Method for preparing modification aluminoxane

A modification technology of alkyl aluminoxane, which is applied in the field of preparation of modified alkyl aluminoxane, which can solve the problem of affecting the storage stability and use effect of aluminoxane, the content of active ingredients of target products caused by local overheating, and the effect of catalytic effect and other problems, to achieve good catalytic effect, improve storage stability and use effect, and improve production flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

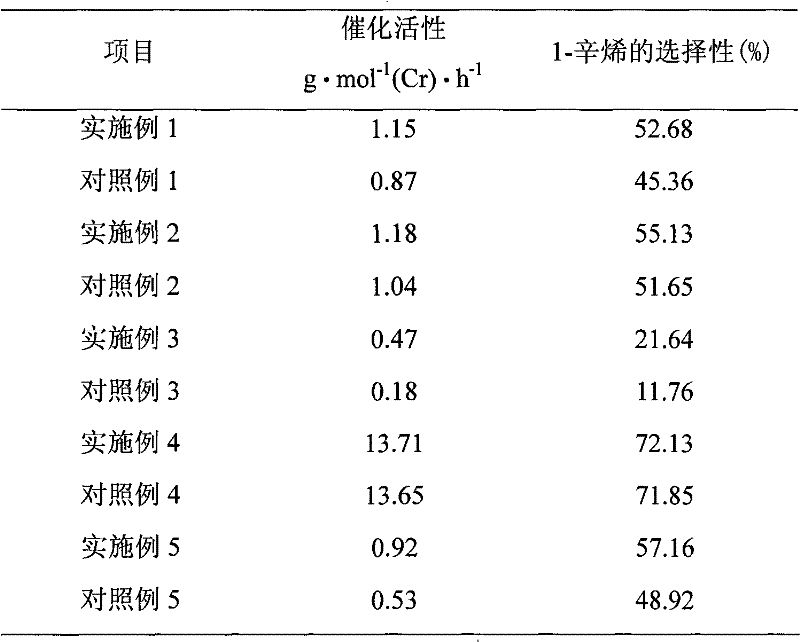

Examples

Embodiment 1

[0030] Under the protection of high-purity nitrogen, make triethylaluminum into 500mL of 2.5mol / L toluene solution, transfer it to the storage tank of alkylaluminum solution; , the modifier (methanol) and toluene were mixed and stirred at high speed for 10 minutes to form a mixture of 350 mL of hydrolyzing agent, which was transferred to the hydrolyzing agent storage tank and kept stirring at a speed of 1000 rpm.

[0031] After the reaction device equipped with nitrogen, venting system and cooling system is fully vacuumed-nitrogen replacement operation, two feed pumps are turned on, the flow rate of triethylaluminum solution is 4mL / min, and the flow rate of hydrolyzing agent is 2.8mL / min. material. The two feeds are cooled to -15°C through the cooling coil immersed in the cold bath, and then enter the T-shaped tube reactor for mixing and then flow into the reactor 1. The reaction liquid enters the continuously stirred reactor 1 from the upper part for degassing and further Re...

Embodiment 2

[0036] Under the protection of high-purity nitrogen, make triethylaluminum into 500mL of 2.5mol / L toluene solution, and transfer it to the storage tank of alkylaluminum solution; : After mixing in the ratio of 75 (V / V / V), high-speed stirring was carried out for 10 minutes, and the formed mixture was 850 mL of hydrolyzing agent, which was transferred to the hydrolyzing agent storage tank, kept stirring, and the stirring speed was 600 rpm.

[0037] After the reaction device equipped with nitrogen, venting system and cooling system is fully deoxygenated-nitrogen replacement operation, two feed pumps are turned on, the flow rate of triethylaluminum solution is 5mL / min, and the flow rate of hydrolyzing agent is 8.4mL / min. material. The two feeds are cooled to -10°C through the cooling coil immersed in the cold bath, and then enter the T-shaped tube reactor for mixing and then flow into the reactor 1. The reaction liquid enters the continuously stirred reactor 1 from the upper part ...

Embodiment 3

[0042] Under the protection of high-purity nitrogen, make triisobutylaluminum into 500mL of 4.0mol / L toluene solution, and transfer it to the storage tank of alkylaluminum solution; Mix at a ratio of 0.25:113 (V / V / V) and then stir at high speed for 10 minutes. The resulting mixture is 910 mL of hydrolyzing agent, which is transferred to the storage tank of hydrolyzing agent and kept stirring at a stirring speed of 1000 rpm.

[0043] After the reaction device equipped with nitrogen, venting system and cooling system is fully deoxygenated-nitrogen replacement operation, two feed pumps are turned on, the flow rate of triethylaluminum solution is 5mL / min, and the flow rate of hydrolyzing agent is 9.1mL / min. material. The two feeds are cooled to -20°C through the cooling coil immersed in the cold bath, and then enter the T-shaped tube reactor for mixing and then flow into the reactor 1. The reaction liquid enters the continuously stirred reactor 1 from the upper part for degassing an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com