Spring removing mechanism

A gantry and gear shaft technology, which is used in grinding machine parts, machine tools suitable for grinding workpiece planes, grinding feed motion, etc., can solve the problem that the panel and the inner table are not coplanar, and the spring needs manual operation , can not work properly and other problems, to achieve the effect of simple structure, reduce energy consumption, reduce friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

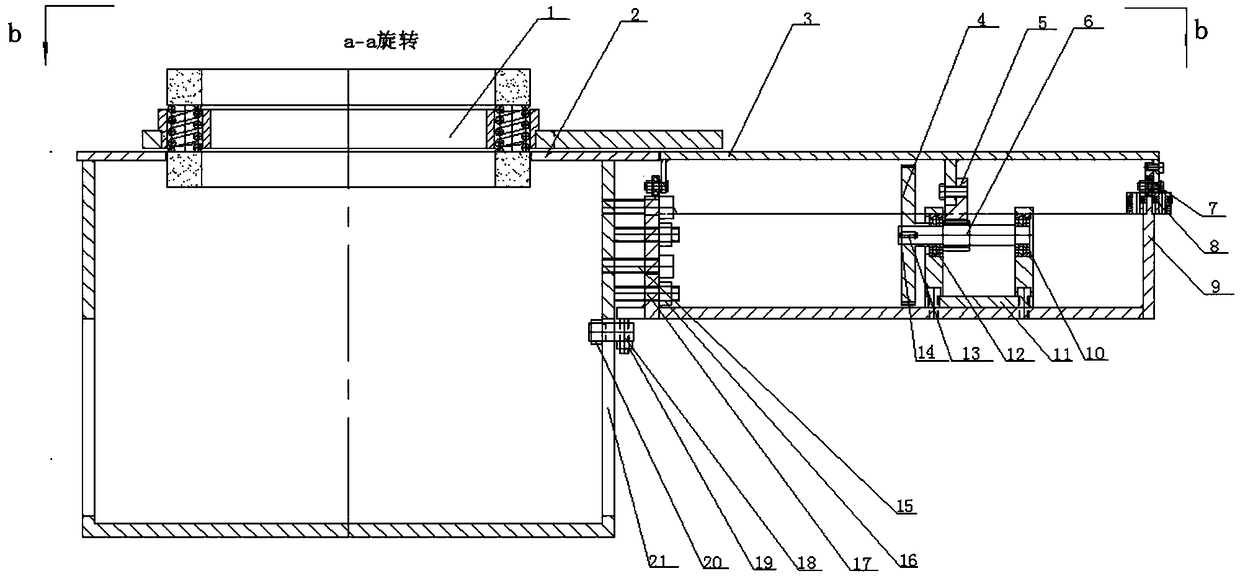

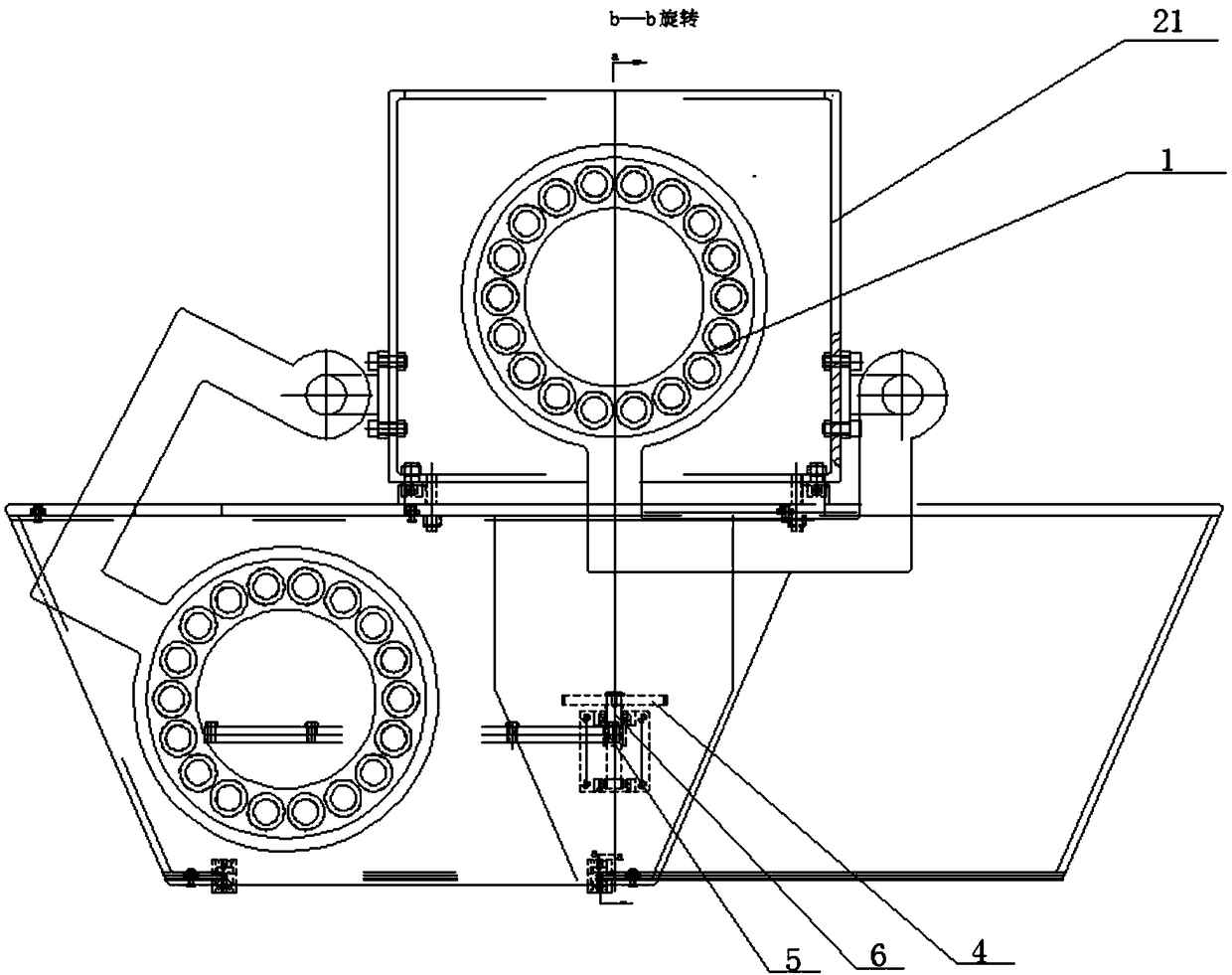

[0016] refer to Figure 1 to Figure 2 A specific embodiment of an automatic spring unloading mechanism of the present invention will be further described.

[0017] A spring unloading mechanism, comprising a box body 21, a door frame 9 is connected to the box body 21, a spring unloading door 3 is slidably connected to the door frame 9, and a bearing seat 11 is fixedly connected inside the door frame 9, The bearing seat 11 is provided with a pinion 6, the bottom of the unloading door 3 is connected with a rack 5 meshing with the pinion 6, and one end of the pinion 6 is provided with a power gear 4, and the power Gear 4 is connected with power unit, and power unit adopts motor, and power gear 4 is connected with the power shaft of motor, and motor operation drives power gear 4 to rotate, thereby drives pinion shaft 6 to rotate, because the tooth bar 5 that is fixed on unloading door 3 and The pinion shaft 6 is meshed, therefore, the pinion shaft 6 rotates to drive the rack 5 to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com