Sandwich structure based on carbon foam as well as preparation method and maintenance method of sandwich structure

A sandwich structure and carbon foam technology, applied in the field of composite materials, can solve the problems of function and performance research and application without carbon foam sandwich structure, and achieve the effects of strong adaptability to complex environments, good machining performance, and long life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

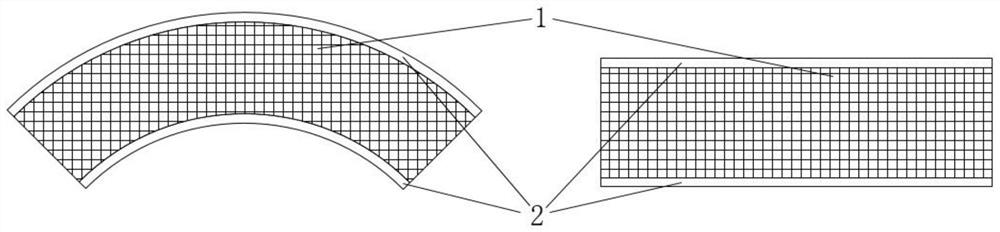

Image

Examples

Embodiment

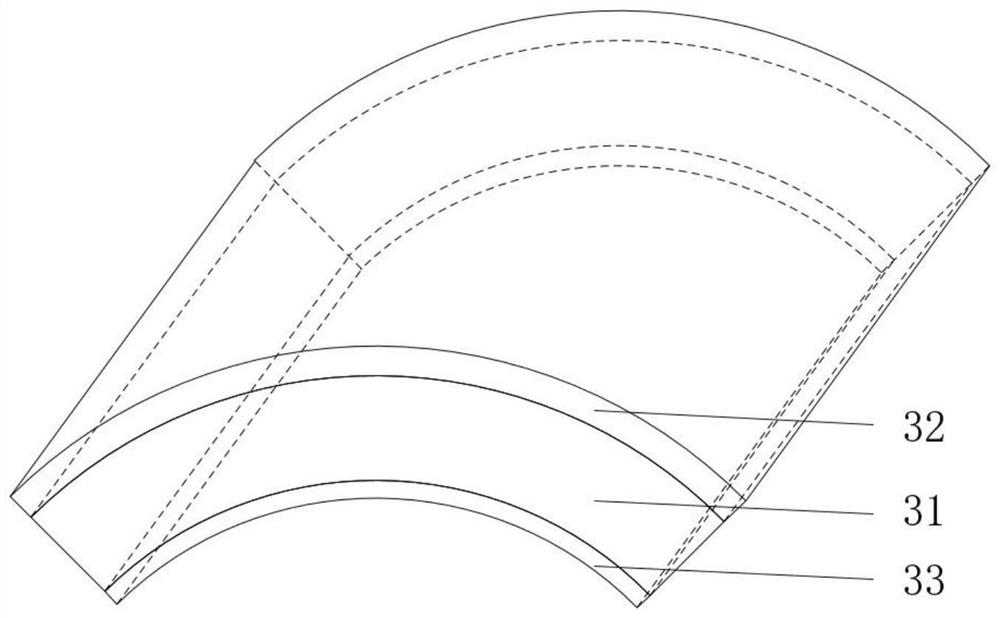

[0070] A lightweight structure-insulation integrated shell sandwich structure based on carbon foam, see image 3 . The sandwich structure includes a coal-based carbon foam sandwich core 31, an outer panel 32, and an inner panel 33, wherein the coal-based carbon foam sandwich core 31 has a density of 0.45 g / cm 3 1. Insulating coal-based carbon foam with room temperature thermal conductivity of 0.08W / (m·K), the outer panel 32 is made of carbon / carbon composite material, and the inner panel 33 is made of Shuangma resin-based carbon fiber reinforced composite material.

[0071] The preparation method of the sandwich structure described in this example comprises the following operations:

[0072] 1) The coal-based carbon foam sandwich core 31 is machined. Foam the coal-based carbon into the desired shape with a CNC machine tool, and the thickness of the foam is 25mm;

[0073] 2) Forming and compounding of the outer panel 32 . The outer surface of the foam is covered with a carb...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com