Preparation method of iron oxide/cuprous oxide photoelectric film

A photoelectric thin film, cuprous oxide technology, applied in catalyst activation/preparation, metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, etc., can solve the problems of lack of bifunctional catalysts, scarcity of precious metals, and high cost , to achieve the effect of good photoelectric catalysis, good stability of active material and high repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

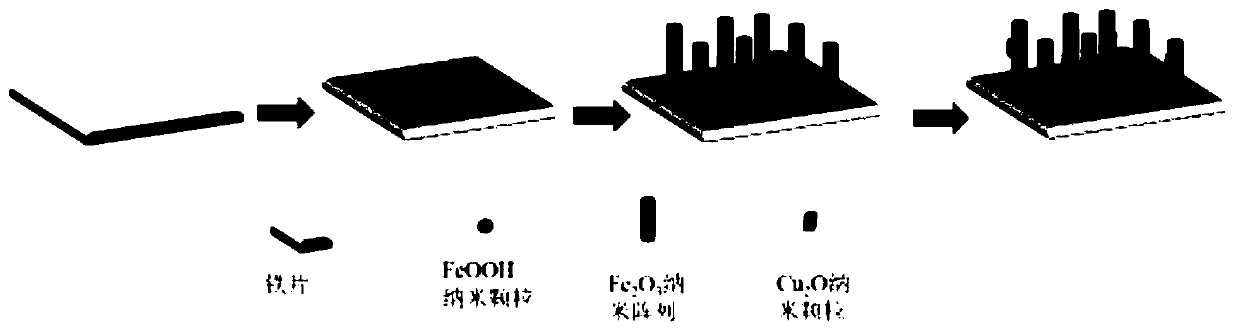

[0031] A kind of preparation method of iron oxide / cuprous oxide photoelectric thin film (flow process sees figure 2 ):

[0032] (1) Sonicate the iron sheet in acetone, ethanol, and deionized water for 30 minutes in sequence, dry it in the air, and perform electroetching in 0.1M ammonia water with a voltage of 8V and a time of 150s. Perform electro-etching pretreatment to obtain mesoporous active sites, ready for use;

[0033](2) Immerse the etched iron substrate in Fe 3+ Precursor solution, put it in a high-pressure reactor for hydrothermal film-forming reaction, after the reaction, take out the FTO conductive substrate for constant temperature calcination to obtain Fe 2 o 3 film;

[0034] Fe in this example 3+ The precursor solution is ferric chloride hexahydrate (FeCl 3 ·6H 2 O), the mixed solution of urea and water; The concentration of ferric chloride hexahydrate is 0.15M, and the concentration of urea is 0.25M;

[0035] In the present embodiment, adopt hydrotherm...

Embodiment 2

[0041] A kind of preparation method of iron oxide / cuprous oxide photoelectric thin film (flow process sees figure 2 ):

[0042] (1) Sonicate the iron sheet in acetone, ethanol, and deionized water for 30 minutes in sequence, dry it in the air, and perform electroetching in 0.1M ammonia water with a voltage of 8V and a time of 150s. Perform electro-etching pretreatment to obtain mesoporous active sites, ready for use;

[0043] (2) Immerse the etched iron substrate in Fe 3+ Precursor solution, put it in a high-pressure reactor for hydrothermal film-forming reaction, after the reaction, take out the FTO conductive substrate for constant temperature calcination to obtain Fe 2 o 3 film;

[0044] Fe in this example 3+ The precursor solution is ferric chloride hexahydrate (FeCl 3 ·6H 2 O), the mixed solution of urea and water; The concentration of ferric chloride hexahydrate is 0.15M, and the concentration of urea is 0.25M;

[0045] In the present embodiment, adopt hydrother...

Embodiment 3

[0051] A kind of preparation method of iron oxide / cuprous oxide photoelectric thin film (flow process sees figure 2 ):

[0052] (1) Sonicate the iron sheet in acetone, ethanol, and deionized water for 30 minutes in sequence, dry it in the air, and perform electroetching in 0.1M ammonia water with a voltage of 8V and a time of 150s. Perform electro-etching pretreatment to obtain mesoporous active sites, ready for use;

[0053] (2) Immerse the etched iron substrate in Fe 3+ Precursor solution, put it in a high-pressure reactor for hydrothermal film-forming reaction, after the reaction, take out the FTO conductive substrate for constant temperature calcination to obtain Fe 2 o 3 film;

[0054] Fe in this example 3+ The precursor solution is ferric chloride hexahydrate (FeCl 3 ·6H 2 O), the mixed solution of urea and water; The concentration of ferric chloride hexahydrate is 0.15M, and the concentration of urea is 0.25M;

[0055] In the present embodiment, adopt hydrother...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com