Measurement method of retained austenite content in high nickel alloy steel

A technology of retained austenite and measurement method, applied in the field of measurement of retained austenite content in high-nickel alloy steel, can solve problems such as uneconomical measurement equipment and measurement costs, and achieve saving measurement costs, high speed, and improved measurement. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

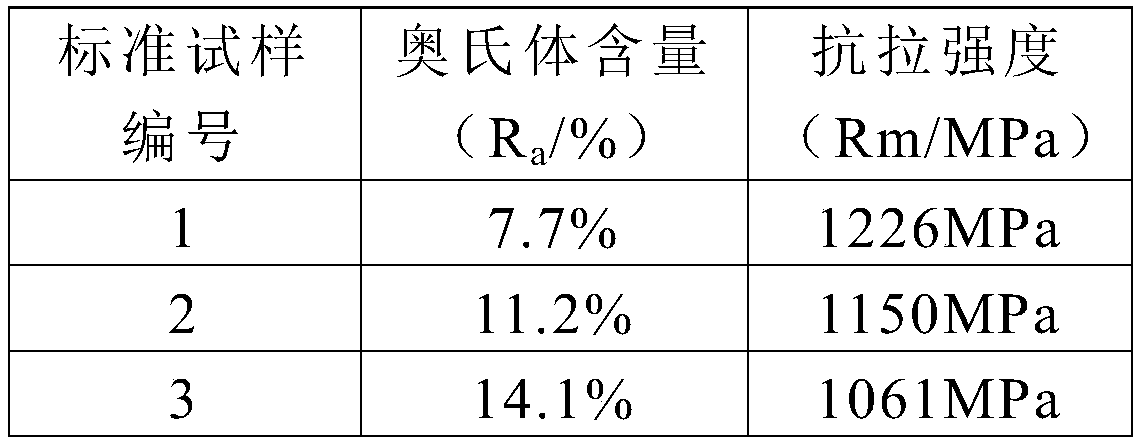

[0015] 1) Select 3 high-nickel alloy steel standard samples, and the residual austenite content R in the 3 high-nickel alloy steel standard samples a are not the same;

[0016] 2) Using X-ray analysis technology and using a tensile testing machine to measure the residual austenite content R in each high-nickel alloy steel standard sample in step 1) a and tensile strength Rm, three groups of retained austenite content R a And the data of tensile strength Rm, as shown in table 1;

[0017] Table 1

[0018]

[0019] 3) The data in Table 1 in step 2) is plotted on the coordinate axis, and the retained austenite content R a is the axis of abscissa, the tensile strength Rm is the axis of ordinate, according to the square of the correlation coefficient of the straight line fitting=0.990, the points in the coordinate axis are fitted to form a fitted straight line, and the fitted straight line equation Rm=-25.64R a +1427;

[0020] 4) Carry out the tensile test on the high-nickel...

Embodiment 2

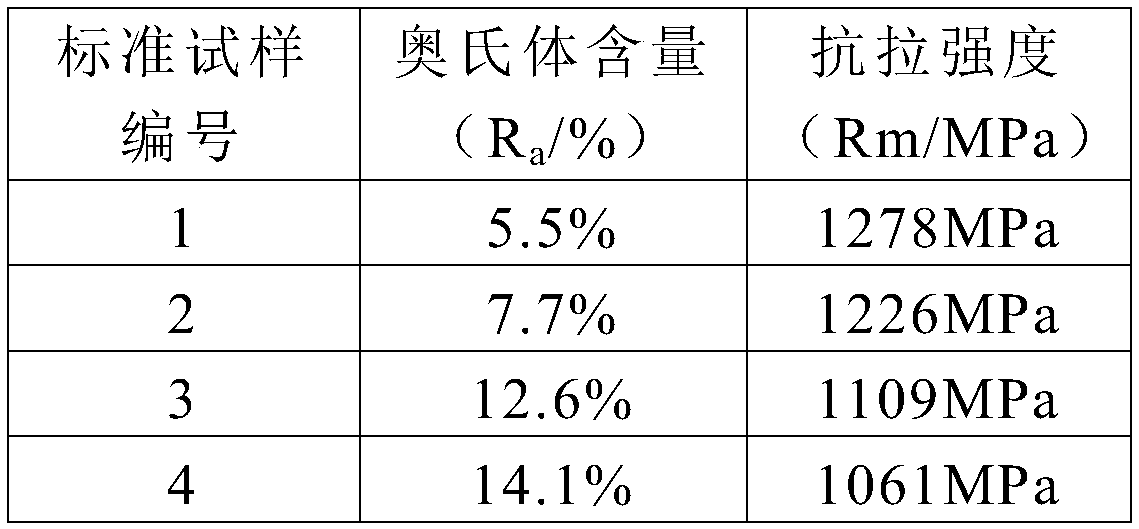

[0022] 1) Select 4 high-nickel alloy steel standard samples, and the residual austenite content R in the 4 high-nickel alloy steel standard samples a are not the same;

[0023] 2) Using X-ray analysis technology and using a tensile testing machine to measure the residual austenite content R in each high-nickel alloy steel standard sample in step 1) a and tensile strength Rm, four groups of retained austenite content R a And the data of tensile strength Rm, as shown in table 2;

[0024] Table 2

[0025]

[0026] 3) The data in Table 2 in step 2) is plotted in the coordinate axis, and the retained austenite content R a is the axis of abscissa, the tensile strength Rm is the axis of ordinate, according to the square of the correlation coefficient of the straight line fitting=0.998, the points in the coordinate axis are fitted to form a fitted straight line, and the fitted straight line equation Rm=-24.85R is obtained a +1416;

[0027] 4) Carry out the tensile test on the ...

Embodiment 3

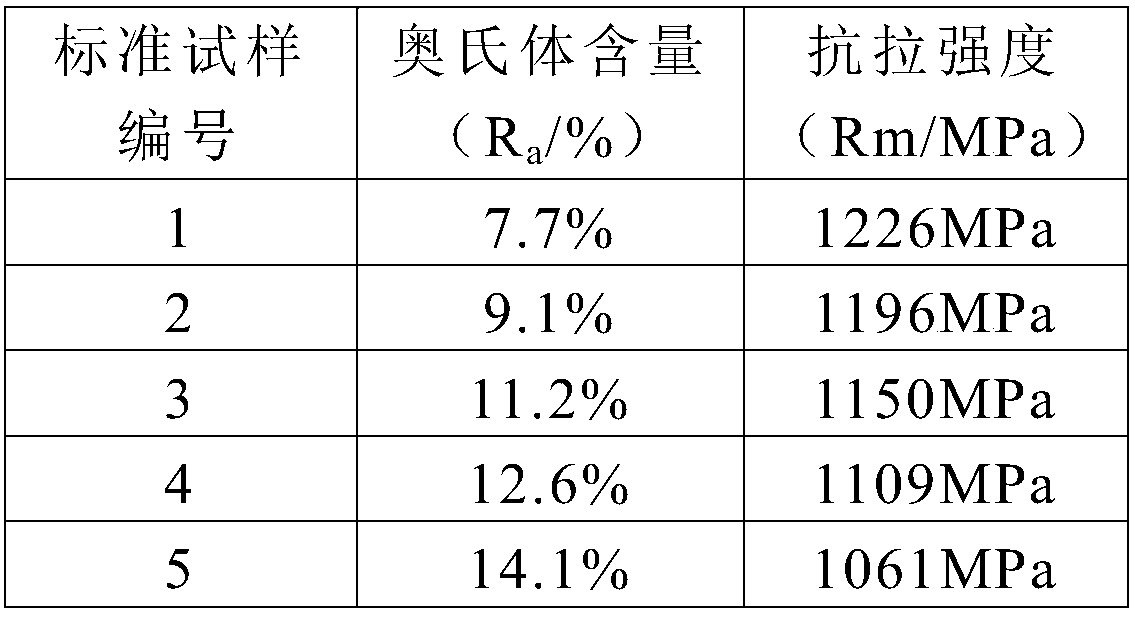

[0029] 1) Select 5 high-nickel alloy steel standard samples, and the residual austenite content R in the 5 high-nickel alloy steel standard samples a are not the same;

[0030] 2) Using X-ray analysis technology and using a tensile testing machine to measure the residual austenite content R in each high-nickel alloy steel standard sample in step 1) a and tensile strength Rm, 5 groups of retained austenite content R a And the data of tensile strength Rm, as shown in table 3;

[0031] table 3

[0032]

[0033] 3) The data in Table 1 in step 2) is plotted on the coordinate axis, and the retained austenite content R a is the axis of abscissa, the tensile strength Rm is the axis of ordinate, according to the square of the correlation coefficient of the straight line fitting=0.991, the points in the coordinate axis are fitted to form a fitted straight line, and the fitted straight line equation Rm=-25.48R a +1427;

[0034] 4) Carry out the tensile test on the high-nickel all...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com