High-strain creep-fatigue coupling test method for material in low-temperature corrosion environment

A technology of low temperature corrosion and test method, which is applied in analyzing materials, testing material strength by applying stable tension/pressure, and testing material strength by applying repetitive force/pulse force, etc. It can solve the problem that the temperature control torque effect is difficult to eliminate and the system is stable for a long time. issues of sex

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

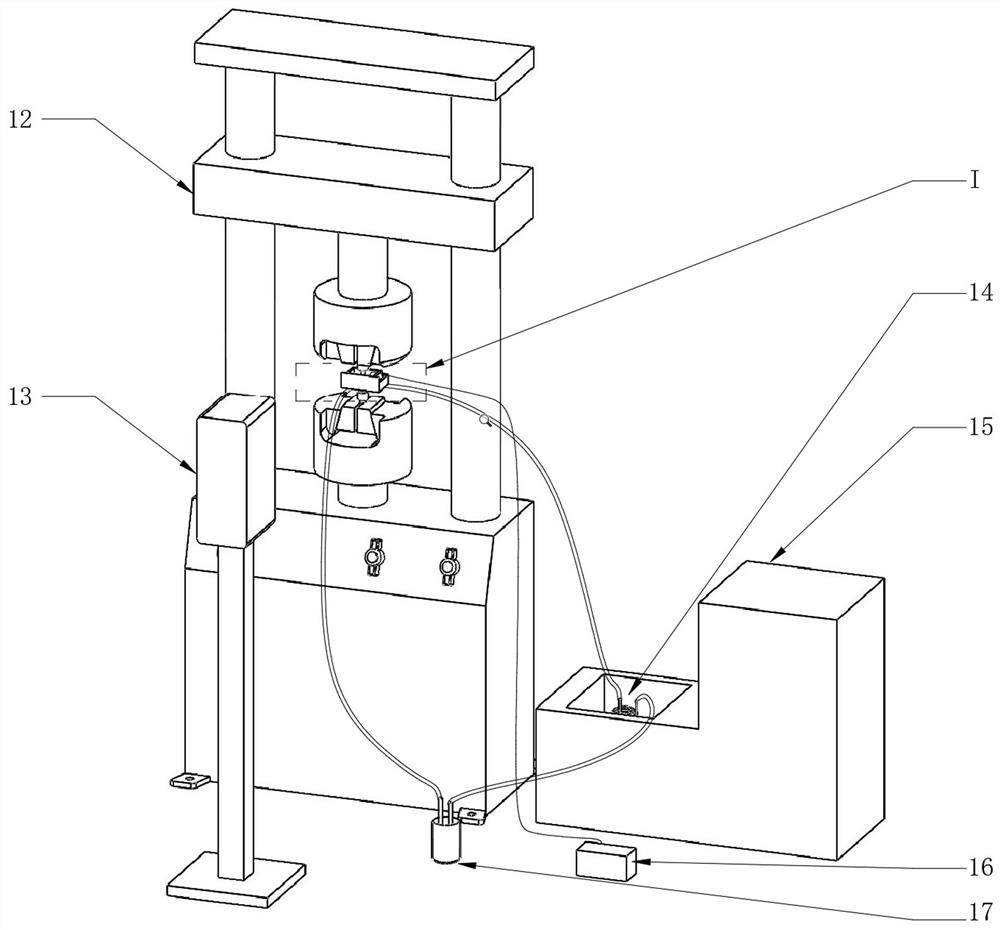

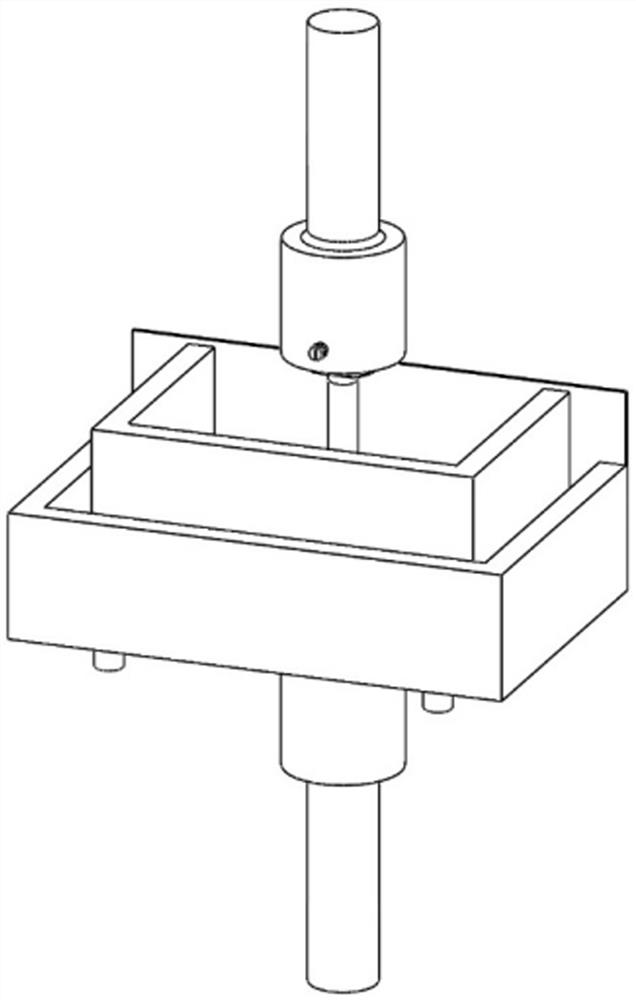

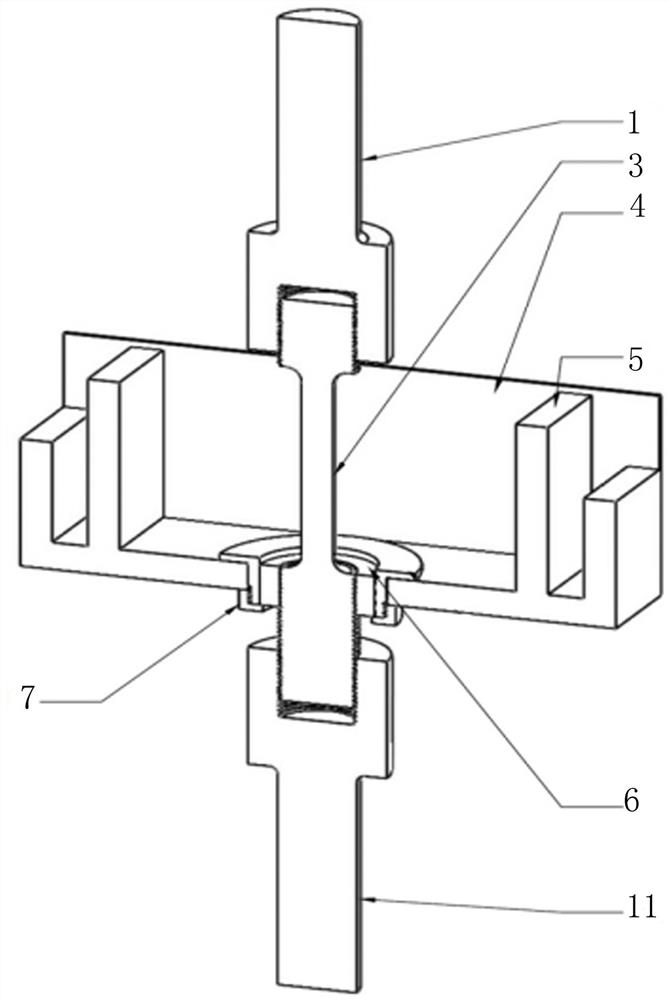

[0045] Titanium alloy high strain creep-fatigue coupling test method under low temperature corrosion environment, described high strain creep-fatigue coupling test device includes a fatigue testing machine 12, a low temperature instrument 15, a video extensometer 13, a submersible pump, A corrosion solution container 17, a multi-layer spiral pipe 14, a box-shaped corrosion tank and a pair of upper and lower clamping rods that can be relatively arranged and clamped on the fatigue testing machine 12;

[0046] Both the upper clamping rod 1 and the lower clamping rod 11 are provided with cylindrical grooves capable of matching the metal sample 3;

[0047] The front wall of the box-shaped corrosion tank adopts a test plate 4 that can be used in conjunction with the video extensometer 13. The box-shaped corrosion tank is provided with a U-shaped overflow plate 5 that is fixedly connected to the test plate 4. The U-shaped overflow plate The two parallel surfaces of the plate 5 are pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com