Unwinding feeding frame for glass fiber tape

A technology of glass fiber tape and feeding frame, which is applied in the direction of winding strips, sending objects, and thin material processing, etc., which can solve the problems of reduced production efficiency, low production efficiency, and high labor intensity, so as to ensure impregnated feeding and reduce friction Resistance, the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

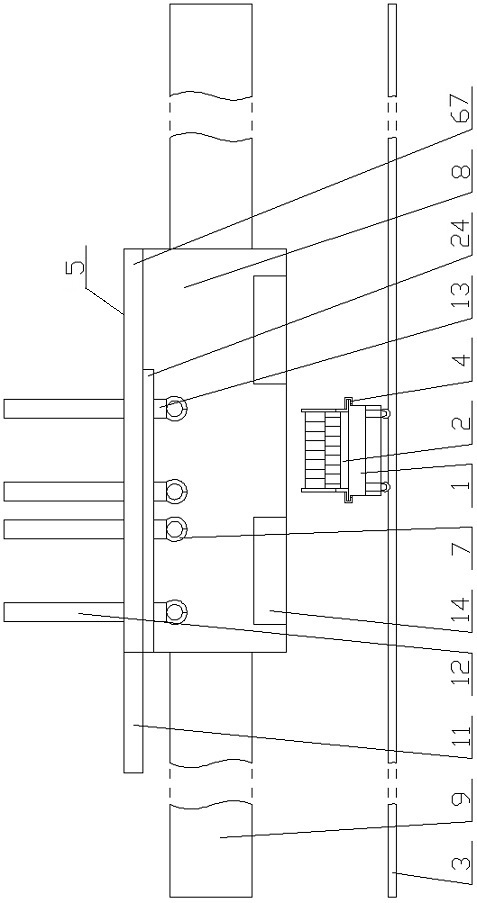

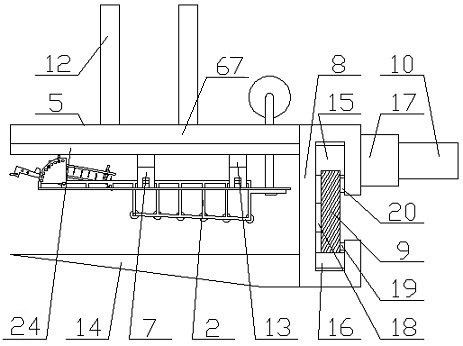

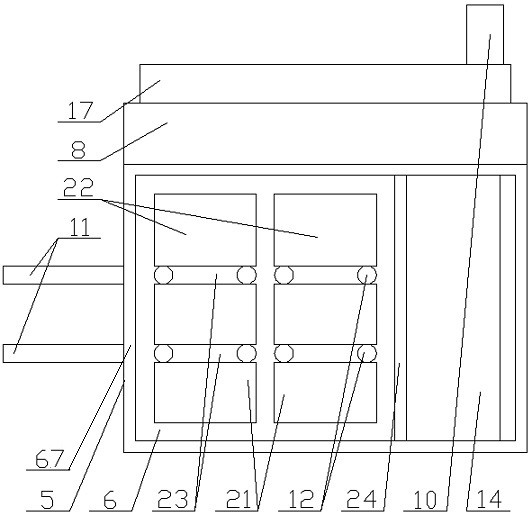

[0061] combine Figure 1~Figure 5 It can be seen that the unwinding feeding frame of the glass fiber tape includes an epoxy impregnation tank 1 that reciprocates along the track 3 through the driving device A, and the notch of the epoxy impregnation tank 1 is detachably fixedly connected with a glass fiber tape 68 The unwinding feeding frame 2 of the above-mentioned unwinding feeding frame 2 is located in the range of the epoxy impregnation tank 1, and also includes an unwinding feeding frame located above the epoxy impregnation tank 1 and reciprocatingly moving along the track beam 9 through the driving device B10 Replacement device 5, the track beam 9 is located behind the epoxy impregnation tank 1 and the unwinding feeding frame replacement device 5, and is arranged in parallel with the track 3, and the unwinding feeding frame replacement device 5 includes a horizontally arranged base frame 67, The bottom of one side of the base frame 67 is fixedly connected with the movabl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com