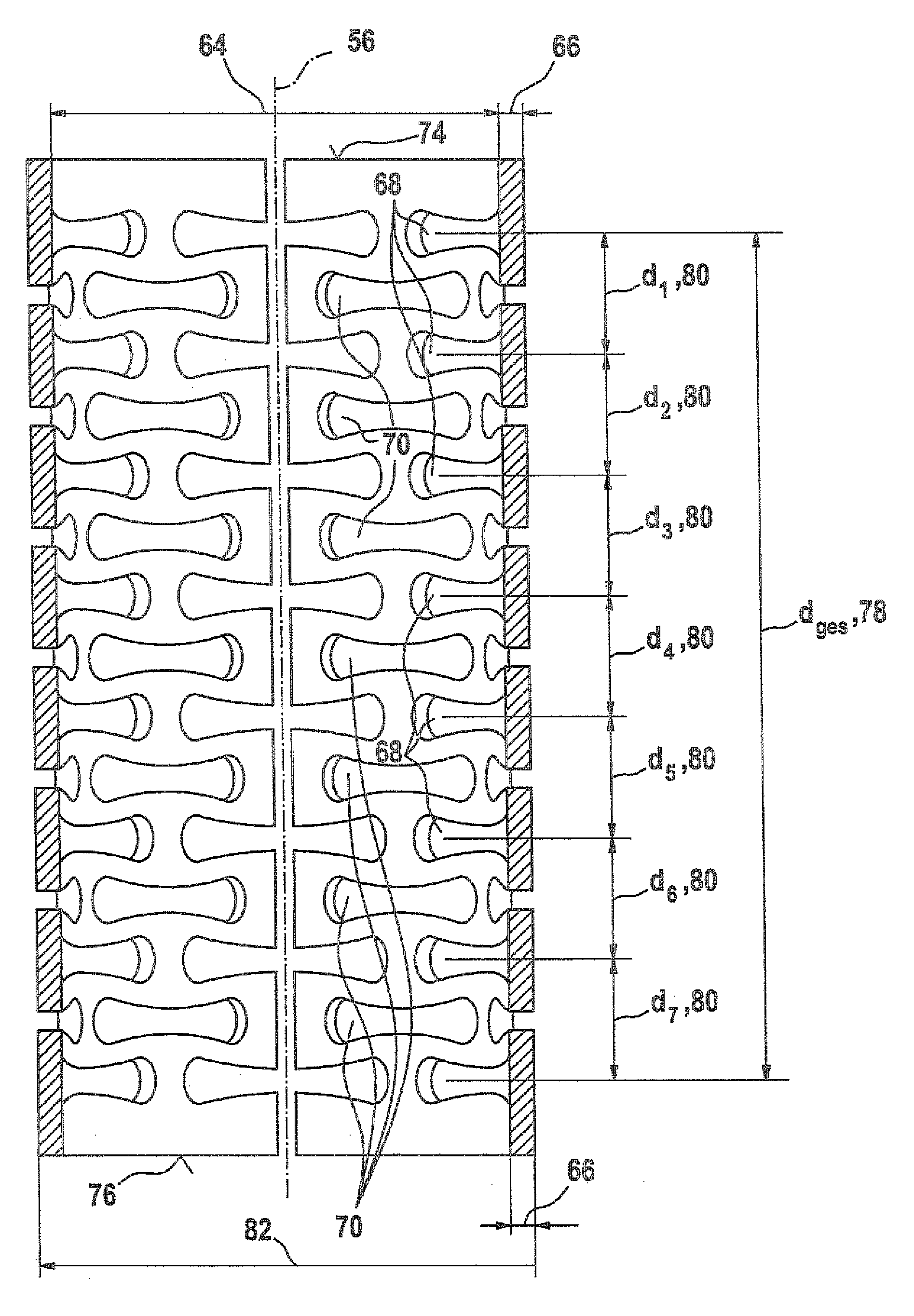

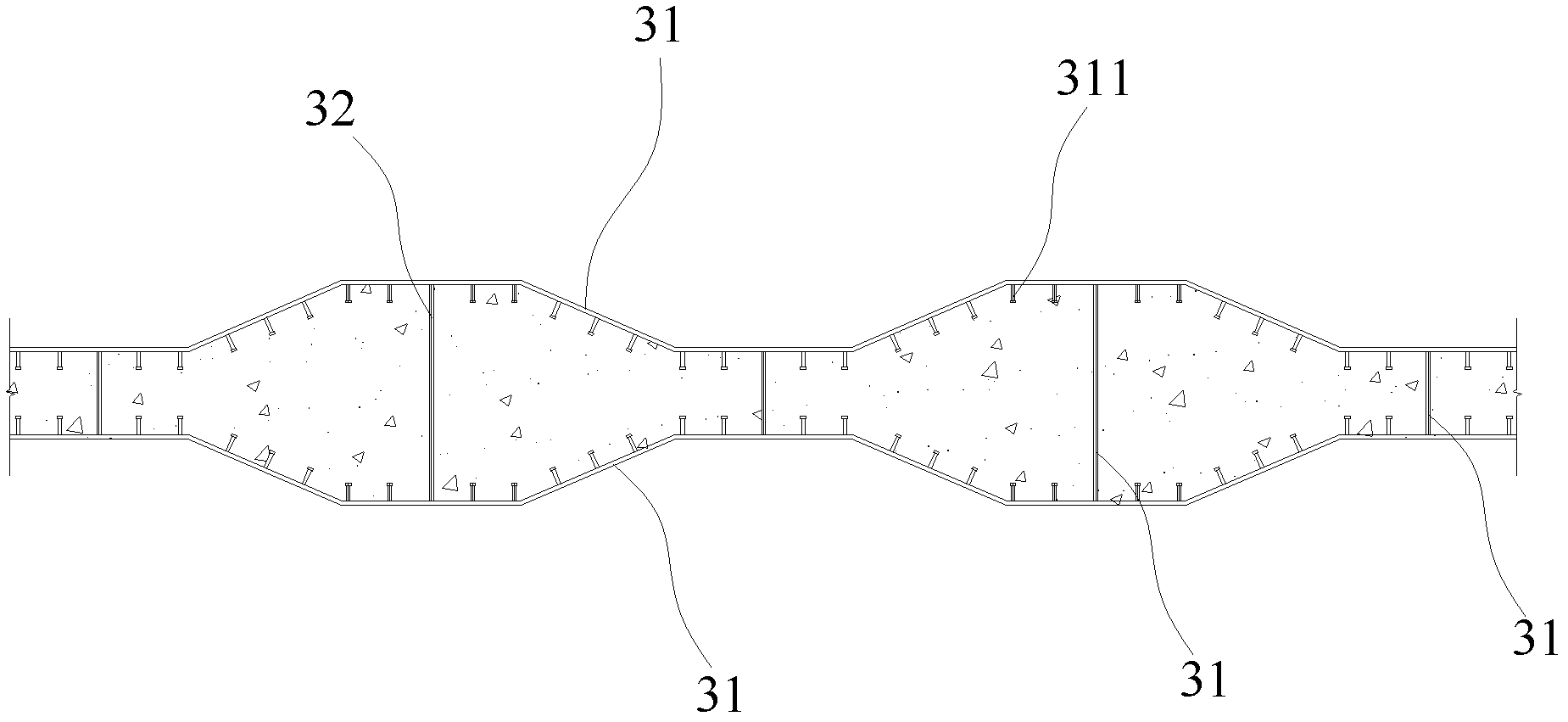

Battery structure and protector

ActiveUS20200001728A1Less spaceGood performanceElectric propulsion mountingSecondary cellsAutomotive engineeringElectrical battery

The present disclosure relates to a battery structure for an electric vehicle. The battery structure comprises a battery case for at least one battery module and a protector including a top belt, a bottom belt and a core arranged between and interconnecting the top belt and the bottom belt. The top belt has a wavelike cross section.

Owner:MUBEA CARBO TECH

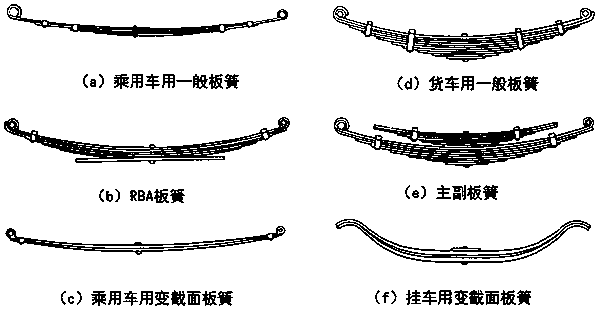

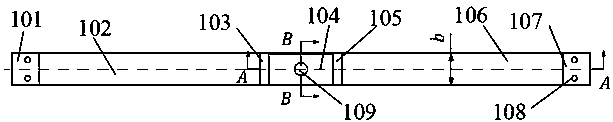

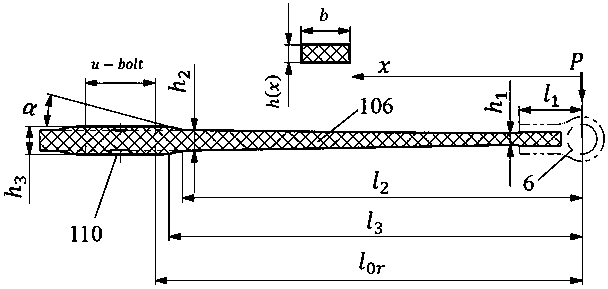

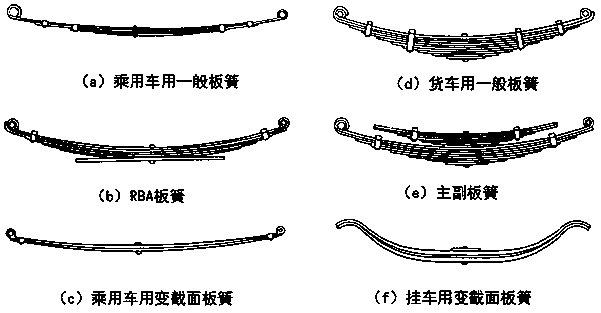

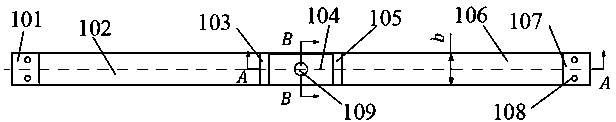

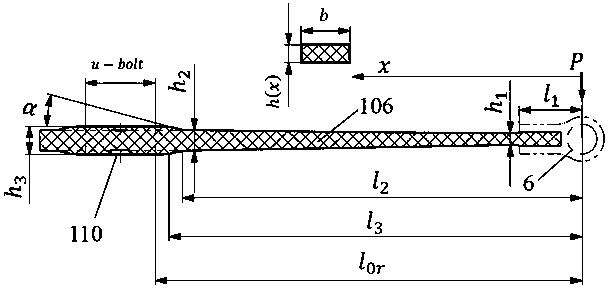

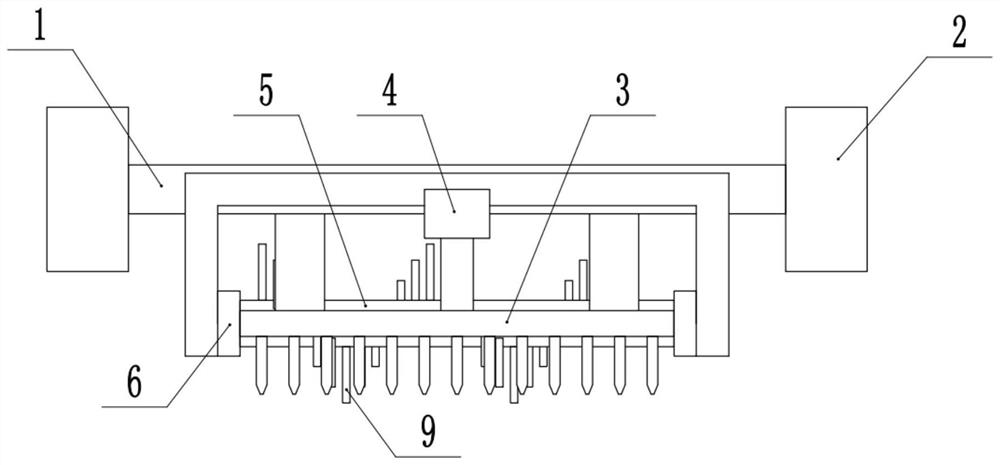

Leaf spring and manufacturing technology thereof

ActiveCN107606014AReduce weightImprove local stressLeaf springsDomestic articlesDynamic stiffnessFiber

The invention relates to a leaf spring and a manufacturing technology thereof. The leaf spring comprises a leaf middle section, a transition section, a variable-section section and a winding lug installing section, and all the sections are the same in width. The material of the leaf spring is an FRP composite material. The manufacturing technology comprises the fiber cloth weaving procedure, the fiber cloth laminating procedure, the laminated layer spot welding procedure, the pre-forming procedure, the cutting procedure, the HP-RTM procedure, the unloading and shaping procedure and the post-machining procedure. The technical scheme solves the problems of design and process of leaf spring leaves in the prior art, the leaf spring leaf performance is improved, the volume production beat is fast, and the market value of the leaf spring is huge; one leaf spring can be independently used, two leaf springs can be combined to form a main and auxiliary spring structure, different loads are achieved, and all steel plate spring structures can be replaced by changing structures of winding lugs and other accessories; complete fracture at a time is avoided, the active failure mode is achieved, and the vehicle running safety is sufficiently guaranteed; the weight of a leaf spring suspension is reduced, the dynamic stiffness is very small, the vehicle running smoothness is improved, and fuel affinity is improved as well; and the service life is 5 or more times of the steel plate springs, and the cost of using the leaf spring by users is greatly reduced.

Owner:合肥前卫复合材料有限公司 +1

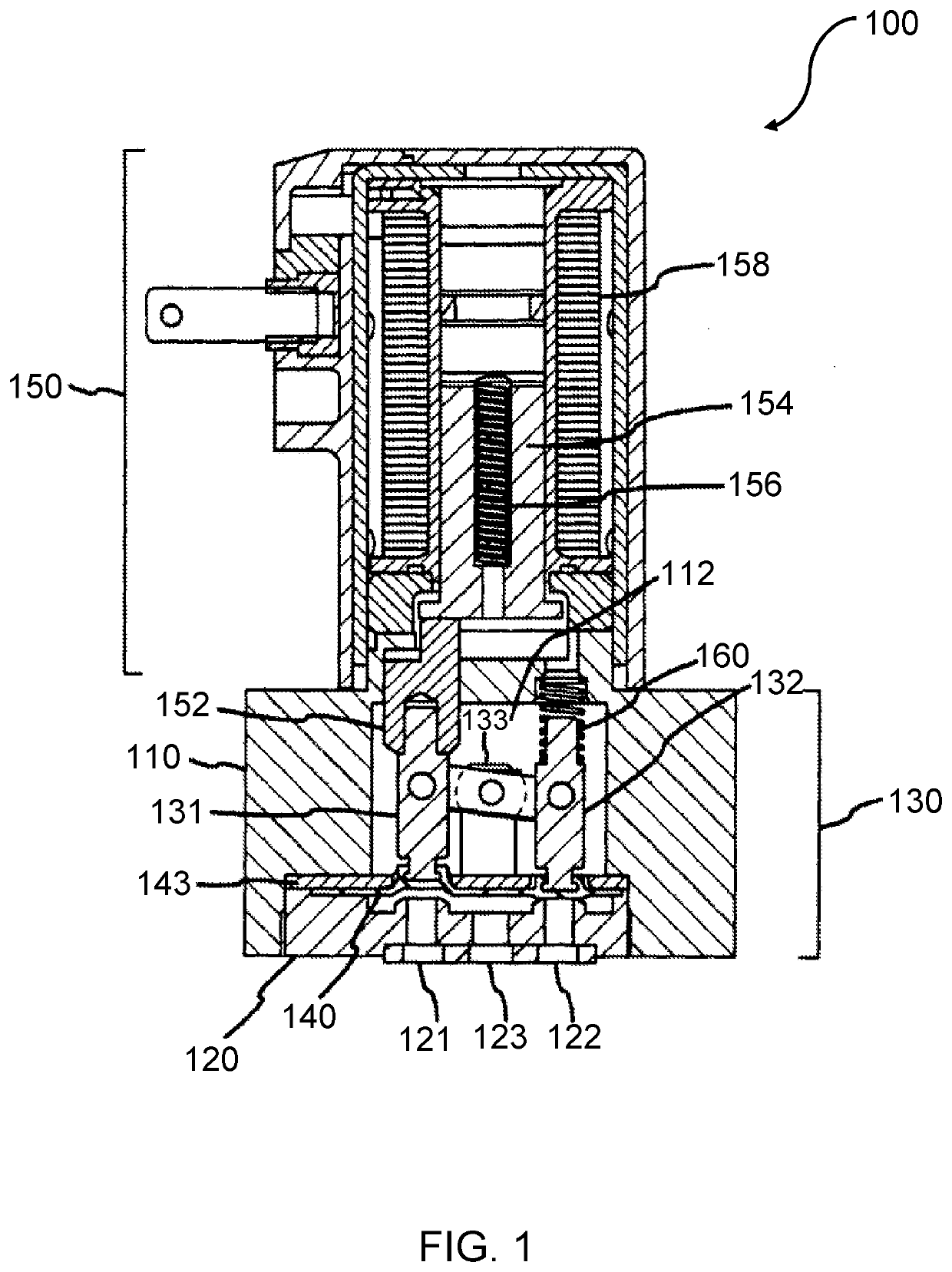

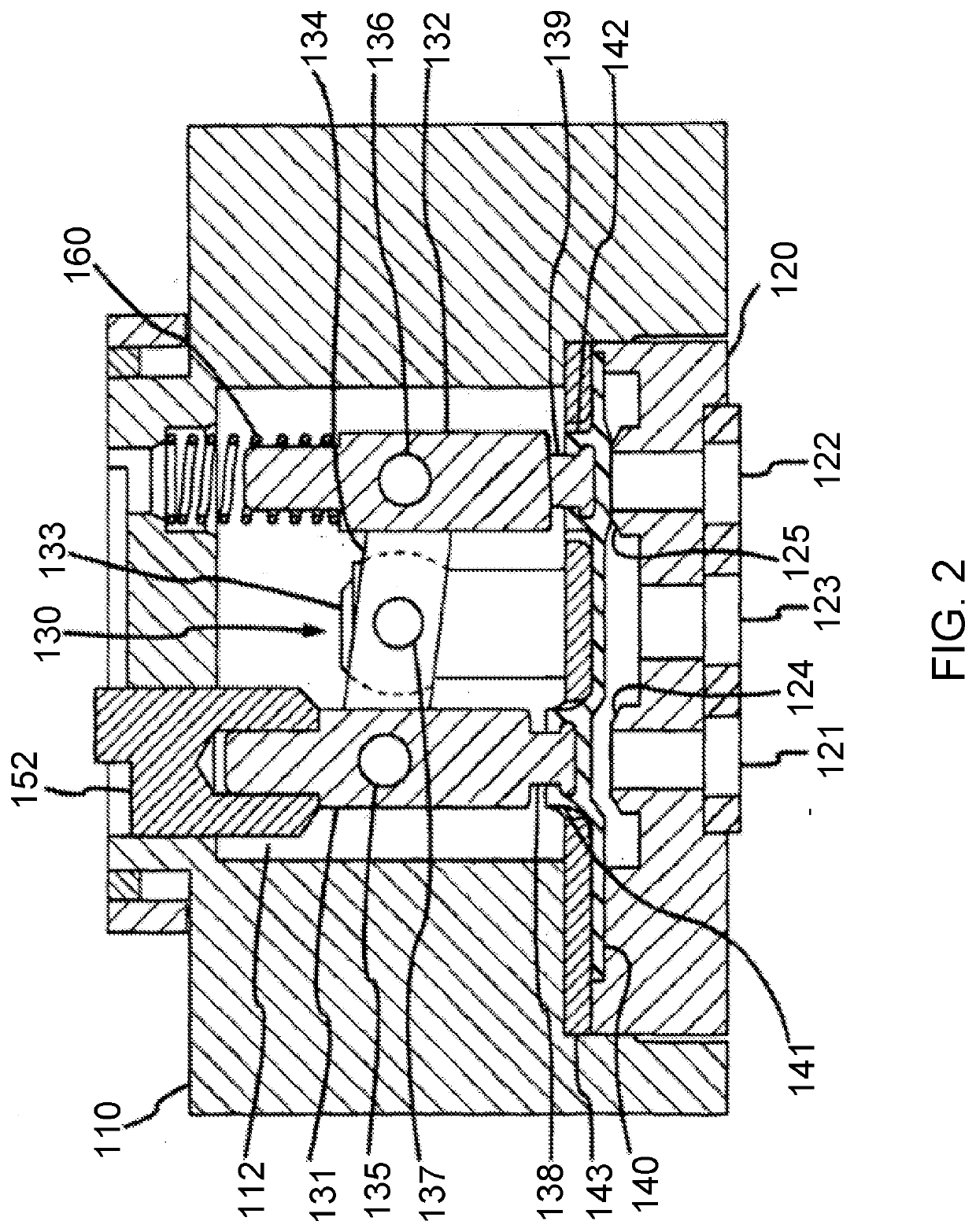

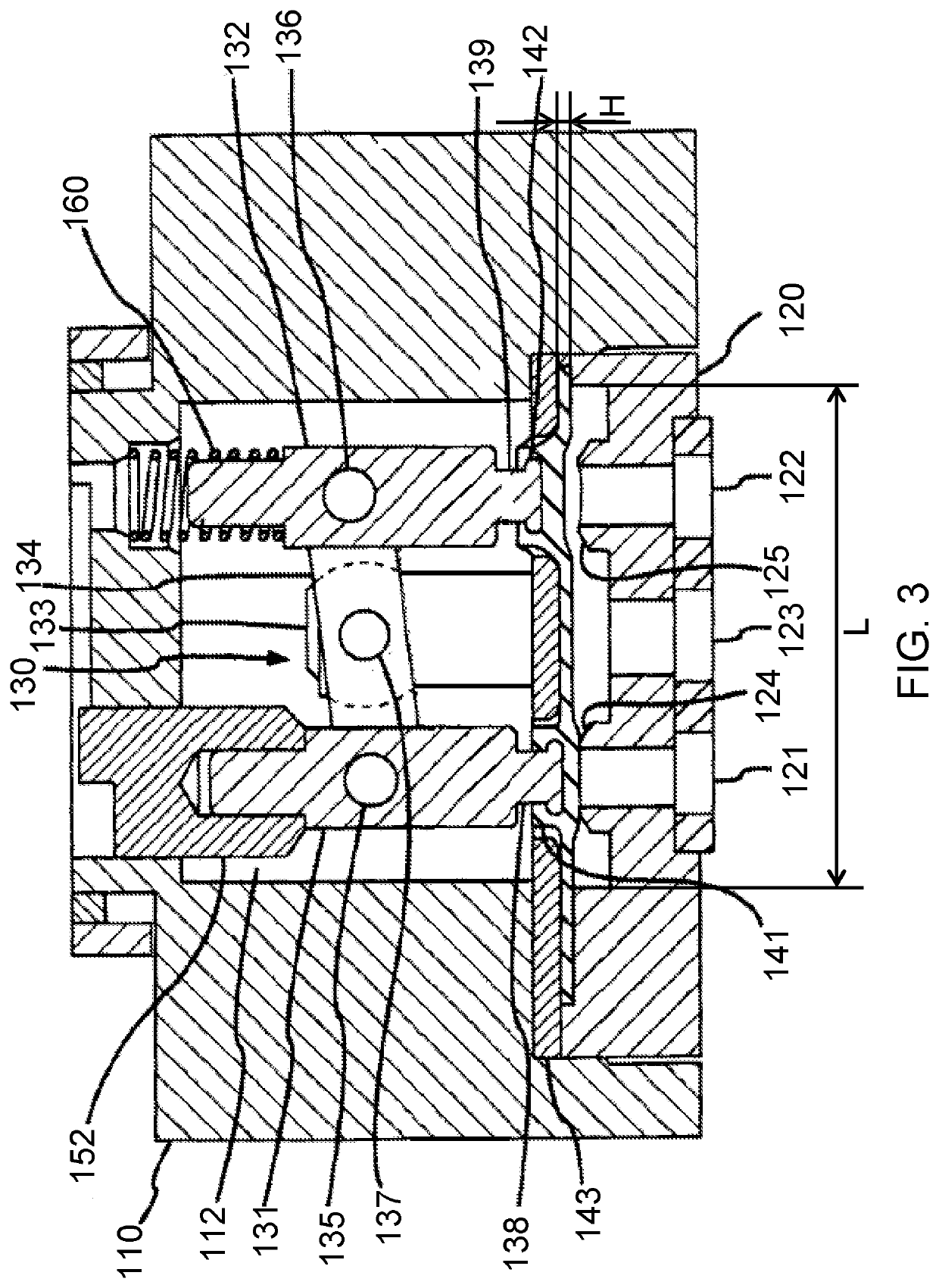

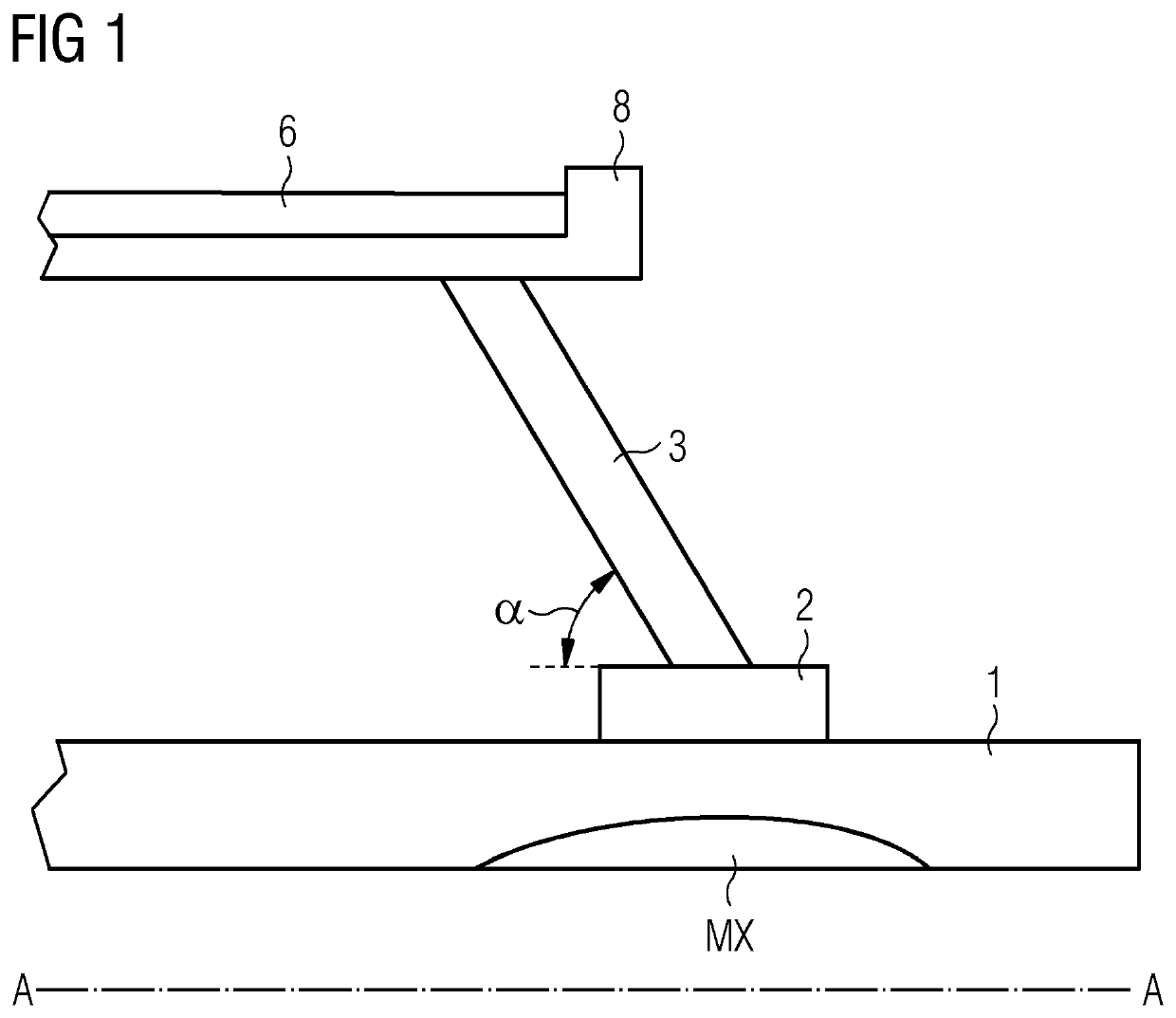

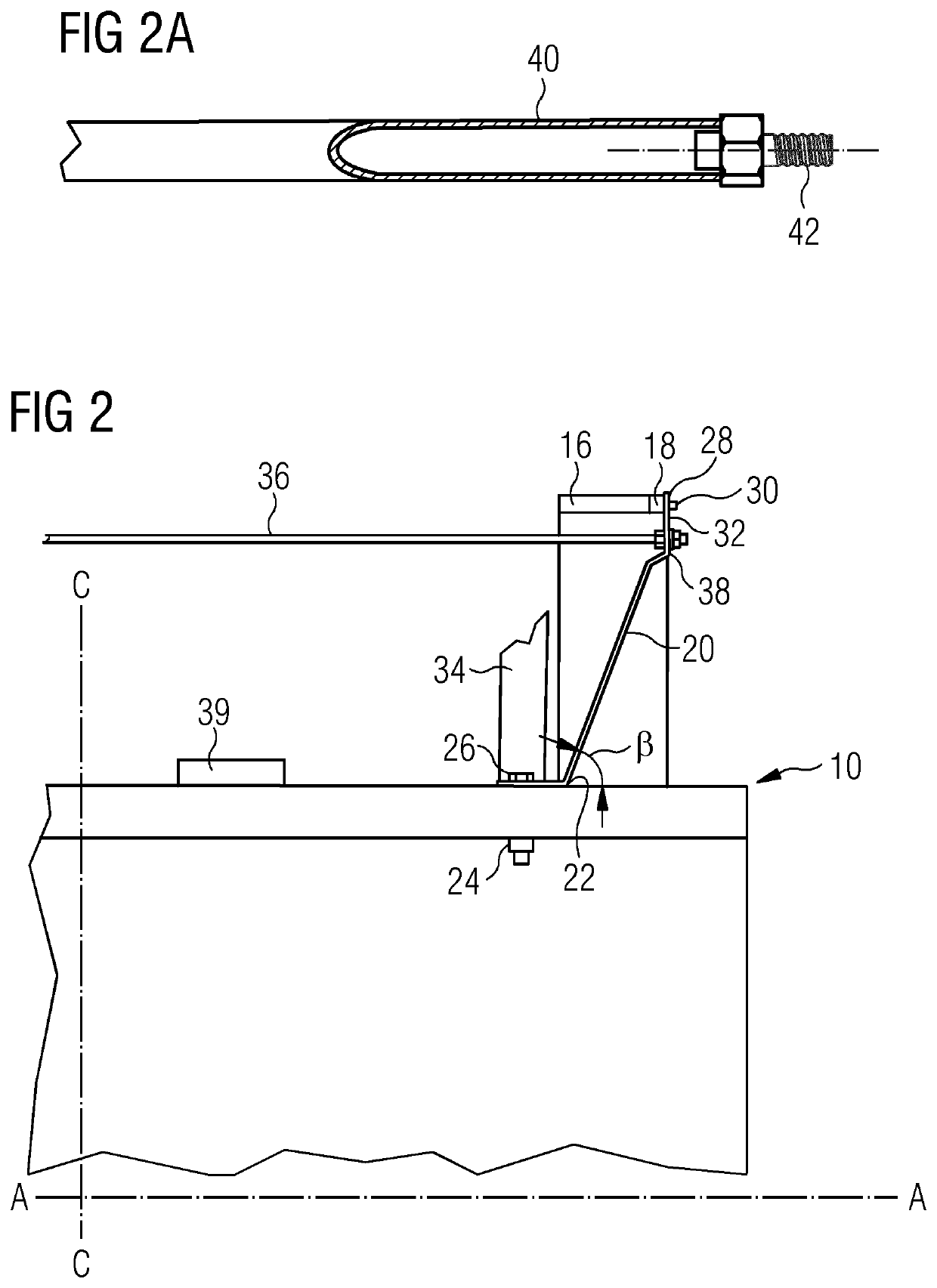

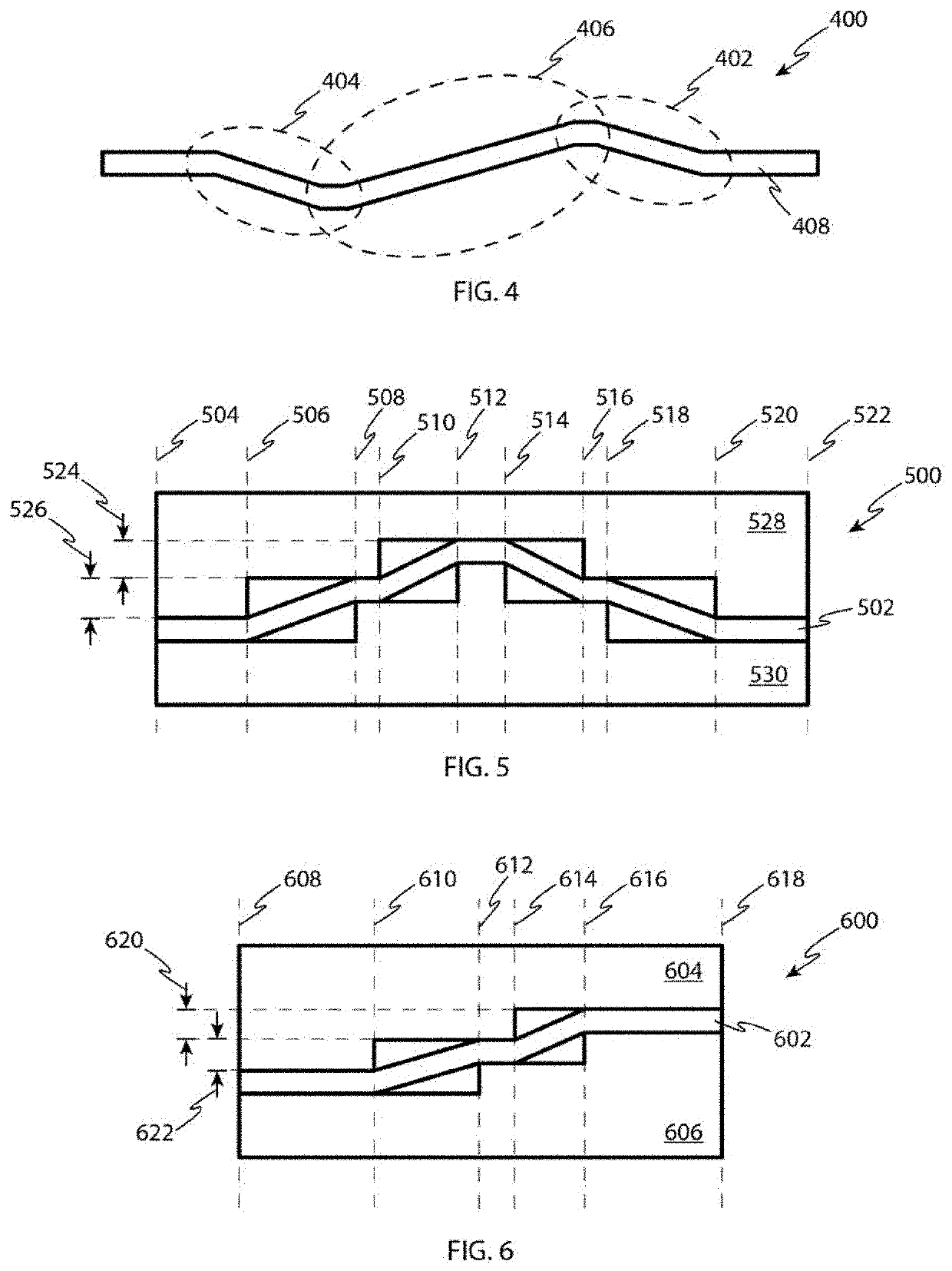

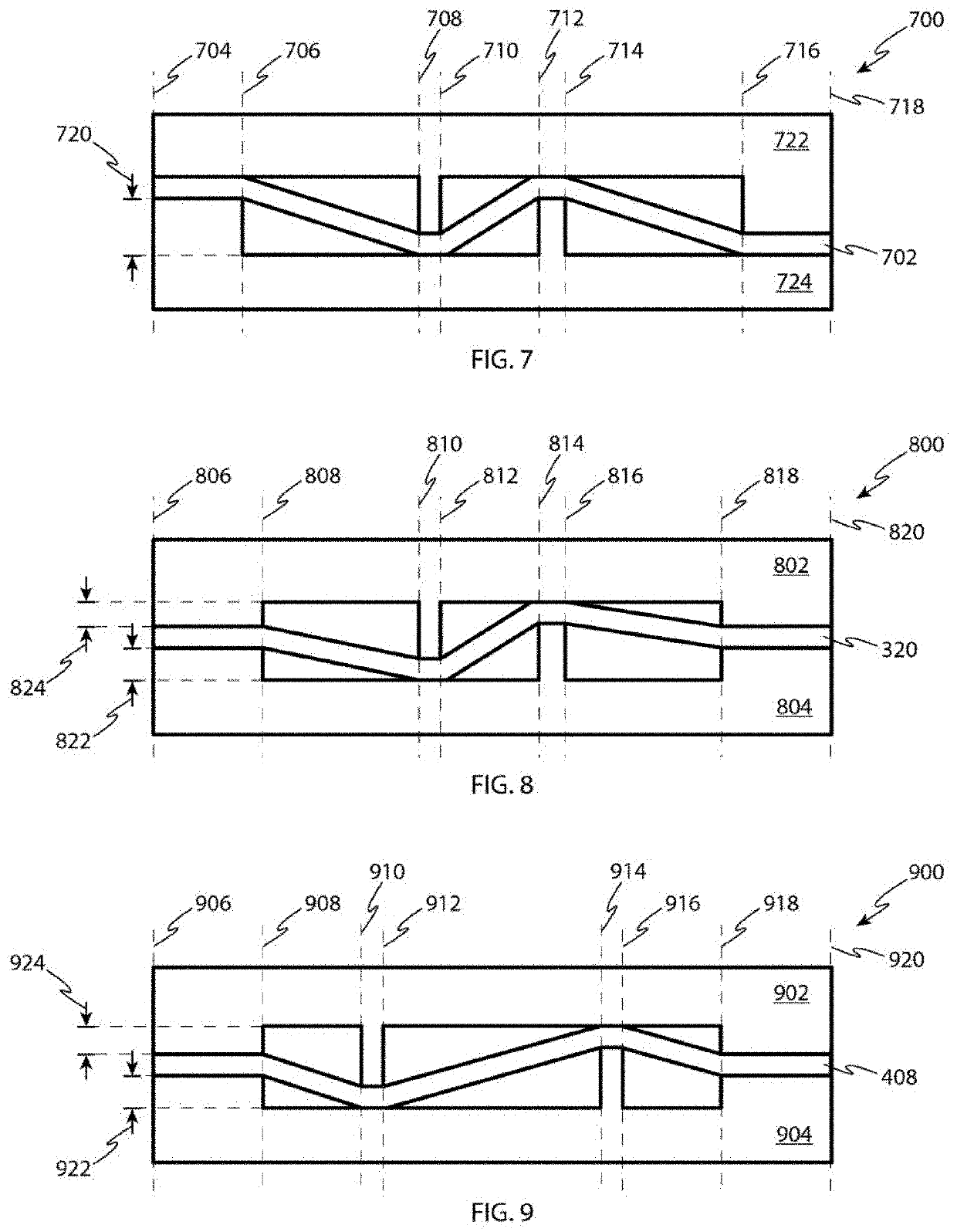

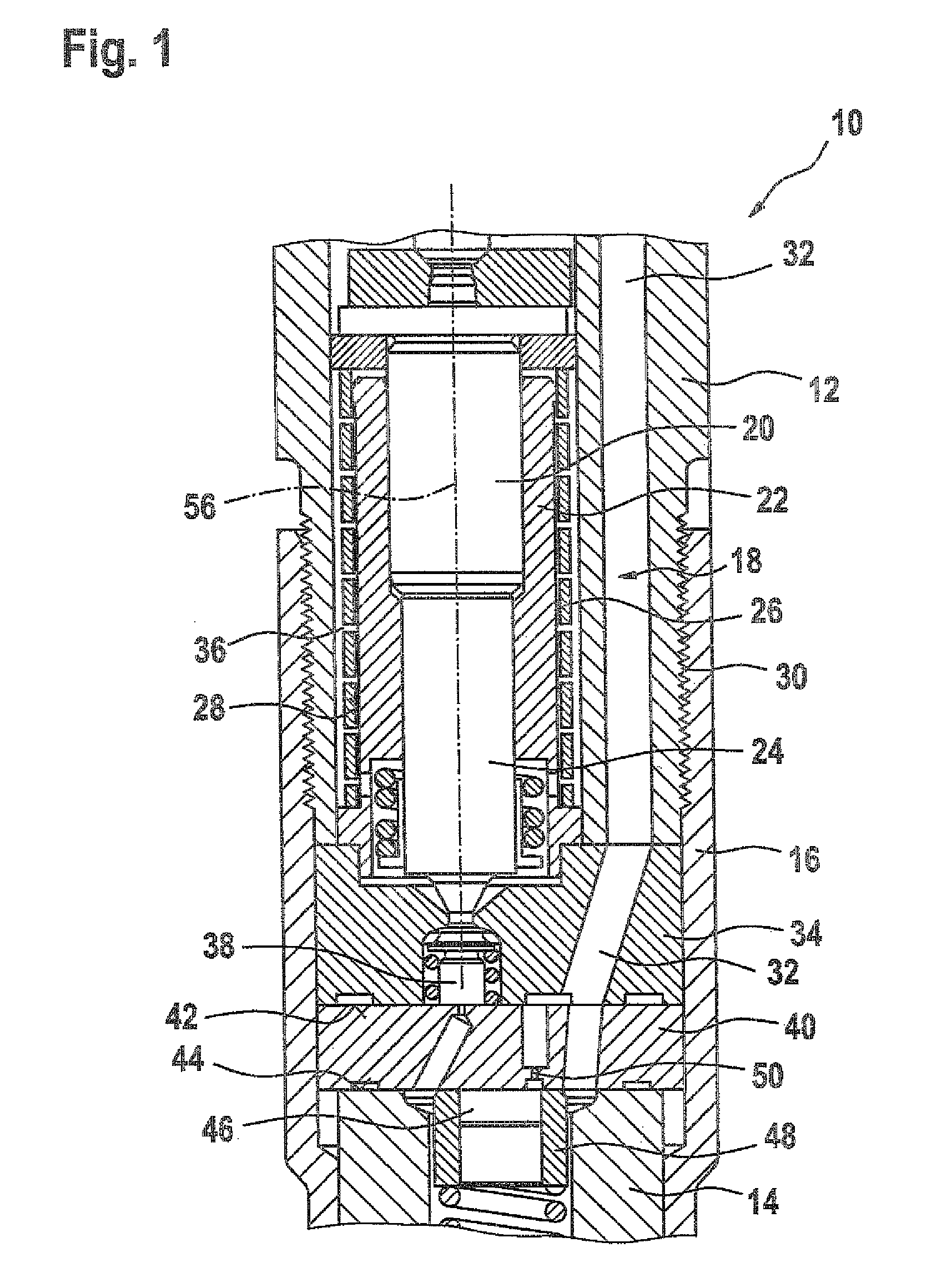

Rocker Valve With Rocker Valve Mechanism

PendingUS20190353272A1Improve unblocking actionIncrease flow volumeOperating means/releasing devices for valvesMultiple way valvesEngineeringVALVE PORT

The present invention provides a rocker valve comprising a valve body including first and second fluid ports and a rocker valve mechanism in the valve body. The mechanism comprises a single pivot arm rotatable relative to the valve body, and first and second plungers pivotally fixed to the single pivot arm. The second plunger acts in opposition to the first plunger when the single pivot arm is pivoted relative to the valve body. The rocker valve includes a flexible seal member extending laterally across the first and second fluid ports. The flexible seal member has a first sealing region attached to the first plunger and a second sealing region attached to the second plunger and is movable by the first and second plungers between a first position in which the first fluid ports is closed by the first sealing region, and a second position in which the second fluid port is closed by the second sealing region. When the single pivot arm is pivoted relative to the valve body, a rotation of at least one of the first and second plungers about its respective fixed pivot is constrained solely by the flexible seal member.

Owner:FAS MEDIC SA

Battery structure and protector

ActiveUS11034227B2Improve performanceLess spaceElectric propulsion mountingSecondary cellsElectrical batteryElectric cars

The present disclosure relates to a battery structure for an electric vehicle. The battery structure comprises a battery case for at least one battery module and a protector including a top belt, a bottom belt and a core arranged between and interconnecting the top belt and the bottom belt. The top belt has a wavelike cross section.

Owner:MUBEA CARBO TECH GMBH

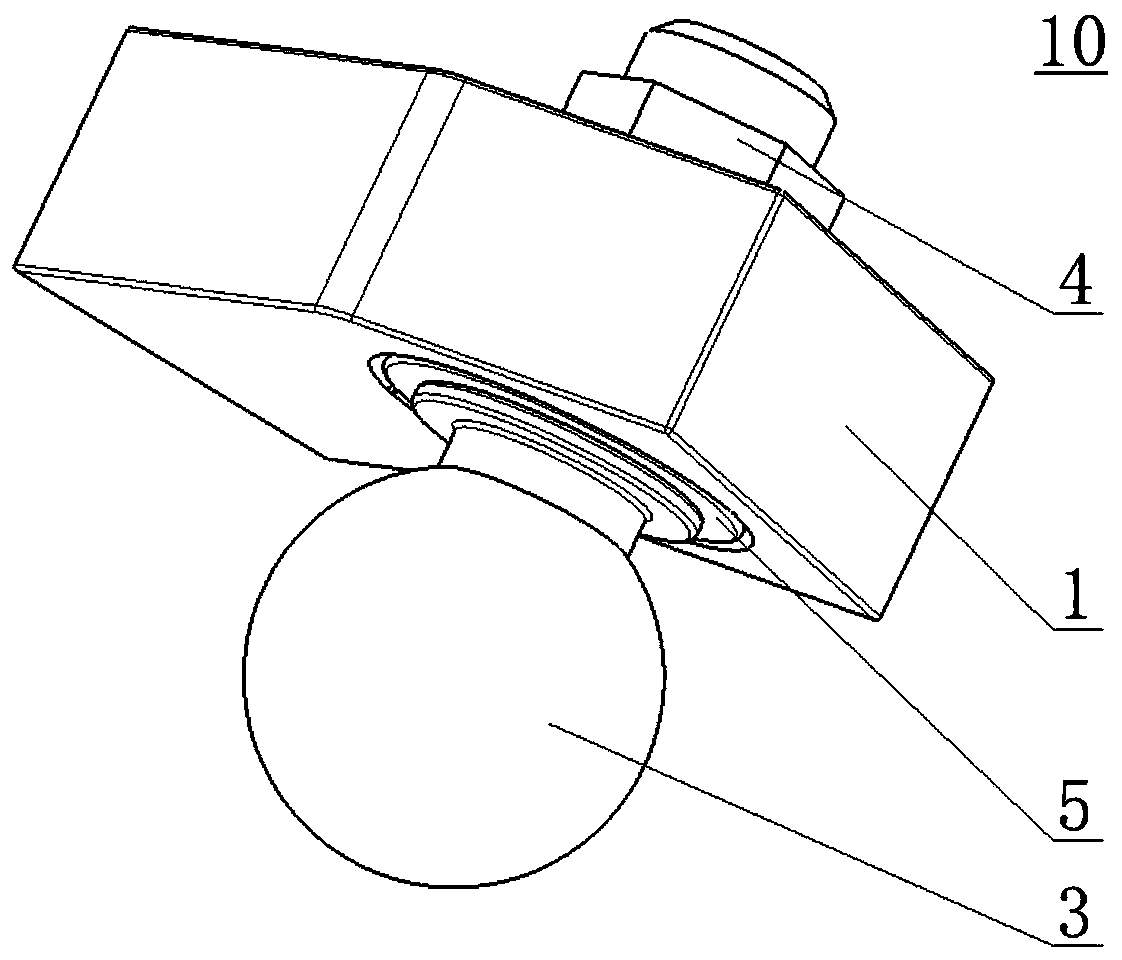

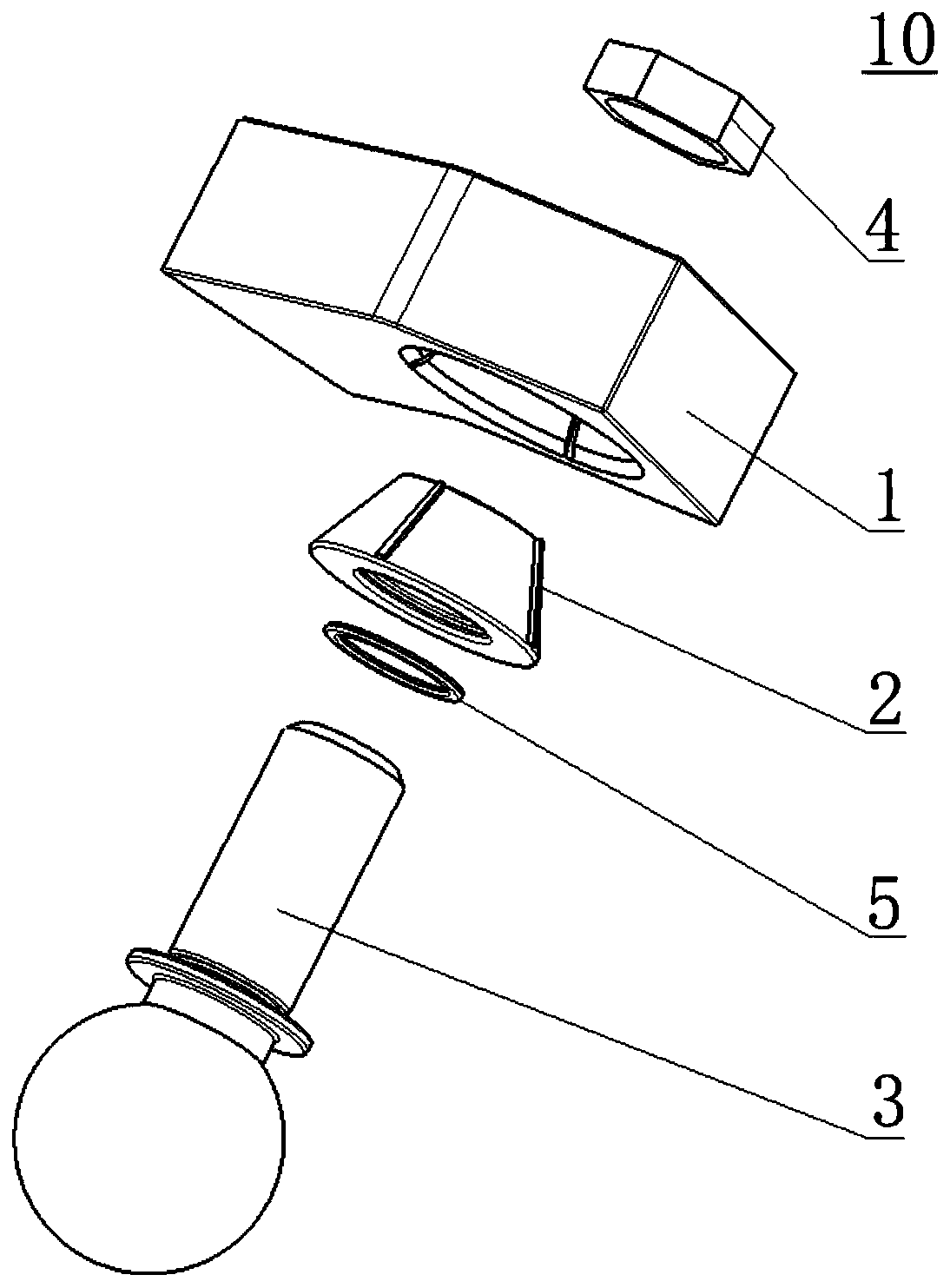

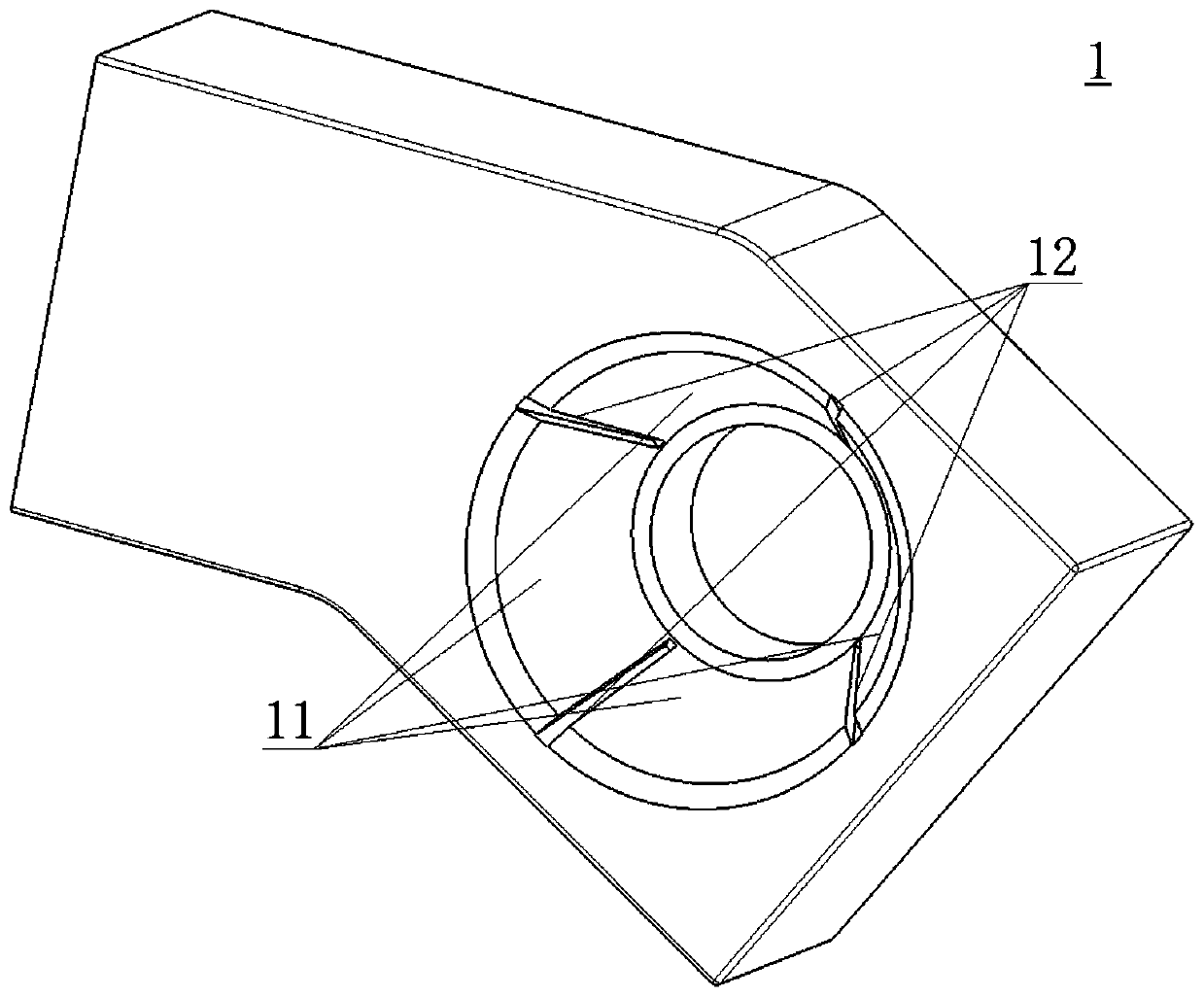

Ball head assembly and vehicle provided with same

ActiveCN109695625AImprove the safety of useAvoid breakingPivotal connectionsStress concentrationStress conditions

The invention discloses a ball head assembly and a vehicle provided with the same. The ball head assembly comprises a connecting piece, a tapered seat, and a ball head. The adapting piece is providedwith an inner tapered hole; the tapered seat penetrates through the inner tapered hole, and the tapered seat is provided with an outer tapered surface matched with the inner tapered hole; and the ballhead penetrates through the tapered seat and is fastened on the connecting piece through a fastener. According to the ball head assembly, the tapered seat and the connecting piece are connected through a tapered surface, the partial stress condition is greatly improved, stress concentration is lowered, thus connecting part breaking is avoided, and using safety of the ball head assembly is improved advantageously.

Owner:BAIC MOTOR CORP LTD

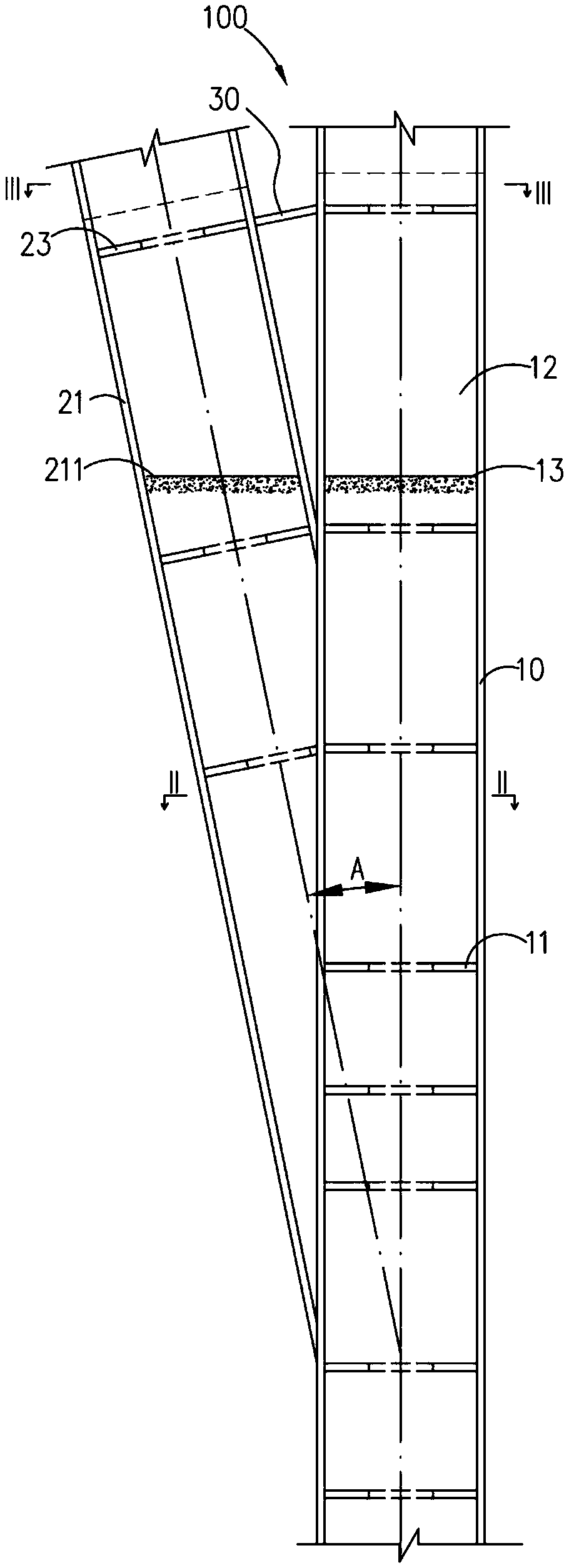

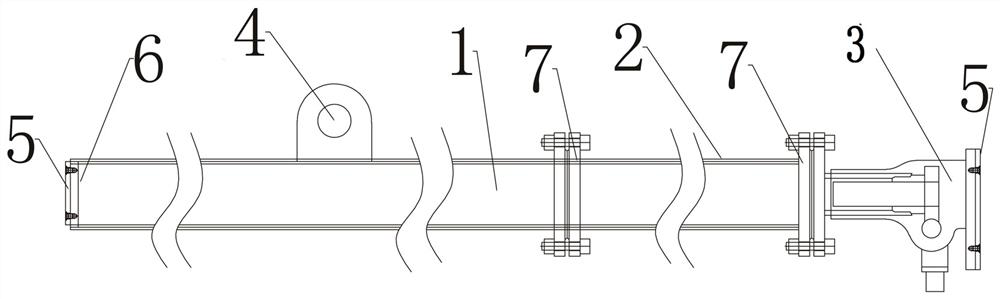

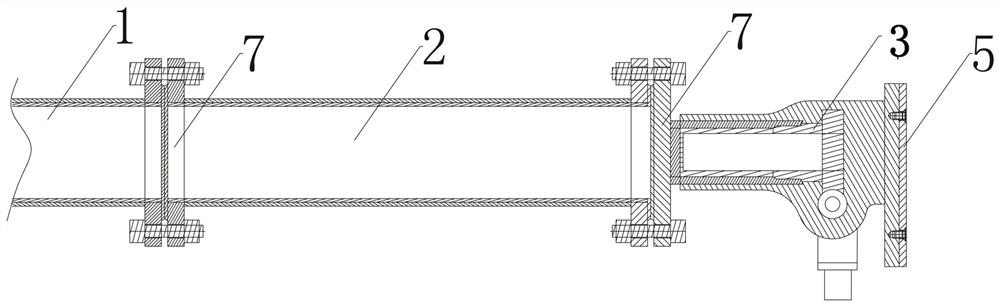

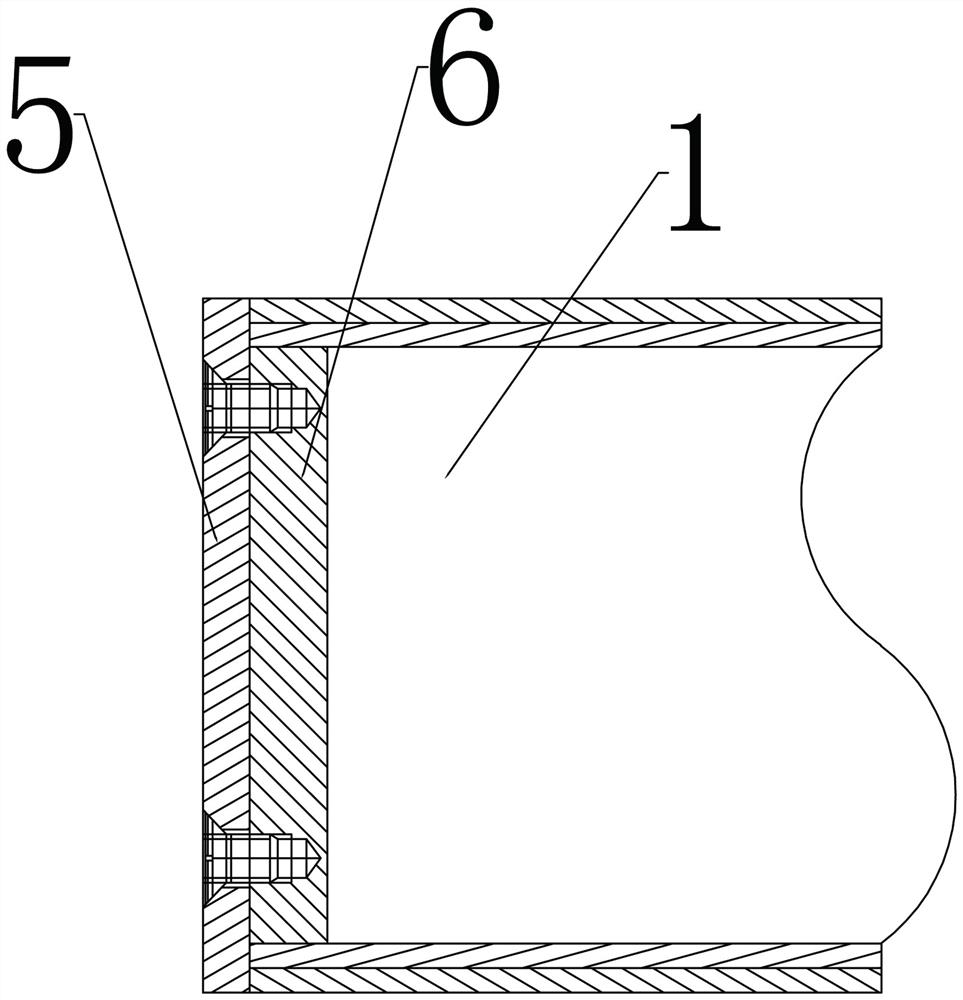

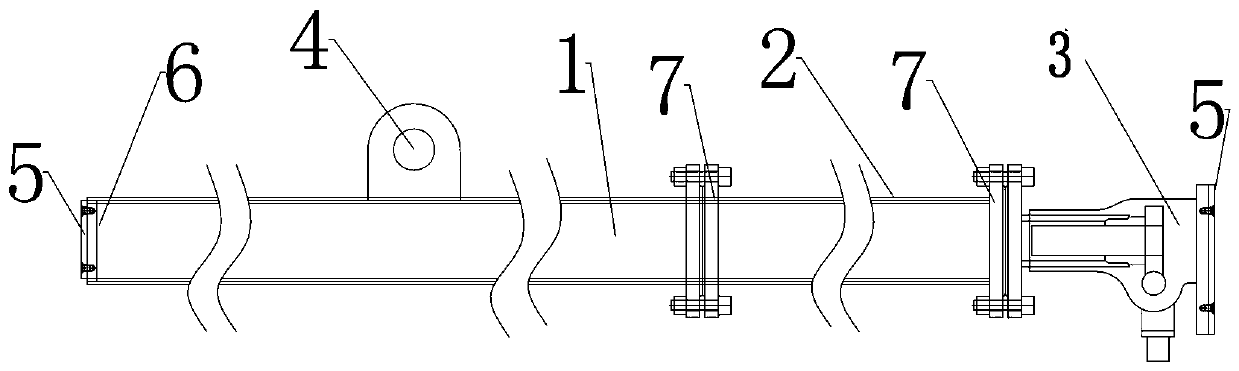

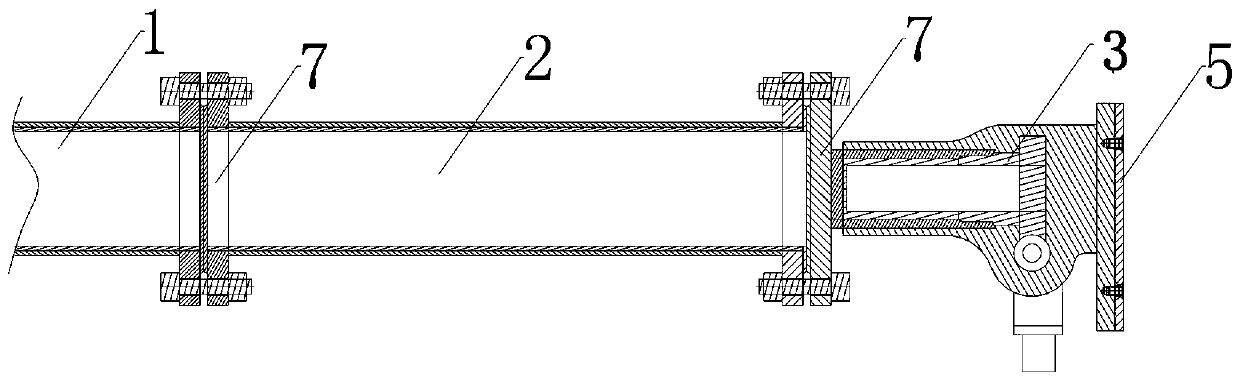

Anchor rod and anchor cable protecting mechanism for roadway support hydraulic bracket

The invention discloses an anchor rod and anchor cable protecting mechanism for a roadway support hydraulic bracket. The anchor rod and anchor cable protecting mechanism comprises a fixing beam installed on a hydraulic bracket top beam. The fixing beam is provided with a sliding beam driven by a hydraulic cylinder, and the sliding beam is slidably connected with the fixing beam through a guide rail. The upper surface of the sliding beam is provided with at least two convex structures contacting with a roadway top plate. An avoidance groove matched with an anchor rod or an anchor cable is formed between the neighboring convex structures. The anchor rod and anchor cable protecting mechanism is simple in structure, convenient to operate, and capable of adequately preventing the top beam of the roadway support hydraulic bracket from directly contacting with the anchor rod or the anchor cable so as to generate a higher local stress, meeting a requirement of improving support quality, and meeting a demand of rapidly moving the bracket, and has very strong applicability.

Owner:ZHENGZHOU COAL MINING MACHINERY GRP

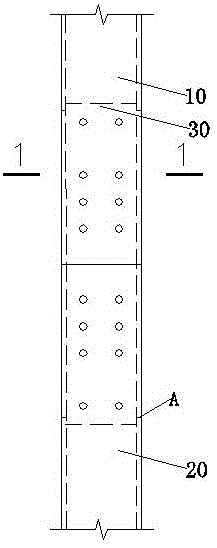

Joint structure of multi-coupled steel component

PendingCN107806178AImprove local stiffnessMeet structural strength requirementsBuilding constructionsStructural engineeringSteel casting

The invention discloses a joint structure of a multi-coupled steel component. The joint structure of the multi-coupled steel component comprises a main component and a plurality of connecting components, the main component is of a hollow tubular structure, the main component is provided with a connection joint area, a plurality of first inner strengthening ring plates are arranged in the position,corresponding to the connection joint area, in the main component, and all the first inner strengthening ring plates are arranged in the height direction of the main component at intervals in an arrayed mode; and the multiple connecting components are fixedly connected with the main component, and the ends, fixedly connected with the main component, of the multiple connecting components are located in the connecting joint area. The joint structure of the multi-coupled steel component can effectively optimize local force of the main component, an existing method by adopting cast steel joints or increasing the wall thickness of the main component is replaced, the wall thickness of the main component is effectively controlled, the machining period is shortened, and the weight of the multi-coupled steel component is reduced. Therefore, the whole structure cost of the joint structure of the multiple-limb steel component is lower than that of the method by adopting cast steel joint design and increasing the wall thickness of the main component.

Owner:深圳华森建筑与工程设计顾问有限公司

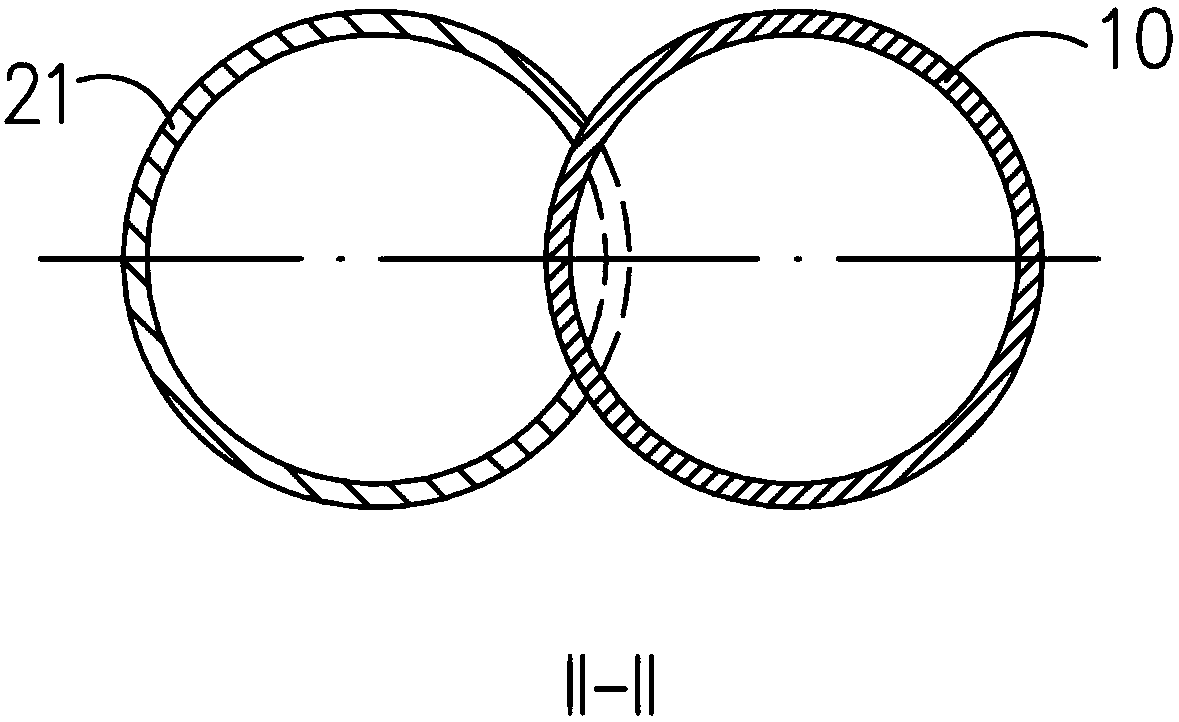

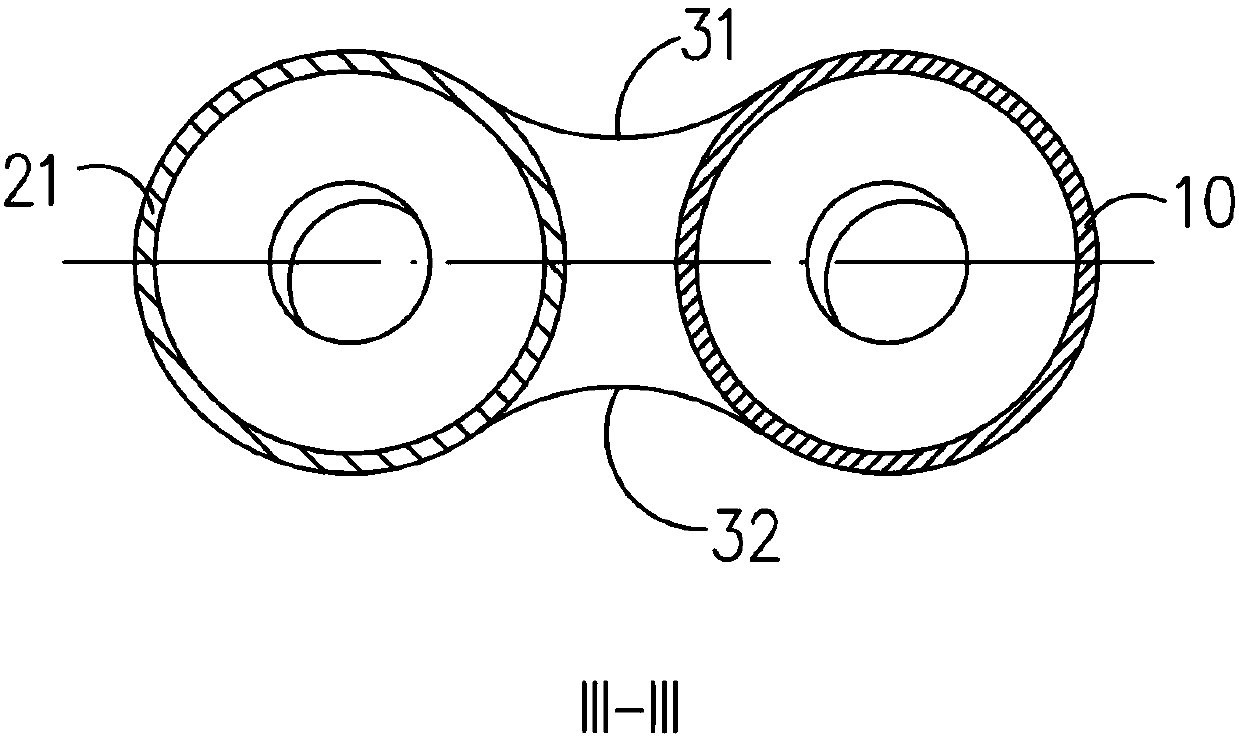

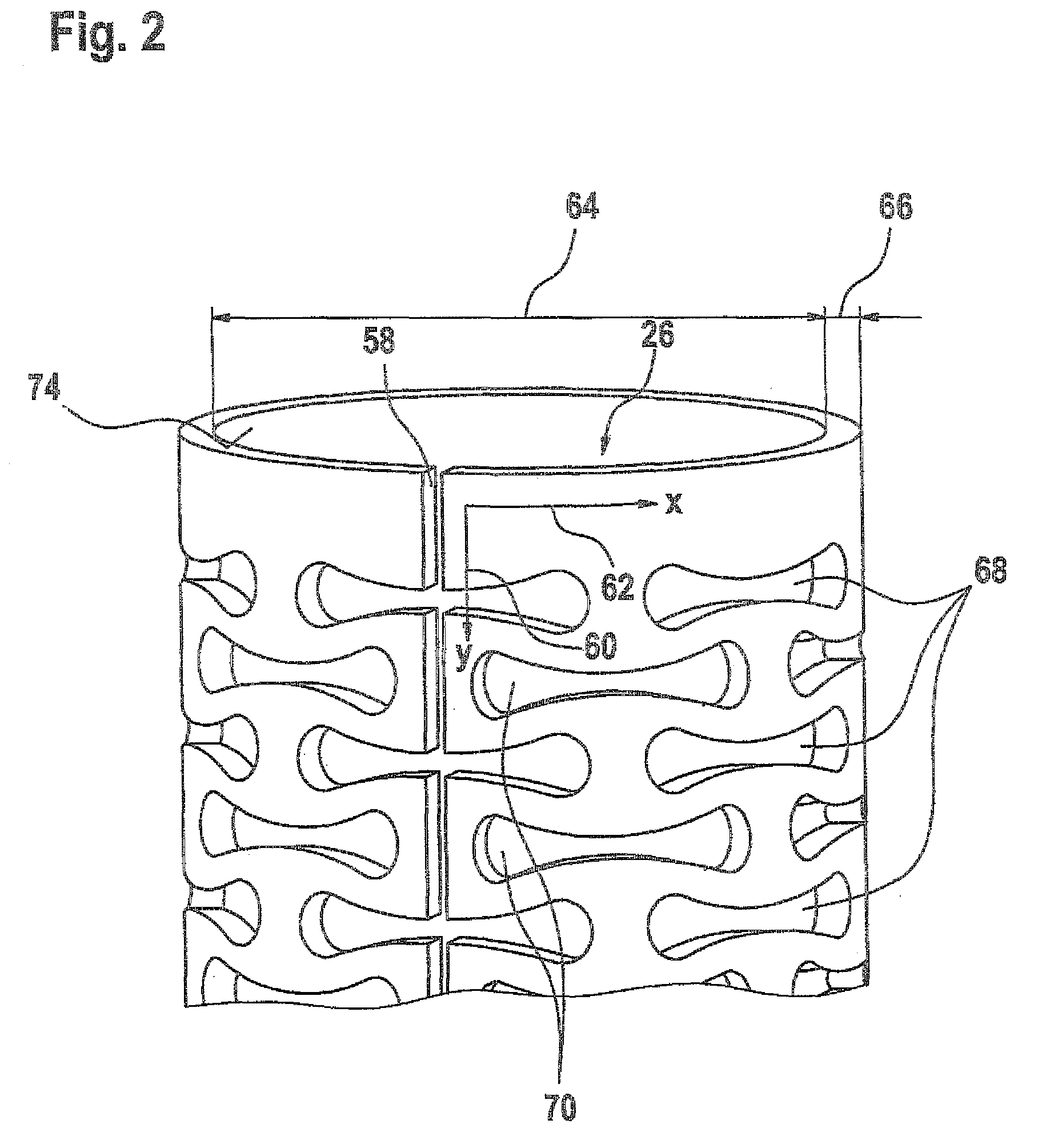

Coil Support

PendingUS20220326325A1Minimises degradation of magneticImprove local stressSuperconducting magnets/coilsMeasurements using magnetic resonanceSuperconducting CoilsEngineering

A superconducting magnet assembly may include a main magnet assembly having at least one annular coil arranged about an axis, and at least one shield coil, of greater diameter than the main magnet assembly, arranged about the axis. At least one support may be provided, attached to the shield coil and to the main magnet assembly.

Owner:SIEMENS HEALTHCARE LTD

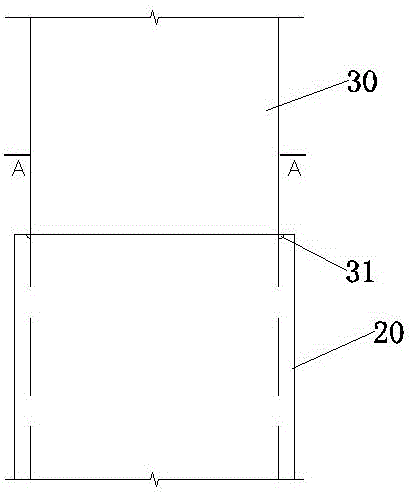

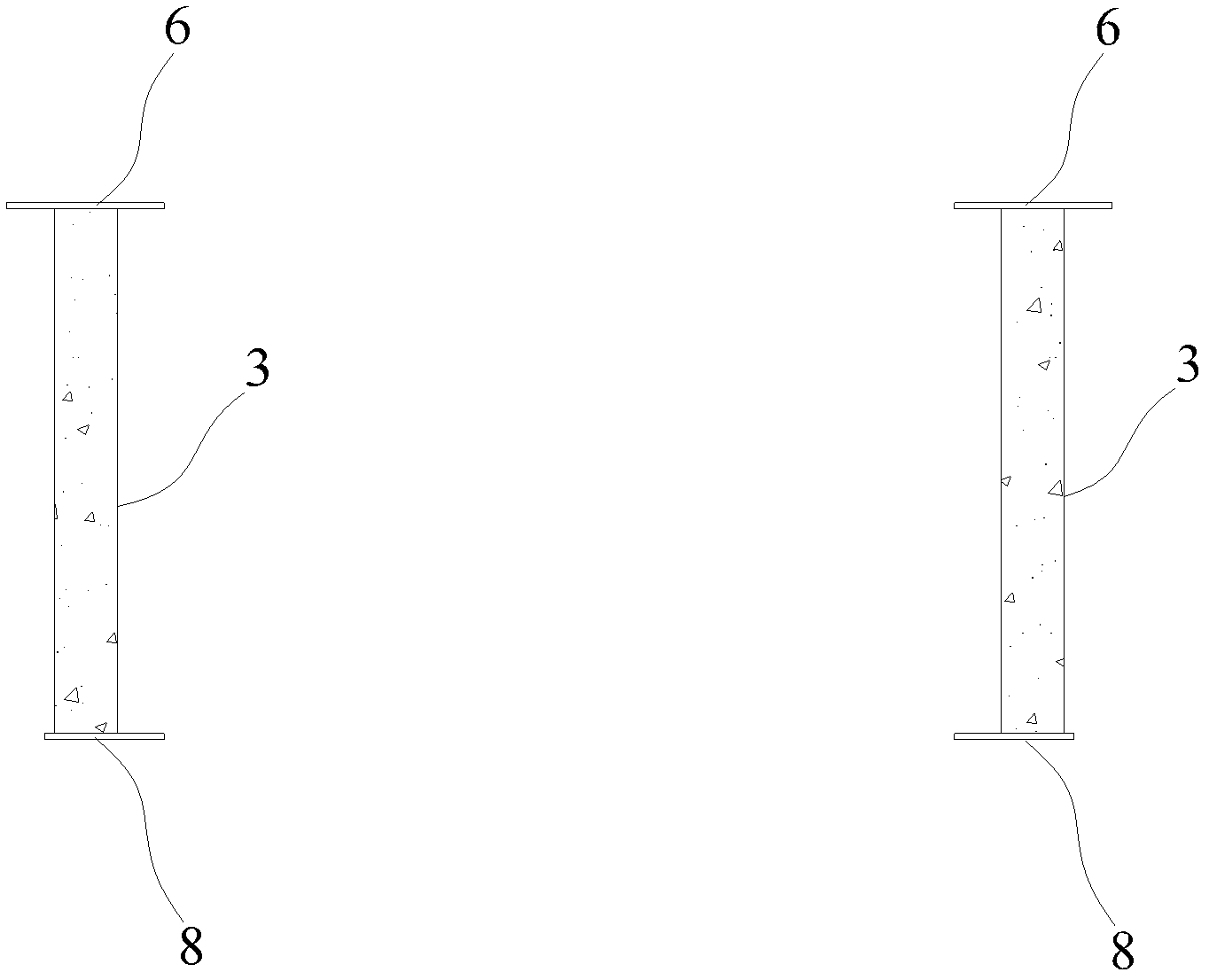

Connecting device for box-shaped section steel tube components

InactiveCN106193331ASplicing speed is fastSimple and fast operationBuilding constructionsMaterials scienceSteel tube

The invention discloses a connecting device for box-shaped section steel tube components. The connecting device comprises an upper box-shaped section steel tube component section and a lower box-shaped section steel tube component section. The upper box-shaped section steel tube component section and the lower box-shaped section steel tube component section are connected through connecting inner cores arranged in the upper box-shaped section steel tube component section and the lower box-shaped section steel tube component section. The upper box-shaped section steel tube component section and the lower box-shaped section steel tube component section are fixed to the connecting inner cores through bolts. Welding can be avoided during field splicing of the box-shaped section steel tube components with small sections, the bolt connecting operation is simple and convenient, and the connecting requirements of anti-knock steel structure frame beams and columns can be met.

Owner:TUS DESIGN GRP CO LTD

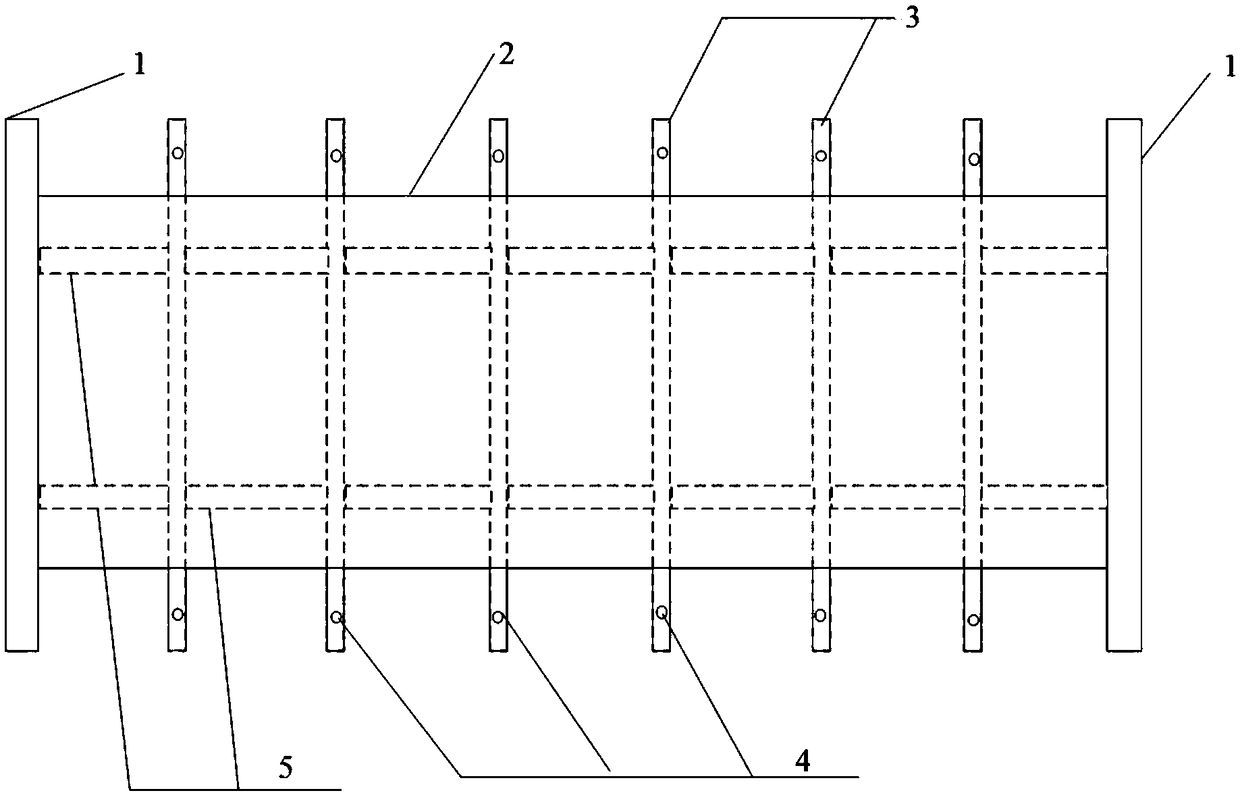

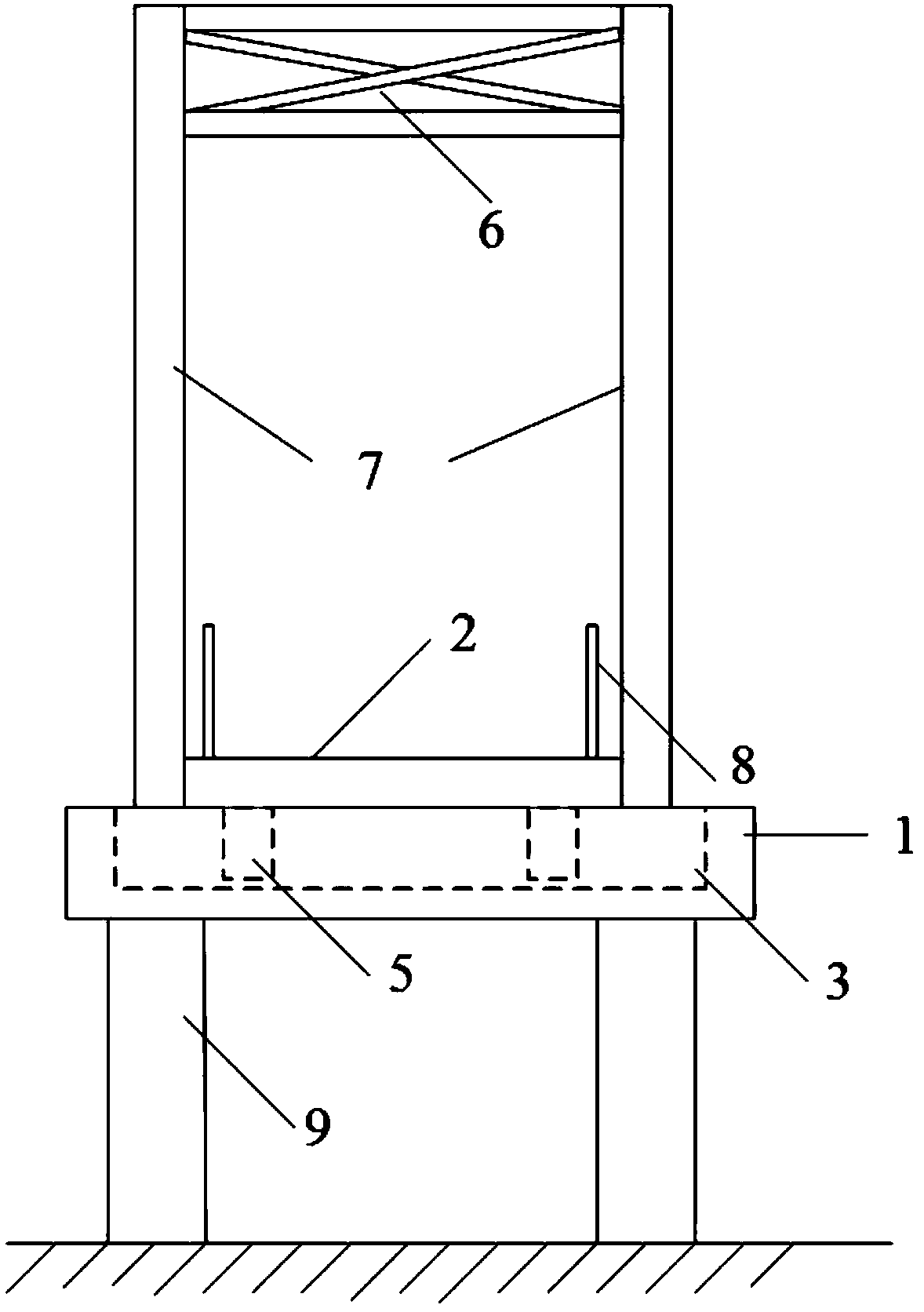

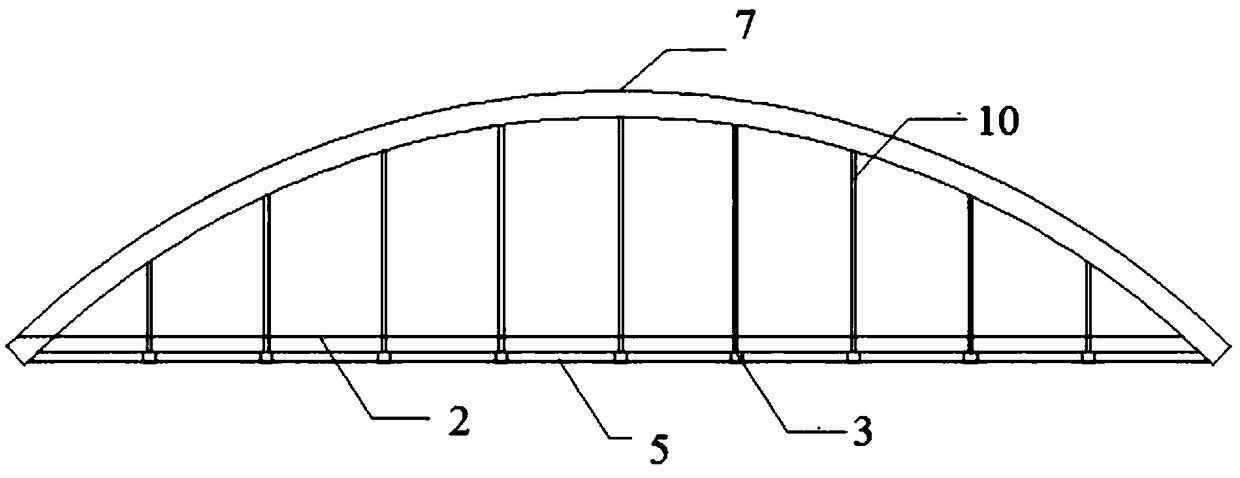

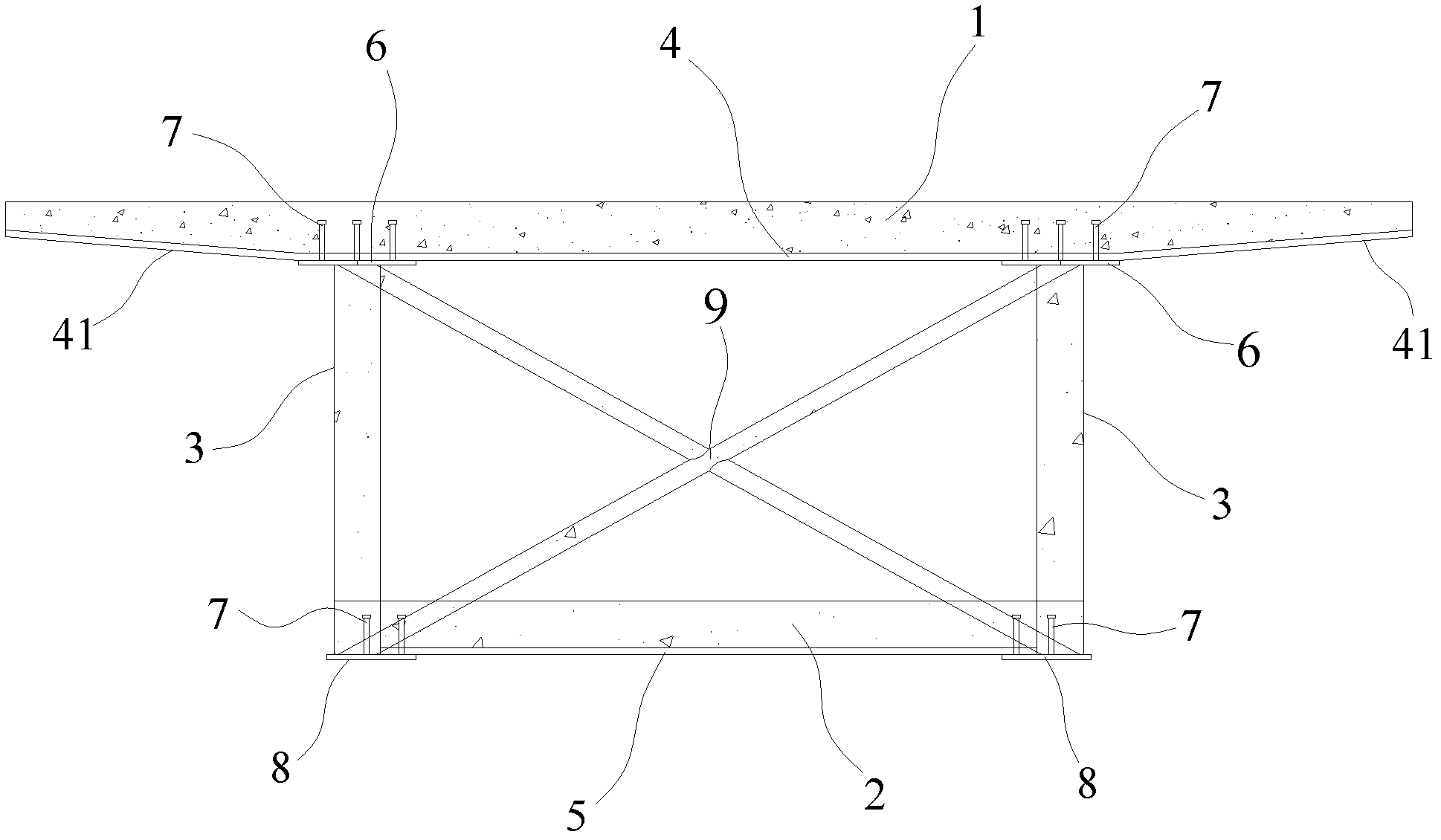

Arch bridge boom structure

PendingCN108442230AEliminate detection blind spotsImprove securityBridge structural detailsArch-type bridgeLap jointEngineering

The invention discloses an arch bridge boom structure which comprises bridge piers, horizontal beams, longitudinal beams, a bridge floor and arch ribs which are sequentially arranged from bottom to top, wherein the horizontal beams and the longitudinal beams are mutually in lap joint and fixed to the bridge piers, the bridge floor is arranged at the tops of the horizontal beams, the arch ribs arearranged on the two sides of the bridge floor, the top ends of the arch ribs on the two sides of the bridge floor are fixedly connected through steel supports, booms are evenly distributed among the arch ribs and the bridge floor, the length of the horizontal beams is larger than the width of the bridge floor, the bottom ends of the booms are in threaded connection to the two ends of the horizontal beams, and the top ends of the booms are fixed to the arch ribs. The invention aims at providing the arch bridge boom structure. According to the structure system, as the horizontal beams extends outwards, the booms can be disassembled and replaced conveniently; meanwhile, the novel boom structure can be directly connected with the arch ribs and the horizontal beams on the bridge floor and can be stretched and drawn on the bridge floor, so that the problems of rust and corrosion of existing boom anchoring areas is completely solved, and safety of a boom arch bridge is improved.

Owner:SHENZHEN MUNICIPAL DESIGN & RES INST

Display panel and electronic device

PendingCN112397453AImprove local stressReduce stress concentration factorSemiconductor/solid-state device detailsSolid-state devicesEngineeringStructural engineering

The invention discloses a display panel and an electronic device. The display panel comprises a flexible display panel which comprises a display region and a bending region disposed outside the display region. The display region and the bending region are of an integrated structure, the bending area is provided with a bending part and a bending protection part, and a metal wire is arranged in thebending part. The bending protection cloth is distributed at the two sides of the bending part, and the bending part and the bending protection part are of an integrated structure. According to the embodiment of the invention, the bending protection part is additionally arranged in the bending area, the bending protection part is provided with the plurality of protection part metal wires, and themetal wires in the bending protection cloth are used for improving the local stress borne by the source and drain metal wires of the bending part during bending, so that the stress concentration coefficient of the metal wires in the bending area during bending is reduced, and accordingly the phenomenon that the source and drain metal wires in the bending area are broken is improved, the bending resistance is improved, and the production yield of products is improved.

Owner:WUHAN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

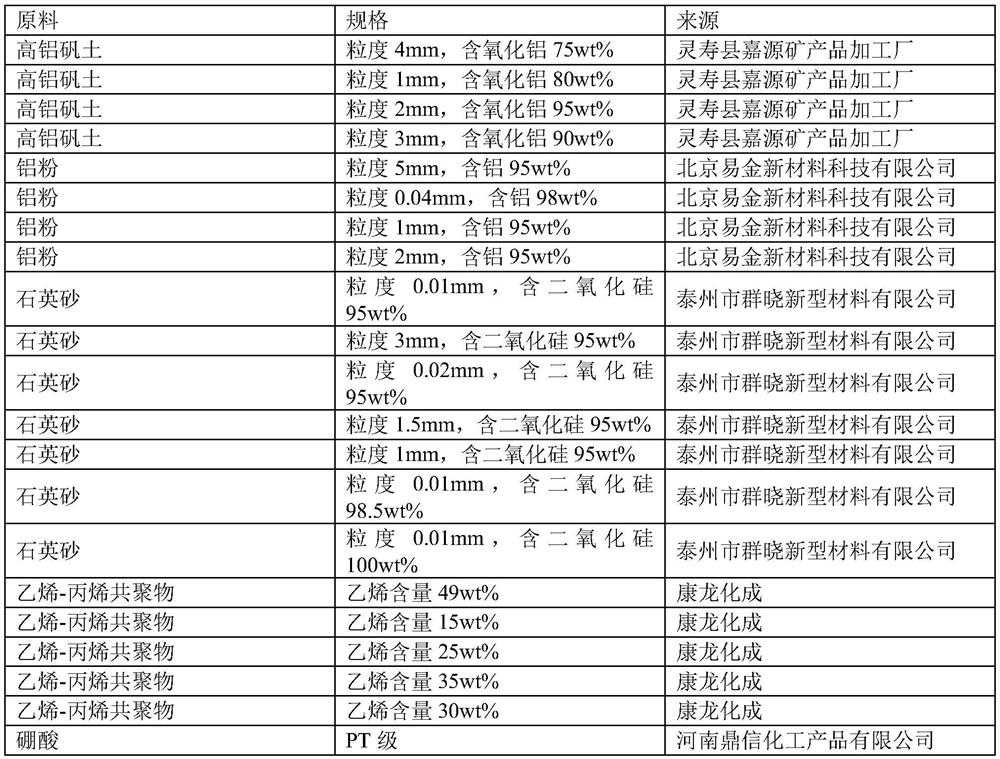

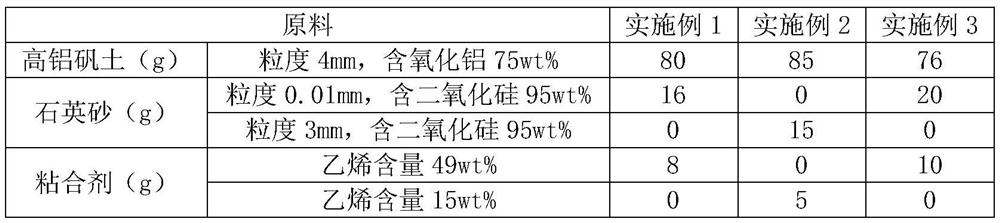

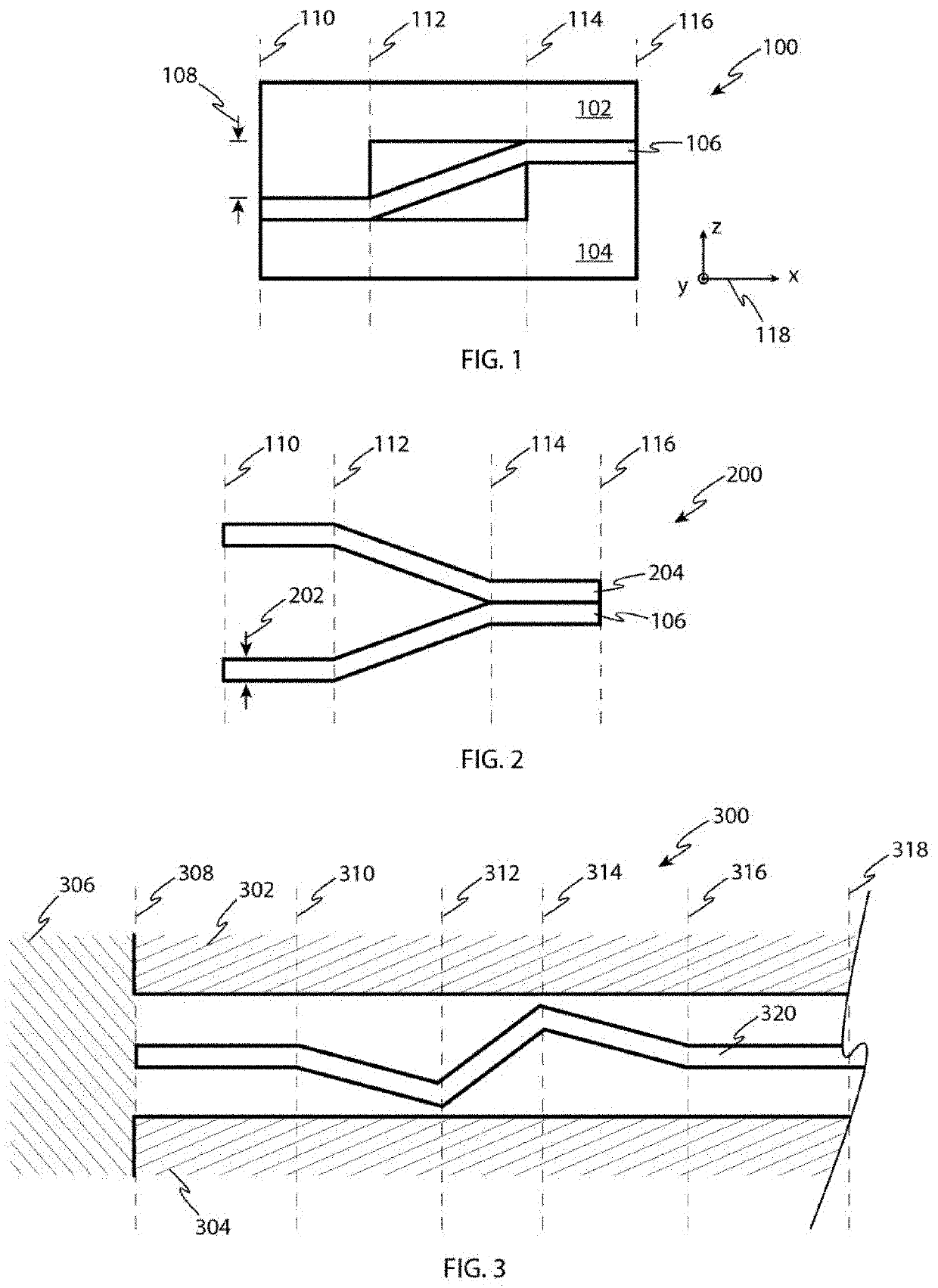

Refractory furnace lining material and ramming method thereof

The invention relates to the field of furnace lining materials, and particularly discloses a refractory furnace lining material and a ramming method thereof. The refractory furnace lining material isprepared by mixing the following raw materials in parts by weight: 76-85 parts of high-alumina bauxite, 15-20 parts of quartz sand and 5-10 parts of an adhesive, wherein the adhesive is an ethylene-propylene copolymer. The method comprises the following steps: ramming of a furnace lining: subjecting the refractory furnace lining material to filling and ramming layer by layer, wherein the thicknessof each filling layer is not more than 100 mm; and baking: conducting baking in an empty furnace, baking scrap steel and sintering molten steel so as to obtain the refractory furnace lining, whereinthe temperature of baking in the empty furnace is 100-500 DEG C, the temperature of baking the scrap steel is 500-1100 DEG C, and the temperature of sintering the molten steel is 1620-1780 DEG C. Therefractory furnace lining material has the advantages of high refractoriness and long service life.

Owner:JIANGSU ZHUHONG FORGING

Sealing gasket with optimized profile

PendingUS20220163114A1Prevent leakageGasket degradeEngine sealsSealing arrangements for enginesAutomotive engineeringCombustion chamber

A sealing system for an engine comprising a single layer of sheet material, the sheet having an upper surface adapted to sealably contact a first engine component and a lower surface adapted to sealably contact a second engine component, and bead portions profiled on the gasket, where the gasket profile is optimized with varying heights and widths so as to create portions of varying stiffness adjacent to one another. The bead portions are profiled so as to be concentric with a combustion or cylinder chamber of the engine, and the bead portions include a portion of high stiffness adjacent to a portion of high recovery, the portion of high stiffness having a sharper angle protruding away from the plane comprising the single layer gasket than for the adjacent portion of high recovery. The optimized profile allows use of single layer gaskets to replace multiple layer gaskets.

Owner:DANA AUTOMOTIVE SYST GRP LLC

A leaf spring and its manufacturing process

ActiveCN107606014BReduce weightImprove local stressLeaf springsDomestic articlesFiberDynamic stiffness

The invention relates to a leaf spring and a manufacturing technology thereof. The leaf spring comprises a leaf middle section, a transition section, a variable-section section and a winding lug installing section, and all the sections are the same in width. The material of the leaf spring is an FRP composite material. The manufacturing technology comprises the fiber cloth weaving procedure, the fiber cloth laminating procedure, the laminated layer spot welding procedure, the pre-forming procedure, the cutting procedure, the HP-RTM procedure, the unloading and shaping procedure and the post-machining procedure. The technical scheme solves the problems of design and process of leaf spring leaves in the prior art, the leaf spring leaf performance is improved, the volume production beat is fast, and the market value of the leaf spring is huge; one leaf spring can be independently used, two leaf springs can be combined to form a main and auxiliary spring structure, different loads are achieved, and all steel plate spring structures can be replaced by changing structures of winding lugs and other accessories; complete fracture at a time is avoided, the active failure mode is achieved, and the vehicle running safety is sufficiently guaranteed; the weight of a leaf spring suspension is reduced, the dynamic stiffness is very small, the vehicle running smoothness is improved, and fuel affinity is improved as well; and the service life is 5 or more times of the steel plate springs, and the cost of using the leaf spring by users is greatly reduced.

Owner:合肥前卫复合材料有限公司 +1

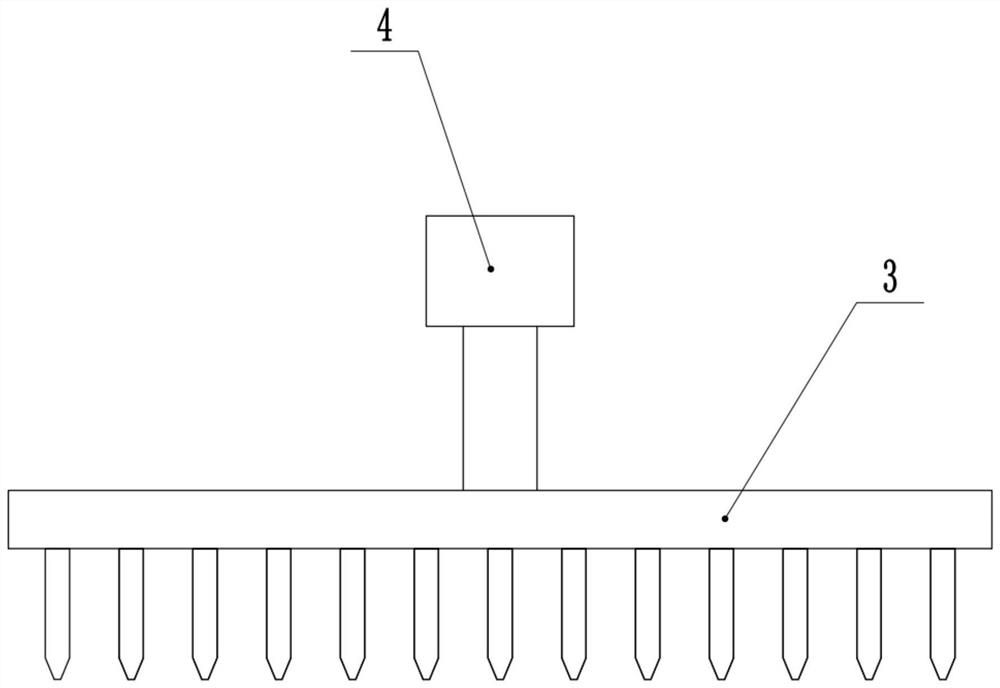

Spring sleeve for fuel injector

InactiveUS8446073B2Increased durabilityImprove local stressRing springsPiezoelectric/electrostriction/magnetostriction machinesInjectorNozzle

The invention relates to a fuel injector with a holding body and a nozzle body which are joined together and which accommodate a coupler module which has a coupler body enclosed by a spring sleeve. The spring sleeve is open in a circumferential direction at a seam thereof which extends in the longitudinal direction. Either the wall thickness of the spring sleeve varies in the longitudinal direction, or a width of at least one hole geometry in the sheathing of the spring sleeve varies in the longitudinal direction.

Owner:ROBERT BOSCH GMBH

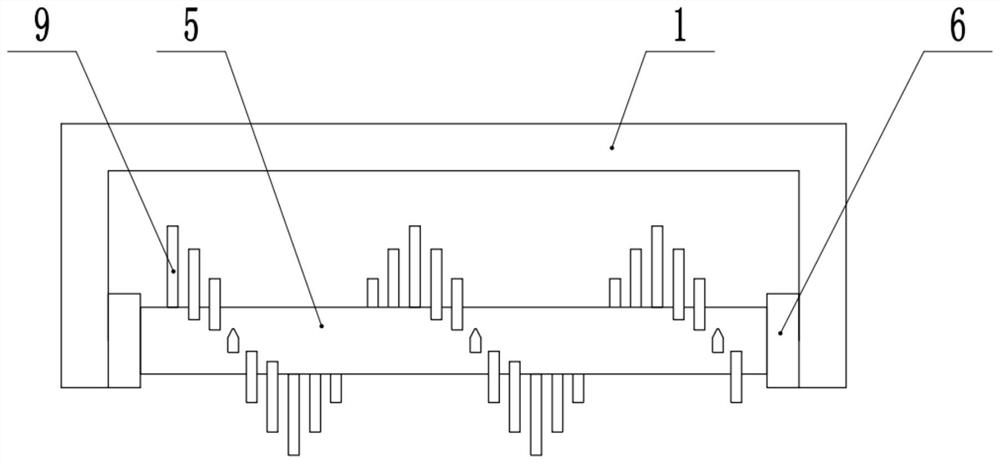

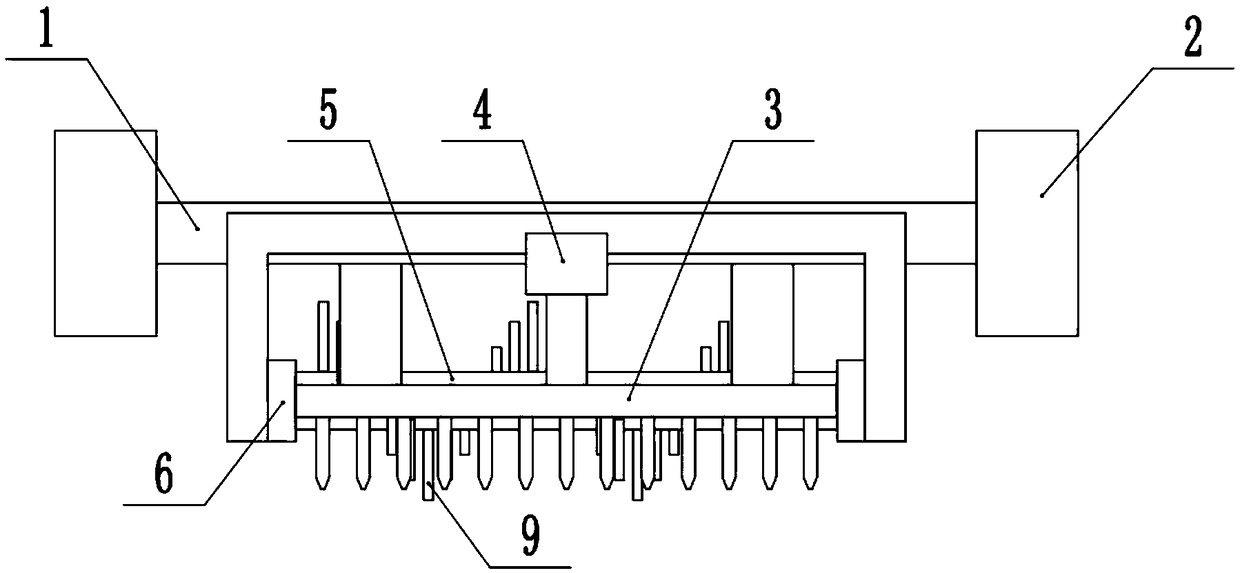

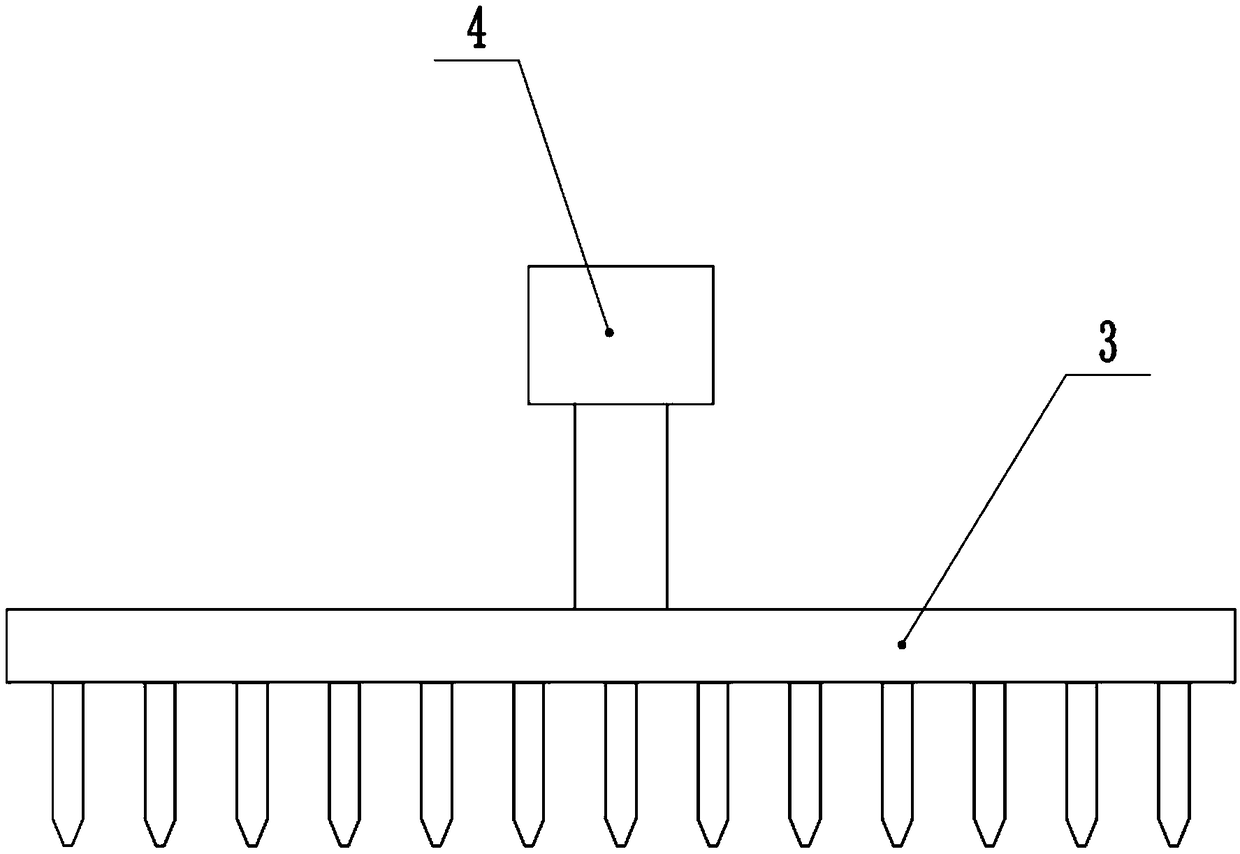

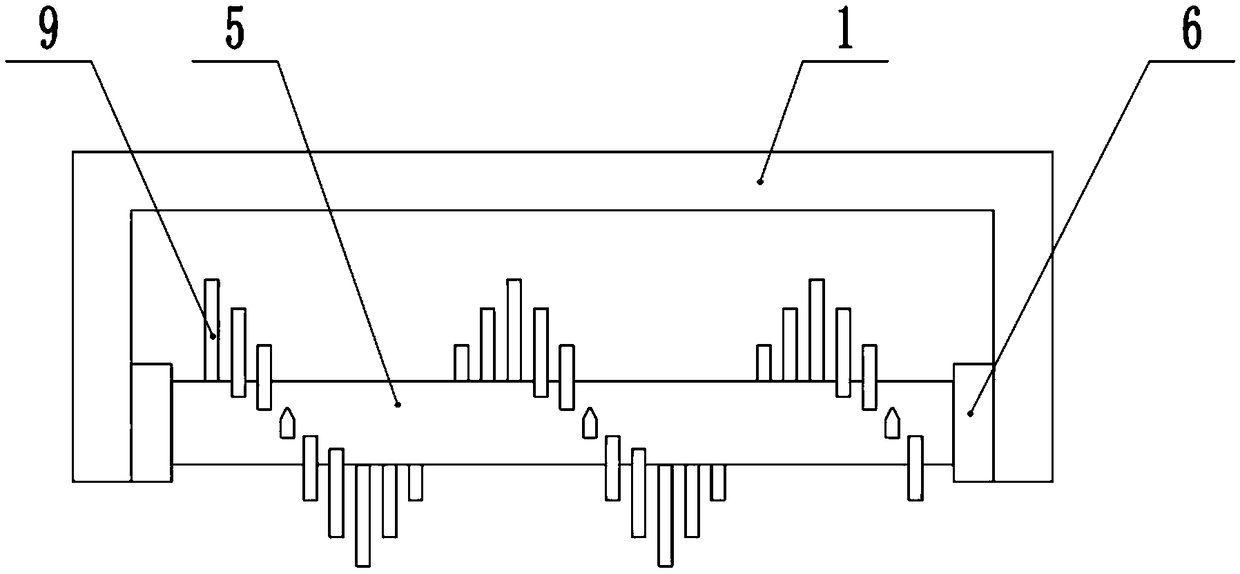

Mobile high-efficiency live slag machine

ActiveCN108996522BAchieve the first crushing effectRealize QiAlkali metal chloridesGrain treatmentsDrive wheelSlag

The invention relates to the field of salt field operation machinery, and discloses a movable high-efficiency slag activation machine including a frame; a driving wheel is arranged on the frame; a first crushing mechanism and a second crushing mechanism are arranged on the frame; the first crushing mechanism includes a slag activation rake and a cylinder, and the second crushing mechanism includesa hollow rotating shaft; the rotating shaft is internally provided with rotating blades, through holes are formed in the rotating shaft, and convex teeth are arranged on the rotating shaft; a first cylinder body and a second cylinder body are fixedly connected on the frame, a first one-way valve is arranged between the first cylinder body and the rotating shaft, and a second one-way valve is arranged between the second cylinder body and the rotating shaft; a first one-way gas intake valve is arranged on the first cylinder body, and a first piston is slidingly connected in the first cylinder body; a second one-way gas intake valve is arranged on the second cylinder body, and a second piston is slidingly connected inside the second cylinder body; a piston rod is arranged between the first piston and the second piston and is fixedly connected with a cylinder output rod. By arrangement of the first crushing mechanism and the second crushing mechanism, a crystallizing layer is crushed twice, and the effect and efficiency of salt mining are improved.

Owner:和布克赛尔蒙古自治县宏达盐业有限责任公司

Movable high-efficiency slag activation machine

ActiveCN108996522AAchieve the first crushing effectRealize QiAlkali metal chloridesGrain treatmentsDrive wheelSlag

The invention relates to the field of salt field operation machinery, and discloses a movable high-efficiency slag activation machine including a frame; a driving wheel is arranged on the frame; a first crushing mechanism and a second crushing mechanism are arranged on the frame; the first crushing mechanism includes a slag activation rake and a cylinder, and the second crushing mechanism includesa hollow rotating shaft; the rotating shaft is internally provided with rotating blades, through holes are formed in the rotating shaft, and convex teeth are arranged on the rotating shaft; a first cylinder body and a second cylinder body are fixedly connected on the frame, a first one-way valve is arranged between the first cylinder body and the rotating shaft, and a second one-way valve is arranged between the second cylinder body and the rotating shaft; a first one-way gas intake valve is arranged on the first cylinder body, and a first piston is slidingly connected in the first cylinder body; a second one-way gas intake valve is arranged on the second cylinder body, and a second piston is slidingly connected inside the second cylinder body; a piston rod is arranged between the first piston and the second piston and is fixedly connected with a cylinder output rod. By arrangement of the first crushing mechanism and the second crushing mechanism, a crystallizing layer is crushed twice, and the effect and efficiency of salt mining are improved.

Owner:和布克赛尔蒙古自治县宏达盐业有限责任公司

Structural weak spot analysis

ActiveUS10642945B2Improve powerImprove local stressDesign optimisation/simulationSpecial data processing applicationsComputational physicsModal analysis

A system and methods for weak spot analysis. A mesh shape is preprocessed to approximate an input model for an object. The mesh shape is analyzed with modal analysis to identify weak regions. A method and system for determining weak spots in an object. The method and system uses an optimization problem which is solved to determine a pressure distribution on the object maximizing maximal principal stress by solving a set of optimization problems maximizing stress for each point of the object.

Owner:NEW YORK UNIV

Combination method of circular low-temperature multi-effect seawater desalination evaporators

ActiveCN110357187BAdjust roundnessAvoid forceGeneral water supply conservationSeawater treatmentButt weldingEngineering

The invention discloses a pairing method of a circular low-temperature multi-effect seawater desalination evaporator, which includes the following steps: Step 1: Select an adjustable support rod whose diameter is suitable for the first circular evaporator and connect it to the fixed support rod Between the telescopic part; Step 2: The lower half circle of the first circular evaporator is welded to the lower half circle of the second circular evaporator; Step 3: The upper half circle of the first circular evaporator is welded to the upper half circle of the second circular evaporator connected. The invention can evenly disperse the welding stress on the evaporator and ensure the welding quality. The invention is suitable for circular evaporators and used for butt welding.

Owner:中国电建集团河北工程有限公司

Assembly method for square low-temperature multi-effect seawater desalination evaporator

ActiveCN110316777AAdjust flatnessMeet flatness requirementsGeneral water supply conservationSeawater treatmentStress concentrationEngineering

The invention discloses an assembly method for a square low-temperature multi-effect seawater desalination evaporator. An assembly device for the low-temperature multi-effect seawater desalination evaporator is used for adjusting the flatness of a first square evaporator. The method includes the following steps that 1, a bottom plate of the first square evaporator and a bottom plate of a second square evaporator are welded to be assembled; 2, a left side plate of the first square evaporator and a left side plate of the second square evaporator are welded to be connected, and a right side plateof the first square evaporator and a right side plate of the second square evaporator are welded to be connected; 3, a top plate of the first square evaporator and a top plate of the second square evaporator are welded to be connected. According to the method, welding stress is dispersed on the square evaporators, welding stress concentration is avoided, and welding quality is ensured. The methodis suitable for the assembly welding of square evaporators.

Owner:中国电建集团河北工程有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com