Testing clamp for testing tensile stress-tensile strain of metal bar samples

A tensile stress and tensile strain technology, applied in the direction of measuring devices, analytical materials, instruments, etc., can solve the problems of large amount of blanks, insufficiency, high price, etc., to save testing costs, easy installation, and alignment. good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

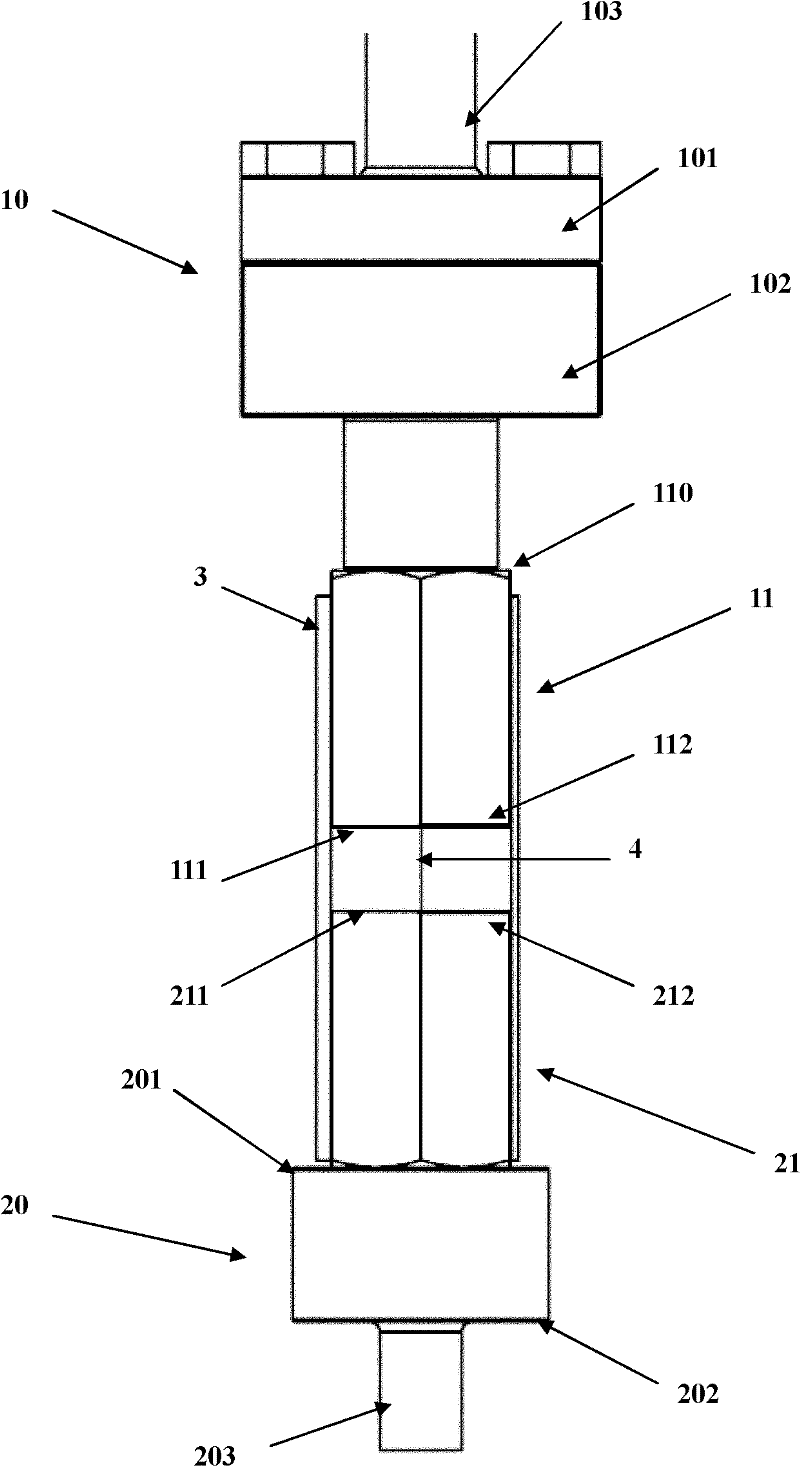

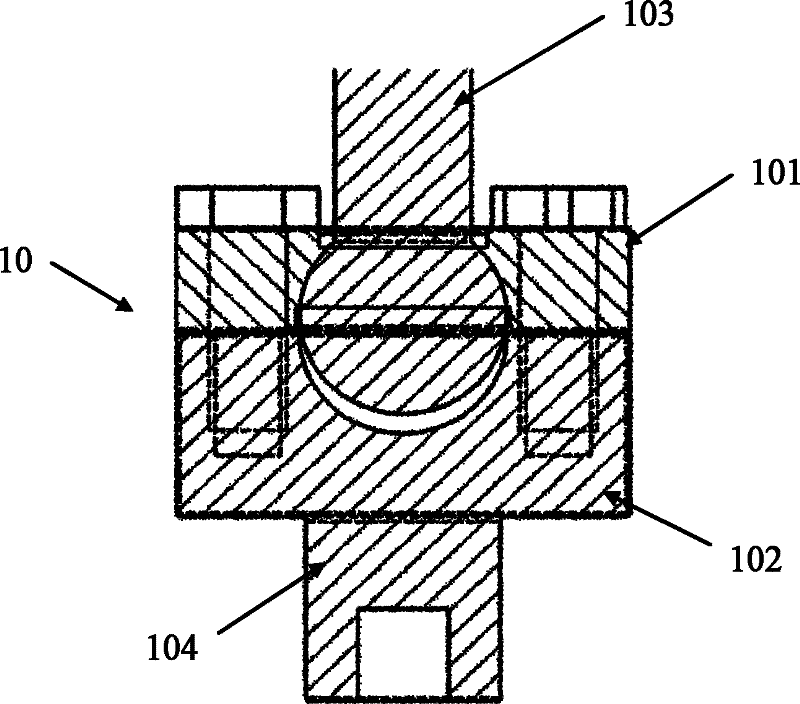

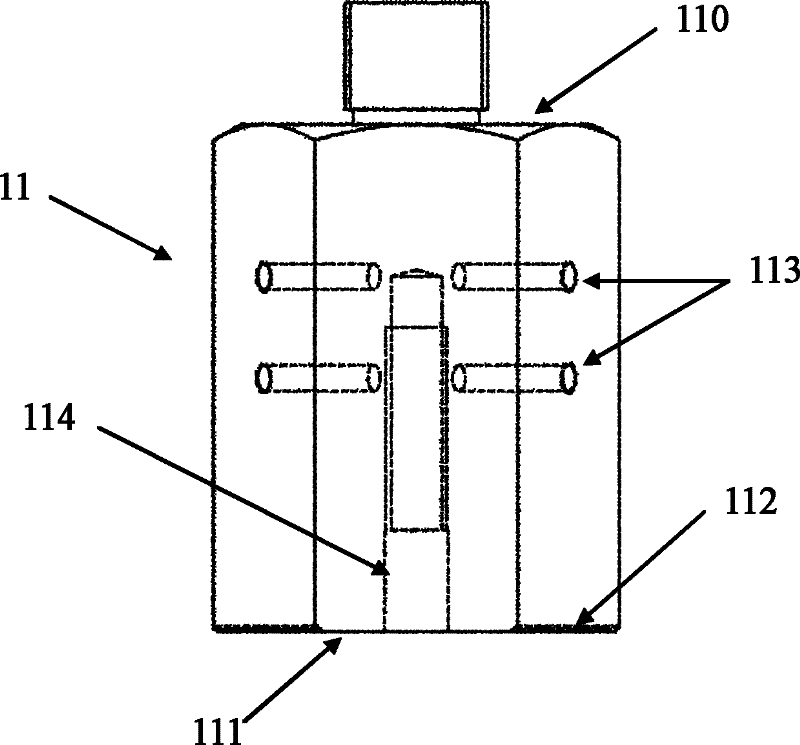

[0033] figure 1 It is a structural schematic diagram of the present invention; figure 2 It is a schematic structural view of the upper connection part 10; image 3 It is a structural schematic diagram of the upper chuck 11; Figure 4 It is a structural schematic diagram of the lower chuck 21; Figure 5 It is a schematic structural diagram of the lower connection tooling 20; Image 6 It is a schematic diagram of the assembly of the upper chuck 11, the lower chuck 21 and the guide baffle 3; Figure 7 It is a schematic diagram of the upper horizontal knife-edge groove 112 and the lower horizontal knife-edge groove 212 . As can be seen from the figure, the test fixture for testing the tensile stress-tensile strain of the metal bar sample provided by the present invention consists of an upper connection part 10, an upper clamp 11, a lower clamp 21, a l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com