Carbon board and preparation method

A technology of carbon and bamboo charcoal, applied in the direction of layered products, etc., can solve the problems of bamboo charcoal brittleness and application limitations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

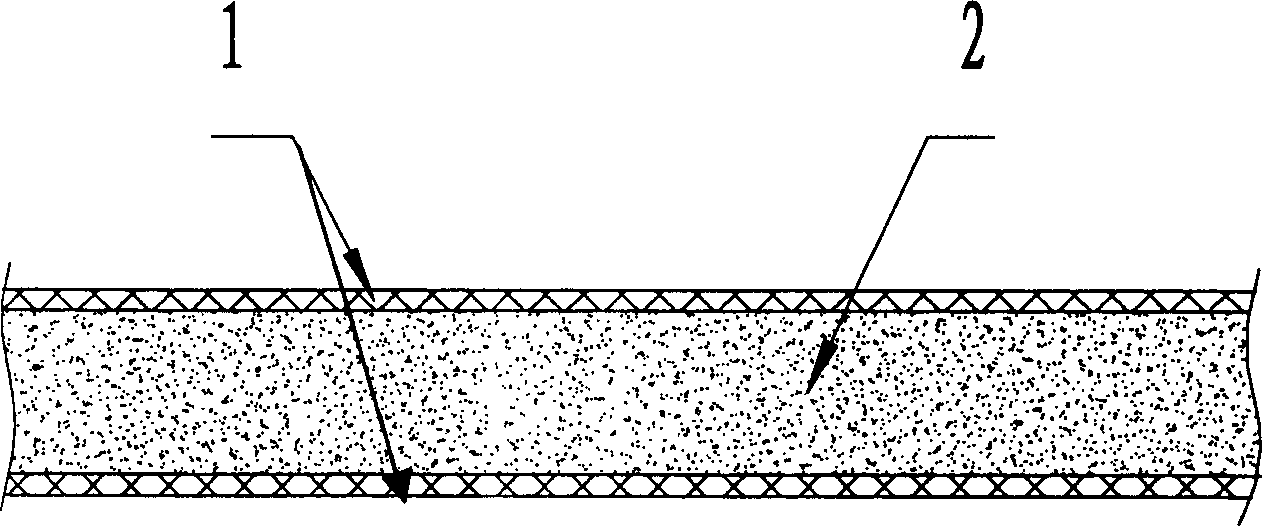

Embodiment 1

[0017] Based on weight, granular bamboo charcoal (in dry basis): granular tourmaline (in dry basis): polyvinyl acetate emulsion (in terms of solid content 100%) is 77: 5: 15 ingredients, bamboo charcoal particle diameter It is 25 μm to 800 μm, and the particle size of tourmaline is 10 μm to 1 mm. Mix the adhesive diluted to a solid content of 50% with granular bamboo charcoal and granular tourmaline, and evenly coat the mixture of glue, granular bamboo charcoal, and granular tourmaline on one surface of the veneer material 1 , cover the veneer material 1 on the other side of the mixture of glue and granular bamboo charcoal required by a certain thickness. Roll the mixture of glue, granular bamboo charcoal, and granular tourmaline sandwiched by the veneer material 1 together with the veneer material 1 into a plate shape, and dry it with hot air at 50-120°C in a drying oven for 2- After 10 minutes, a carbon plate is formed.

Embodiment 2

[0019] Based on weight, according to granular bamboo charcoal (in dry basis): polyvinyl acetate emulsion (in terms of solid content 100%): decabromodiphenylethane is 82: 15: 1.5 ingredients, and the particle size of bamboo charcoal is 25 μm~ 800 μm. The adhesive that is diluted to 50% solid content is mixed with decabromodiphenylethane and granular bamboo charcoal, and the mixture of glue after mixing and decabromodiphenylethane and granular bamboo charcoal is coated according to the method described in Example 1. Cloth, rolling and drying methods are formed and dried into carbon plates.

Embodiment 3

[0021] Based on weight, granular bamboo charcoal (in dry basis): polyvinyl acetate emulsion (in terms of solid content 100%): polystyrene-acrylic acid ester emulsion (in terms of solid content 100%): glyceryl triacetate The ingredients are 82:7.5:7.5:0.7, and the particle size of bamboo charcoal is 25 μm to 800 μm. Be diluted to the solid content of 50% mixed adhesive and triacetin, granular bamboo charcoal mix uniformly, the mixture of glue after mixing and triacetin, granular bamboo charcoal is by the coating described in embodiment 1, roll pressing and The drying method is to form and dry into a carbon plate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com