Loading plate of reduction gear used for mixing

A technology of reducer and bearing plate, which is applied in the direction of mixer accessories, mixers, dissolution, etc., to achieve the effects of easy and fast, improved internal stress, and small height space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with specific drawings and embodiments.

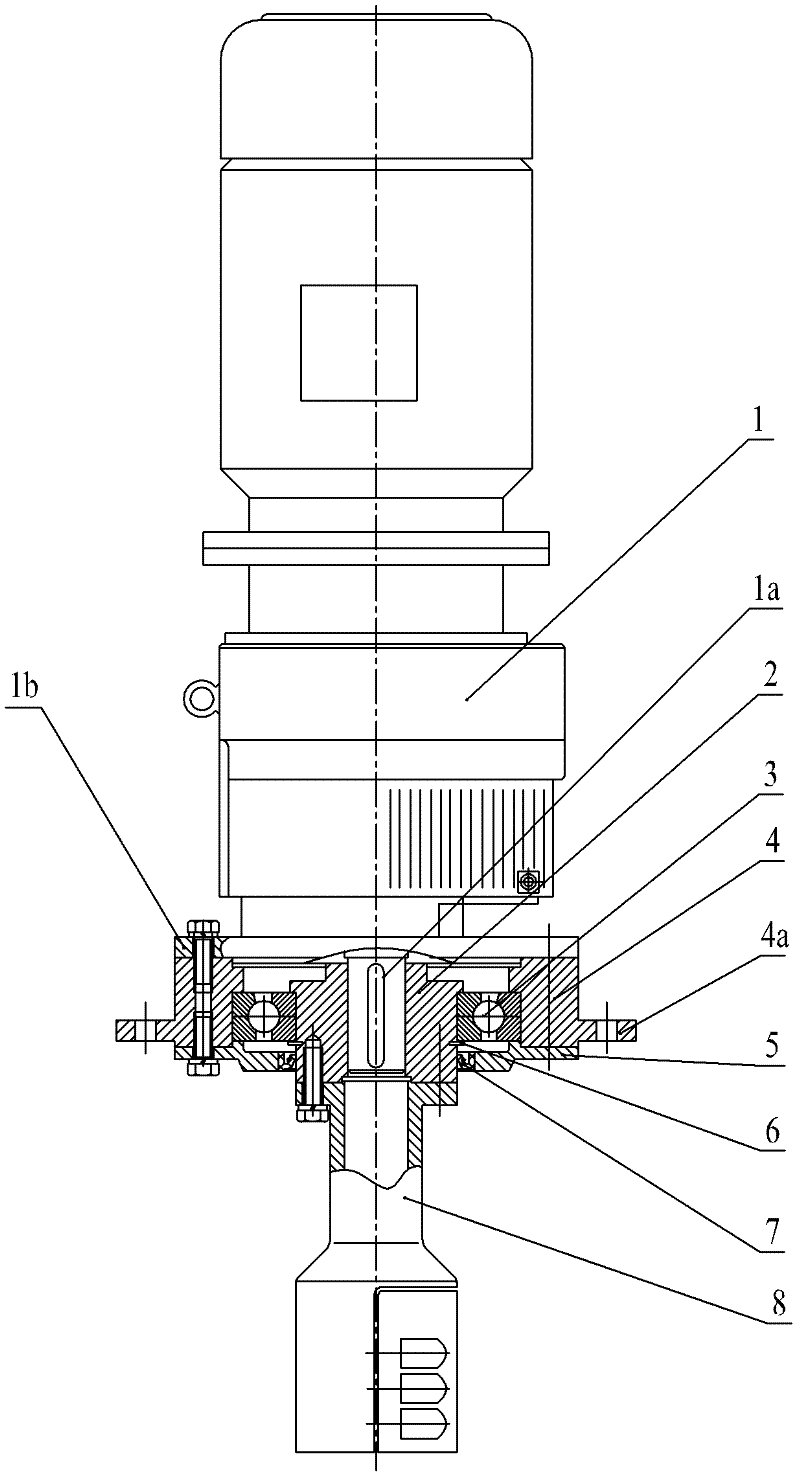

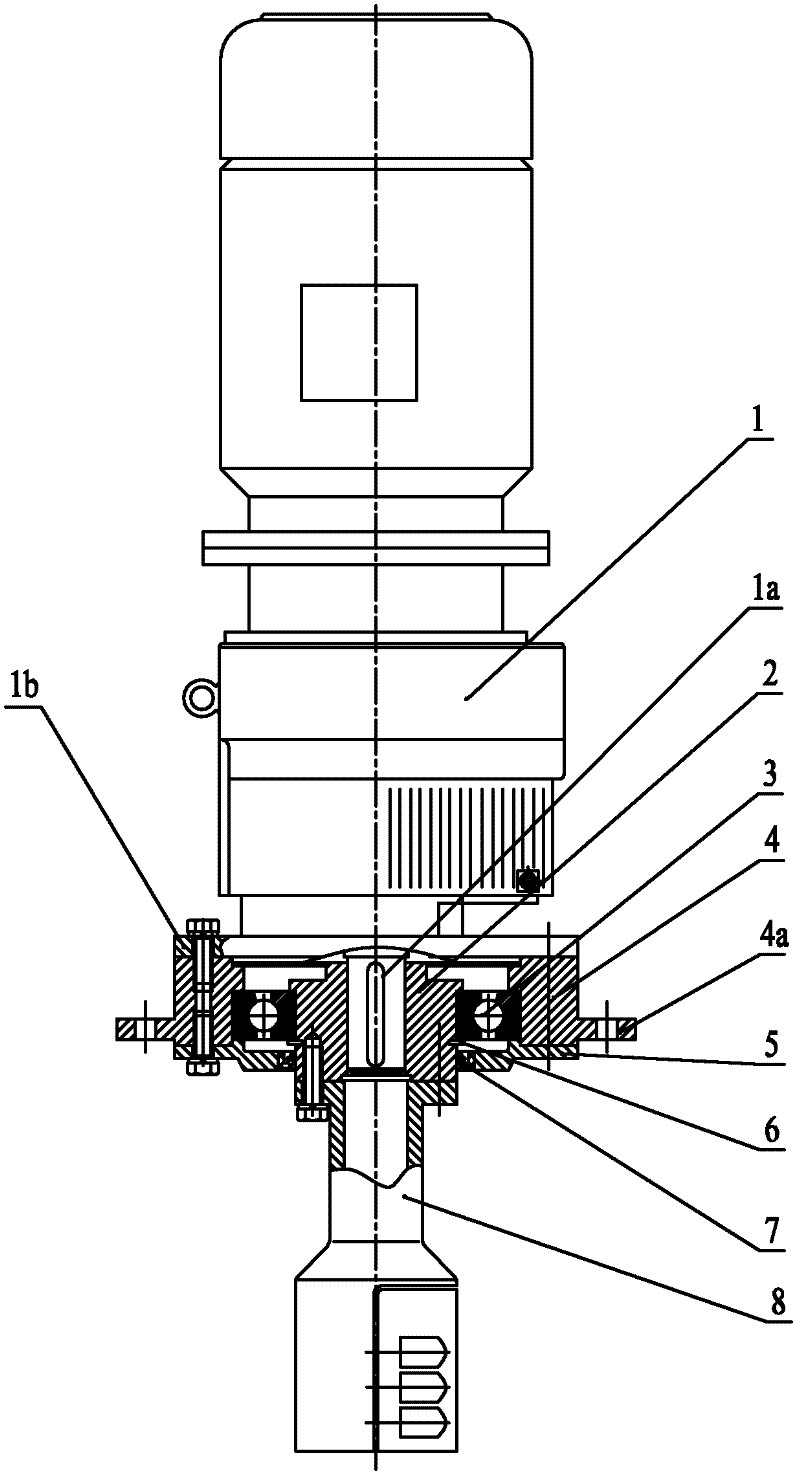

[0012] As shown in the figure: the carrying plate of the present invention is mainly composed of sleeve 2, rolling bearing 3, bearing seat 4, bearing gland 5 and coupling 8 and other components; the sleeve 2 is used to insert the output of the reducer 1 The shaft 1a and the sleeve 2 are assembled in the bearing seat 4 through the rolling bearing 3, and the bearing seat 4 is fixed on the flange 1b of the reducer 1 by bolts, and the bearing seat 4 is provided with a flange 4a for connecting and fixing the tank mouth support The bearing gland 5 is fixed on the bearing seat 4 by bolts, and a sealing ring 7 is installed between the bearing gland 5 and the sleeve 2, and the sealing ring 7 preferably adopts a skeleton rubber sealing ring 7; one end of the shaft coupling 8 passes through The bolts are connected and fixed with the sleeve 2, and the coupling 8 is used to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com