Production method of low-sulfur marine fuel oil

A production method and fuel oil technology, applied in the petroleum industry, hydrocarbon oil treatment, hydrogenation process, etc., can solve the problems of unstable operation of the filter device, high liquid recovery loss, easy blockage of the filter, etc., and achieve long cycle operation, save production cost, and improve the effect of utilization value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

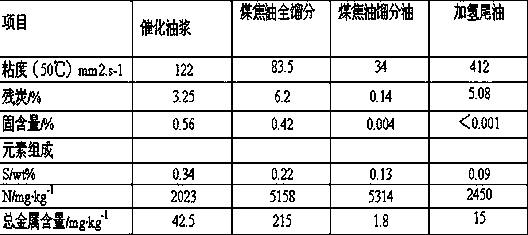

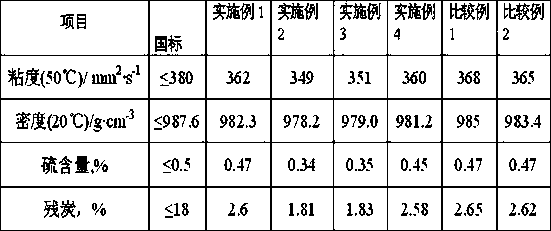

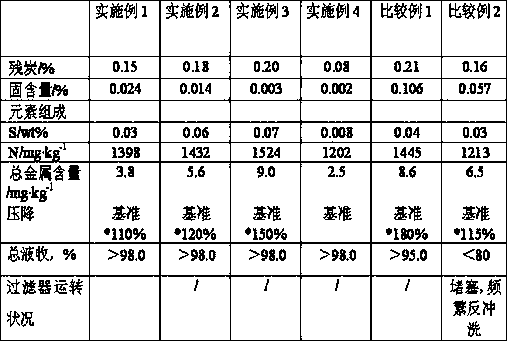

Embodiment 1

[0047] Embodiment 1 uses catalytic oil slurry as a raw material, adopts the catalytic oil slurry treatment method of the present invention, and firstly mixes the catalytic oil slurry with the first auxiliary agent coal tar whole fraction, and the proportioning of the catalytic oil slurry and the first auxiliary agent is 17 : 1, the mixing treatment temperature and mixing treatment time of the catalytic oil slurry and the first auxiliary agent are 72°C and 1.2h respectively, remove part of the large particles, and then enter the hydrogenation pretreatment reactor together with the hydrogen for shallow hydrogenation Reaction to remove easily condensed coke substances, the reaction conditions of the hydrogenation pretreatment reactor are: reaction temperature 337°C, reaction pressure 6.5Mpa, volume space velocity 0.7h -1 , the volume ratio of hydrogen to oil is 600; then enter the hydrotreating reactor for deep depurification reaction, the reaction conditions of the hydrotreating ...

Embodiment 2

[0049] Embodiment 2 takes catalytic oil slurry as raw material, adopts the catalytic oil slurry processing method of the present invention, first catalytic oil slurry is mixed with the first auxiliary agent coal tar whole fraction and the second auxiliary agent tetrahydronaphthalene, and the catalytic oil slurry is mixed with the second auxiliary agent tetrahydronaphthalene. The ratio of the first auxiliary agent and the second auxiliary agent is 18:1 and 65:1 respectively, and the mixing treatment temperature and mixing treatment time of the catalytic oil slurry, the first auxiliary agent and the second auxiliary agent are 82°C and 1.5h respectively, Remove part of the large particles, and then enter the hydrotreating reactor together with hydrogen for deep impurity removal reaction. The reaction conditions of the hydrotreating reactor are: reaction temperature 389 ° C, reaction pressure 8.9Mpa, volume space velocity 1.2h -1 , The volume ratio of hydrogen to oil is 650, and th...

Embodiment 3

[0051] Embodiment 3 uses catalytic oil slurry as a raw material, adopts the catalytic oil slurry treatment method of the present invention, and mixes the catalytic oil slurry with the first auxiliary agent coal tar whole fraction, and the proportioning ratio of the catalytic oil slurry and the first auxiliary agent is respectively 21 : 1, the mixing treatment temperature and mixing treatment time of the catalytic oil slurry and the first auxiliary agent are respectively 87°C and 1.6h to remove part of the large particles, and then enter the hydrotreating reactor together with hydrogen for deep depurification reaction, The reaction conditions of the hydrotreating reactor are: reaction temperature 394°C, reaction pressure 9.3Mpa, volume space velocity 1.4h -1 , the volume ratio of hydrogen to oil is 700, and the hydrotreating reactor uses an ebullating bed reactor. The mixed system after the impurity removal reaction is respectively treated by the clarification unit and the forc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com