Energy-saving zero-emission low-temperature normal-pressure evaporation and crystallization system and working method thereof

A technology of low temperature and atmospheric pressure, evaporation and crystallization, applied in chemical instruments and methods, multi-stage water/sewage treatment, heating water/sewage treatment, etc., can solve problems such as complex operation and maintenance, large steam consumption, and large pollution, and achieve enhanced Mass transfer effect, obvious advantages in environmental protection, and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in further detail below in conjunction with accompanying drawing and specific embodiment, and its content is explanation of the present invention rather than limitation:

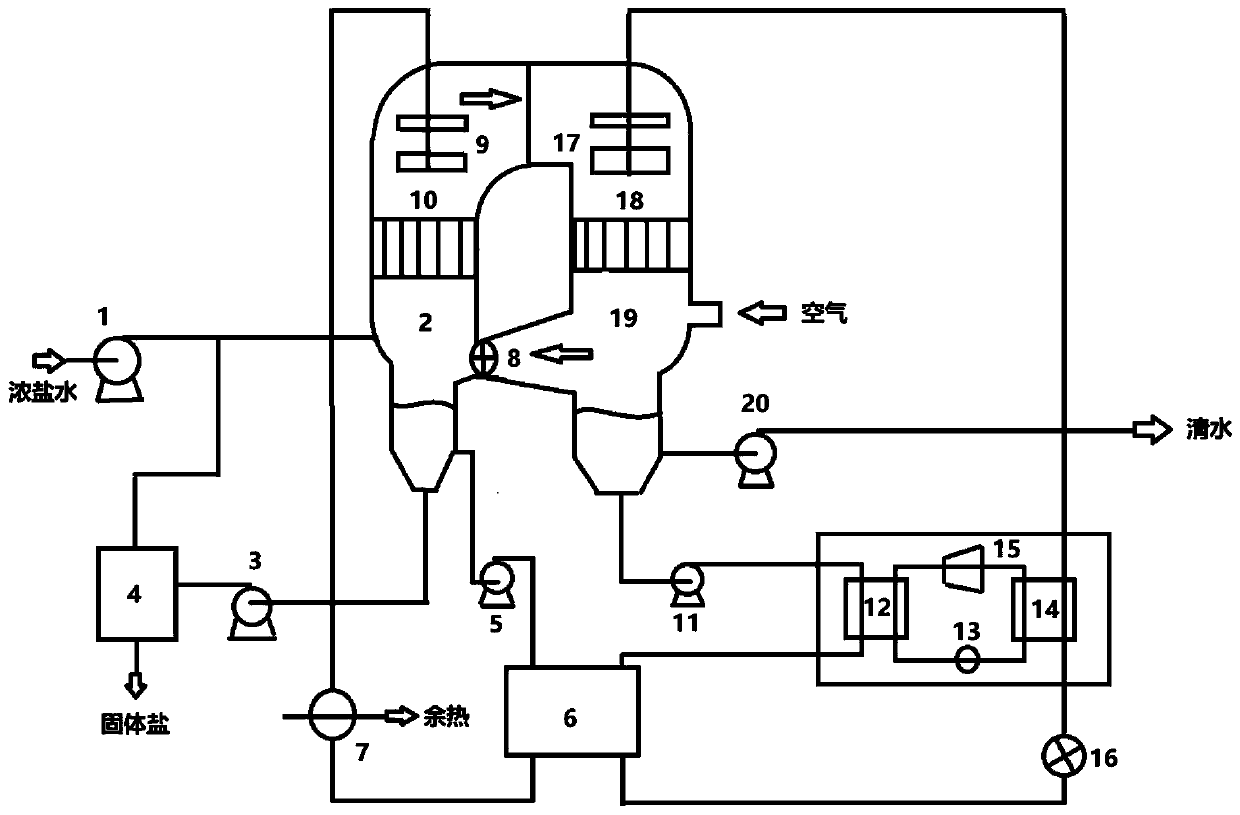

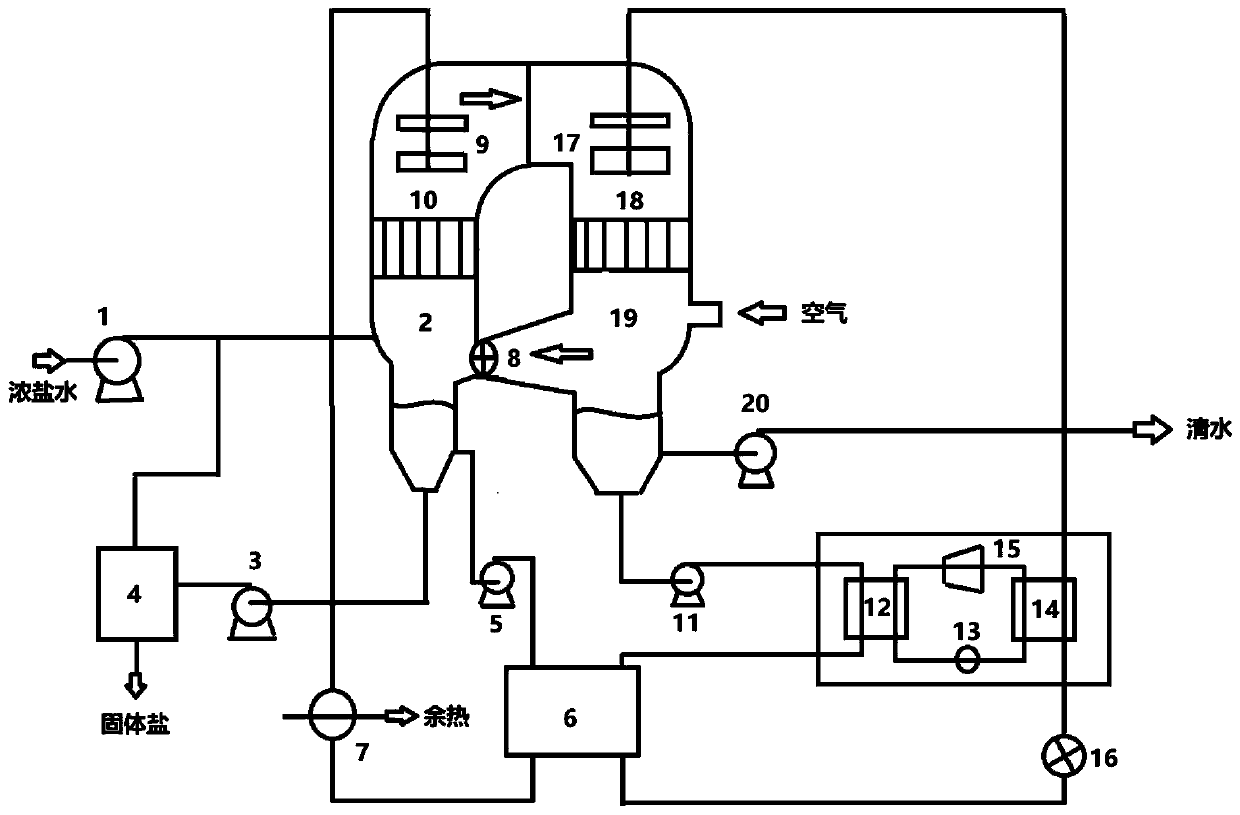

[0030] Such as figure 1 , The present invention's energy-saving zero-emission low-temperature atmospheric-pressure evaporation crystallization system includes an evaporation chamber 2, a crystallization kettle 4, an evaporation-condensation heat exchanger 6, a condensation chamber 19 and a refrigeration chamber unit.

[0031] The top and bottom of the evaporation chamber 2 and the condensation chamber 19 communicate with each other to form a circular gas circulation channel. The top connection between the evaporation chamber 2 and the condensation chamber 19 is provided with an insulating layer, which can be made of silicate with a filter membrane. The partition reduces the heat exchange between the system and the outside, while gas and water vapor can pass thro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com