Recovery of waste graphite crucibles and high-purity carbon powder

A graphite crucible, high-purity technology, applied in carbon compounds, chemical instruments and methods, inorganic chemistry, etc., to achieve the effects of low preparation cost, full utilization, and wide particle size distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

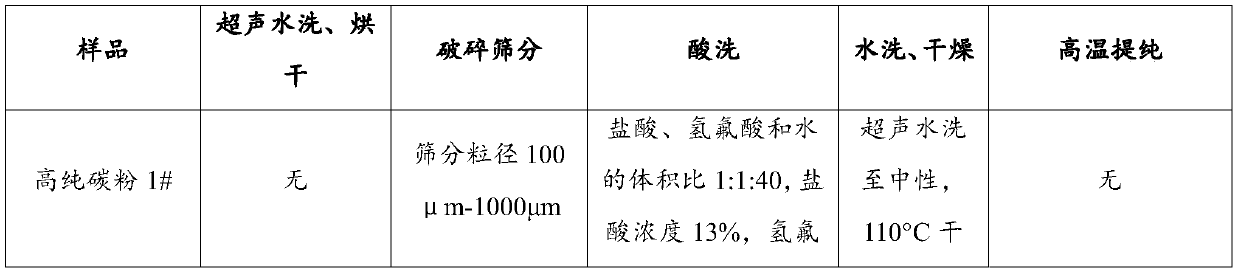

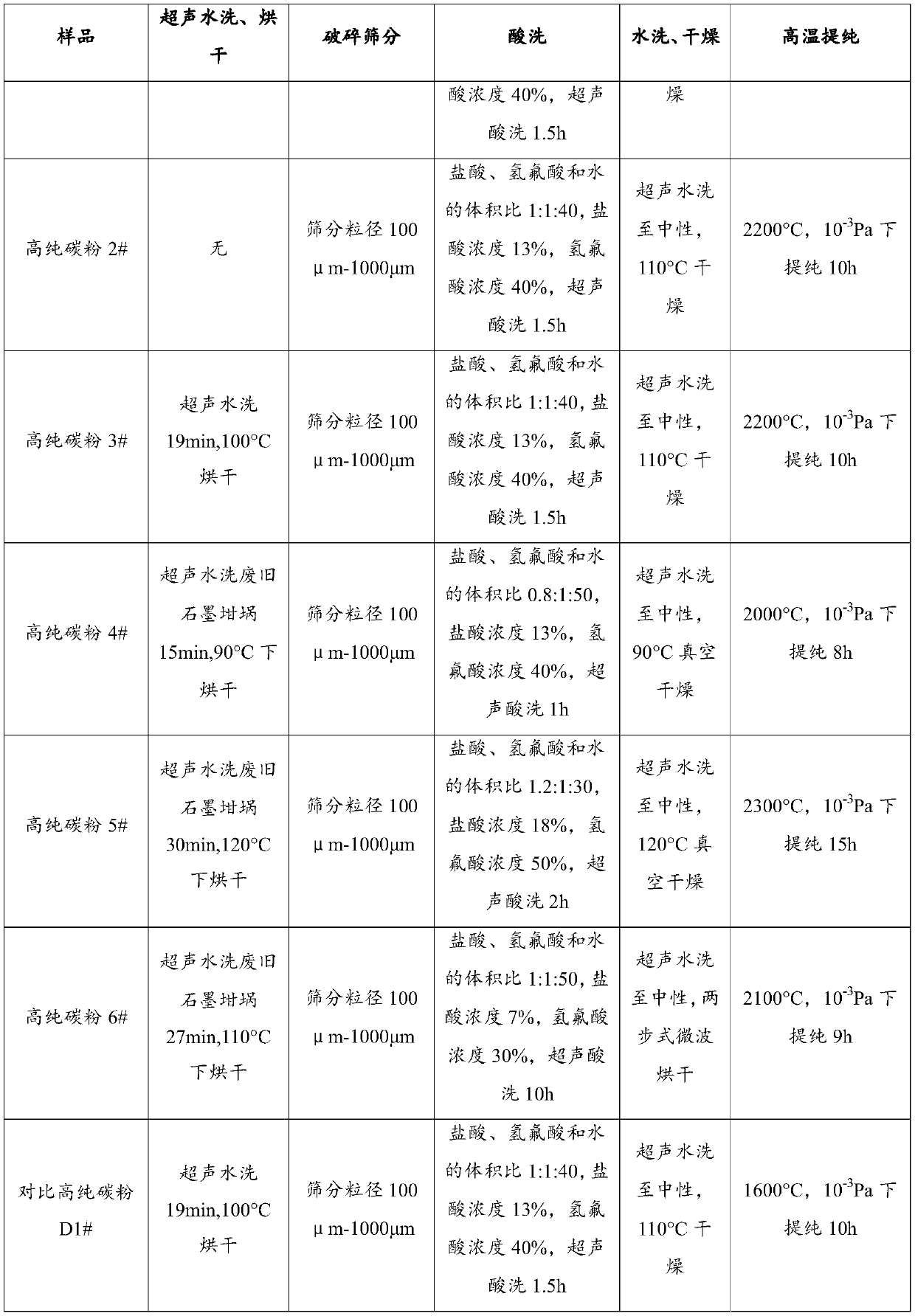

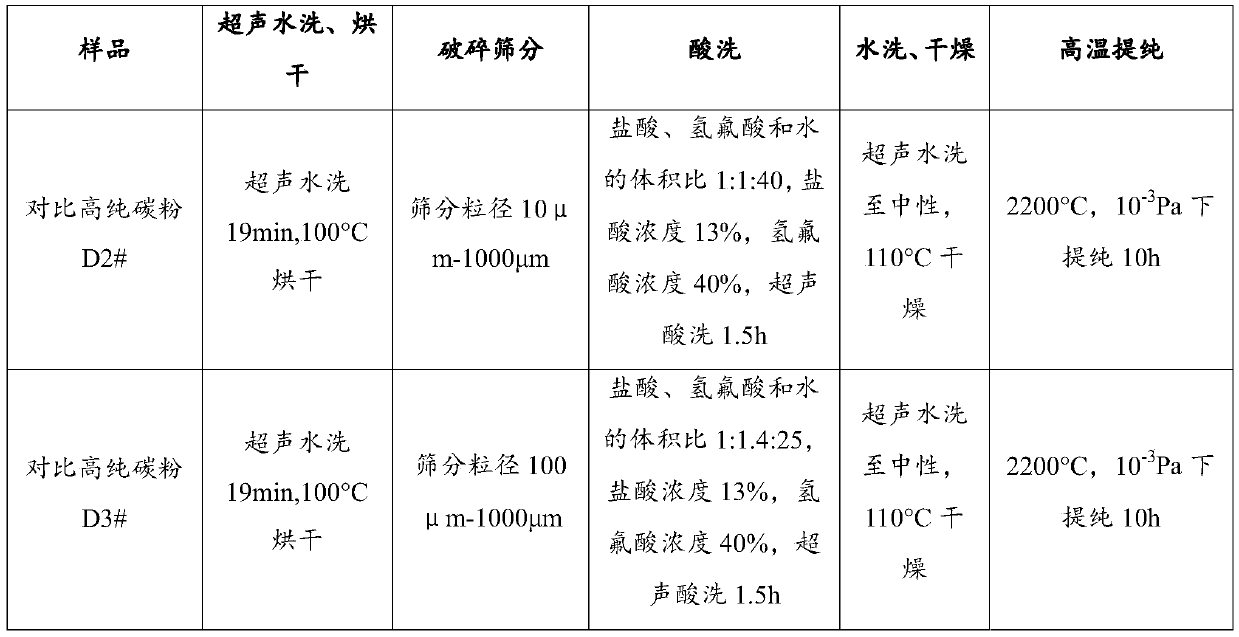

[0039] The application will be described in detail below with reference to the embodiments, but the application is not limited to these embodiments.

[0040] Unless otherwise specified, the raw materials and catalysts in the examples of the present application are all purchased through commercial channels. Among them, the waste graphite crucible comes from the graphite crucible used to prepare silicon carbide powder or high-purity silicon carbide single crystal.

[0041] The analysis method in the embodiment of this application is as follows:

[0042] B, Al, V, Ni, Fe and other impurity elements content and total ash are tested using Thermo Fisher's ElementGD-PLUS high flow rate glow discharge instrument.

[0043] According to the embodiment of the present application, the method for recycling waste graphite crucible includes the following steps:

[0044] 1) Ultrasonic water washing and drying: Place the waste graphite crucible in a cleaning tank, add deionized water and ultrasonically ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com