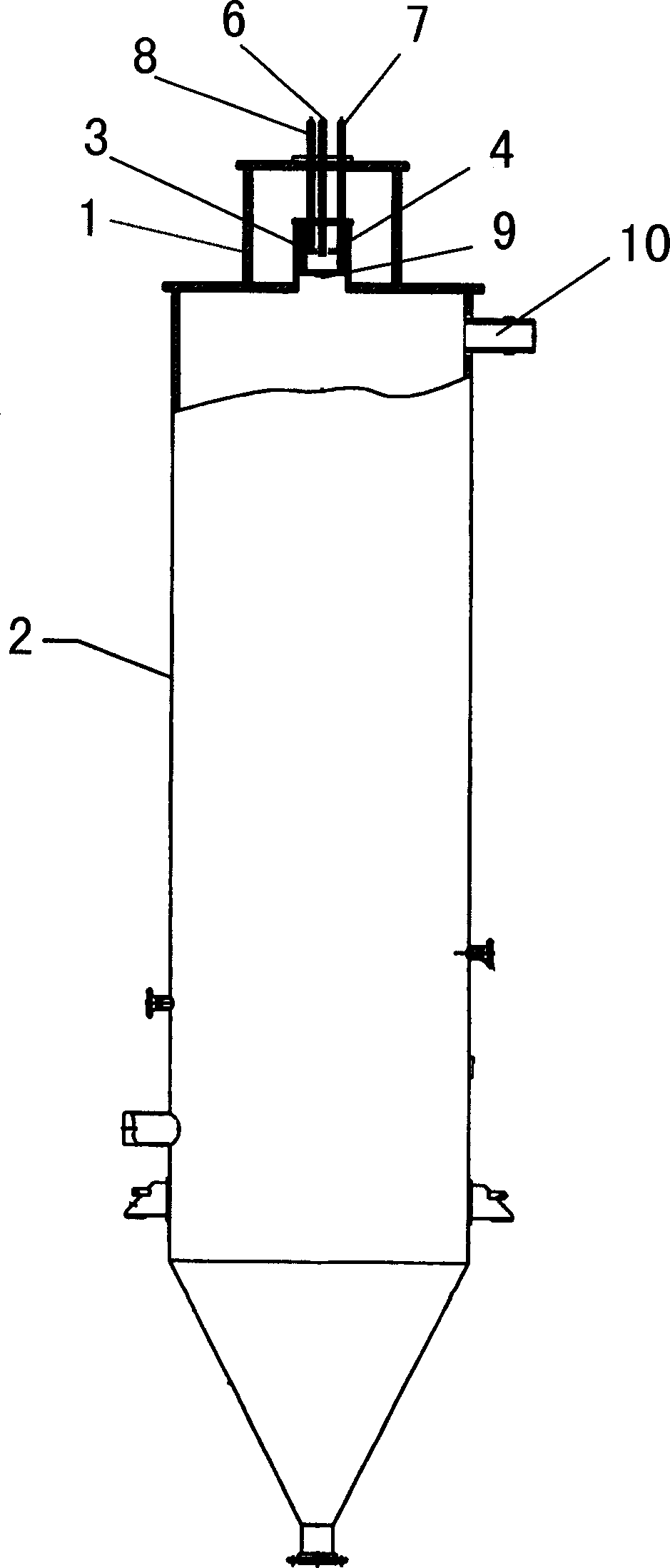

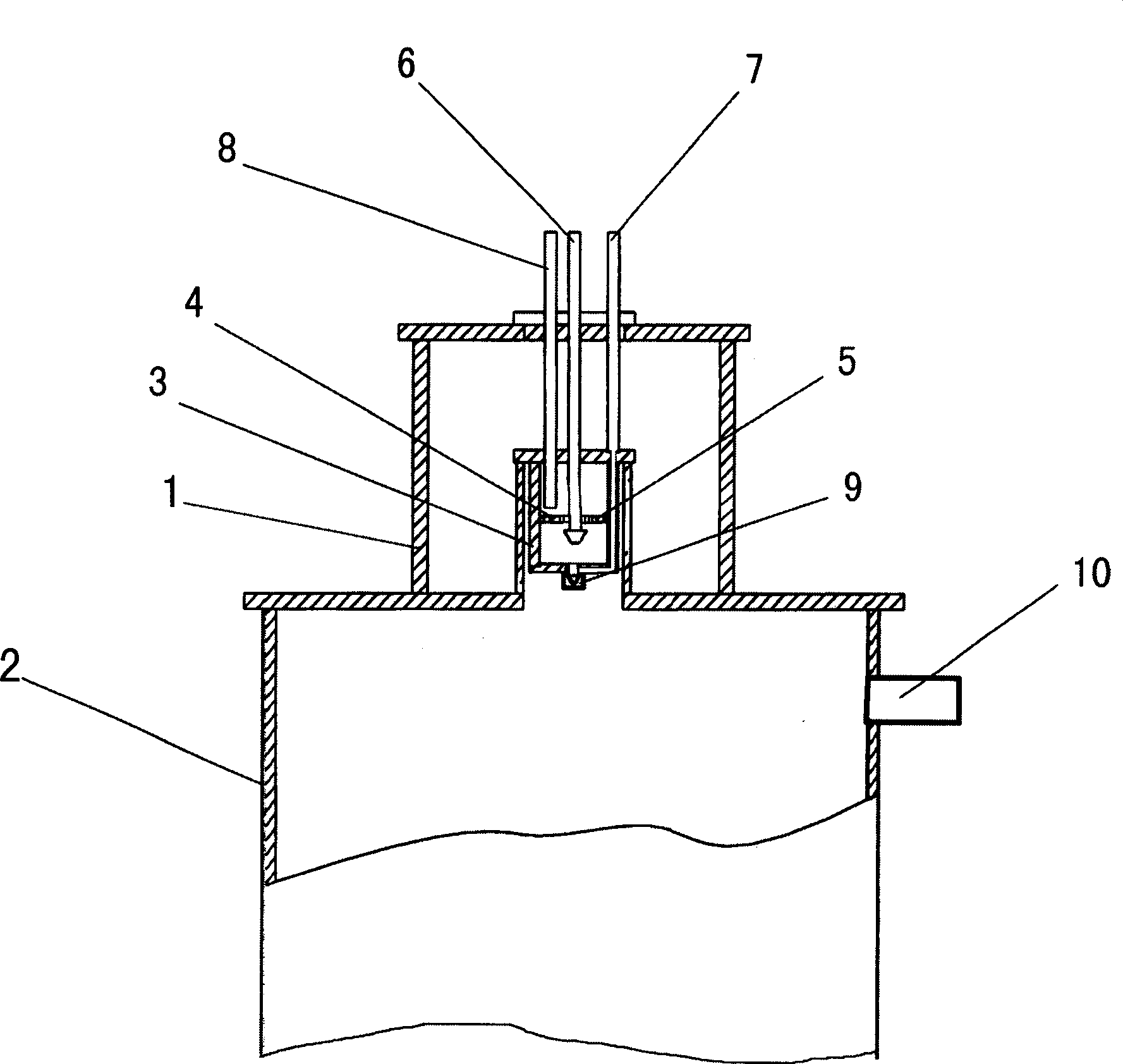

Method and equipment for preparing nano grade biological powder material

A nano-scale powder, nano-scale technology, applied in grain processing and other directions, can solve the problems of uneven particle size distribution, unsatisfactory product stability, low product purity, etc., achieving large specific surface area and high energy utilization rate. , the effect of improving solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific example 1

[0044] Preparation of nano-scale powder raw materials of Liuwei Dihuang (pills, tablets).

[0045] Ingredients: Yam, Poria, Cornus officinalis, Alisma, Rehmannia glutinosa, Atractylodes macrocephala

[0046] 1. Liquid preparation:

[0047] 1. Soaking:

[0048] Equipment used: heatable microwave multifunctional extraction tank

[0049] Put the medicinal materials in the extraction tank, add the prepared 70-75% solvent ethanol into the extraction tank, completely immerse the raw materials, supply heat, heat the temperature in the tank to 50----60°C, and the pressure in the tank must not exceed 0.02Mpa. Turn off the heat and let stand for 12-14 hours.

[0050] 2. Extraction:

[0051] Equipment used: heatable microwave multifunctional extraction tank

[0052] Stand still for a specified time, supply heat, heat the temperature in the tank to 50--60°C, turn on the circulation pump and microwave generator, and circulate and extract for 10 minutes under heat preservation, then clos...

specific example 2

[0069] Preparation of nanoscale powder of Ganoderma lucidum:

[0070] 1. Liquid preparation:

[0071] 1. Soaking:

[0072] Equipment used: heatable microwave multifunctional extraction tank

[0073] Add drinking water to the extraction tank, submerge the raw materials completely, supply heat, heat the temperature inside the tank to 50----60°C, the pressure inside the tank should not exceed 0.02Mpa, turn off the heat supply, and let it stand for 12-14 hours.

[0074] 2. Extraction:

[0075] Equipment used: heatable microwave multifunctional extraction tank

[0076] Stand still for a specified time, supply heat, heat the temperature in the tank to 50--60°C, turn on the circulation pump and microwave generator, and circulate and extract for 10 minutes under heat preservation, then close the steam valve and continue heat preservation and extraction for 50 minutes , the pressure in the tank shall not exceed 0.02Mpa, turn off the microwave generator and circulation pump, dischar...

specific example 3

[0092] Preparation of Nanoscale Pearl Powder

[0093] 1. Liquid preparation:

[0094] 1. Dissolving:

[0095] Equipment used: heatable microwave multifunctional extraction tank

[0096] Add the prepared aqueous solution with a pH value of 3 into the extraction tank, completely immerse the raw materials, turn on the microwave generator, make it move at a speed of 2-3 billion times / second, and shake and dissolve until the raw materials are completely dissolved into a uniform liquid .

[0097] 2. Concentration:

[0098] Equipment used: low temperature decompression vacuum thin film evaporation concentration equipment

[0099] After transferring the completely dissolved liquid to about 100L in the evaporator, turn on the vacuum pump, start the vacuum system, open the steam valve, and start to concentrate. Control the steam flow rate to keep the temperature at 60±5°C. During the concentration process, the high-concentration and low-concentration ethanol are respectively sent ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com