Low-temperature antibacterial drying equipment and drying processing method of material

A drying equipment and low temperature technology, applied in the direction of drying solid materials, drying solid materials without heating, drying gas arrangement, etc., can solve the problems of high equipment requirements, nutrient loss, multi-energy input, etc., to reduce heat loss and reduce waste , cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

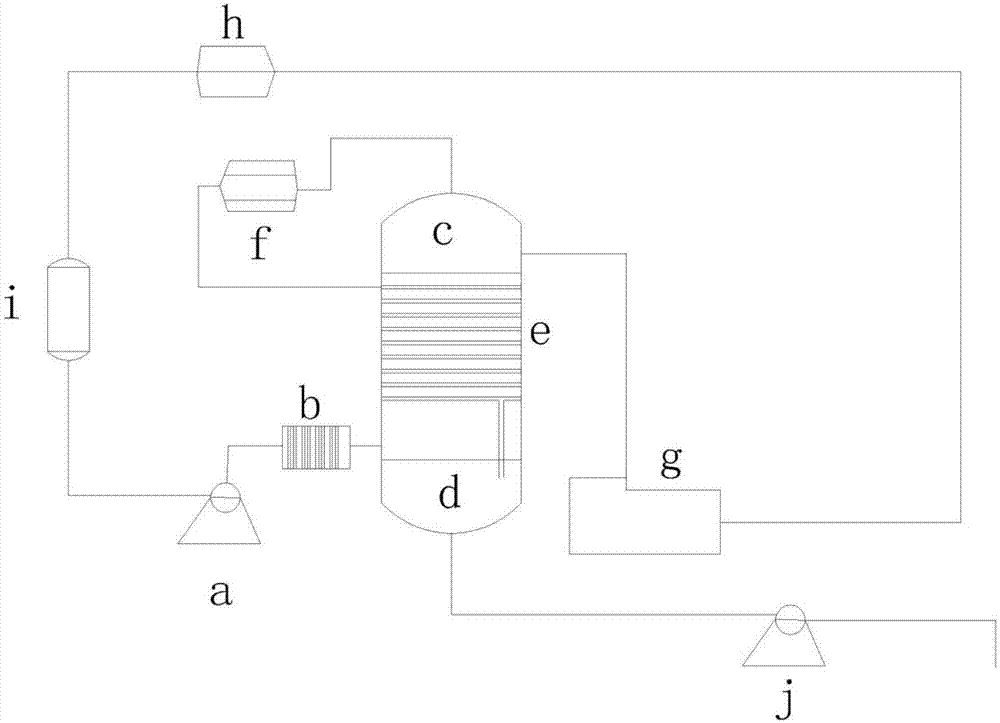

[0041] 1) The apples are cleaned and sliced for color protection and placed in the shell side of the heat exchanger in the drying tower;

[0042] 2) The compressed nitrogen gas is heated to 45 ℃ through the heat exchanger b by the blower a;

[0043] 3) the heated nitrogen enters the shell side of the heat exchanger e in the drying tower c; carry out low temperature drying;

[0044] 4) The drying tower is operated by vacuum pump g to vacuumize the drying tower, the vacuum degree is controlled at 30kpa, and the vacuum exhaust is compressed and recovered to nitrogen tank i by the compressor h to the discharged nitrogen gas;

[0045] 5) Part of the drying waste heat is compressed and heated by the compressor f and then enters the tube side of the heat exchanger e for heat recovery and evaporative water collection, and the collected evaporative water enters the condensed water tank d;

[0046] 6) After the moisture content of the dried material is reduced to 5%, it is cooled and p...

Embodiment 2

[0050] 1) After the strawberries are cleaned and sliced for color protection, they are placed in the shell side of the heat exchanger in the drying tower;

[0051] 2) The compressed nitrogen gas is heated to 55 ℃ through the heat exchanger b by the blower a;

[0052] 3) the heated nitrogen enters the shell side of the heat exchanger e in the drying tower c; carry out low temperature drying;

[0053] 4) The drying tower is operated by vacuum pump g to vacuumize the drying tower, the vacuum degree is controlled at 30kpa, and the vacuum exhaust is compressed and recovered to nitrogen tank i by the compressor h to the discharged nitrogen gas;

[0054] 5) Part of the drying waste heat is compressed and heated by the compressor f and then enters the tube side of the heat exchanger e for heat recovery and evaporative water collection, and the collected evaporative water enters the condensed water tank d;

[0055] 6) After the moisture content of the dried material is reduced to 4%...

Embodiment 3

[0059] 1) Put the carrots in the shell side of the heat exchanger in the drying tower after cleaning and slicing for color protection;

[0060] 2) The compressed nitrogen gas is heated to 35 ℃ through the heat exchanger b by the blower a;

[0061] 3) the heated nitrogen enters the shell side of the heat exchanger e in the drying tower c; carry out low temperature drying;

[0062] 4) The drying tower is operated by vacuum pump g to vacuumize the drying tower, the vacuum degree is controlled at 30kpa, and the vacuum exhaust is compressed and recovered to nitrogen tank i by the compressor h to the discharged nitrogen gas;

[0063] 5) Part of the drying waste heat is compressed and heated by the compressor f and then enters the tube side of the heat exchanger e for heat recovery and evaporative water collection, and the collected evaporative water enters the condensed water tank d;

[0064] 6) After the moisture content of the dried material is reduced to 5%, it is cooled and pac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com