Movable high-efficiency slag activation machine

A live slag machine, high-efficiency technology, applied in the direction of alkali metal chloride, grain processing, etc., can solve the problems of low salt mining efficiency of salt mining equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The following is further described in detail through specific implementation methods:

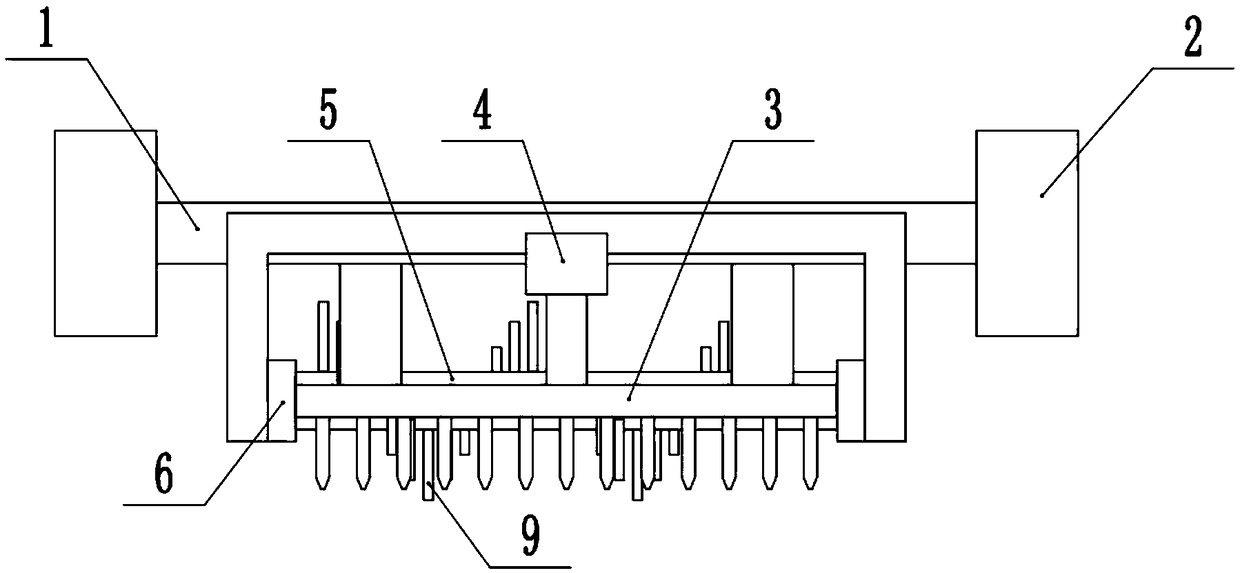

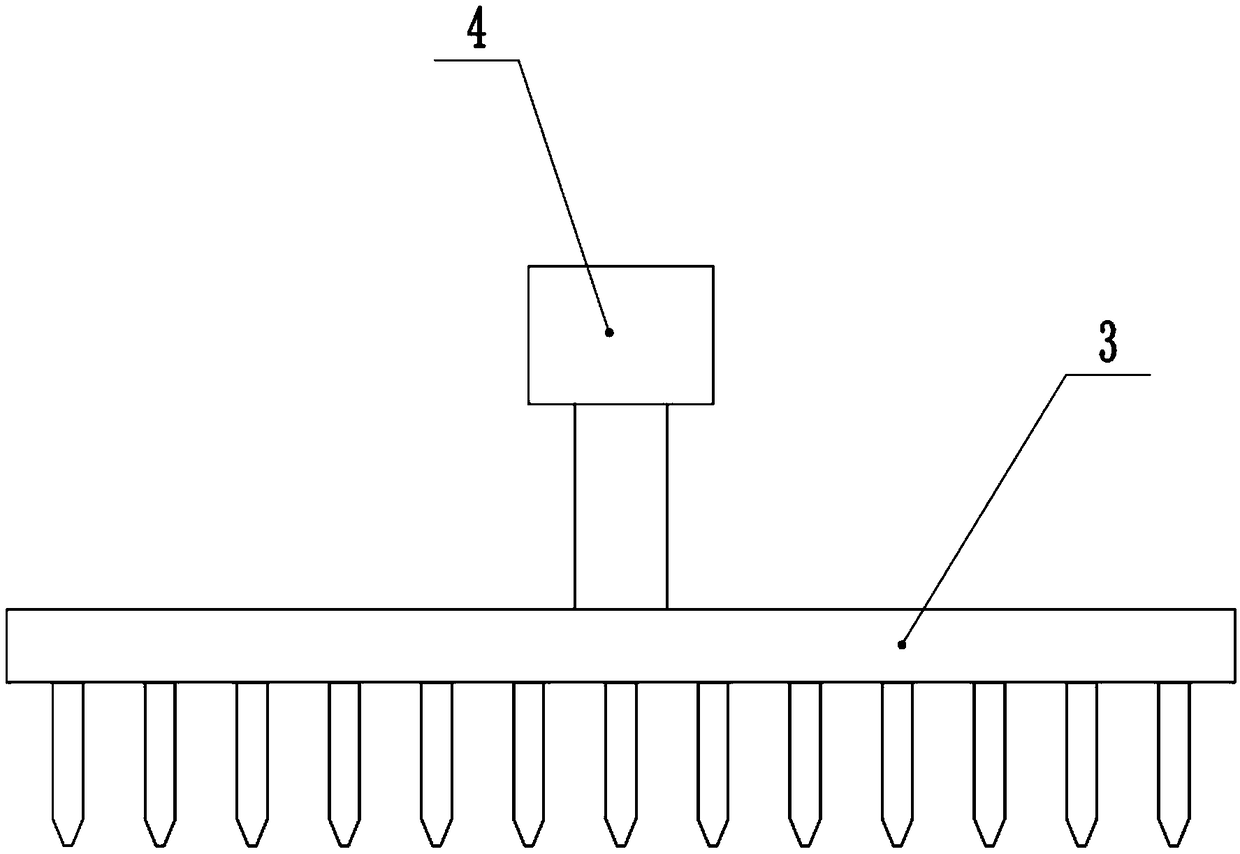

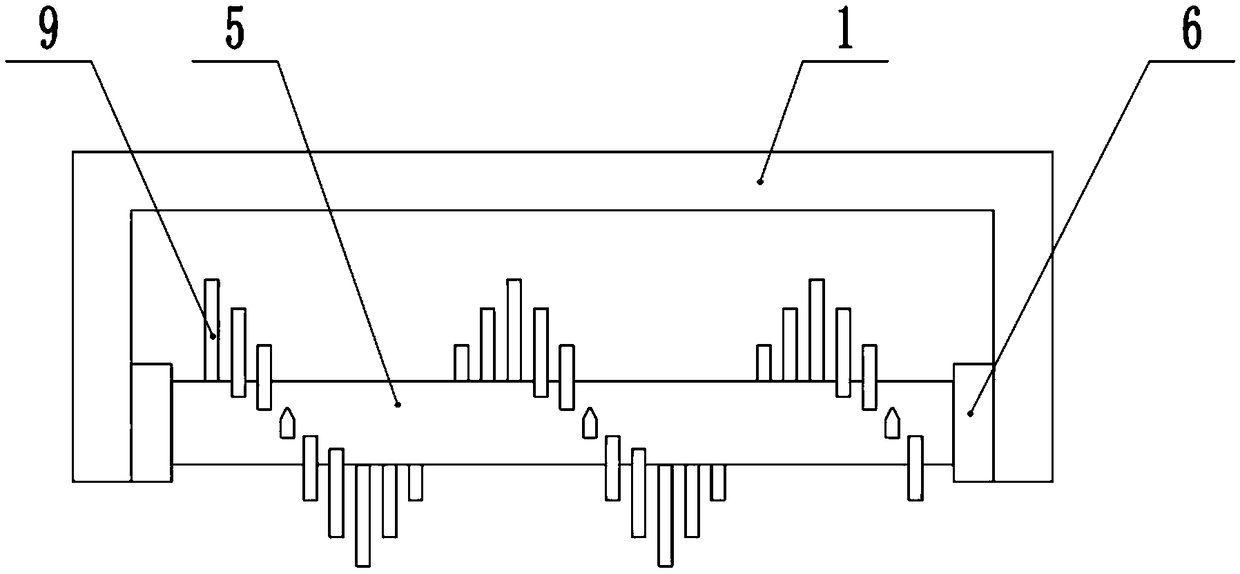

[0024] The reference signs in the drawings of the description include: frame 1, driving wheel 2, live slag rake 3, cylinder 4, rotating shaft 5, sleeve block 6, rotating blade 7, through hole 8, convex teeth 9, first cylinder 10 , The second cylinder 11, the heating wire 12, the first piston 13, the second piston 14, the piston rod 15.

[0025] The embodiment is basically as attached Figure 1 to Figure 6 Shown:

[0026] The mobile high-efficiency live slag machine includes a frame 1 on which a drive wheel 2 is rotatably connected. The frame 1 is provided with a first crushing mechanism and a second crushing mechanism, and the first crushing mechanism is located on the front side of the second crushing mechanism. , the first crushing mechanism includes a live slag rake 3 and a cylinder 4 for driving the live slag rake 3 (such as figure 2 shown); the second crushing mechanism incl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com