Preparation method of hydrophobic and oleophylic porous material

A porous material, hydrophobic and lipophilic technology, applied in the direction of separation methods, chemical instruments and methods, liquid separation, etc., can solve the problems of cumbersome and complicated preparation process, limit the application range of graphene-based oil-absorbing materials, and the high price of graphene, and achieve The effect of good hydrophobicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

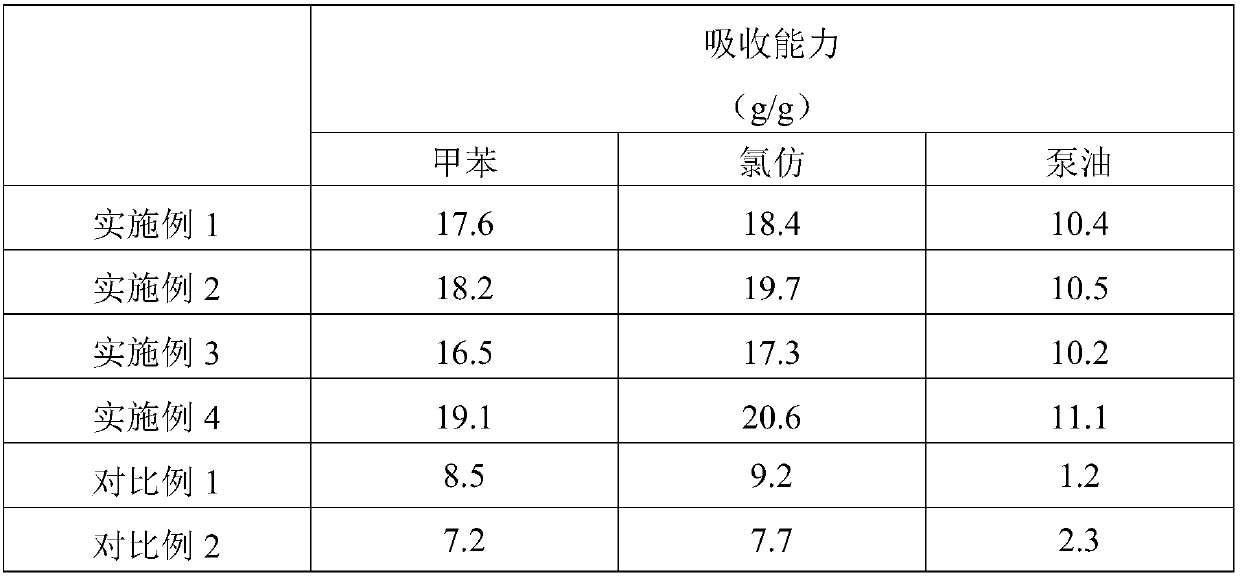

Examples

Embodiment 1

[0053] A. Preparation of precursor solution

[0054] The concentration of preparing sodium bicarbonate in the volumetric flask is 5% sodium bicarbonate (cell opener) aqueous solution and the concentration of sorbitan oleate is 0.36% sorbitan oleate (surfactant) aqueous solution.

[0055] 0.075 g of graphite particles (325 mesh in particle size) were added to 5 g of isooctyl acrylate, and dispersed by ultrasonic, the ultrasonic power was 300 W, and the ultrasonic time was 5 min.

[0056] Then, 15 g of sodium bicarbonate aqueous solution was added, and then 0.02 g of sorbitan oleate aqueous solution was added, and blended for 5 min at a speed of 500 r / min by means of mechanical stirring.

[0057] After that, add 0.05g of azobisisobutyronitrile (initiator) and 0.05g of ethylene glycol dimethacrylate (EGDMA, cross-linking agent), by means of mechanical stirring, at a speed of 500r / min Mix for 5 minutes to obtain a water-in-oil (water phase) type inverse Pickering emulsion (precu...

Embodiment 2

[0063] A. Preparation of precursor solution

[0064] Add 0.05g of hexane (cell opener) in 5g of mixed monomers that are used in a ratio of 3:1 by butyl acrylate monomer and methyl methacrylate monomer, and then 0.25g of graphite particles ( The particle size is 1000 mesh) was added into the mixed monomer, and dispersed by ultrasonic, the ultrasonic power was 300W, and the ultrasonic time was 5min.

[0065] Then, add 17g of water, then add 0.1mg of sorbitan monolaurate-40 (surfactant), 0.1mg of Tween-60 (surfactant), by mechanical stirring, at 500r / min Blending for 5 min at a rotational speed.

[0066] Afterwards, add the potassium persulfate (initiator) of 0.04g and the sodium bisulfite (initiator) of 0.02g and the divinylbenzene (DVB, linking agent) of 0.1g, by the mode of mechanical stirring, at 500r / The mixture was blended for 5 minutes at a rotation speed of min to obtain an oil-in-oil (polybutylacrylate-methyl methacrylate phase) (water phase) inverse Pickering emulsio...

Embodiment 3

[0071] A. Preparation of precursor solution

[0072] 0.1 g of graphite particles (with a particle size of 5000 mesh) was added to 5 g of butyl acrylate, and dispersed by ultrasonic, the ultrasonic power was 300 W, and the ultrasonic time was 5 min.

[0073] Add 0.05g of p-toluenesulfonyl hydrazide (cell opener), then add 16g of water, then add 0.2mg of N,N-dimethyloctadecylamine hydrochloride (surfactant), by mechanical stirring , Blending for 5min at a speed of 500r / min.

[0074] Afterwards, add the benzoyl peroxide (initiator) of 0.1g and the pentaerythritol triacrylate (crosslinking agent) of 0.1g, by the mode of mechanical agitation, under the rotating speed of 500r / min, blend 5min, obtain graphite in the form of flakes A water-in-water (water phase) type inverse Pickering emulsion (precursor solution) dispersed in oil (polybutyl acrylate phase).

[0075] B. Preparation of porous materials

[0076] The precursor solution prepared in step (A) was pre-polymerized in a wat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| water contact angle | aaaaa | aaaaa |

| water contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com