Preparation method of zinc oxide nanotube array

A technology of zinc oxide nanotubes and arrays, applied in the field of preparation of nanotube arrays, to achieve the effects of convenient and simple product processing, convenient post-processing, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

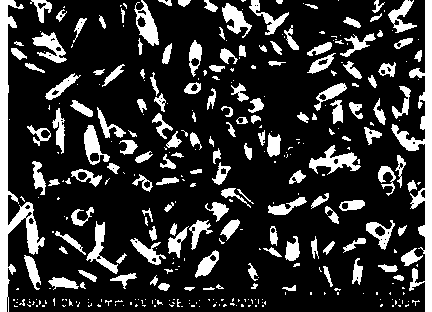

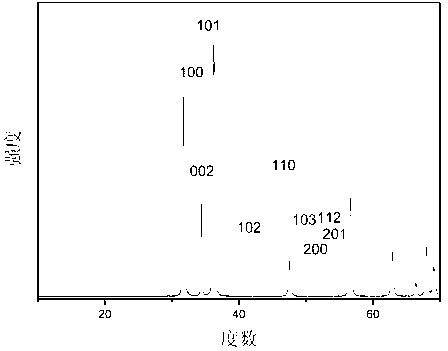

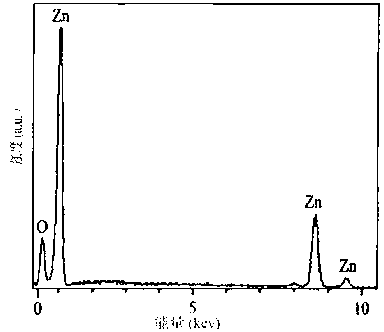

Image

Examples

Embodiment 1

[0026] The present invention adopts the low temperature solution method to prepare the zinc oxide nanotube array, and the method comprises the following steps:

[0027] (1) Base material: Put the cut base material into acetone and ethanol for 15 minutes respectively, and then blow dry with nitrogen after taking it out; put the cleaned base material in an atmosphere of ultraviolet light and ozone for 15 minutes to remove surface organic matter;

[0028] (2) Configuration of the reaction solution: respectively configure a zinc salt solution with a concentration of 0.01mol / L and a urotropine solution with a concentration of 0.01mol / L, and mix the solutions in a volume ratio of 2:1;

[0029] (3) Put the treated base material into the solution of (2) and seal it well;

[0030] (4) Put the sealed bottle containing the reaction solution and the base material into an oven, react at 85°C for a period of 15 hours, take out the sample, cool it to room temperature naturally, rinse with d...

Embodiment 2

[0033] (1) Base material: Put the cut base material into acetone and ethanol for 15 minutes respectively, and then blow dry with nitrogen after taking it out; put the cleaned base material in an atmosphere of ultraviolet light and ozone for 15 minutes to remove surface organic matter;

[0034] (2) Configuration of the reaction solution: respectively configure a zinc salt solution with a concentration of 0.02mol / L and a urotropine solution with a concentration of 0.02mol / L, and mix the solutions in a volume ratio of 2:1;

[0035] (3) Put the treated base material into the solution of (2) and seal it well;

[0036] (4) Put the sealed bottle containing the reaction solution and the base material into an oven, react at 95°C for a period of 10 hours, take out the sample, cool it to room temperature naturally, rinse with deionized water, and dry it.

Embodiment 3

[0038] The present invention adopts the low temperature solution method to prepare the zinc oxide nanotube array, and the method comprises the following steps:

[0039] (1) Base material: Put the cut base material into acetone and ethanol for 15 minutes, respectively, and blow dry with nitrogen after taking it out; put the cleaned base material in an atmosphere of ultraviolet light and ozone for 15 minutes, remove the surface organic matter;

[0040] (2) Configuration of reaction solution: respectively configure zinc salt solution with a concentration of 0.02mol / L and ammonia water with a concentration of 0.02mol / L, and mix the solutions in a volume ratio of 1:1;

[0041] (3) Put the treated base material into the solution of (2) and seal it well;

[0042] (4) Put the sealed bottle containing the reaction solution and the base material into an oven, react at 95°C for a period of 15 hours, take out the sample, cool it to room temperature naturally, rinse with deionized water, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com