Plastic electrode and preparation method thereof, and aqueous sodium-ion battery and preparation method thereof

A sodium-ion battery, plasticity technology, applied in electrode manufacturing, electrode rolling/calendering, battery electrodes, etc., can solve problems such as poor process controllability, poor consistency of battery performance, complex production and assembly, etc., to achieve increased production flexibility , ionic impedance and electronic impedance reduction, the effect of ion diffusion path reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

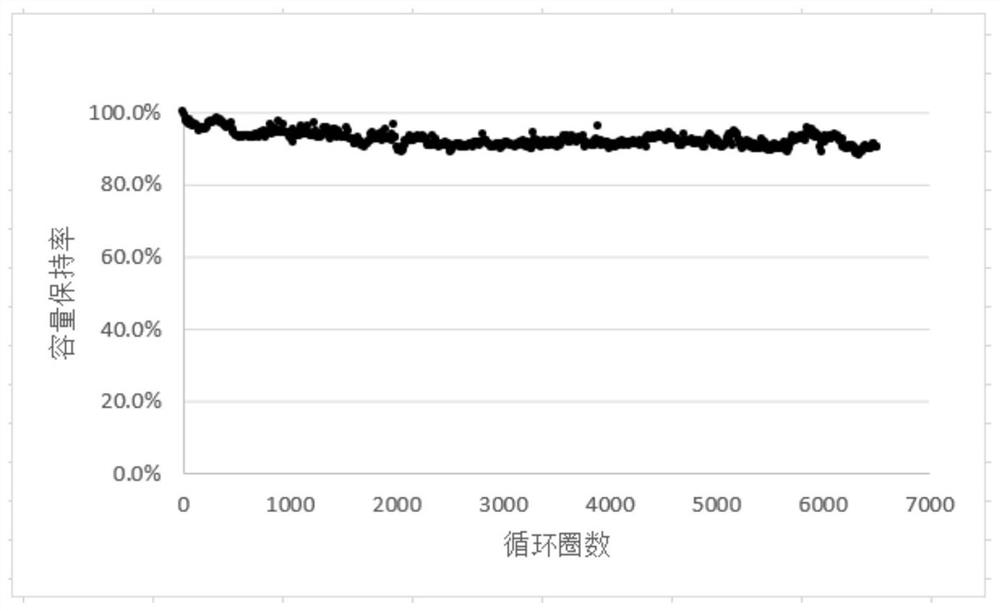

Examples

preparation example Construction

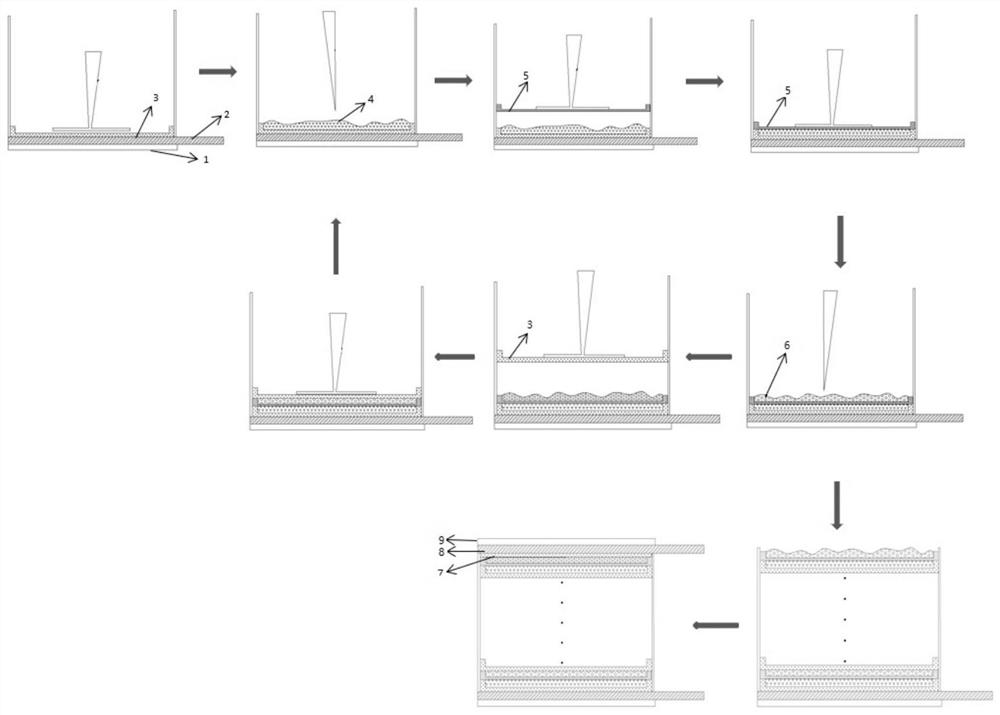

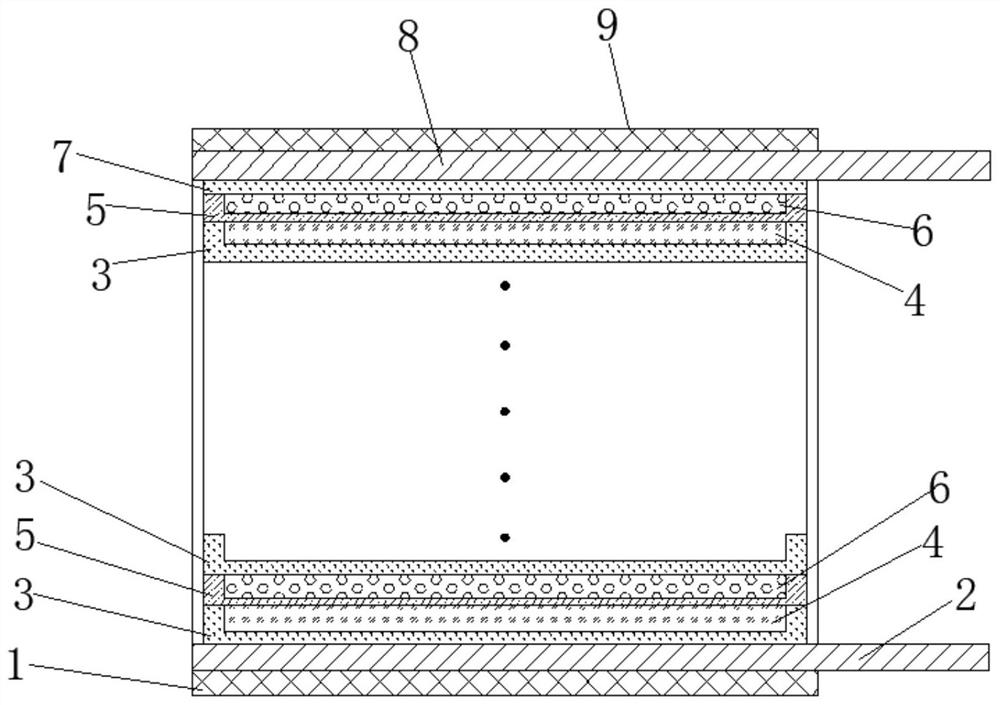

[0044] A method for preparing a plastic electrode of an aqueous sodium ion battery, comprising the following steps: S1 uniformly mixing electrolyte salt and deionized water to form an electrolyte solution;

[0045] S2 Add surfactant and humectant to electrolyte solution and mix into a uniform solvent matrix;

[0046] S3 Add the conductive material to the solvent matrix, and disperse the conductive material evenly in the solvent matrix by high-speed stirring;

[0047] S4 If a positive electrode is to be prepared, the positive active material and a binder are added, and if a negative electrode is to be prepared, a negative active material and a binder are added, and then stirred at a high speed to mix evenly;

[0048] S5 is mixed with cross-linking agent at low speed to make it cross-link with the binder to form a three-dimensional network structure of plastic electrode paste for aqueous sodium-ion batteries;

[0049] In the above preparation steps, the weight percentage of eac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com