Upright spinning machine tool device with spinning roller pose adjustable

A spinning machine and vertical technology, which is applied in the field of vertical spinning machine devices, can solve the problems of not effectively solving the problem of twisting and wrinkling of the edge of the board and high machining accuracy, and achieves improving the wrinkling phenomenon of the edge of the board, improving the degree of flexibility, and improving the effect on neutral

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

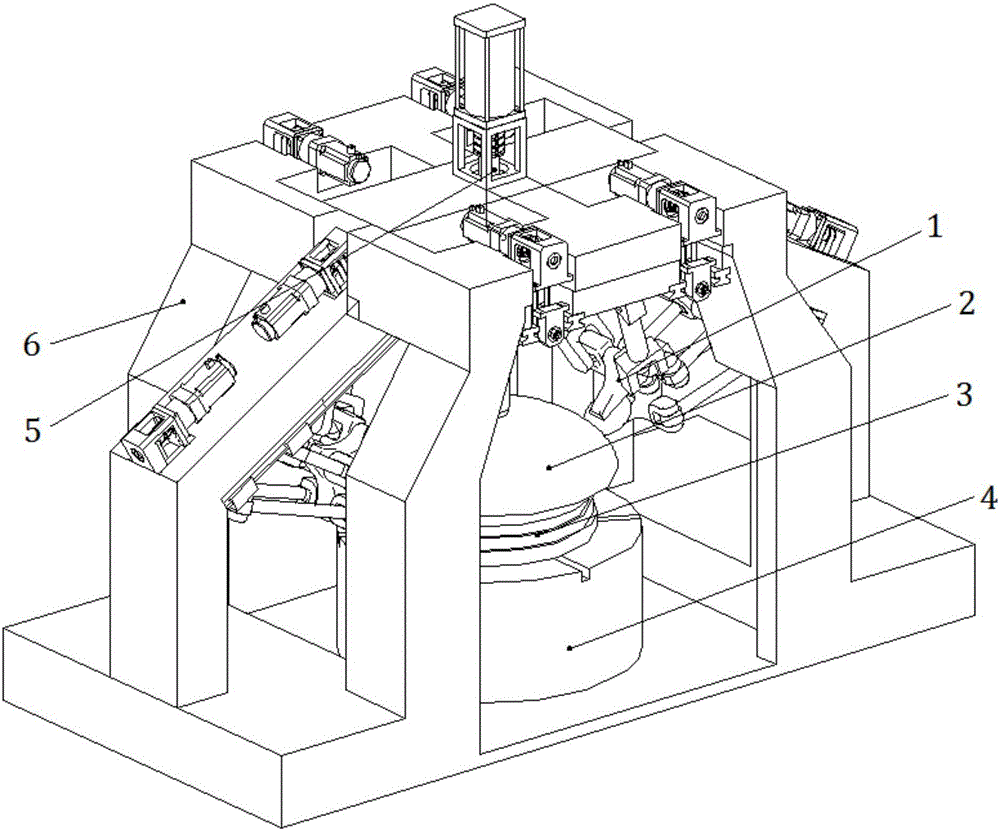

[0026] like figure 1 As shown, this embodiment includes: parts to be processed, oblique spinning mechanism 1, membrane 2, main shaft 3, controller 4, ejector pin 5 and fuselage shell 6, wherein: membrane 2, main shaft 3 and control The device 4 is sequentially connected and arranged in the fuselage shell 6, and the ejector rod 5 is arranged on the top of the fuselage shell 6 corresponding to the main shaft 3, and the parts to be processed are fixed on the tire membrane 2; the oblique spinning mechanism 1 It is symmetrically arranged on both sides of the ejector rod 5 and embedded with the fuselage shell 6; the controller 4 drives the oblique spinning mechanism 1 and drives the main shaft 3 to rotate.

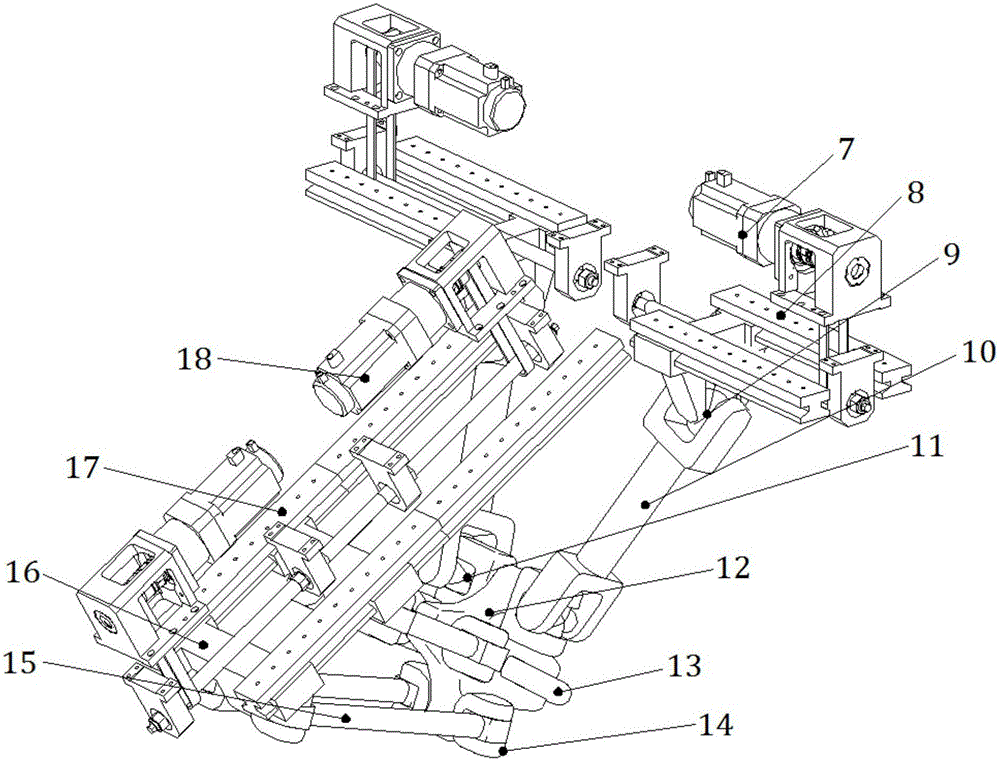

[0027] like figure 2 As shown, the oblique spinning mechanism 1 includes: a four-degree-of-freedom parallel robot, two lateral motors 7, two oblique motors 18, two parallel lateral screw guide rails 8 and two serial oblique wires rod guide rail 17, wherein: two horizontal scr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com