Single-sided thinning treatment method for liquid crystal display screen

A technology of liquid crystal display screen and processing method, which is applied in the direction of chemical instruments and methods, surface etching compositions, non-surface active detergent compositions, etc., and can solve the problems of low equipment investment, affecting product quality, and high product yield. Achieve the effects of reducing the generation of concave and convex points, facilitating full contact, and ensuring single-sided processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

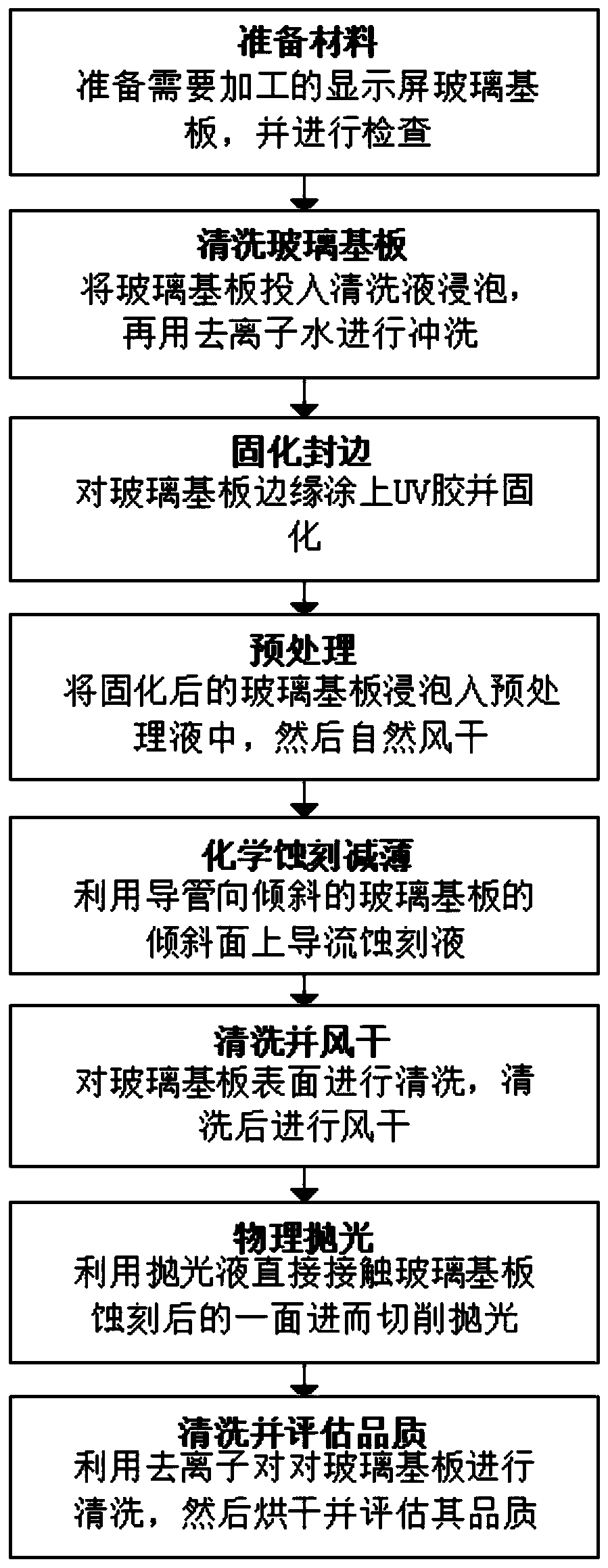

[0032] according to figure 1 As shown, this embodiment provides a method for thinning a single side of a liquid crystal display, comprising the following steps:

[0033] Step 1: Prepare materials

[0034] Prepare the display glass substrate that needs to be processed, first inspect the surface of the glass substrate, observe the surface with an optical magnifying glass, and select a glass substrate with a smooth, flat and scratch-free surface for processing;

[0035] Step 2: Clean the glass substrate

[0036] Preparation of cleaning solution: put acetone, ethanol and pure water into a stirring container according to the ratio of 1:1:10 and stir for 10 minutes, pour it into the container, then put the glass substrate rotated in step 1 into the container, use the cleaning Soak in the solution for 4 minutes and take it out, then rinse the surface of the glass substrate with deionized water, put the glass substrate in an air dryer after rinsing, and air-dry it to remove dust and...

Embodiment 2

[0050] according to figure 1 As shown, this embodiment provides a method for thinning one side of a liquid crystal display, comprising the following steps:

[0051] Step 1: Prepare materials

[0052] Prepare the display glass substrate that needs to be processed, first inspect the surface of the glass substrate, observe the surface with an optical magnifying glass, and select a glass substrate with a smooth, flat and scratch-free surface for processing;

[0053] Step 2: Clean the glass substrate

[0054] Preparation of cleaning solution: put acetone, ethanol and pure water into a stirring container according to the ratio of 1:1:10 and stir for 10 minutes, pour it into the container, then put the glass substrate rotated in step 1 into the container, use the cleaning Soak in the solution for 4 minutes and take it out, then rinse the surface of the glass substrate with deionized water, put the glass substrate in an air dryer after rinsing, and air-dry it to remove dust and grea...

Embodiment 3

[0068] according to figure 1 As shown, this embodiment provides a method for thinning one side of a liquid crystal display, comprising the following steps:

[0069] Step 1: Prepare materials

[0070] Prepare the display glass substrate that needs to be processed, first inspect the surface of the glass substrate, observe the surface with an optical magnifying glass, and select a glass substrate with a smooth, flat and scratch-free surface for processing;

[0071] Step 2: Clean the glass substrate

[0072] Preparation of cleaning solution: put acetone, ethanol and pure water into a stirring container according to the ratio of 1:1:10 and stir for 10 minutes, pour it into the container, then put the glass substrate rotated in step 1 into the container, use the cleaning Soak in the solution for 4 minutes and take it out, then rinse the surface of the glass substrate with deionized water, put the glass substrate in an air dryer after rinsing, and air-dry it to remove dust and grea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com