A kind of catalytic oxidation catalyst and preparation method thereof

A technology of catalytic oxidation and ozone catalytic oxidation, applied in the direction of physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, etc., can solve the problem that the activity needs to be further improved, and achieve the goal of promoting catalysis The effect of activity and stability, simple preparation process and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

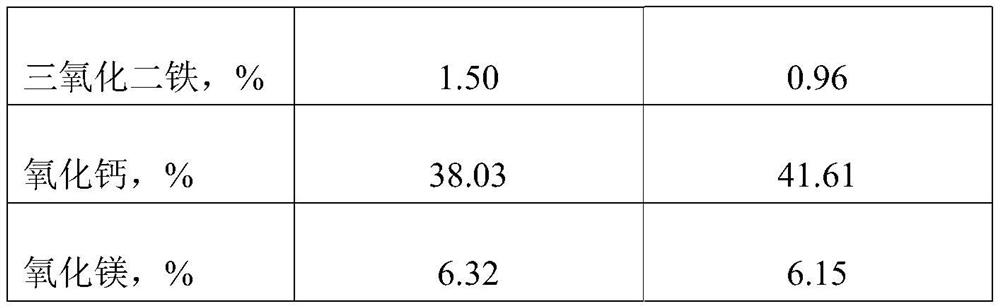

Embodiment 1

[0031] After kaolin saturated adsorption weight concentration is 15% ammonium carbonate solution, then mixed with activated carbon, manganese ferromanganese slag A, lanthanum oxide, granulated 2-3mm, dried at 100°C for 8 hours, and then under nitrogen atmosphere, Roasting at a temperature of 1300° C. for 5 hours to obtain catalyst A, the composition of which is as follows: the content of activated carbon is 25%, the content of ferromanganese slag is 25%, the content of lanthanum oxide is 3%, and the balance is kaolin.

Embodiment 2

[0033] Replace manganese ferromanganese slag A in embodiment 1 with ferromanganese slag B, replace lanthanum oxide with cerium oxide, preparation process is the same as embodiment 1, obtains catalyst B, and its composition is as follows: the content of activated carbon is 30%, manganese ferrosite The content of slag is 30%, the content of cerium oxide is 2.5%, and the balance is kaolin.

Embodiment 3

[0035] Kaolin is directly mixed with activated carbon, ferromanganese slag A, and lanthanum oxide without modification, granulated to 2-3mm, dried at 100°C for 8h, and then roasted at 1300°C for 5h under nitrogen atmosphere to obtain Catalyst C, its composition is as follows: the content of activated carbon is 25%, the content of ferromanganese slag is 25%, the content of lanthanum oxide is 3%, and the balance is kaolin.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com