Method for continuously measuring temperature of molten metal

A technology of molten metal and temperature measuring element, which is applied in the field of continuous measurement of molten metal temperature, can solve the problems of no widely applicable correspondence, inability to realize continuous measurement of molten steel, and difficulty in compensating for wire connection, etc., and achieves convenient measurement and measurement cost. Low, easy-to-achieve effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

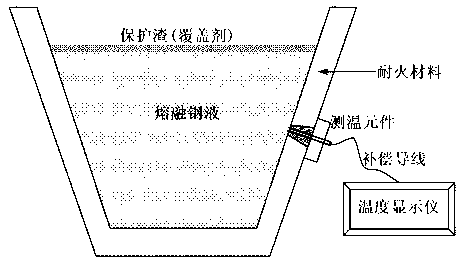

[0024] After the continuous casting tundish refractory material masonry is completed, press figure 2 In the shown assembly method, a fixed temperature measuring element is installed on the tundish, and the casting operation is performed after high-temperature baking. During the casting process, use the compensation wire to connect the temperature measuring element and the temperature display instrument, and measure the temperature change range of the molten steel in real time from 1560°C to 1570°C. For comparison, during the casting process, a standard thermocouple protected by a corundum tube was inserted into the molten steel from the upper part of the tundish to measure the temperature of the molten steel every half an hour. Compared with the temperature obtained by the temperature measuring device of the present invention, the temperature difference is ±2°C.

Embodiment 2

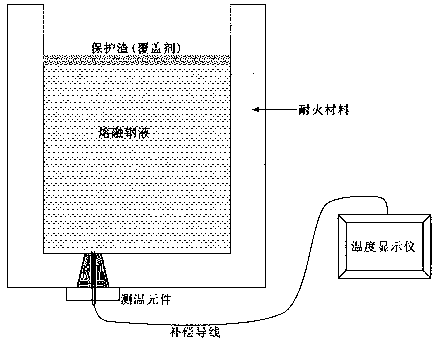

[0026] After the ladle refractory masonry is completed, press image 3 In the shown assembly method, a fixed temperature measuring element is installed on the ladle, and the refining operation is carried out after high-temperature baking. During the refining process, the temperature measuring element is connected with the temperature display instrument by using the compensation wire, and the temperature range of the molten steel in the ladle is measured in real time to be 1580°C-1610°C. For comparison, a standard thermocouple protected by a corundum tube was inserted into the molten steel from the upper part of the ladle to measure the temperature of the molten steel every half an hour. Compared with the temperature obtained by the temperature measuring device of the present invention, the temperature difference is ±2°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com