Antibacterial watercolor and preparation method thereof

A technology of watercolor pigments and sodium benzoate, which is applied in the field of chemical pigments, can solve the problems of easy breeding of mold and other problems, and achieve the effect of simple addition method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

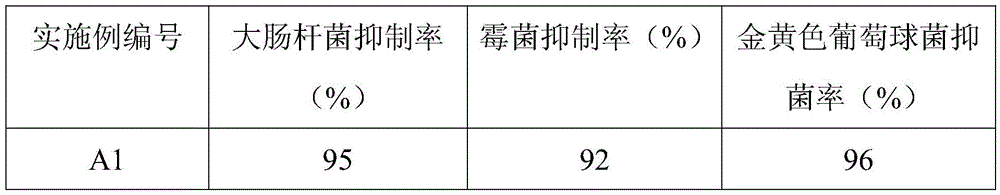

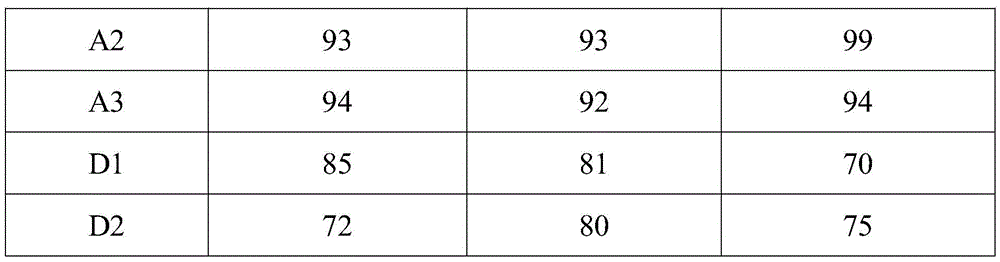

Examples

Embodiment 1

[0023] Mix 100g of rare earth, 70g of cycloethanol, 10g of 8-carboxyquinoline and 50g of cyclohexane, and stir thoroughly for 15 minutes, then add 2g of sodium m-carboxybenzoate to obtain microemulsion M; suction filter microemulsion M, and add 15g of Tetra-n-butyl titanate, centrifuged after fully stirring, centrifuged for 3 times, washed alternately with acetone-ethanol mixture (the content of acetone is 20%, the content of ethanol is 80%) and deionized water, at 120 ℃ After baking for 20 minutes, it was ground into powder to obtain antibacterial powder N; 300g epoxy resin, 150g sodium benzoate, 20g aluminum silicate, 105g calcium carbonate, and 20g titanium white powder were mixed and heated in a water bath, and then the obtained antibacterial powder was added. Bacteria powder N was subjected to ultrasonic dispersion for 10 minutes at an ultrasonic frequency of 20KHz to obtain the antibacterial watercolor pigment A1.

Embodiment 2

[0025] Mix 100g of rare earth, 95g of cycloethanol, 25g of 8-carboxyquinoline and 75g of cyclohexane, stir thoroughly for 25min, then add 10g of sodium m-carboxybenzoate to obtain microemulsion M; suction filter microemulsion M, and add 35g of Tetra-n-butyl titanate, centrifuged after fully stirring, and washed alternately with acetone-ethanol mixture (the content of acetone is 45%, the content of ethanol is 55%) and deionized water after centrifugation for 5 times, at 200 ° C After baking for 30 minutes, grind it into powder to obtain antibacterial powder N; mix 400g epoxy resin, 200g sodium benzoate, 30g aluminum silicate, 120g talcum powder, and 45g carbon black powder, heat in a water bath, and then add the prepared antibacterial powder. Bacteria powder N was subjected to ultrasonic dispersion for 20 minutes at an ultrasonic frequency of 25KHz to obtain the antibacterial watercolor pigment A2.

Embodiment 3

[0027] Mix 100g of rare earth, 80g of cycloethanol, 15g of 8-carboxyquinoline and 60g of cyclohexane, and stir thoroughly for 17 minutes, then add 6g of sodium m-carboxybenzoate to obtain microemulsion M; perform suction filtration on microemulsion M, and add 20g of Tetra-n-butyl titanate, centrifuged after fully stirring, and washed alternately with acetone-ethanol mixture (the content of acetone is 30%, and the content of ethanol is 70%) and deionized water after centrifugation for 4 times, at 160 ° C After drying for 25 minutes, grind it into powder to obtain antibacterial powder N; mix 350g of epoxy resin, 170g of sodium benzoate, 25g of aluminum silicate, 110g of kaolin, and 30g of light-resistant yellow powder, heat it in a water bath, and then add the prepared antibacterial powder. Bacteria powder N was subjected to ultrasonic dispersion for 15 minutes at an ultrasonic frequency of 22KHz to obtain the antibacterial watercolor pigment A3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com