Preparation method for hydrophobic associated amphoteric flocculant used for industrial wastewater treatment

An amphoteric flocculant, hydrophobic association technology, applied in the direction of flocculation/sedimentation water/sewage treatment, etc., can solve the problems of unstable composition, small flocs, complex components, etc. Simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

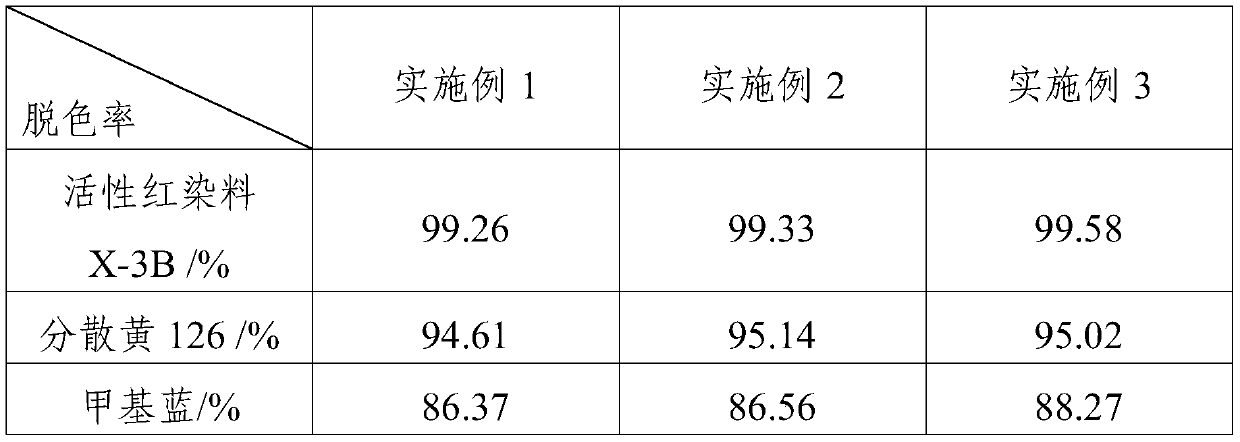

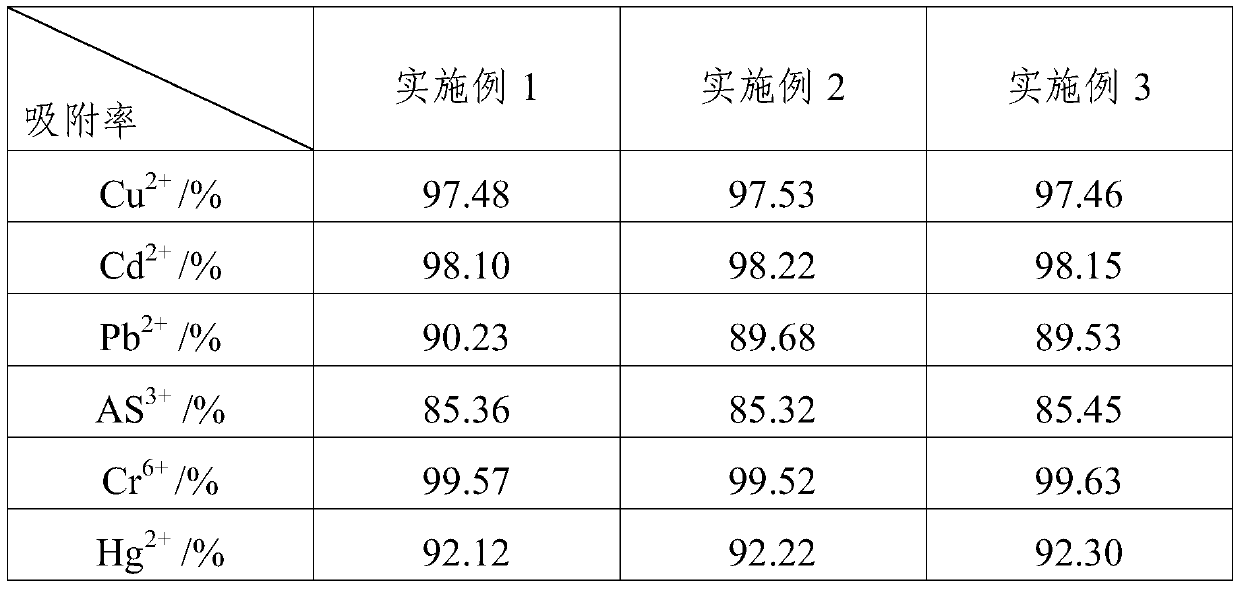

Examples

Embodiment 1

[0028] A kind of preparation method of hydrophobic association type amphoteric flocculant for industrial waste water treatment is as follows:

[0029] Pulverize the montmorillonite with a pulverizer and pass through an 80-mesh sieve, then mix it with sulfuric acid with a mass concentration of 25%, the mass ratio of montmorillonite to sulfuric acid is 1:4, stir evenly at room temperature, let it stand for 5 hours, suction filter, filter After the cake was washed with deionized water until it was neutral, it was dried at 100°C for 8 hours, and then activated at 305°C for 10 hours to obtain modified montmorillonite; add dodecafluoroheptyl ethyl acrylate and OP-10 to the deionized In water, stir and dissolve to obtain a homogeneous solution, then add acrylamide, 2-acrylamido-2-methylpropanesulfonic acid, itaconic acid, dimethyl diallyl ammonium chloride, stir at 300r / min for 12min and then Add triethylamine to adjust the pH of the system to neutral, add the above-mentioned modifie...

Embodiment 2

[0031] A kind of preparation method of hydrophobic association type amphoteric flocculant for industrial waste water treatment is as follows:

[0032] Crush the montmorillonite with a pulverizer and pass through an 80-mesh sieve, then mix it with sulfuric acid with a mass concentration of 35%, the mass ratio of montmorillonite to sulfuric acid is 1:2, stir evenly at room temperature, let stand for 5 hours, suction filter, filter After the cake was washed with deionized water until it was neutral, it was dried at 100°C for 8 hours, and then activated at 300°C for 11 hours to obtain modified montmorillonite; add dodecafluoroheptyl ethyl acrylate and OP-4 to the deionized In water, stir and dissolve to obtain a homogeneous solution, then add acrylamide, 2-acrylamido-2-methylpropanesulfonic acid, itaconic acid, dimethyl diallyl ammonium chloride, stir at 250r / min for 12min and then Add triethylamine to adjust the pH of the system to neutral, add the above-mentioned modified montmo...

Embodiment 3

[0034] A kind of preparation method of hydrophobic association type amphoteric flocculant for industrial waste water treatment is as follows:

[0035] Pulverize the montmorillonite with a pulverizer and pass through an 80-mesh sieve, then mix it with sulfuric acid with a mass concentration of 32%. The cake was washed with deionized water to neutrality, dried at 100°C for 6h, and then activated at 300°C for 10h to obtain modified montmorillonite; add dodecafluoroheptyl ethyl acrylate and OP-7 to the deionized In water, stir to dissolve to obtain a homogeneous solution, then add acrylamide, 2-acrylamido-2-methylpropanesulfonic acid, itaconic acid, dimethyl diallyl ammonium chloride, stir at 300r / min for 10min and then Add triethylamine to adjust the pH of the system to neutral, add the above-mentioned modified montmorillonite, stir at 900r / min for 2min, and then pass nitrogen for 60min to remove oxygen, and the nitrogen flow rate is 15cm 3 / min, then add potassium persulfate an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com