Purifying coating as well as preparation method and application thereof

A paint and raw material technology, applied in the field of purification paint and its preparation, can solve the problems of diatom mud's water resistance, scrub resistance, and fineness that are difficult to compare with latex paint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

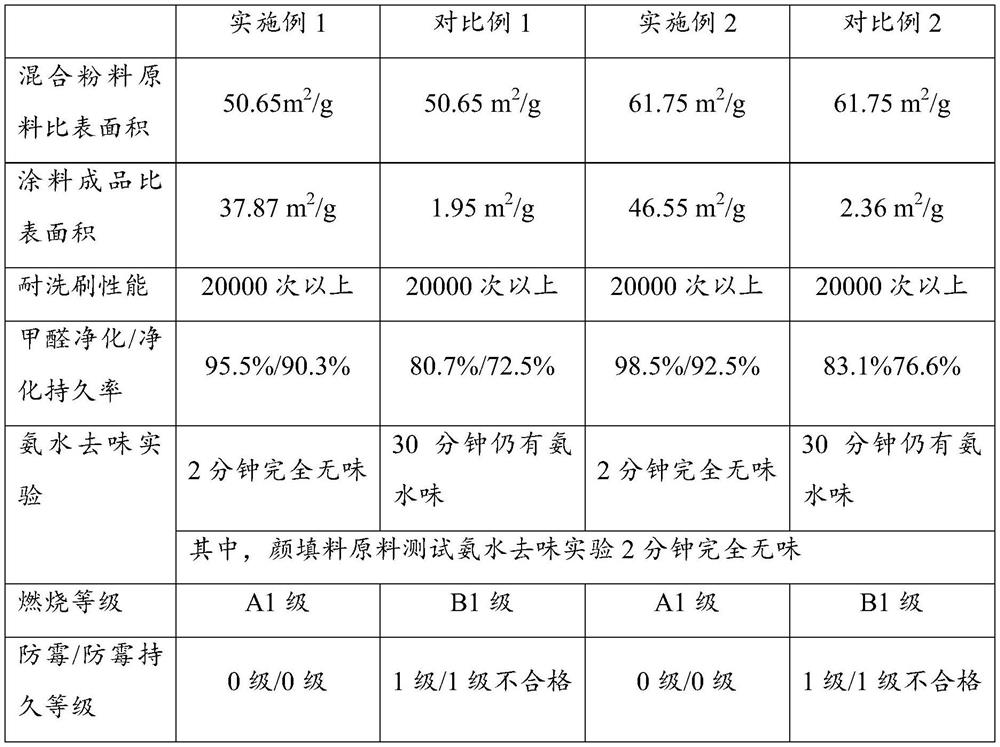

Examples

Embodiment 1

[0080] This embodiment specifically prepares a purification coating, which includes the following components by weight:

[0081] water 32%,

[0082] Dispersant 0.5%,

[0083] Wetting agent 0.1%,

[0084] cellulose 0.3%,

[0085] Defoamer 0.1%,

[0086] Stabilizer 0.3%,

[0087] Anti-settling agent 0.2%,

[0088] Filler 37.5%,

[0089] Molecular Sieve Porous Adsorbent 6%,

[0090] Photocatalyst 0.3%,

[0091] lotion 7%,

[0092] Potassium silicate solution 15%,

[0093] Thickener 0.5%,

[0094] Defoamer 0.1%,

[0095] Water resistant agent 0.1%.

[0096] The preparation method is as follows:

[0097] Add 320kg of water to the mixing tank, start the mixer to stir at a speed of 500r / min, and add 3kg of cellulose, 5kg of dispersant, 1kg of wetting agent, 1kg of defoamer, 3kg of stabilizer, and stir for 8min. Increase the speed to 1200r / min, then add 2kg of anti-settling agent, 375kg of other fillers (respectively 100kg of titanium dioxide, 50kg of sericite powder, 22...

Embodiment 2

[0101] This embodiment specifically prepares a purification coating, which includes the following components by weight:

[0102] water 27.5%,

[0103] Dispersant 0.6%,

[0104] Wetting agent 0.2%,

[0105] cellulose 0.5%,

[0106] Defoamer 0.2%

[0107] Stabilizer 0.4%,

[0108] Anti-settling agent 0.3%,

[0109] 30% of other fillers,

[0110] Porous Adsorbent 10%

[0111] Photocatalyst 0.5%

[0112] Lotion 5%

[0113] Potassium silicate solution 24%,

[0114] Thickener 0.3%,

[0115] Defoamer 0.2%,

[0116] Water resistant agent 0.3%.

[0117] The preparation method of the water-based interior wall paint is as follows: add 275kg of water in the mixing tank, start the mixer to stir at a rotational speed of 500r / min, and add 6kg of dispersant, 2kg of wetting agent, 5kg of cellulose, and 2kg of defoaming agent accordingly, and stir. After 10min, increase the speed to 1200r / min, then add 3kg of anti-settling agent, 300kg of other fillers (respectively, 125kg of titan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com