Preparation method of perovskite single crystals

A technology of perovskite and perovskite precursors, which is applied in the directions of single crystal growth, single crystal growth, chemical instruments and methods, etc., can solve the problems of component control that cannot be single crystal, and achieve low cost and no danger of raw materials. The effect of convenience and convenience of raw material supply

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] CsPb with an average side length of 120µm 2 Br 5 Fabrication of Perovskite Single Wafers

[0024] 1) The silica substrate was ultrasonically cleaned with acetone, 70% ethanol and deionized water for 20 minutes respectively; then placed in an oven at 60°C for overnight drying;

[0025] 2) In 5mL hydrobromic acid, the concentration of CsBr is 0.06mol / L, PbBr 2 The concentration is 0.12mol / L, and the precursor solution of perovskite is configured;

[0026] 3) Heat the perovskite precursor solution to 90 °C, and drop 10 μL on the silica substrate. Then put it in the air and dry it to get CsPb with an average side length of 120µm 2 Br 5 Perovskite single crystal.

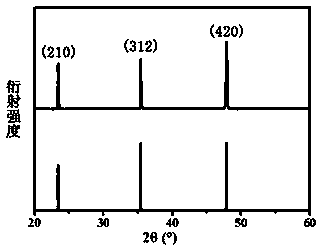

[0027] figure 1 CsPb in this example 2 Br 5 Micrograph of a perovskite single wafer. Such as figure 1 Shown, CsPb 2 Br 5 The perovskite single crystals are uniform in size with an average side length of 120 µm. Such as figure 2 Shown is the XRD pattern of a CsPb2Br5 perovskite single wafer, and the...

Embodiment 2

[0029] CsPbBr with an average length of 150 µm 3 Preparation of Perovskite Single Crystal Rods

[0030] 1) The silica substrate was ultrasonically cleaned with acetone, 75% ethanol and deionized water for 25 minutes respectively; then placed in an oven at 70°C for overnight drying;

[0031] 2) In 5mL dimethyl sulfoxide, the concentration of CsBr is 0.06mol / L, PbBr 2 Concentration is 0.12mol / L, obtains the precursor solution of perovskite;

[0032] 3) Heat the perovskite precursor solution to 90 °C, and drop 10 μL on the silica substrate. After drying in the atmosphere, a CsPbBr with a length of 150 µm was obtained. 3 Perovskite single crystal rods.

[0033] image 3 CsPbBr in this example 3 A micrograph of a perovskite single crystal rod, as figure 2 Shown, CsPbBr 3 The perovskite single crystal rods are uniform in size with an average length of 150 µm.

Embodiment 3

[0035] CsPbBr with a size of 95 µm 3 Fabrication of Perovskite Single Wafers

[0036] 1) The silica substrate was ultrasonically cleaned with acetone, 75% ethanol and deionized water for 25 minutes respectively; then dried with nitrogen and placed in an oven at 65°C overnight for later use;

[0037] 2) In 5mL dimethyl sulfoxide, the concentration of CsBr is 0.06mol / L, PbBr 2 Concentration is 0.12mol / L, obtains the precursor solution of perovskite;

[0038] 3) Heat the perovskite precursor solution to 90 °C, and drop 10 μL on the silica substrate. Then heat and dry at 50°C to obtain CsPbBr with a side length of 95µm 3 Perovskite single crystal.

[0039] Figure 4 CsPbBr in this example 3 Micrograph of a perovskite single wafer. Such as Figure 4 Shown, CsPbBr 3 The perovskite single crystal is uniform in size, with a size of 95 µm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com