Refractory furnace lining material and ramming method thereof

A refractory furnace lining and raw material technology, applied in the field of furnace lining materials, can solve the problems that the refractoriness does not reach 1700°C, the service life of the furnace lining is not long, and the service life of the furnace lining material is low, so as to increase the wear resistance and refractoriness. Effects of defect reduction and high sticking resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

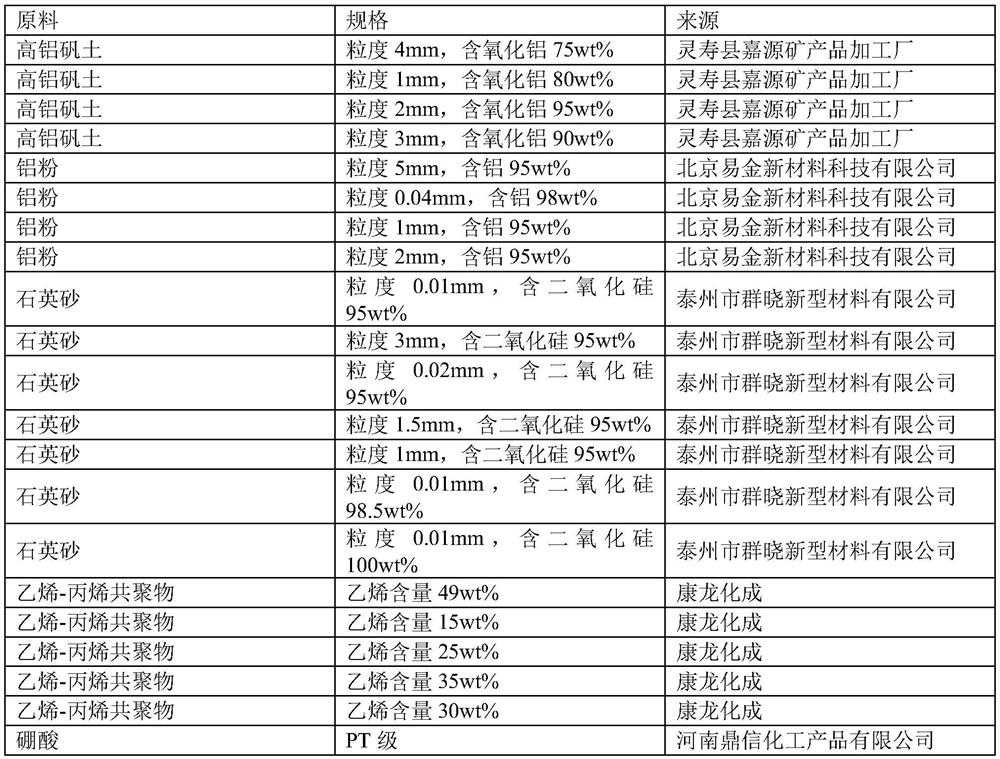

Method used

Image

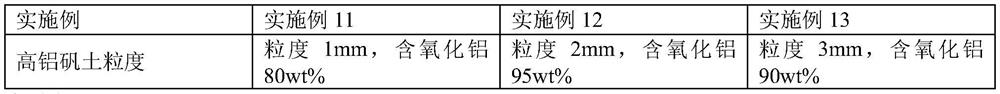

Examples

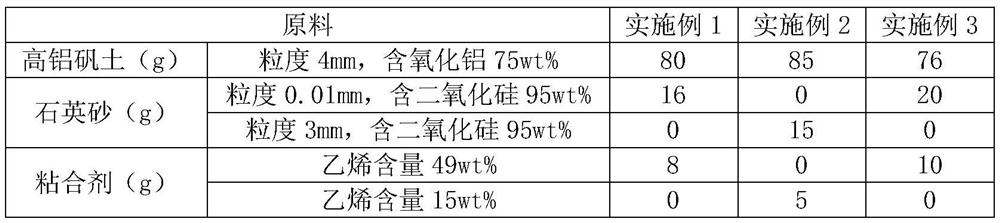

Embodiment 1

[0036] A refractory furnace lining material is prepared by mechanically mixing 80g of high alumina bauxite, 16g of quartz sand, and 8g of a binder, the binder being an ethylene-propylene copolymer containing ethylene with a mass fraction of 49%; the The particle size of the high alumina bauxite is 4mm, containing 75wt% of alumina; the particle size of the quartz sand is 0.01mm, containing 95wt% of silicon dioxide.

Embodiment 2-3

[0038] Embodiments 2-3 are all based on Embodiment 1, and differ from Embodiment 1 only in that the raw material consumption and specifications are different, see Table 2 for details.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com