Device used for testing guided missile model wing or rudder assembling precision

A technology of assembly accuracy and model, which is applied in the field of devices for testing the assembly accuracy of missile model wings or rudders, can solve the problems of low measurement accuracy, cumbersome measurement process, expensive equipment, etc., and achieves simple measurement process, high measurement accuracy and low measurement cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

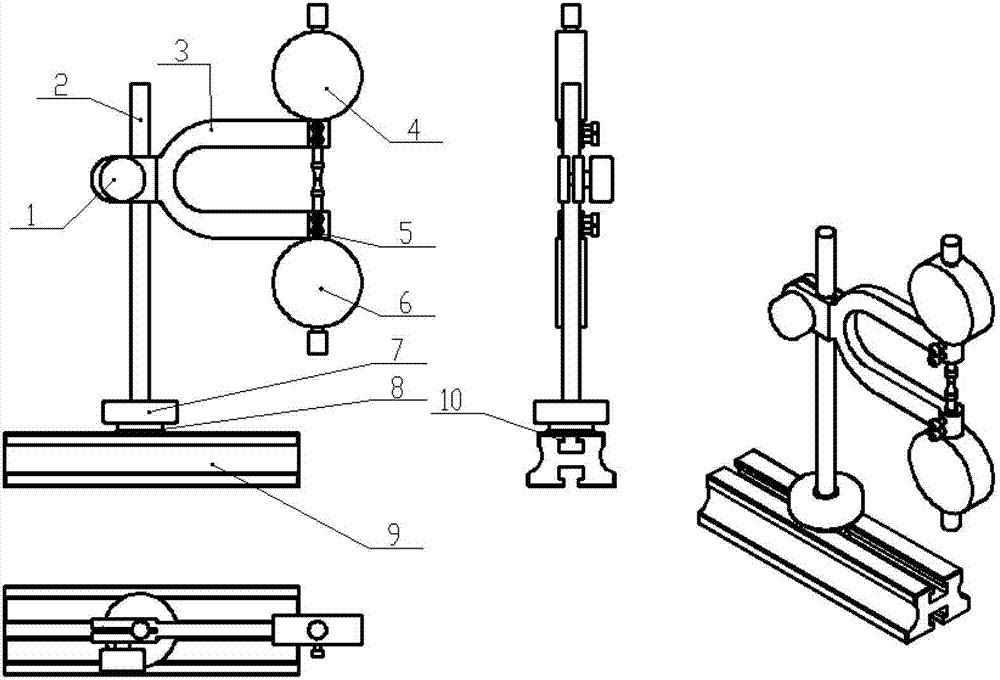

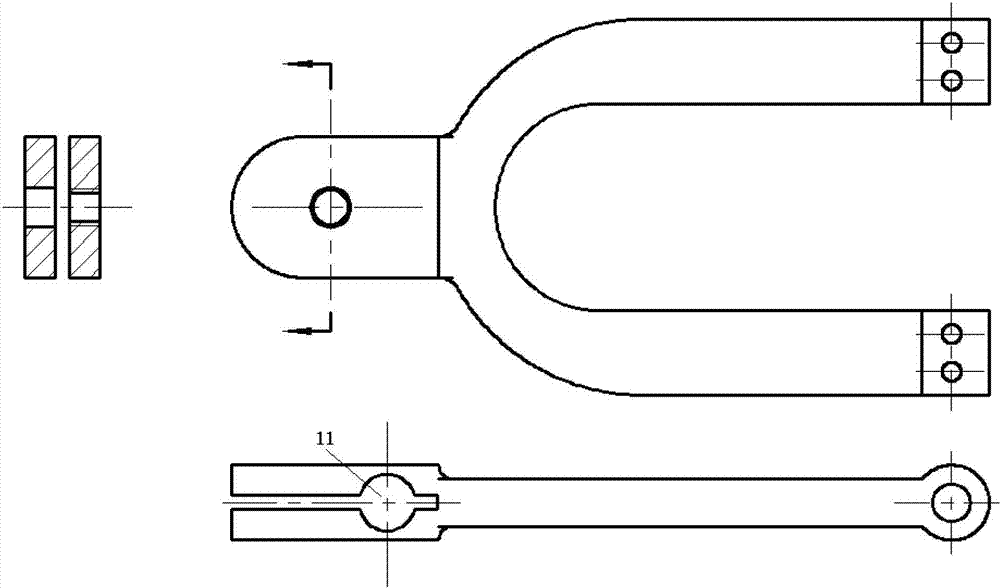

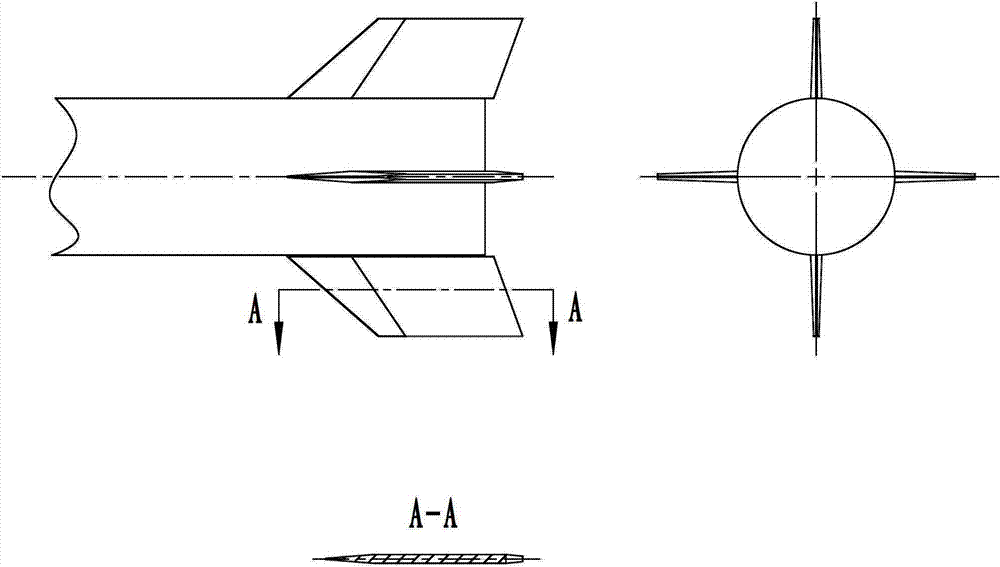

[0021] exist figure 1 Insert the T-slot nut into the T-slot of the base 9, screw the column 2 into the T-slot nut 10, put the gasket 8 on the column 2, tighten the lock nut 7 to fix the column 2 on the base 9 superior. Insert the U-shaped table frame 3 onto the column 2, and tighten the locking screw 1 to fix the U-shaped table frame 3 to the column 2. Insert the upper dial indicator 4 and the lower dial indicator 6 into the two holes of the U-shaped meter frame 3 respectively, and screw four jacking screws 5 at the side threaded holes of the U-shaped meter frame 3, and put the upper dial indicator 4 and lower dial gauge 6 are fixed with U-shaped table frame 3. By tightening and loosening the locking nut, the position of the T-slot nut 10 in the trapezoidal groove of the base 9 can be adjusted. Such as figure 2 Show, this U-shaped table frame 3 is processed into with the higher tool steel of hardness or quenched structural steel. There is a groove on its left end, when t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com