Poly-sulfur positive electrode material and lithium-sulfur secondary battery prepared from same

A lithium-sulfur secondary battery and cathode material technology, applied in lithium batteries, battery electrodes, non-aqueous electrolyte batteries, etc., can solve the problems of low reversible capacity and low Coulombic efficiency of batteries, achieve improved polysulfide dissolution shuttle, and simple process , the effect of convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

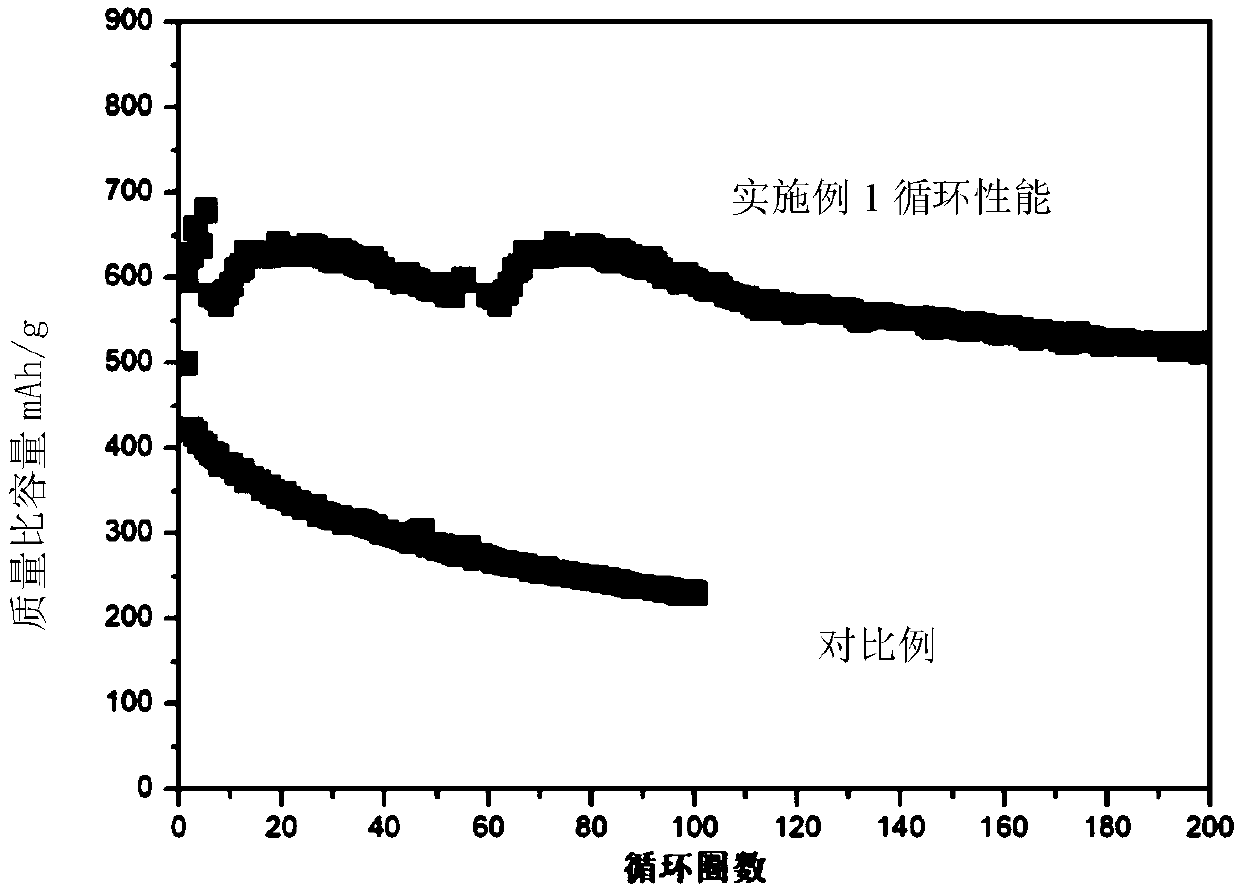

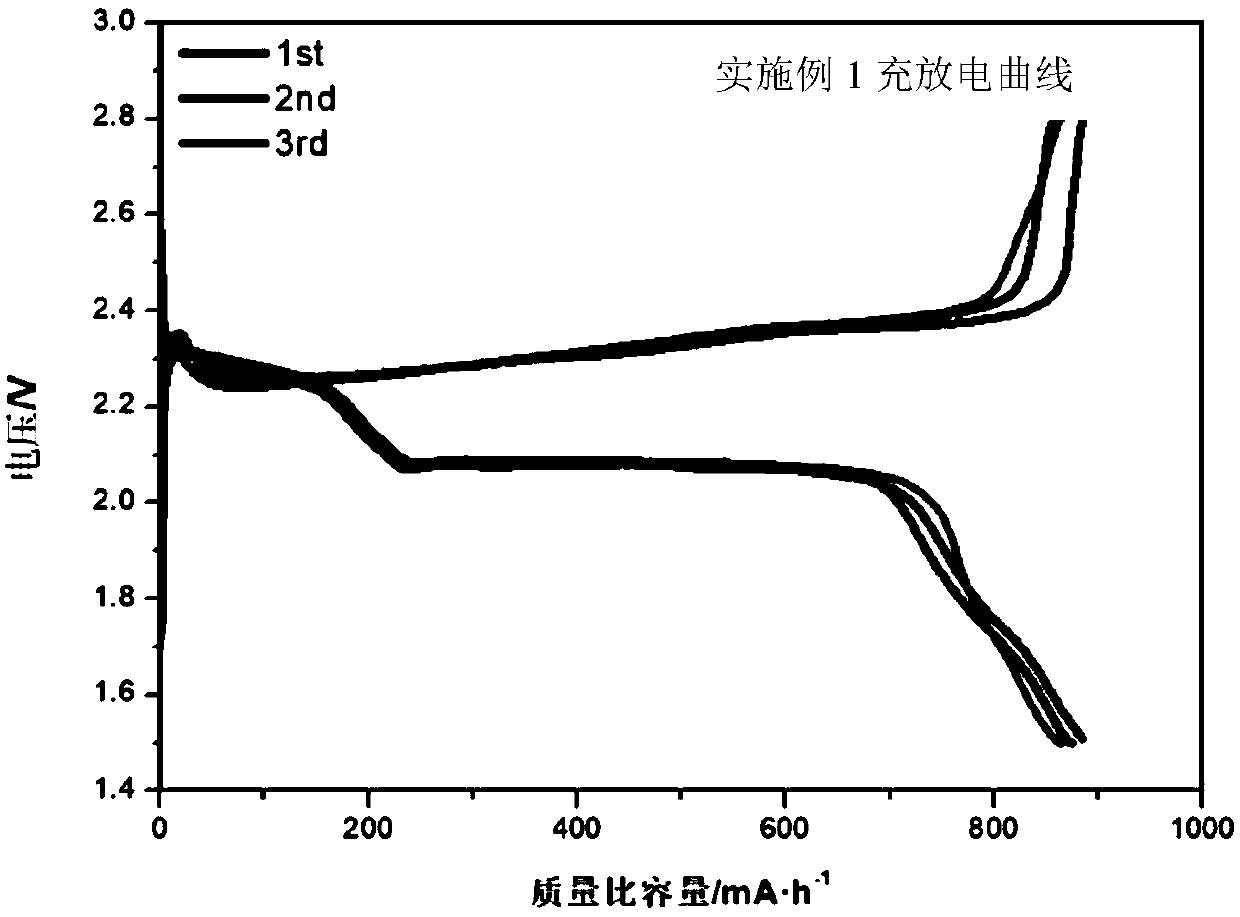

Embodiment 1

[0034] A polymeric sulfur cathode material based on the polymerization of thiuram and sulfur, which is prepared by the following steps:

[0035] Weigh 5g of sublimed sulfur powder (99.5%, see Figure 4 The powder on the far right) is put into a two-necked flask, plug the bottle mouth with a stopper, put a small magnet, and immerse the flask in an oil bath at about 130°C for heating. After the sulfur powder is completely melted, add 5g of dimethylthiuram tetrasulfide, then adjust the temperature to 175°C and keep it warm for 4 hours. During this period, keep magnetic stirring to make the reaction even.

[0036] After natural cooling, the obtained polysulfide was taken out, firstly ground for ten minutes with an agate mortar, then put into a ball mill for grinding at 300 r / min for 15 minutes, and finally vacuum-dried at 60°C for 4 hours.

[0037] The XRD diffraction pattern of the material is shown in Figure 7 , whose XRD peak is the same as that of elemental sulfur. Product...

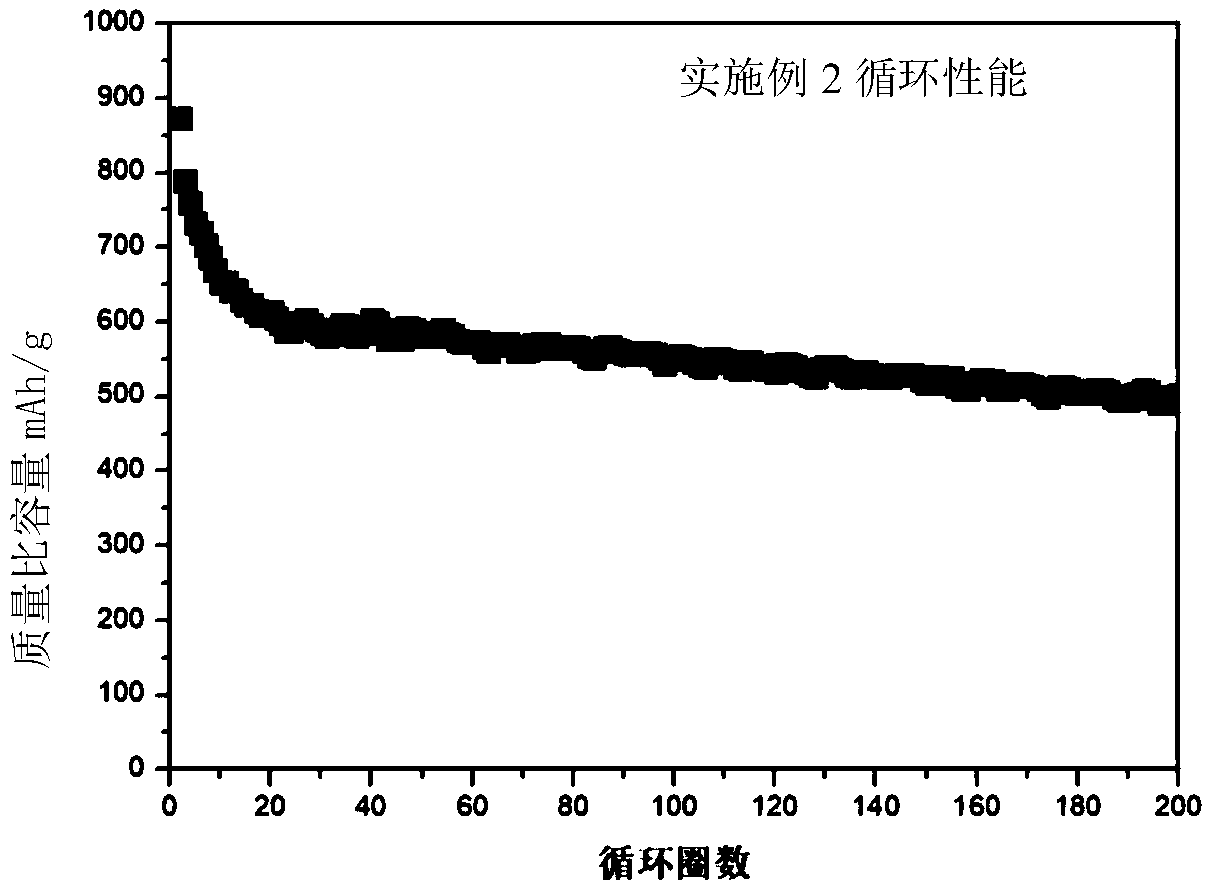

Embodiment 2

[0041] A polymeric sulfur cathode material based on the polymerization of thiuram and sulfur, the preparation method of which is basically the same as in Example 1, except that the conductive agent Super P in the lithium-sulfur battery is changed to reduced graphene (RGO).

[0042] The method for making a lithium-sulfur secondary battery with the obtained polymerized sulfur cathode material is as follows:

[0043] Take 24mg of the polysulfide positive electrode material prepared in Example 1, grind and mix with 3mg reduced graphene and 3mg polyvinylidene fluoride (PVDF) to make a homogeneous slurry, and then coat the homogeneous slurry on Aluminum foil, and then vacuum-dry at 60 degrees, and then take it out and assemble the battery under the protection of argon in the glove box. The negative electrode of the battery is a lithium sheet, the separator is a PE film, and the electrolyte is 1.0M LITFSI dissolved in a lithium-sulfur electrolyte with a volume ratio of DME:DOL=1:1 to...

Embodiment 3

[0045] A polymeric sulfur cathode material based on the polymerization of thiuram and sulfur, the preparation method of which is basically the same as in Example 1, except that the mass ratio of dimethylthiuram tetrasulfide and sulfur in Example 1 is changed to 2:1.

[0046] The resulting powder becomes darker after the polymerization is complete, see Figure 4 Powder on the far left. The electrochemical performance of the obtained polymeric sulfur electrode was characterized, and the initial capacity was only 270mAh g at a current density of 0.2C -1(Based on the total mass of the active material), this is due to the large particles of the material itself in the first cycle, and its poor conductivity. As the charge and discharge progress, ions can slowly enter the interior of the positive electrode material for activation, so the subsequent capacity increases to 540mAh g -1 , the capacity remains at 320mAh g after 200 cycles -1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com