Anchor rod and anchor cable protecting mechanism for roadway support hydraulic bracket

A technology for hydraulic support and roadway support, which is used in the direction of supporting the roof beam of the mine roof, mining equipment, earthwork drilling, etc., can solve the problems of anchor failure, anchor void failure, pallet failure, etc. , Improve the quality of support, the effect of convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

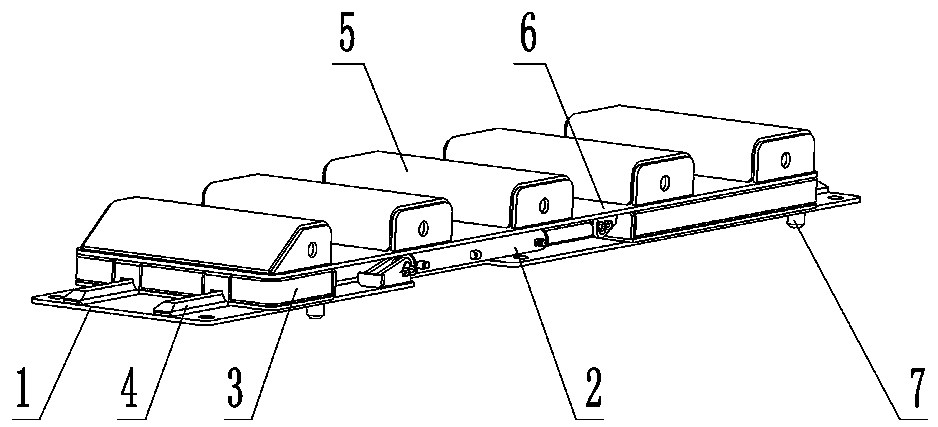

[0011] Such as figure 1 As shown, the anchor rod and anchor cable protection mechanism for roadway support hydraulic support according to the present invention includes a fixed beam 1 installed on the top beam of the hydraulic support. Usually, the lower surface of the fixed beam 1 is welded with a fixed pin 7. The top beam of the hydraulic support is provided with matching mounting holes, through which the fixed beam 1 and the hydraulic support can be connected conveniently and quickly. A sliding beam 3 driven by a hydraulic cylinder 2 is arranged above the fixed beam 1. Specifically, ear plates are welded on the upper surface of the fixed beam 1 and the lower surface of the sliding beam 3, and the piston rod of the hydraulic cylinder 2 passes through the pin shaft. It is hinged with the ear plate on the sliding beam 3, and the cylinder bottom of the hydraulic cylinder 2 is hinged with the ear plate on the fixed beam 1 through a pin; The above structure not only enables the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com