Method for extracting tetrandrine

A technology of tetrandrine and extraction method, applied in the direction of organic chemistry, etc., can solve problems such as unenvironmental protection, and achieve the effect of saving consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

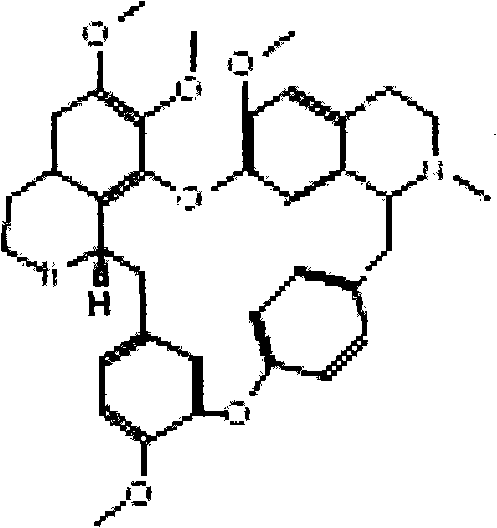

Image

Examples

Embodiment 1

[0033] Take 100g of fresh tetrandrine and crush it to 40 mesh, put it in an extraction tank, add 2g of quicklime, add 1L of 70% ethanol to soak and reflux for extraction for 2 hours, and the obtained extract is concentrated under reduced pressure to obtain an extract. Add 800ml of 1% hydrochloric acid, filter and apply to D72 macroporous cation exchange resin column for saturated adsorption, rinse out the acid solution with 0.5BV deionized water and save it for the next column, stop when it becomes neutral, and then use 0.5mol / L ammonia water The ethanol solution was used at 30 ml / min until no alkaloid reaction was detected by HPLC in the effluent eluate, and a total of 1 L of eluate was obtained. Concentrate the eluent under reduced pressure to 200ml, add 800ml of toluene for extraction, and recover the solvent from the toluene phase to obtain 1.6g of extract, which is dissolved in 16ml of acetone, heated and concentrated to 1.2ml, and the precipitated crystals are dissolved i...

Embodiment 2

[0035] Take 100g of fresh tetrandrine and crush it to 40 mesh, put it in an extraction tank, add 3g of quicklime, add 1.5L of 80% ethanol to soak and reflux for 2.5 hours, and the obtained extract is concentrated under reduced pressure to obtain an extract. Add 500ml of 2% hydrochloric acid, filter and apply to D72 macroporous cation exchange resin column for saturated adsorption, rinse out the acid solution with 0.5BV deionized water and save it for the next column, stop when it becomes neutral, and then use 0.5mol / L ammonia water The ethanol solution was used at 30ml / min until the eluate was detected by HPLC to have no alkaloid reaction, and a total of 900ml eluate was obtained. Concentrate the eluent under reduced pressure to 150ml, add 600ml of toluene for extraction, and recover the solvent from the toluene phase to obtain 1.7g of extract, which is dissolved in 30ml of acetone, heated and concentrated to 3ml, and the precipitated crystals are dissolved in 40ml of 90% ethan...

Embodiment 3

[0037] Take 100g of fresh tetrandrine and crush it to 60 mesh, put it in an extraction tank, add 5g of quicklime, add 2L of 90% ethanol to soak and reflux for extraction for 3 hours, and the obtained extract is concentrated under reduced pressure to obtain an extract. Add 600ml of 1% hydrochloric acid, filter and apply to D72 macroporous cation exchange resin column for saturated adsorption, rinse out the acid solution with 0.5BV deionized water and save it for the next column, stop when it becomes neutral, and then use 0.5mol / L ammonia water The ethanol solution was used at 30ml / min until the eluate was detected by HPLC to have no alkaloid reaction, and a total of 900ml eluate was obtained. Concentrate the eluent under reduced pressure to 120ml, add 600ml of toluene for extraction, recover the solvent from the toluene phase, and obtain 1.5g of extract, dissolve the extract in 30ml of acetone, heat and concentrate to 2ml, dissolve the precipitated crystals in 30ml of 95% ethano...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com