Ultrasonic filling capping method

An ultrasonic heating and ultrasonic technology, applied in the direction of flanged bottle caps, etc., can solve the problems of difficulty in ensuring the accuracy of bottle caps, low efficiency, low efficiency of capping, etc., and achieve good neutrality, high connection strength, and sealing performance Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

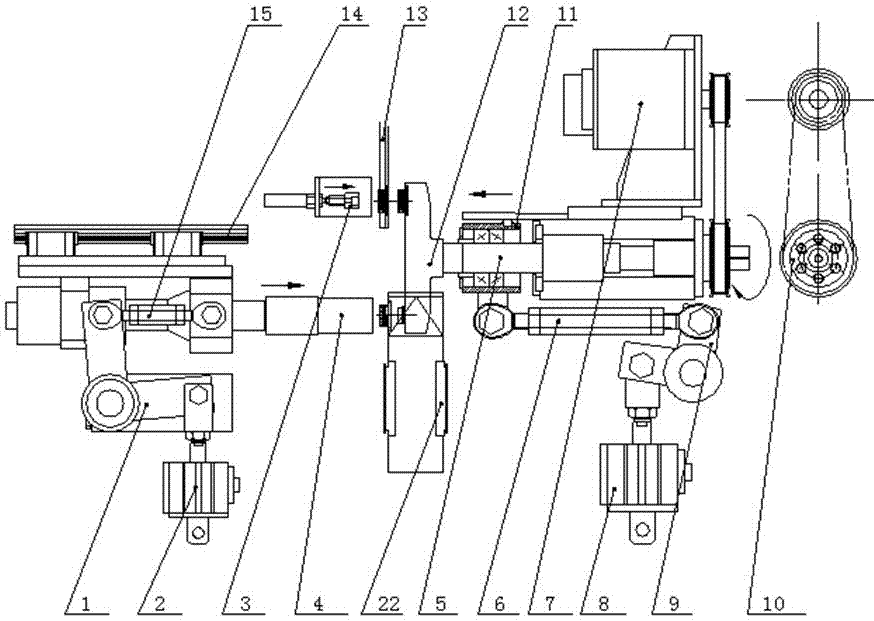

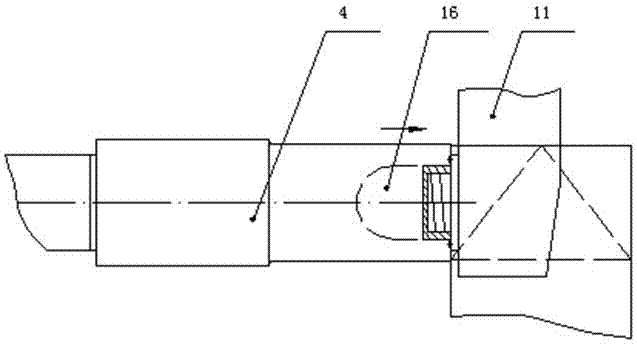

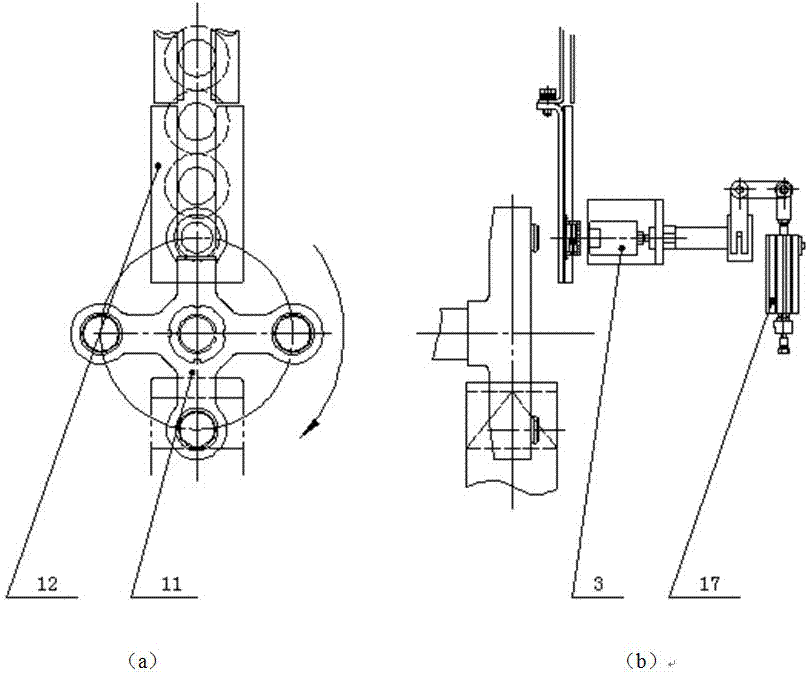

[0024] Example 1: Such as figure 1 As shown, the capping method of the present invention is: the ultrasonic capping device includes a cap removing assembly, an ultrasonic capping assembly, and a conveying mechanism. The cap removing assembly includes a cap removing rotor 12, a cap removing arm 9, and a cap removing connecting rod 6. , Drive shaft 5, timing belt and bottle cap pusher 3. The cap removing cylinder 8 is hinged with the L-shaped cap removing arm 9, the cap removing arm 9 is connected with the cap removing link 6 through the joint bearing, and the cap removing link 6 passes through The joint bearing is connected with the sleeve 11, the sleeve 11 and the transmission shaft 5 are connected by the bearing, the transmission shaft 5 is fixed with the cover removal rotor 12, the upper end of the sleeve 11 is fixed to the frame, and the servo motor 7 is installed on the frame, and the servo motor 7 passes through The synchronous belt drives the transmission shaft 5 to rotate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com