Cloth laser printing machine

A printing machine and cloth technology, applied in printing, winding strips, thin material processing, etc., can solve the problems of laser printing pattern distortion, slow deviation correction speed of deviation correction roller, easy deviation of cloth, etc., to achieve the elimination of longitudinal tension, Good effect of deviation correction, improvement of quality and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Embodiment 1: a kind of cloth laser printing machine.

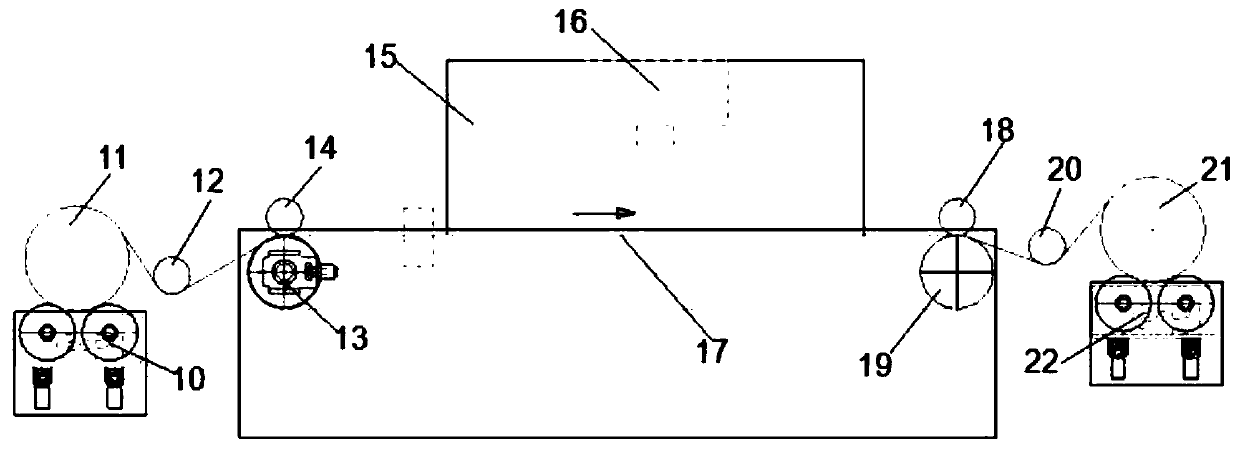

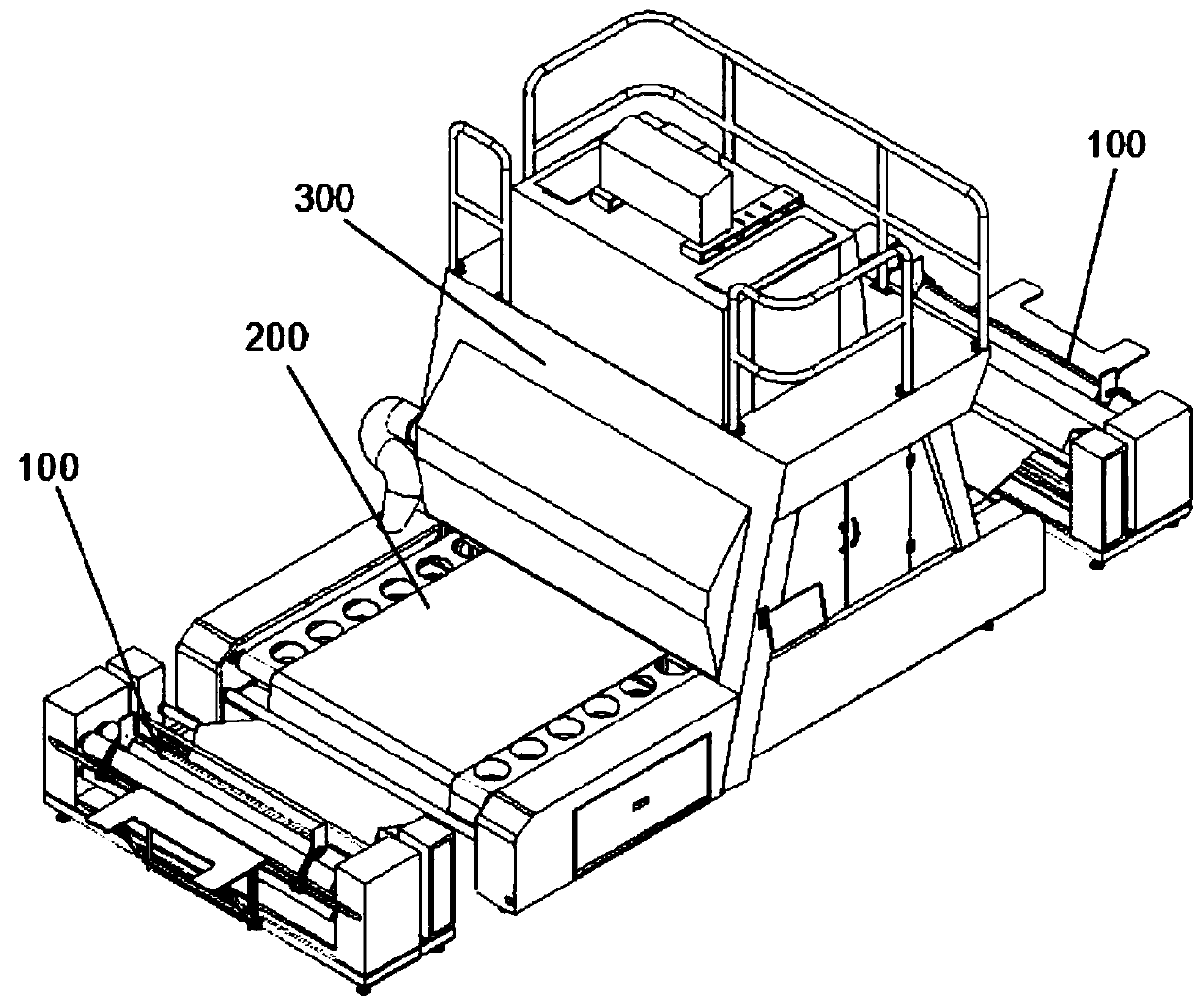

[0035] refer to Figure 2 to Figure 10 As shown, a cloth laser printing machine includes:

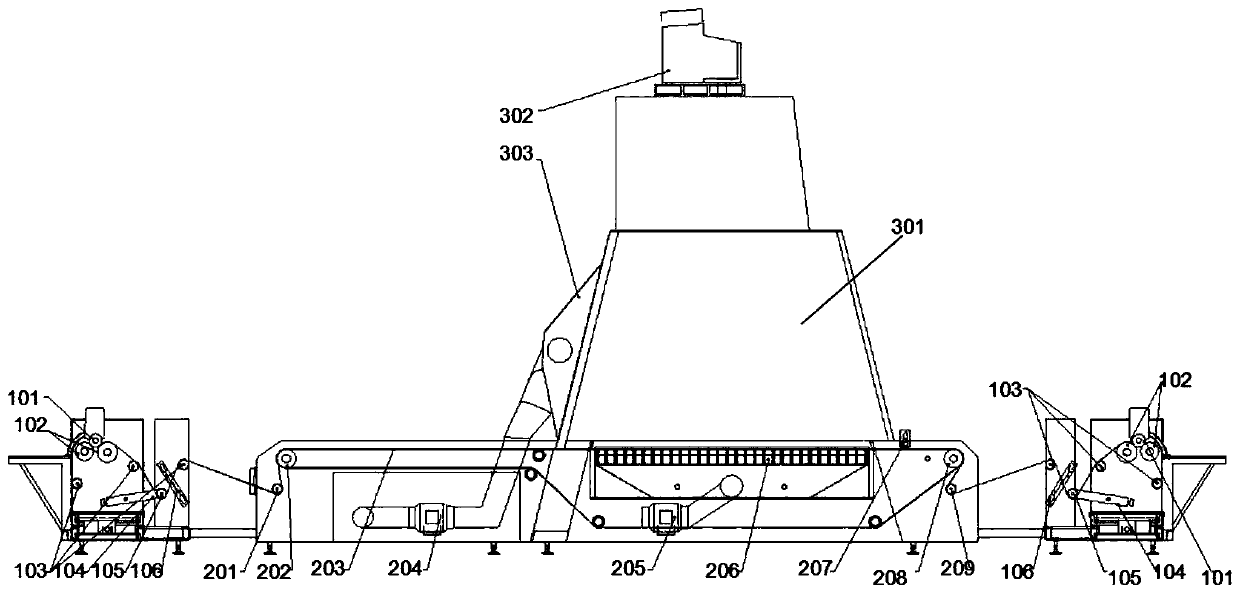

[0036] Two symmetrically installed cloth receiving / unwinding devices 100, one of which is installed at the front end of the laser printing device 300, and the other is installed at the rear end of the laser printing device 300, and the cloth receiving / unwinding device 100 includes installation on the receiving / The take-up / unwind roller 102 on the unwinding frame, the cloth roll 101 is placed on the take-up / unwind roller 102, and the cloth roll 101 is driven by the rotation of the take-up / unwind roller 102 to unwind or rewind at a constant speed. The receiving / releasing guide roller 103 behind the unwinding roller 102, the function of the receiving / releasing guide roller 103 is to guide the cloth to move according to the set route, and it is installed on the first collecting / releasing guide roller and the second collecting / ...

Embodiment 2

[0043] Embodiment 2: a kind of cloth laser printing machine.

[0044] refer to Figure 10 As shown, in this embodiment, the cloth retracting / releasing tension adjustment mechanism adopts servo PID adjustment, and the tension adjustment is more precise. The retracting / releasing tension adjustment mechanism includes a tension detector 1041, a tension adjustment linear motor 1042, and a cloth feeding drive roller 211 and the cloth output driving roller 212, the cloth feeding driving roller 211 and the cloth discharging driving roller 212 are installed on the front end and the rear end of the conveying mesh belt 203 respectively, and the cloth feeding driving roller 211 and the cloth discharging driving roller 212 are all driven by servo motors Drive, one end of the tension adjustment linear motor 1042 is connected with the tension adjustment roller 105, the tension detector 1041 is installed at the tension adjustment roller 105 place, the tension detector 1041, the tension adjust...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com