Continuous carbon fiber composite material forming winding machine

A composite material and winding machine technology, applied in the field of fiber manufacturing, can solve the problems of complex structure and high cost of winding machines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

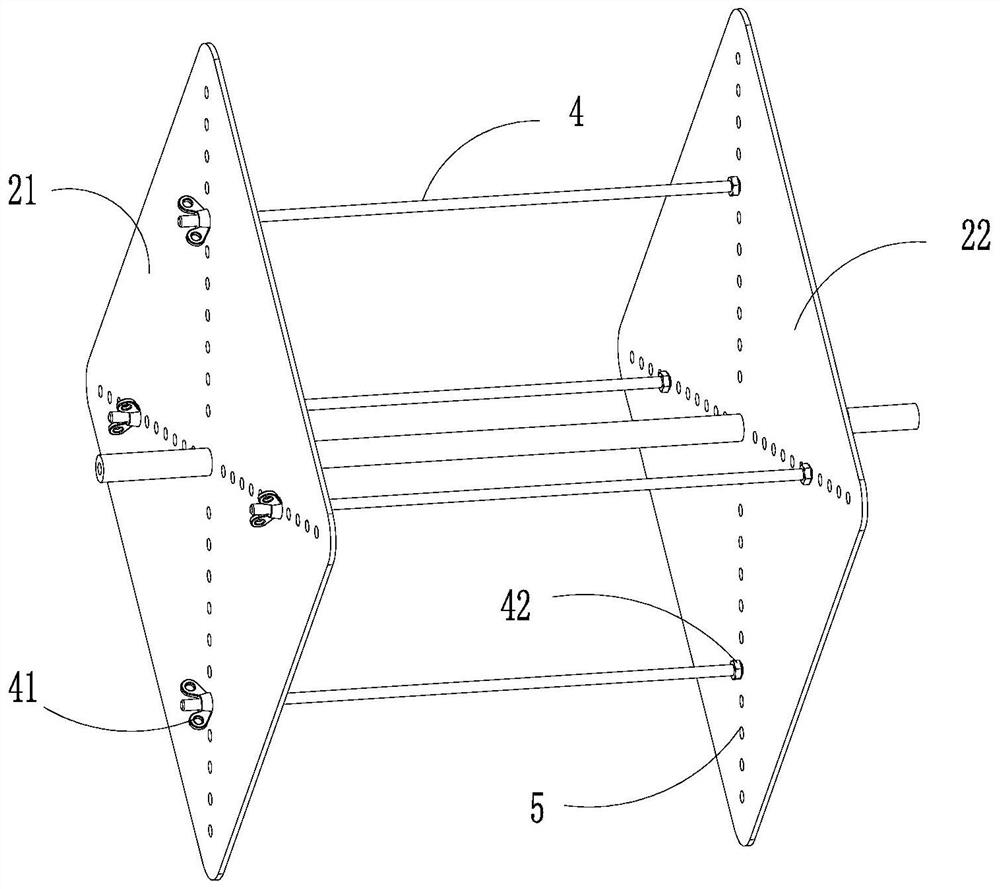

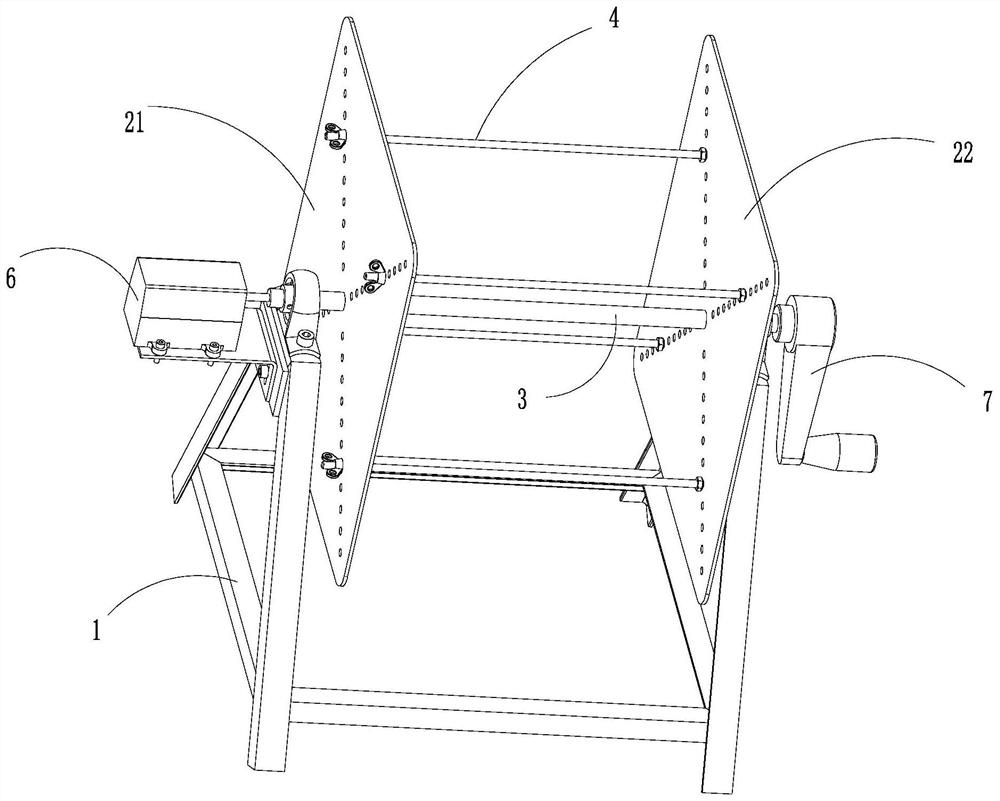

[0026] The present invention will be further described in conjunction with specific embodiment now. These drawings are simplified schematic diagrams only to illustrate the basic structure of the present invention in a schematic way, so they only show the components relevant to the present invention.

[0027] Such as figure 1 figure 2 Shown, a kind of continuous carbon fiber composite material forming winding machine is characterized in that, comprising

[0028] A bracket 1, the two ends of the bracket 1 are respectively provided with bearing seats;

[0029] The winding frame, the two ends of the winding frame are respectively connected to the bearing seat.

[0030] Specifically, in this embodiment, the winding frame includes a rotating shaft 3, a left side plate 21, a right side plate 22, and four connecting rods; the four connecting rods are arranged between the left side plate 21 and the right side plate 22;

[0031] The rotating shaft 3 forms a key connection with the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com