Preparation and application of heteroatom nitrogen surface modified MoS2 nano-material

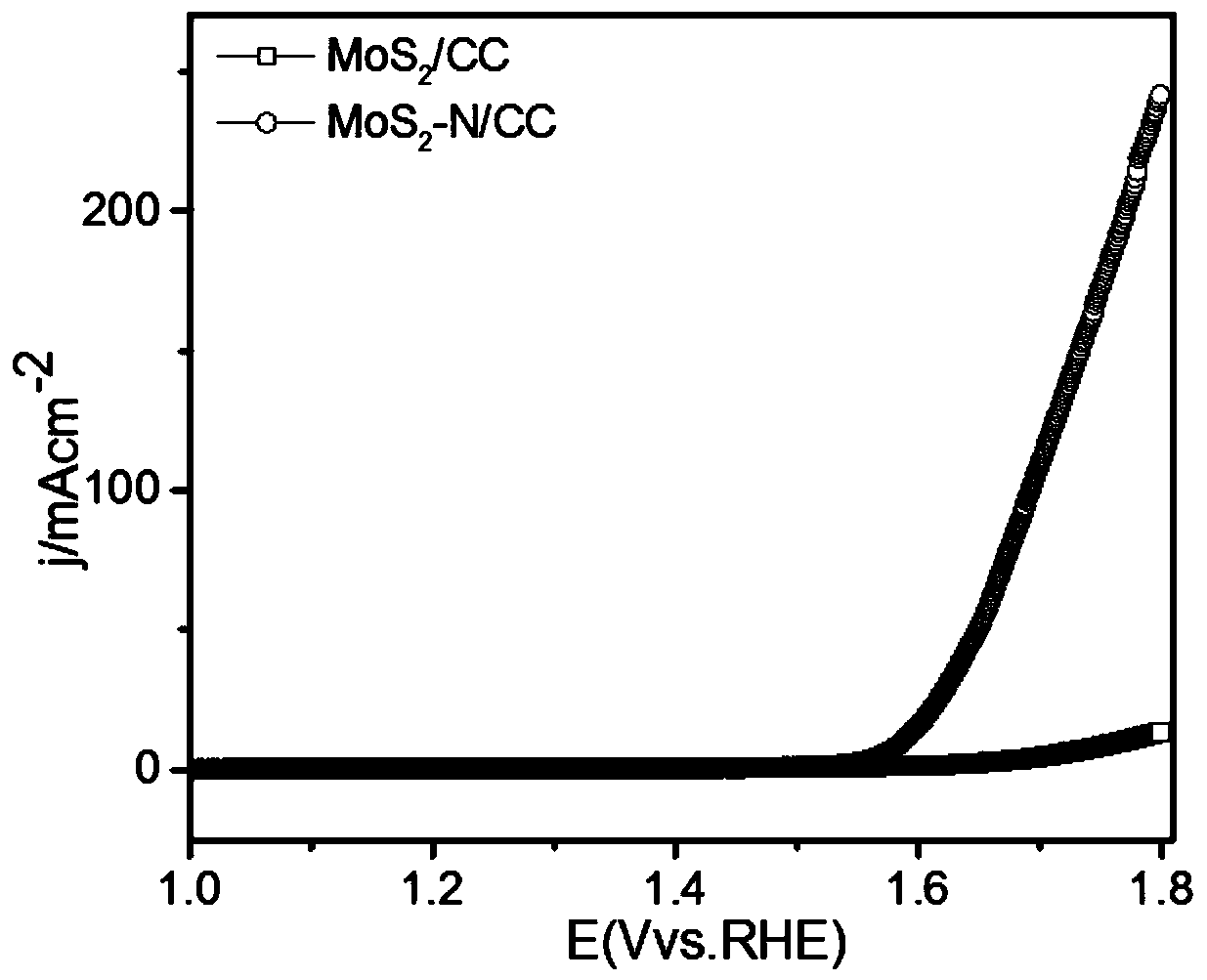

A nano-material and surface modification technology, applied in chemical/physical processes, physical/chemical process catalysts, structural parts, etc., can solve the problems of low oxygen evolution activity and complex catalyst preparation methods, and achieve simple reaction process and suitable for Large-scale production, the effect of improving the catalytic performance of oxygen evolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Step 1: Sonicate carbon cloth (3*3cm) in acetone, ethanol, and water for 10 minutes, and set aside;

[0024] Second step: mix ammonium molybdate and thiourea in water in proportion, wherein the molar ratio of ammonium molybdate and thiourea is 1:5, and the volume of water is 35mL and stirred until fully dissolved to obtain a uniform solution;

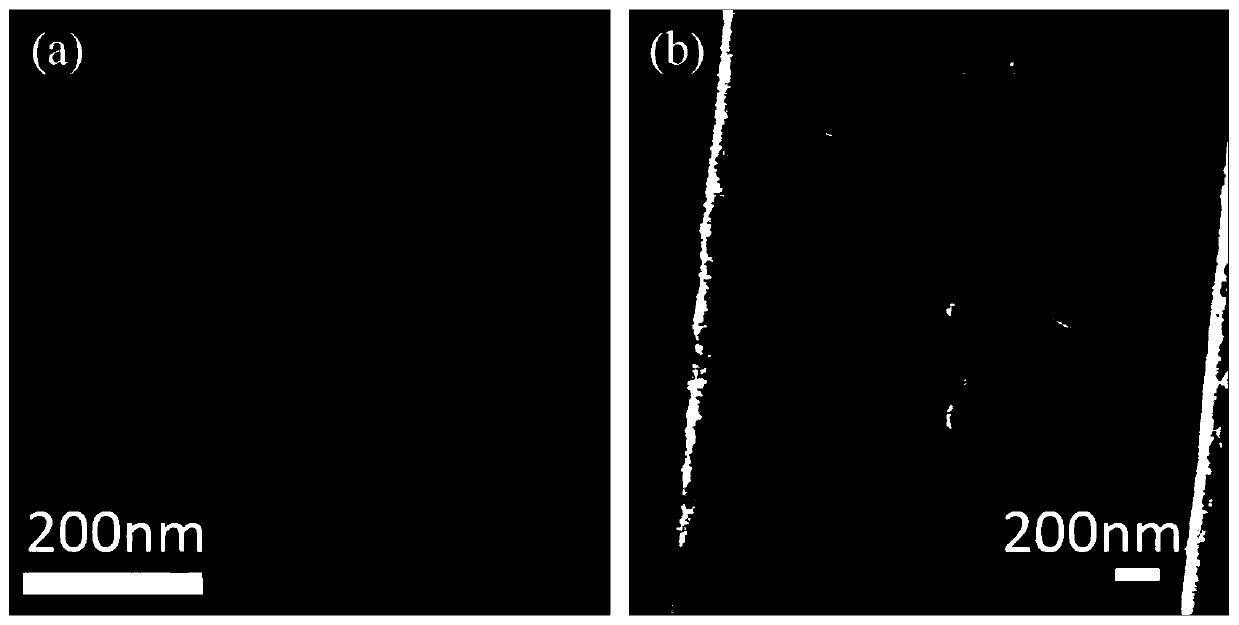

[0025] Step 3: Transfer the uniformly stirred solution to a reaction kettle with a stainless steel substrate and put it into an ultrasonically passed carbon cloth, and place the reaction kettle in a blast drying oven at 180°C for 12 hours; after cooling down to room temperature, put The carbon cloth was taken out and rinsed with ethanol and water in turn, and dried to obtain MoS 2 nanosheet catalysts.

Embodiment 2

[0027] Step 1: Sonicate carbon cloth (3*3cm) in acetone, ethanol, and water for 10 minutes, and set aside;

[0028] Second step: mix ammonium molybdate and thiourea in water in proportion, wherein the molar ratio of ammonium molybdate and thiourea is 1:5, and the volume of water is 35mL and stirred until fully dissolved to obtain a uniform solution;

[0029] Step 3: Transfer the uniformly stirred solution to a reaction kettle with a stainless steel substrate and put it into an ultrasonically passed carbon cloth, and place the reaction kettle in a blast drying oven at 180°C for 12 hours; after cooling down to room temperature, put The carbon cloth was taken out and rinsed with ethanol and water in turn, and dried to obtain MoS 2 nanosheet catalysts.

[0030] The fourth step: 10mL of ammonia water is placed in the reaction kettle, and the MoS 2 The nanosheets are placed above the ammonia water without contact with the ammonia water, and the reaction kettle is placed in a blast...

Embodiment 3

[0032] Step 1: Sonicate carbon cloth (3*3cm) in acetone, ethanol, and water for 10 minutes, and set aside;

[0033] Second step: mix ammonium molybdate and thiourea in water in proportion, wherein the molar ratio of ammonium molybdate and thiourea is 1:5, and the volume of water is 35mL and stirred until fully dissolved to obtain a uniform solution;

[0034] Step 3: Transfer the uniformly stirred solution to a reaction kettle with a stainless steel substrate and put it into an ultrasonically passed carbon cloth, and place the reaction kettle in a blast drying oven at 180°C for 12 hours; after cooling down to room temperature, put The carbon cloth was taken out and rinsed with ethanol and water in turn, and dried to obtain MoS 2 nanosheet catalysts.

[0035] The fourth step: 5mL of ammonia water is placed in the reaction kettle, and the MoS 2 The nanosheets are placed above the ammonia water and not in contact with the ammonia water. The reaction kettle is placed in a blast d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com