Method for extracting cellulose in one step

A cellulose and reaction technology, used in fiber raw material processing, textiles and papermaking, etc., can solve the problems of high cost of ionic liquids, complex reaction conditions, poor environment, etc., and achieve the effects of low price, abundant sources and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

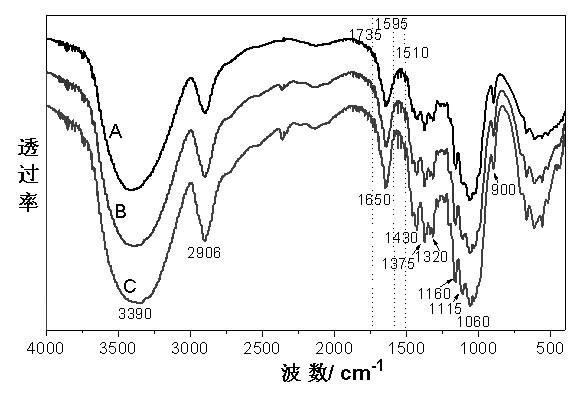

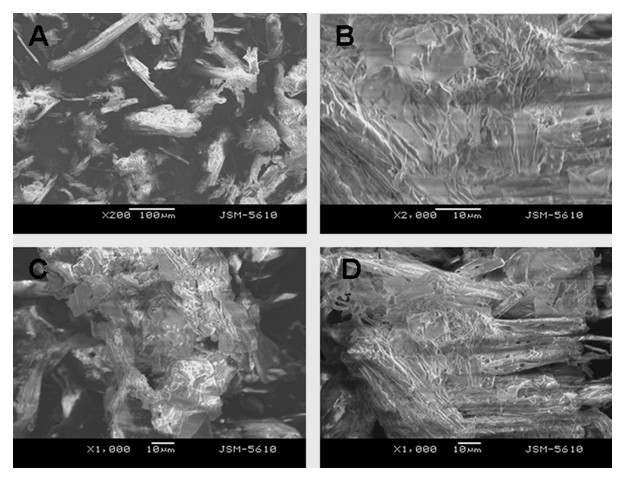

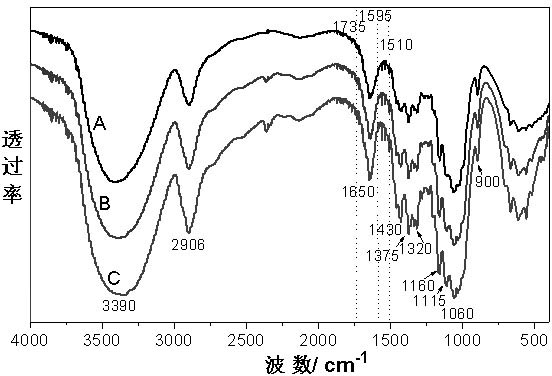

Image

Examples

Embodiment 1

[0020] (1) First dry the corn stalks in the sun, then crush them mechanically, and collect the straw powder through a sieve (200 mesh) to obtain a light yellow solid powder.

[0021] (2) Add 2.0 g of crushed straw powder to the bottom of a 100 mL hydrothermal reactor, measure 40 mL of a mixed solution of ethanol and water with a volume ratio of 1:1, add it to the hydrothermal reactor, and stir to make the straw The rod powder is dispersed in the solution. Then add 4.4 g of sodium hydroxide solid into the hydrothermal reaction kettle, dissolve and then add 9 mL of 30% H 2 o 2 solution. Finally, in the reaction solution in the hydrothermal reactor, the concentration of sodium hydroxide is about 8 wt%, and the H 2 o 2 The concentration is about 5 wt%. Then seal the hydrothermal reactor, the control reaction pressure is 5 MPa, at 150 o C for 10 min. After the reaction was completed and the hydrothermal reactor was cooled, the product was poured out. The product was filtere...

Embodiment 2

[0024] (1) First dry the corn stalks in the sun, then crush them mechanically, and collect the straw powder through a sieve (200 mesh) to obtain a light yellow solid powder.

[0025] (2) Add 2.0 g of crushed straw powder to the bottom of a 100 mL hydrothermal reactor, measure 40 mL of a mixed solution of methanol and water with a volume ratio of 1:1, add it to the hydrothermal reactor, and stir to make the straw The rod powder is dispersed in the solution. Then add 0.5 g of potassium hydroxide solid to the hydrothermal reaction kettle, and then add 2.3 g of sodium chlorite after dissolving. Finally, in the reaction solution of the hydrothermal reactor, the concentration of potassium hydroxide was 1.1 wt%, and the concentration of sodium chlorite was about 5.0 wt%. Then seal the hydrothermal reactor, the control reaction pressure is 3 MPa, at 100 o C for 20 min. After the reaction was completed and the hydrothermal reactor was cooled, the product was poured out. The product...

Embodiment 3

[0028] (1) First dry the corn stalks in the sun, then crush them mechanically, and collect the straw powder through a sieve (200 mesh) to obtain a light yellow solid powder.

[0029] (2) Take 5.0 g of crushed straw powder and add it to the bottom of a 100 mL hydrothermal reactor, measure 60 mL of a mixture of acetone and methanol with a volume ratio of 1:1, add it to the hydrothermal reactor, and stir to make the straw The rod powder is dispersed in the solution. Then add 3.0 g of potassium hydroxide solid into the hydrothermal reaction kettle, dissolve and then add 2.5 mL of 30% H 2 o 2 . Finally, in the reaction solution of the hydrothermal reactor, the concentration of potassium hydroxide was 4.2 wt%, and the H 2 o 2The concentration is about 1.0 wt%. Then seal the hydrothermal reactor. Control the reaction pressure of the hydrothermal reactor to be 1 MPa, at 80 o C for 40 min. After the reaction was completed and the hydrothermal reactor was cooled, the product was...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com