Preparation method of modified alumina carrier, palladium catalyst and preparation method thereof

A technology of alumina carrier and palladium catalyst, applied in metal/metal oxide/metal hydroxide catalyst, physical/chemical process catalyst, catalyst carrier, etc., can solve the problem of increasing energy consumption and cost, strength and ratio of alumina carrier. The surface area is not high and the catalyst activity is affected, so as to achieve the effect of reducing equipment cost, shortening the production process and reducing the waste of water resources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] The method for preparing the modified alumina carrier provided by the present invention does not need to prepare pseudo-boehmite, and the aluminum source can be formed directly after being gelled and filtered through acid dissolution, followed by freeze-drying and roasting treatment, which greatly shortens the production process and reduces equipment cost, and is convenient for industrialized production. The method has the advantages of simple operation process, short process and high production efficiency, and the prepared carrier has the advantages of many acidic active sites, large pore size, high particle strength and large specific surface area, and is suitable for application in the field of petrochemical industry.

[0040] Therefore, another aspect of the present invention provides a palladium catalyst comprising palladium nanoparticles and the above-mentioned carrier, the palladium catalyst can be used in the process of preparing hydrogen peroxide by anthraquinon...

Embodiment 1

[0046] Weigh 20g Al(NO 3 ) 3 9H 2 O was dissolved in 100 mL of absolute ethanol, stirred and heated to 70°C, and ammonium carbonate aqueous solution with a concentration of 1 mol / L was added dropwise to make the pH reach 7, and the reaction was continued for 4 hours after the addition was completed. After the reaction, filter, wash, disperse in 20mL deionized water, add concentrated nitric acid drop by drop, make the acid-aluminum ratio 0.1, and generate alumina colloid. Mix silica sol and alumina colloid evenly at a mass ratio of 0.1, drop it into the oil phase with a dropping pill machine, take out the shaped balls, place the shaped balls at the bottom in ammonia water with a mass concentration of 2%, and the upper layer is a bracket In the aging kettle, the molded pellets were placed on the support, and the aging kettle was heated to make the temperature in the kettle reach 80°C. The molded pellets reacted slowly in an ammonia atmosphere, and the reaction time was 30 minu...

Embodiment 2

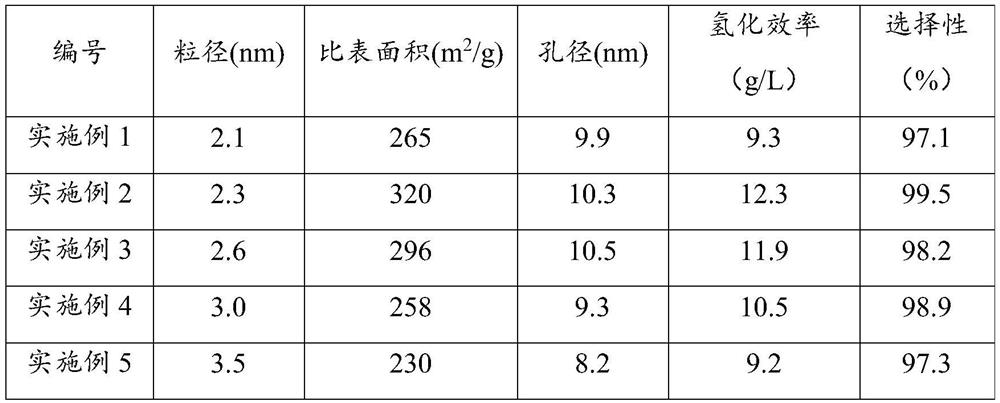

[0050] PdCl 2 and NaCl were dissolved in distilled water, and the aqueous solution with a concentration of 0.03gPd / mL was prepared for subsequent use, and the same method as in Example 1 was used to prepare Pd / Al with a palladium content of 0.3%. 2 o 3 Catalyst, the catalyst Pd particle size, specific surface area, pore size, hydrogenation efficiency, selectivity are measured, and the measurement results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com