Equipment and method for measuring coefficient of collapsibility of loess

A measuring equipment and collapsibility technology, applied in measuring devices, using stable tension/pressure to test material strength, instruments, etc., can solve problems such as difficulty, disturbance, time-consuming and labor-intensive in-situ soil layers, etc., to reduce the test Probability of failure, simple installation and disassembly, effect of saving measurement costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

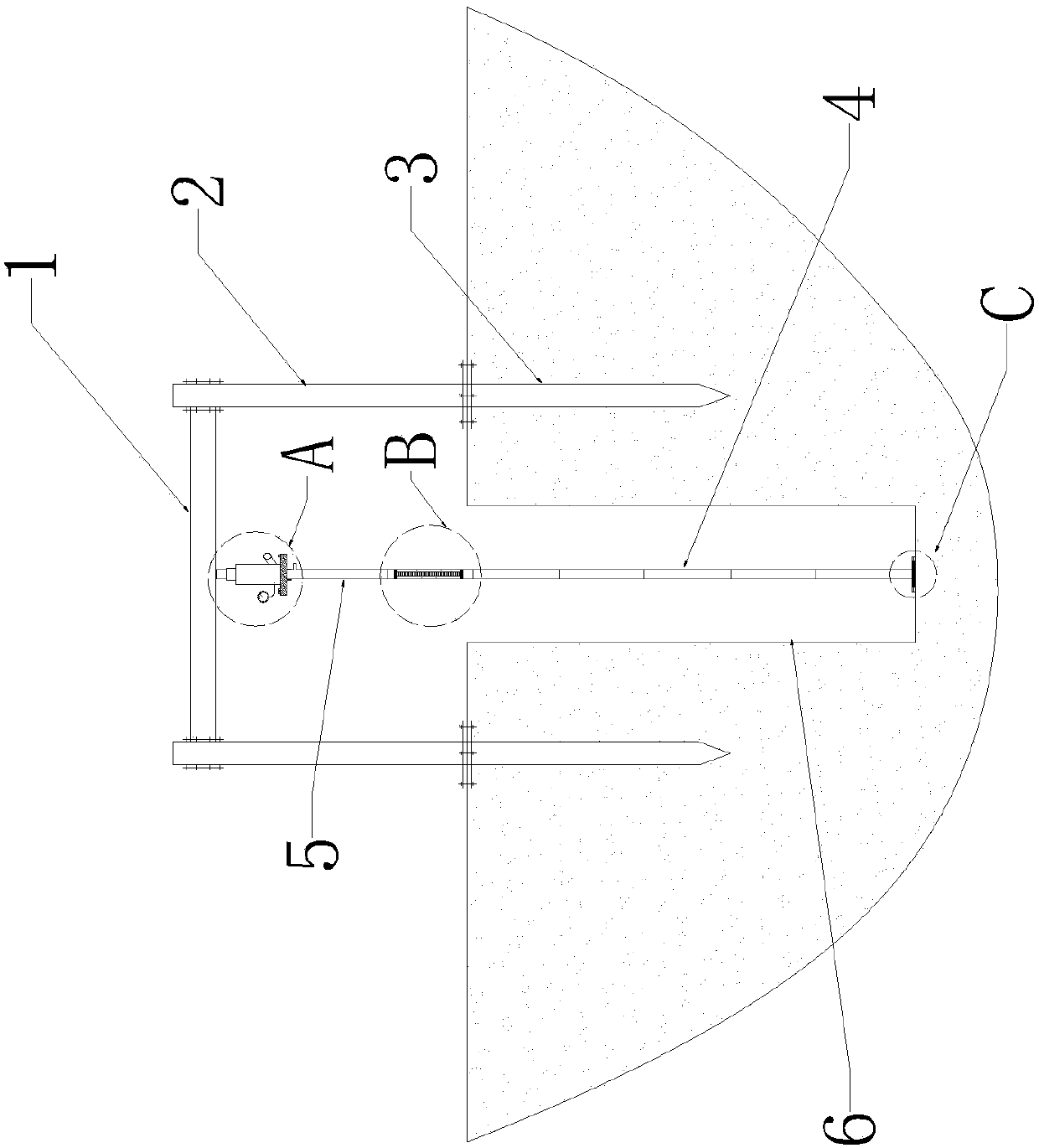

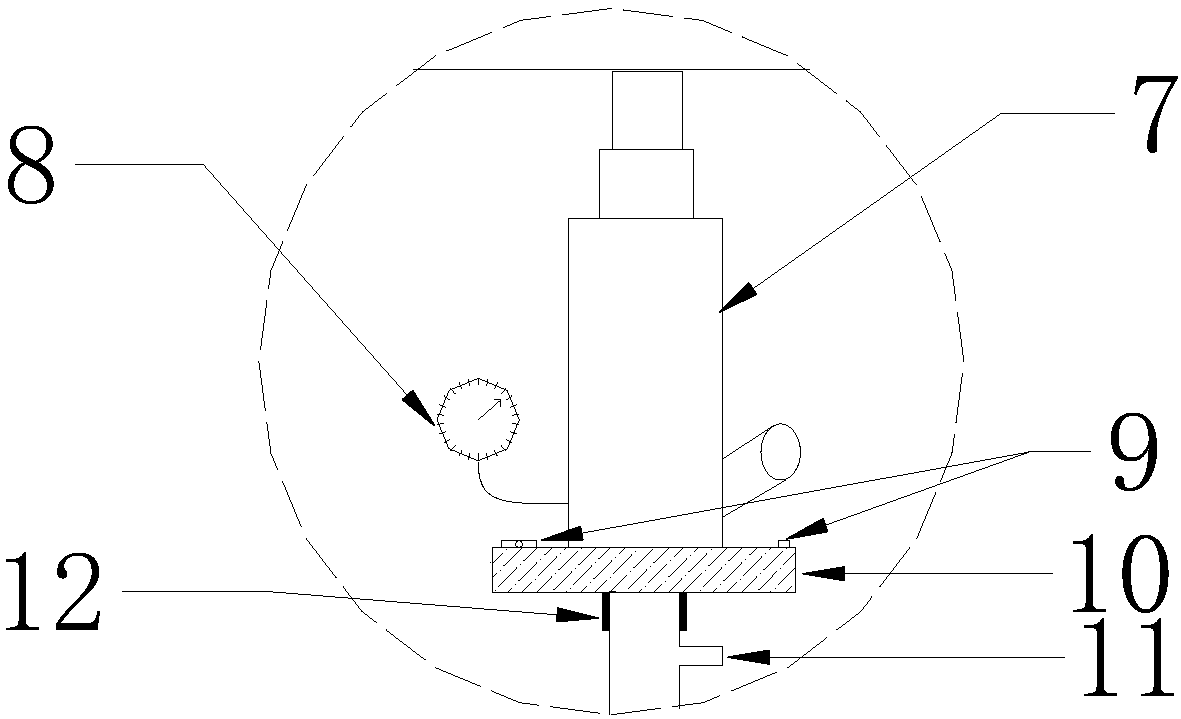

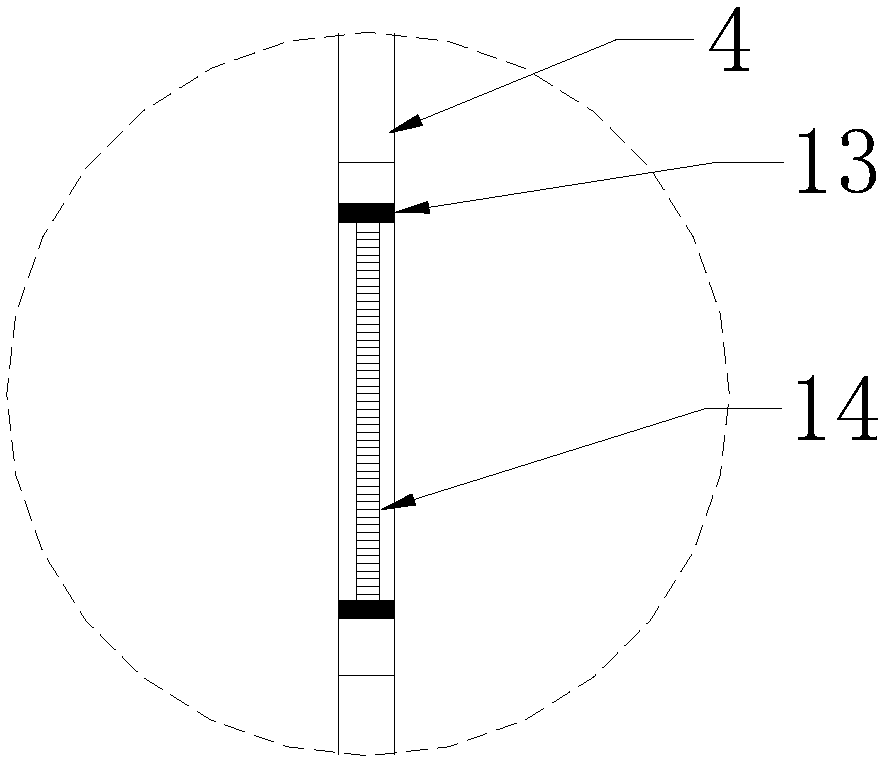

[0039] Using the above-mentioned loess collapsibility coefficient measuring equipment to measure the loess collapsibility coefficient includes the following steps:

[0040] (1) According to the measurement area required on the project site, carry out the design of the test plan, determine the number and location of the measurement points, and design the test sequence and measurement depth of the measurement points;

[0041] (2) At the point to be measured, install the spiral steel pile 3 of the reaction force frame according to the relative position of the measuring point, and excavate the exploratory well 6 according to the required measurement depth of the measuring point. The side length or diameter of the exploratory well 6 should be the bottom bearing plate 15 3 times the side length or diameter, lay 10 to 15 mm thick coarse and medium sand leveling at the bottom of the exploratory well 6, and finally install the column 2 of the reaction frame and the reaction beam 1;

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com