Method and apparatus for producing biological butanol

A production method and technology of bio-butanol, which are applied in the separation/purification, fermentation, organic chemistry and other directions of hydroxyl compounds, can solve the problems of high energy consumption and material consumption, large process water consumption and sewage discharge, and reduce steam consumption, The effect of improving market competitiveness and reducing consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

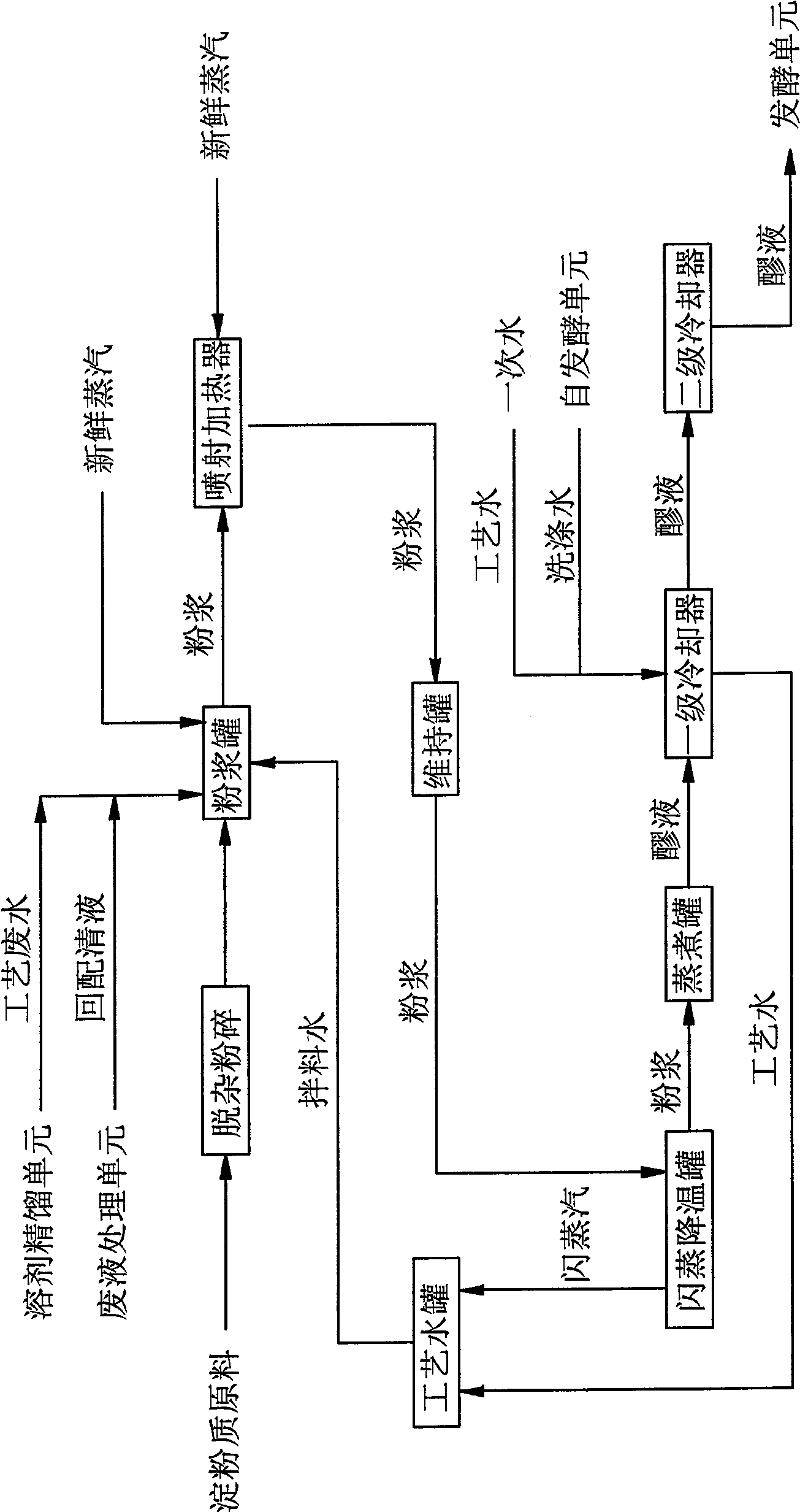

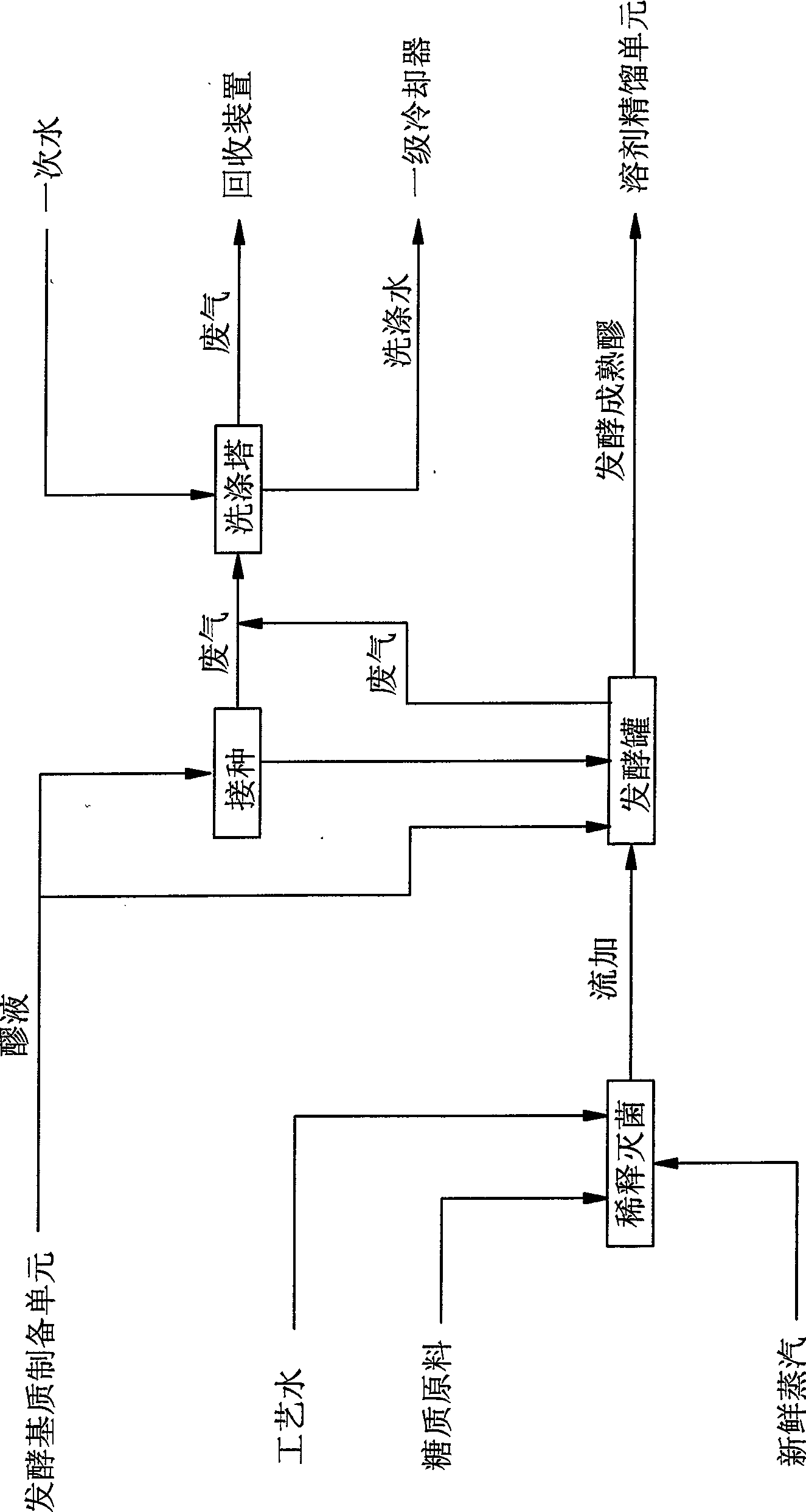

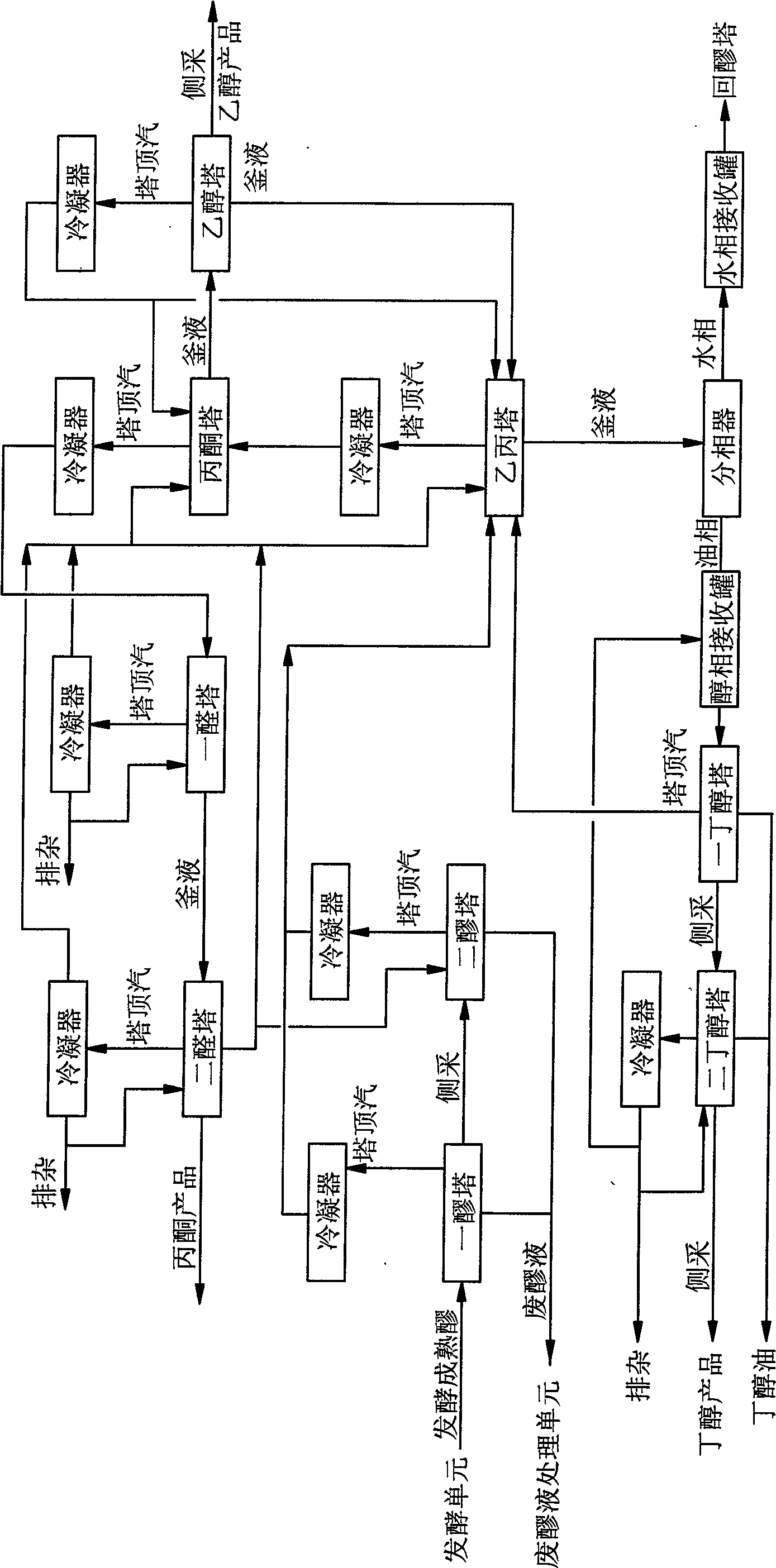

[0049] Using starchy raw materials such as corn, wheat, sorghum, rice, sweet potato, cassava, etc. as raw materials, or sugary raw materials such as sugar cane, molasses, Jerusalem artichoke, etc., using figure 1 , figure 2 , image 3 and Figure 4 The production method shown carries out the production of butanol solvent. In this embodiment, corn is used as raw material to produce acetone and butanol, and the process of producing acetone butanol with other raw materials is roughly the same.

[0050] The corn raw material with a starch content of 64% is continuously cleaned and removed and then pulverized. The pulverized raw material is made into a slurry by adding mixing water in a slurry tank, and the concentration of the slurry is controlled to be 8%. The temperature is about 90°C, and the mixing water is exhaust gas washing water, fresh water, evaporative condensation water, wastewater from the rectification unit and part of the clear liquid from the waste liquid treat...

Embodiment 2

[0059] Using starchy raw materials such as corn, wheat, sorghum, rice, sweet potato, cassava, etc. as raw materials, or sugary raw materials such as sugar cane, molasses, Jerusalem artichoke, etc., using figure 1 , figure 2 , image 3 and Figure 4 The production method shown carries out the production of butanol solvent. In this embodiment, corn is used as raw material to produce acetone and butanol, and the process of producing acetone butanol with other raw materials is roughly the same.

[0060] The implementation process of the fermentation substrate preparation unit, fermentation unit and waste mash treatment unit is the same as that of Example 1.

[0061]The mature mash feed from the fermentation unit is sent to the first beer tower, and the side mining of the first beer tower enters the second beer tower, and the steam at the top of the second beer tower is used as the heating medium for the reboiler of the first beer tower to realize the differential pressure heat...

Embodiment 3

[0065] Using starchy raw materials such as corn, wheat, sorghum, rice, sweet potato, cassava, etc. as raw materials, or sugary raw materials such as sugar cane, molasses, Jerusalem artichoke, etc., using figure 1 , figure 2 , image 3 and Figure 4 The production method shown carries out the production of butanol solvent. In this embodiment, corn is used as raw material to produce acetone and butanol, and the process of producing acetone butanol with other raw materials is roughly the same.

[0066] The implementation process of the fermentation substrate preparation unit, fermentation unit and waste mash treatment unit is the same as that of Example 1.

[0067] The rectification unit is basically the same as in Example 2, and the differences are as follows: the phase separator water layer is sent to a beer tower to reclaim butanol through the water phase receiving tank; the reflux part of the dibutanol tower overhead material part returns to the alcohol phase receiving ta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com