Patents

Literature

35results about "Ammonium sulfides/polysulfides" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Catalyst pretreatment with aldehyde in an oxygenate to olefins reaction system

ActiveUS20050101817A1Ammonium sulfides/polysulfidesMolecular sieve catalystsMolecular sieveOxygenate

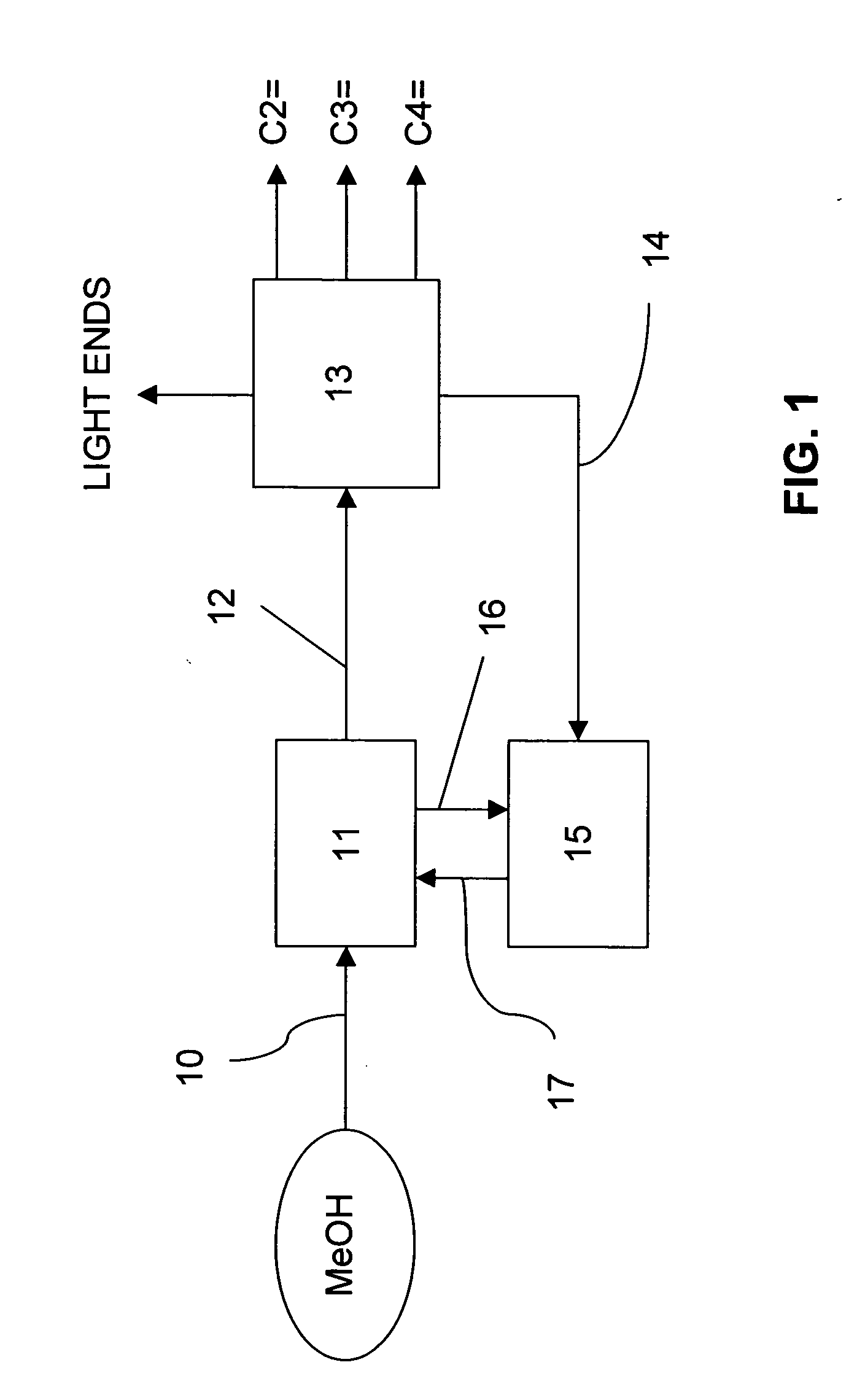

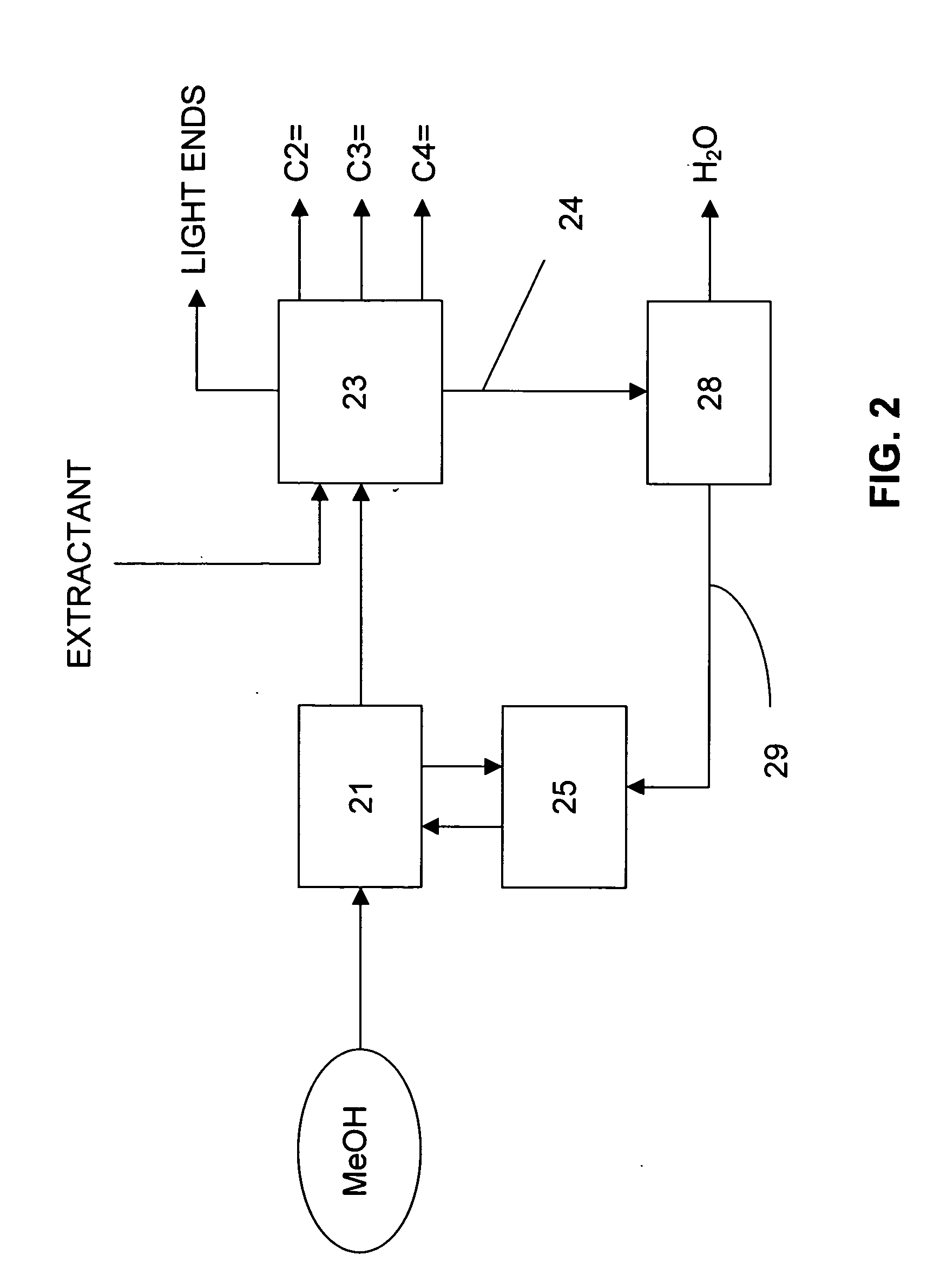

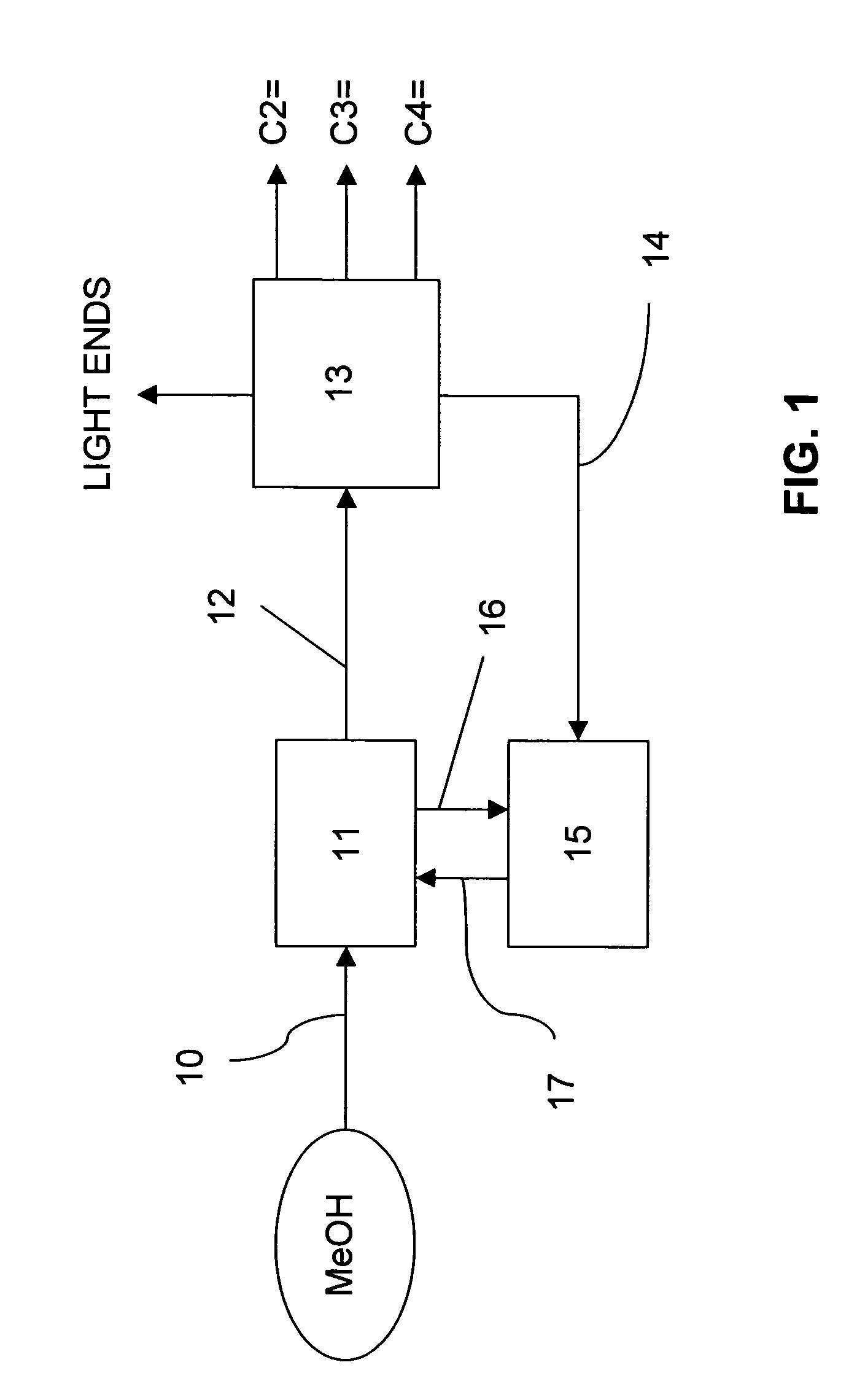

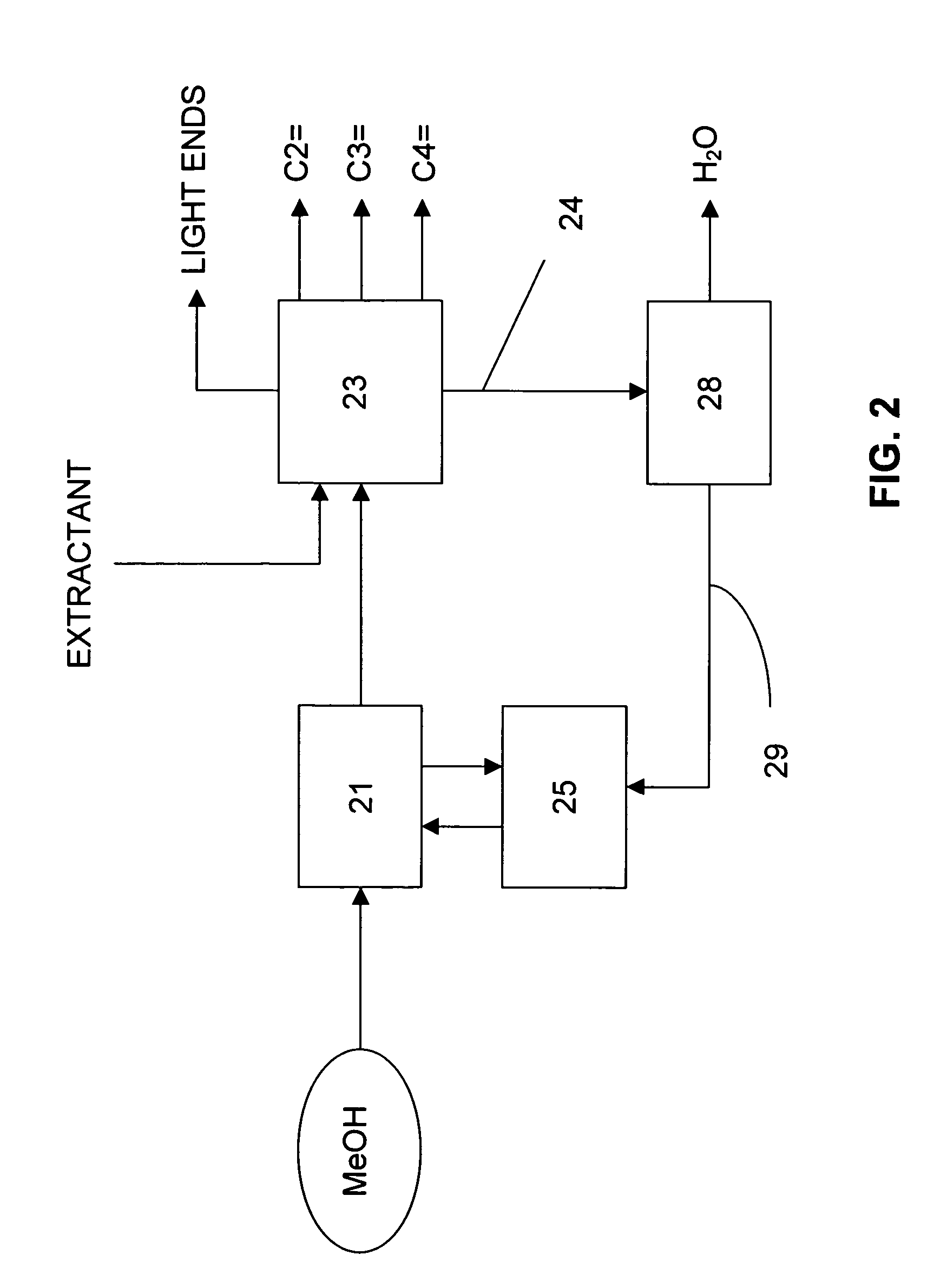

This invention concerns processes for converting oxygenates to olefins that include a step of pretreating catalyst used in the conversion reaction. A fresh or regenerated metalloaluminophosphate molecular sieve, which is low in carbon content, is pretreated with an aldehyde. The aldehyde forms a hydrocarbon cocatalyst within the pore structure of the molecular sieve, and the pretreated molecular sieve containing the co-catalyst is used to convert oxygenate to an olefin product.

Owner:EXXONMOBIL CHEM PAT INC

Catalyst pretreatment with aldehyde in an oxygenate to olefins reaction system

ActiveUS7132581B2Ammonium sulfides/polysulfidesMolecular sieve catalystsMolecular sievePolymer science

Owner:EXXONMOBIL CHEM PAT INC

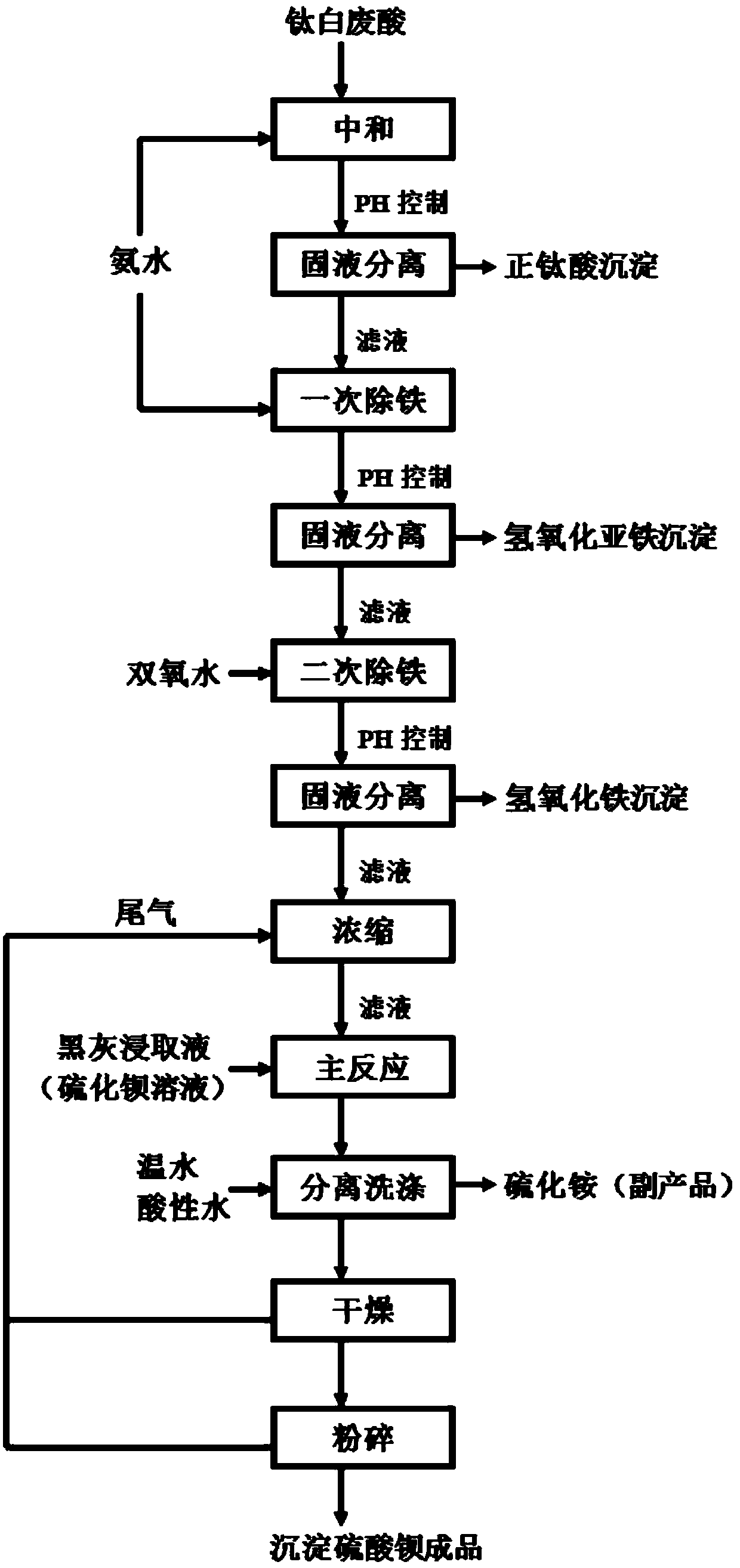

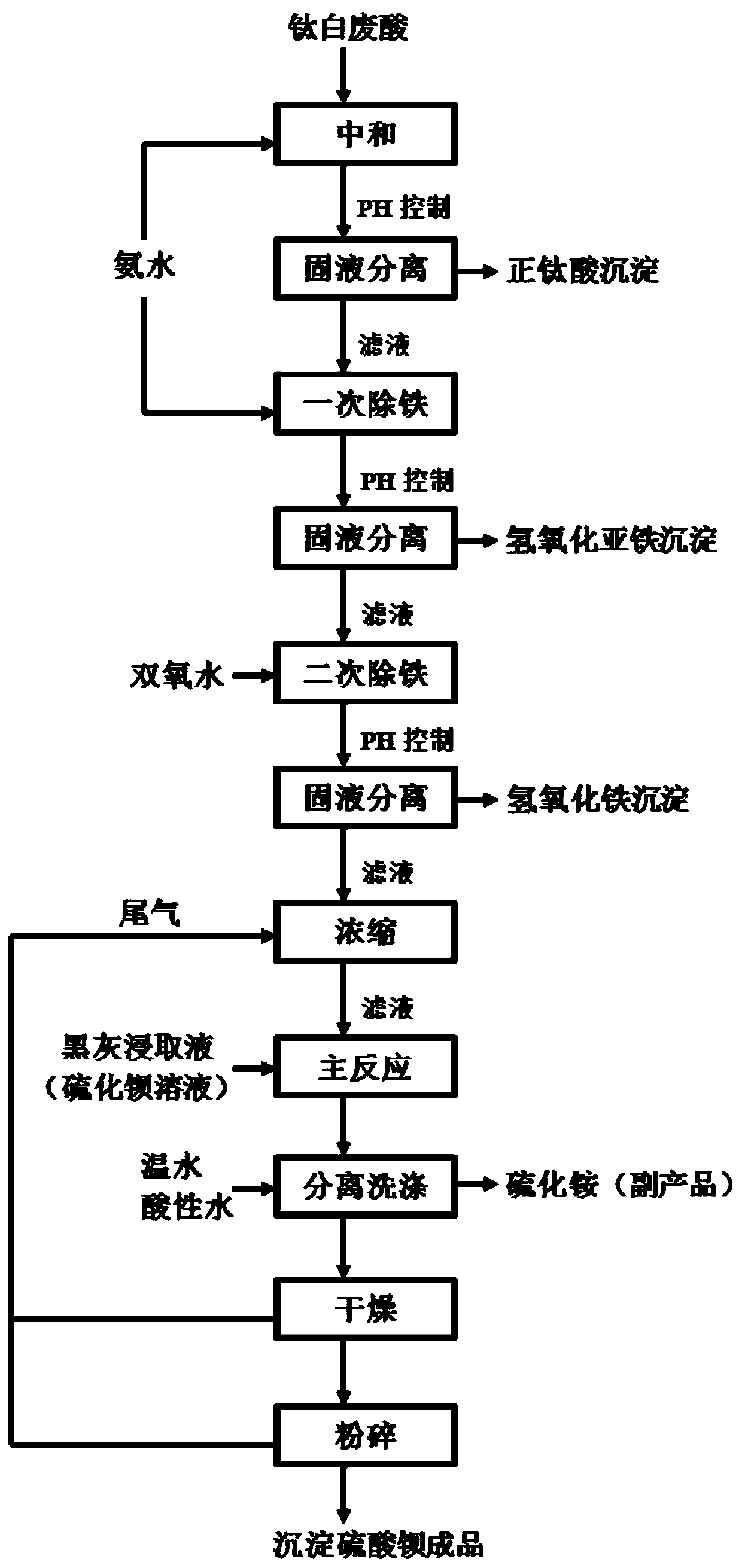

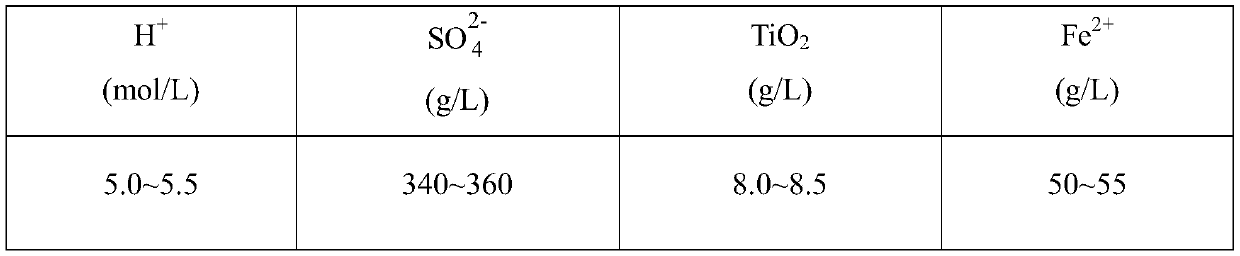

Method for preparing precipitated barium sulfate by utilizing titanium white waste acid

ActiveCN107720801AReduce cost pressureReduce pressure on environmental protectionAmmonium sulfides/polysulfidesCalcium/strontium/barium sulfatesFerric hydroxideSodium sulfate

The invention discloses a method for preparing precipitated barium sulfate by utilizing titanium white waste acid, belonging to the technical field of comprehensive utilization of titanium white wasteacid and preparation of barium sulfate. The method comprises the following steps of adding ammonium hydroxide to neutralize with titanium white waste acid firstly, then generating ammonium sulfate, and controlling a systemic pH to separate out photodegredation sediment; then adding the ammonium hydroxide continuously, and controlling the pH to separate out ferrous hydroxide sediment; then addinghydrogen peroxide in proportion, oxidating residual Fe2<+> into Fe3<+>, and adjusting the pH to separate out ferric hydroxide sediment; condensing an ammonium sulfate solution, then replacing a mirabilite solution in a traditional precipitated barium sulfate production process, enabling the ammonium sulfate solution to generate replacement reaction with a barium sulfide solution, and washing, drying and smashing to prepare a precipitated barium sulfate product. According to the method, after neutralizing the titanium white waste acid with the ammonium hydroxide and performing purification andimpurity removal, a traditional sodium sulfate solution is replaced for producing the precipitated barium sulfate, meanwhile, recycled photodegredation sediment can be further used for titanium dioxide production, not only are resources saved, but also waste can be recycled, and the waste acid treatment costs of titanium dioxide plants and environment protection pressure are reduced.

Owner:ANHUI JXTB GRP

Catalytic dehydration of alcohols and ethers over a ternary mixed oxide

A ternary V—Ti—P mixed oxide is shown to catalytically dehydrate 2-methyl-tetrahydrofuran in high conversion to give piperylene, in good yield. Volatile products collected from this reaction contain piperylene in concentrations as high as 80 percent by weight. Dehydration of glycerol to acrolein in high conversion and moderate selectivity is also demonstrated. The catalyst is also shown to dehydrate other alcohols and ether substrates. The catalyst is resistant to deactivation and maintains activity between runs.

Owner:EASTMAN CHEM CO

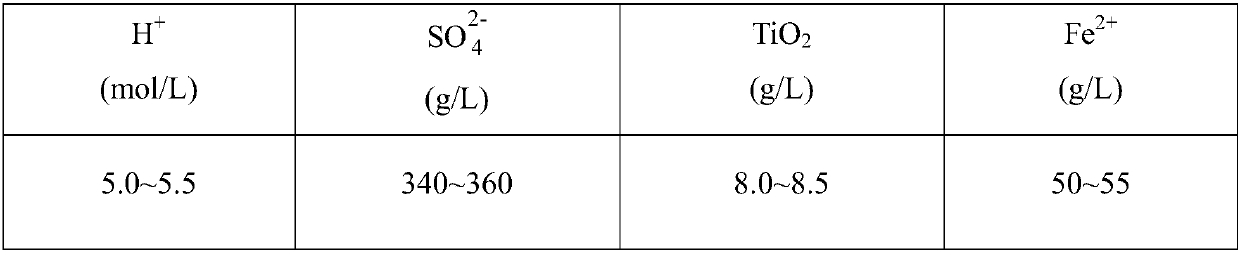

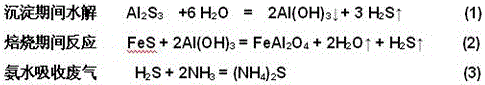

Method for recycling treated ladle refining waste residues

PendingCN113373271APromote leachingReduce pollutionAmmonium sulfides/polysulfidesRecycling and recovery technologiesProcess engineeringSlurry

The invention discloses a method for recycling treated ladle refining waste residues, and belongs to the technical field of secondary resource recycling. The method comprises the following operation steps: solid waste mixing: mixing the ladle refining waste residues and secondary aluminum ash according to a certain proportion, so that N / S in the mixed mixture is 1-2; mixed material water leaching: mixing and stirring the mixture and water according to the proportion of 1: 2-1: 3, and performing leaching at the normal temperature; and solid-liquid separation: after leaching for a period of time, directly discharging an upper-layer solution, carrying out solid-liquid separation on lower-layer slurry, retaining the separated filtrate in next mixed material water leaching for reuse, and heating and roasting the separated filter residues for 2-3 hours. The invention aims to overcome the problem that in the prior art, the ladle refining waste residues are difficult to treat in a large amount and at low cost, and provides the method for recycling the treated steel ladle refining waste residues, so that the desulfurization rate is high, the desulfurization speed is high, the removed sulfur-containing substances can be reused, and the economic benefit is greatly improved.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

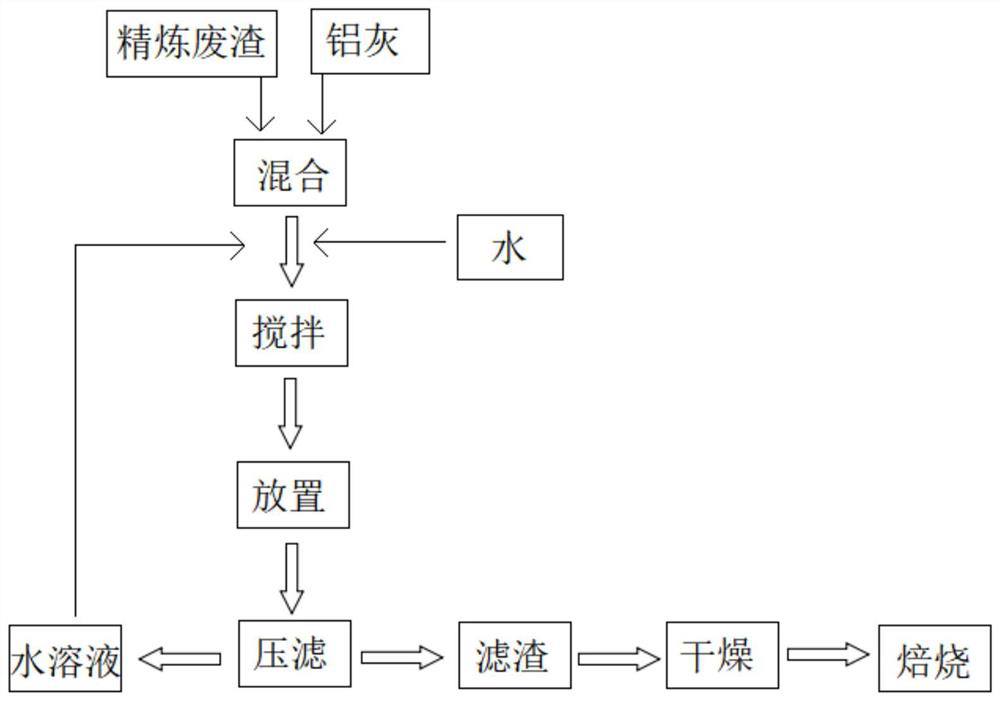

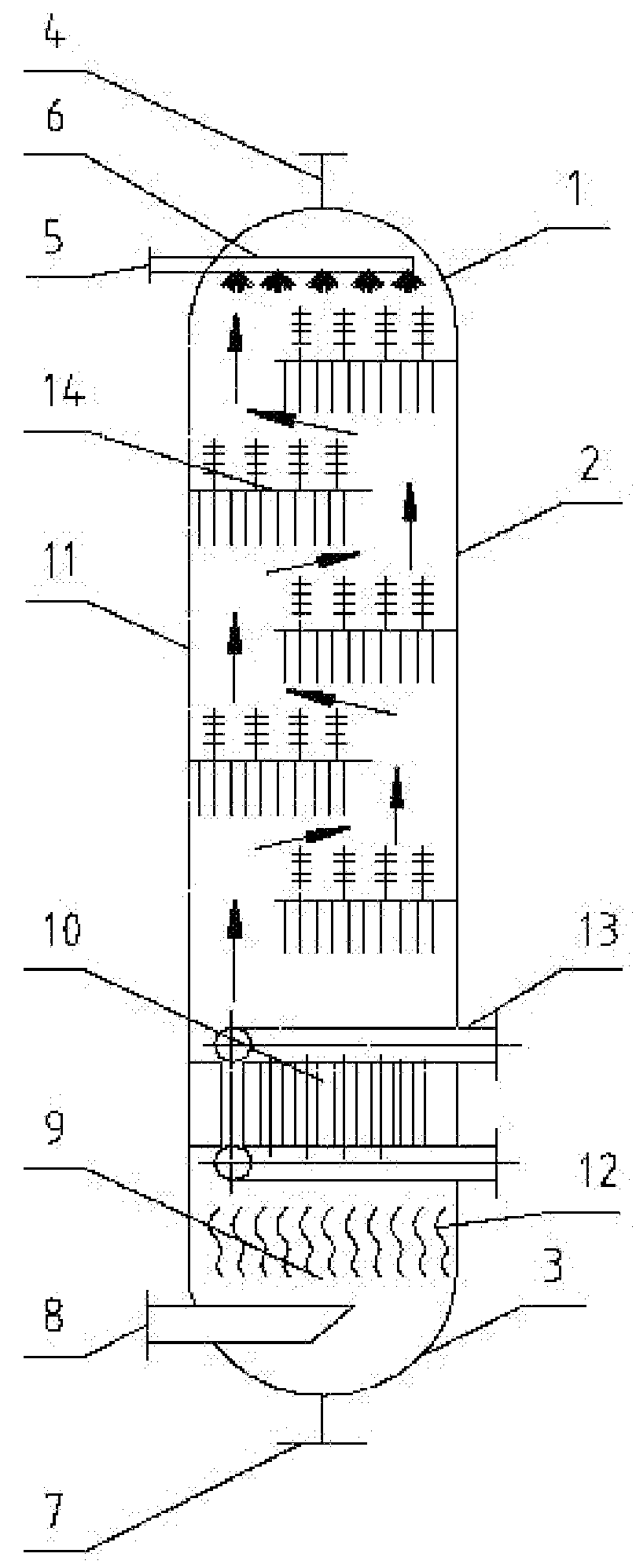

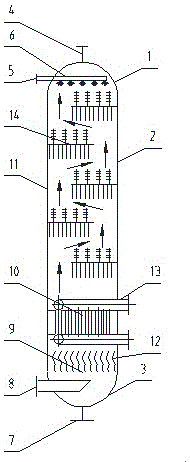

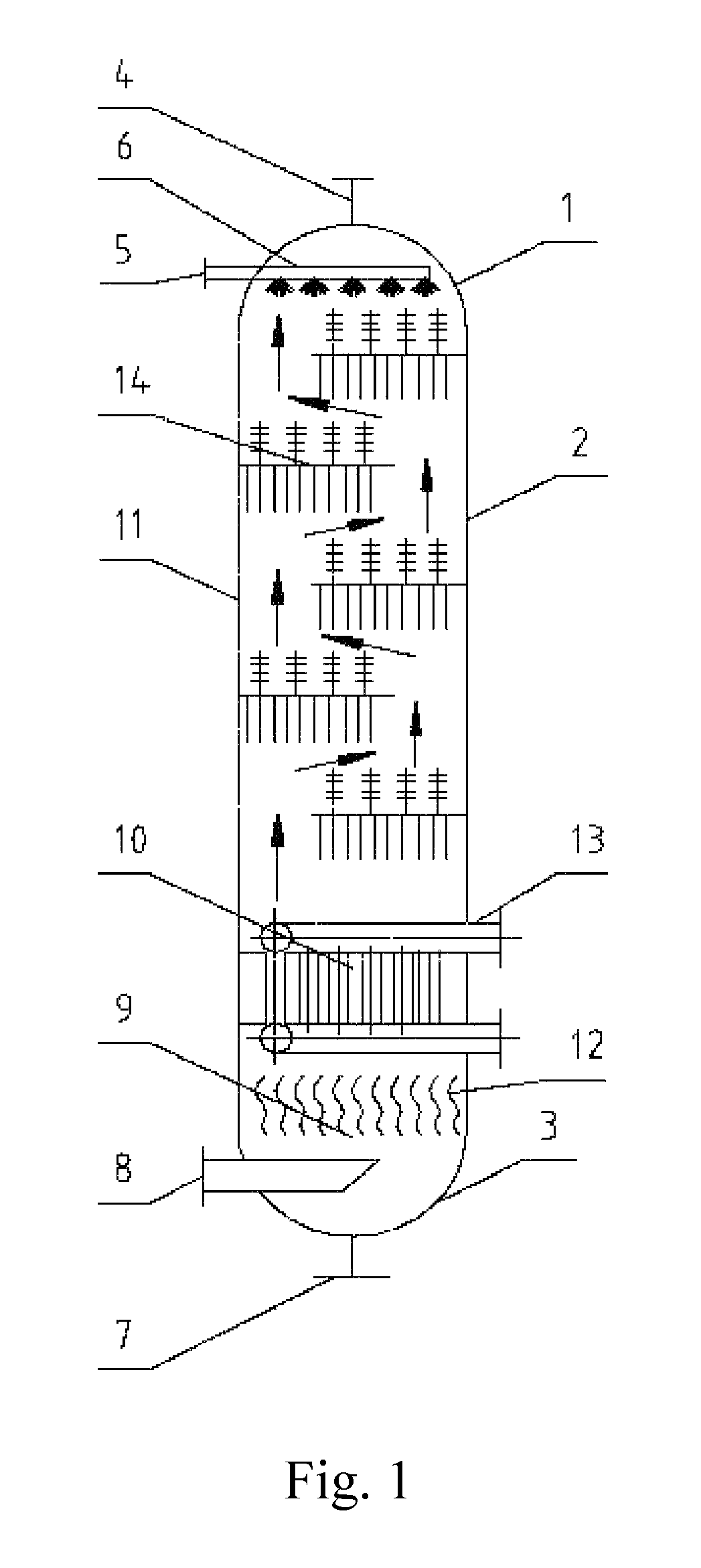

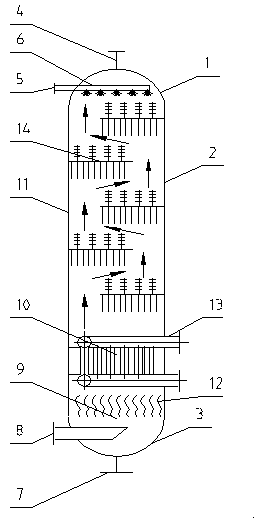

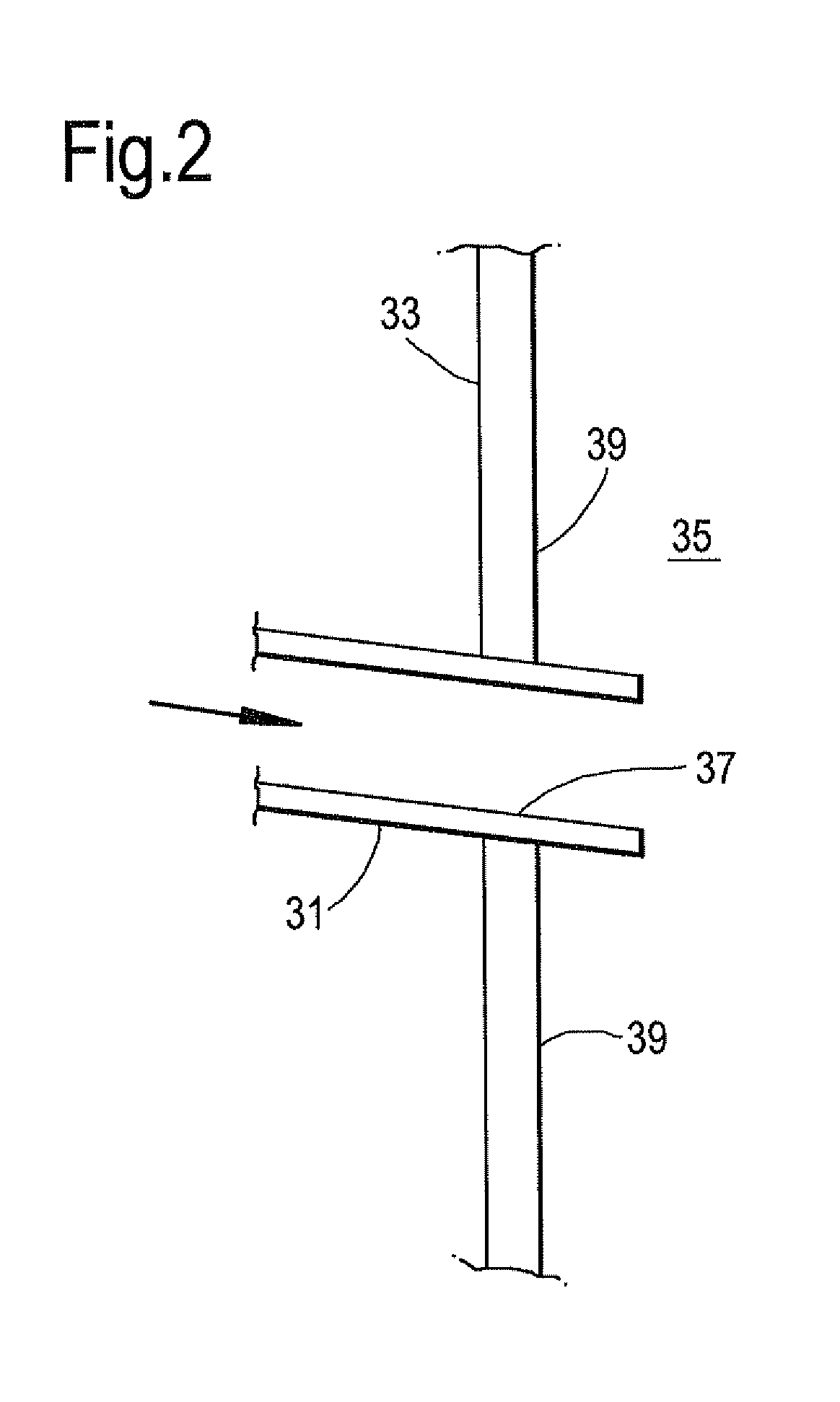

Crystallization column and crystallization method

ActiveUS20180264377A1Simple structureLow costAmmonium sulfides/polysulfidesDispersed particle separationEngineeringTower

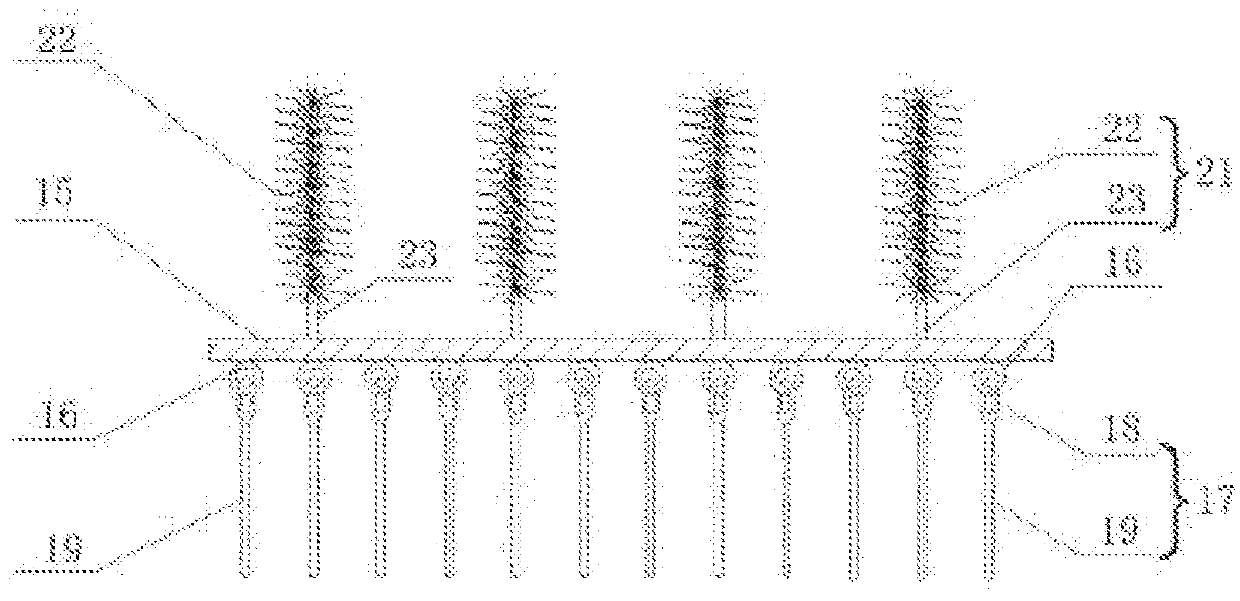

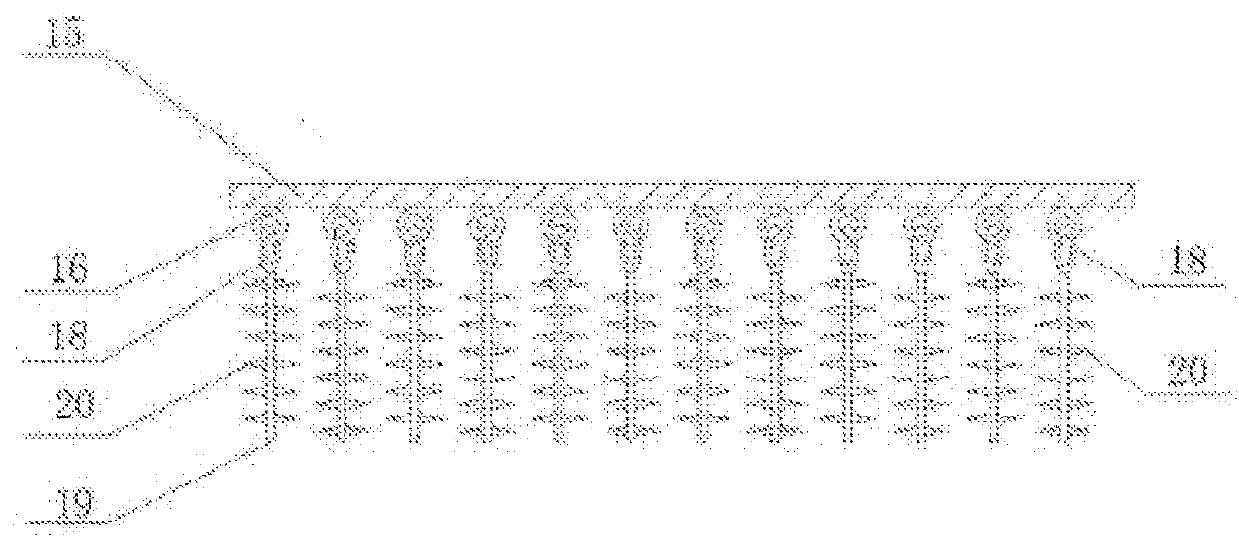

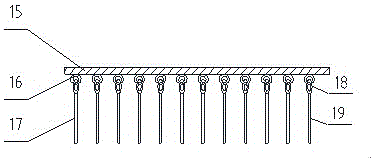

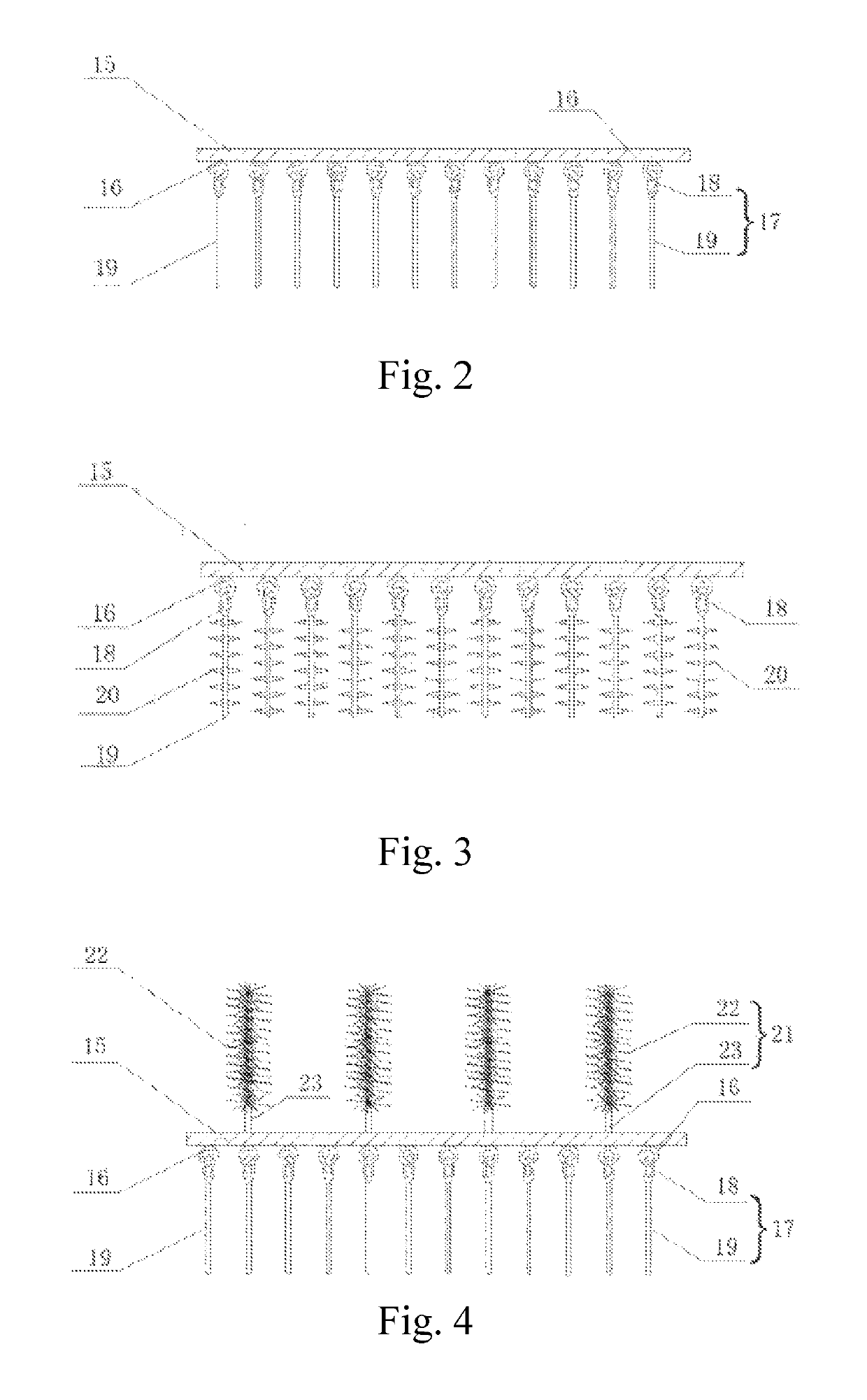

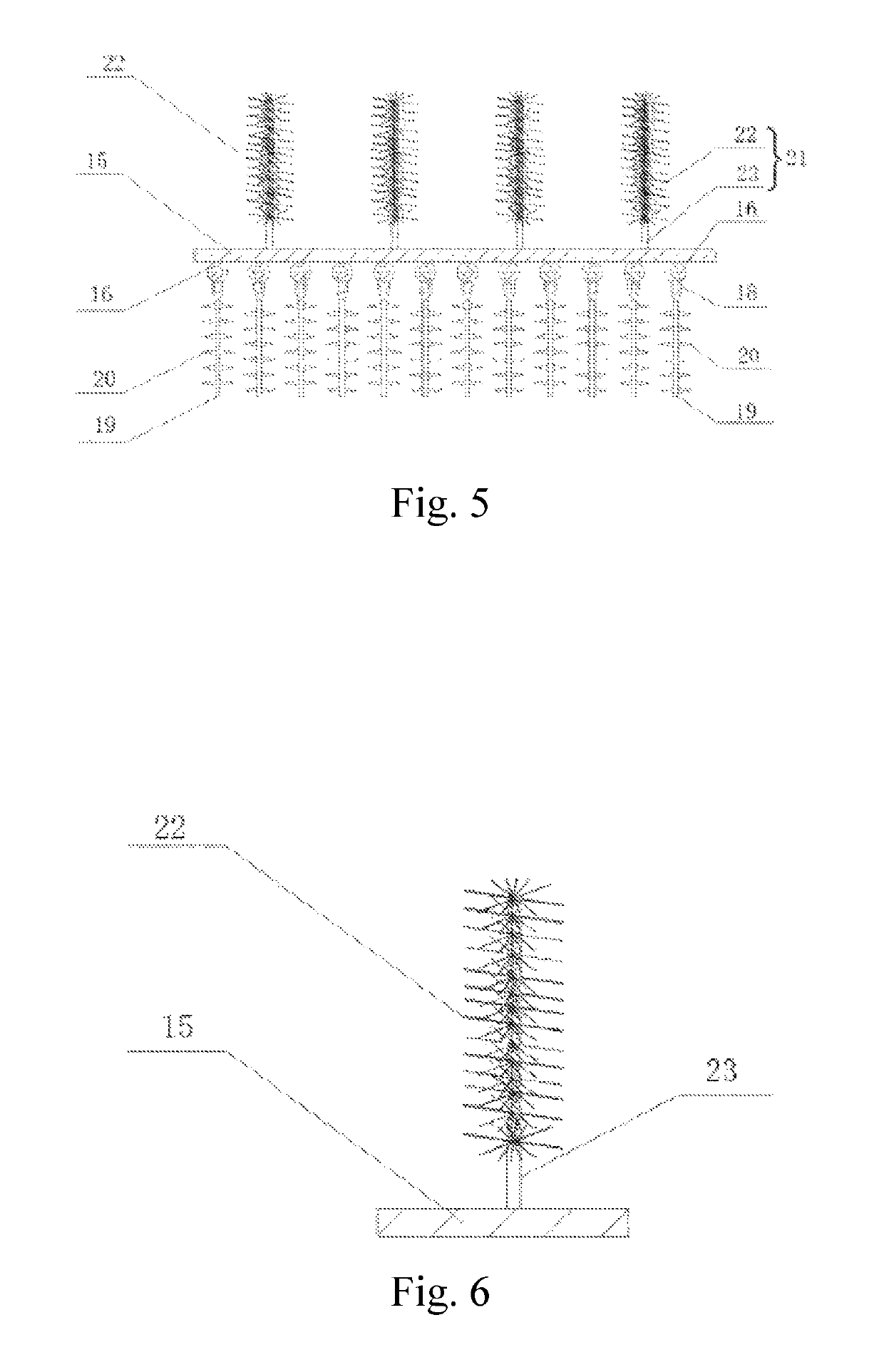

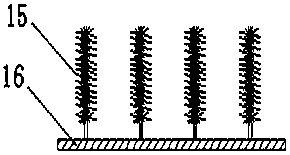

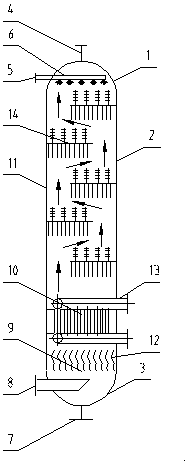

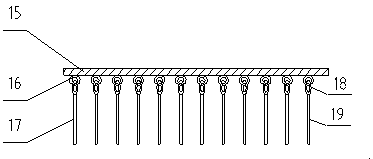

A crystallization column and a crystallization method. The crystallization column comprises an upper head (1), a tower body (2) and a lower head (3), wherein a crystallization section (11) is provided with a tray (14); and the tray (14) comprises a tray plate (15) and a plurality of lower crystallization members (17). The top end of the lower crystallization member (17) can form a movable connection with the tray plate (15), so that the two adjacent lower crystallizing members (17) are capable of oscillating collisions. The tray (14) may also comprise a plurality of upper crystallization members (21) extending upwardly from the upper surface of the tray plate (15).

Owner:CHINA PETROCHEMICAL CORP +1

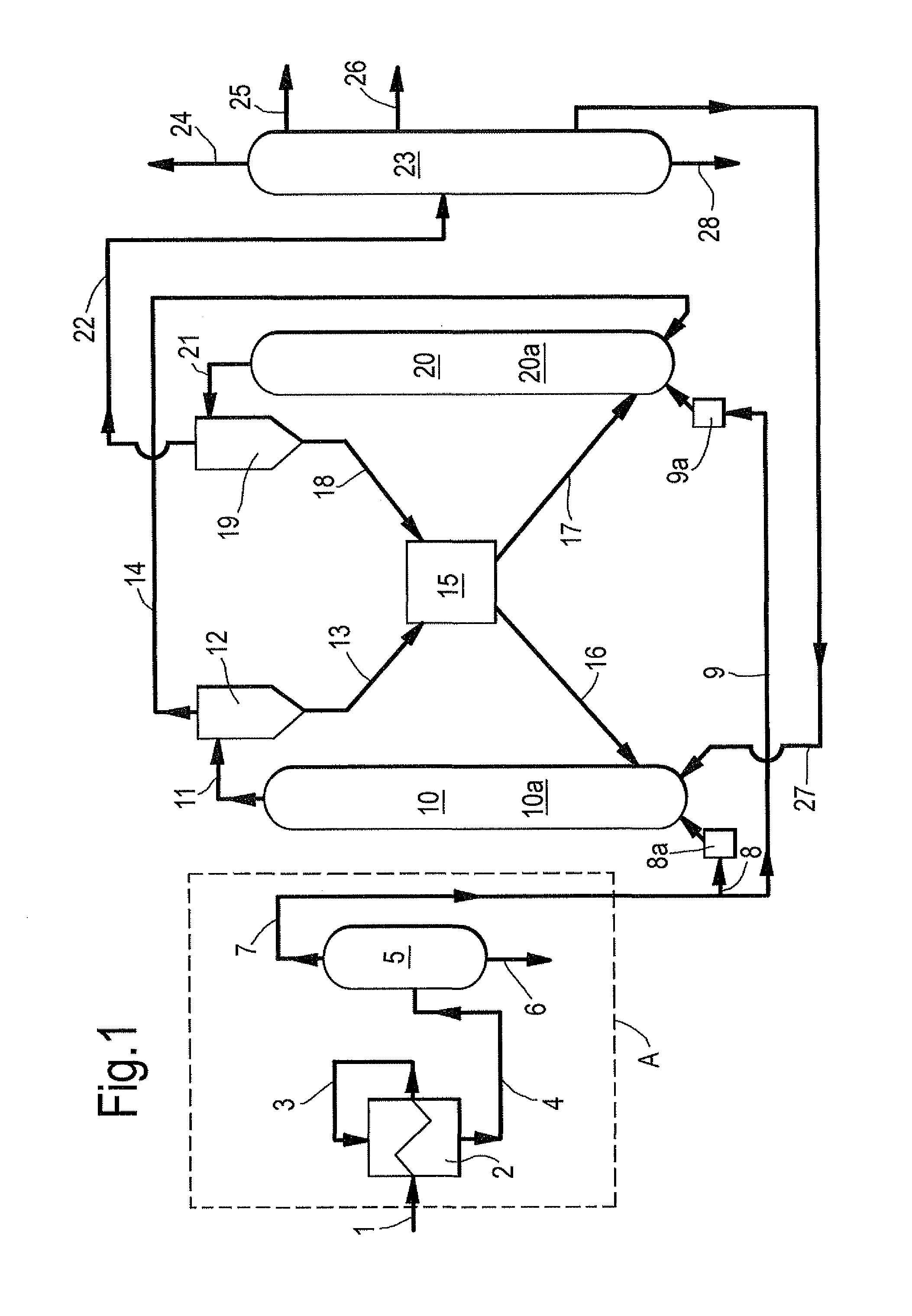

Process for combining the catalytic conversion of organic oxygenates and the catalytic conversion of hydrocarbons

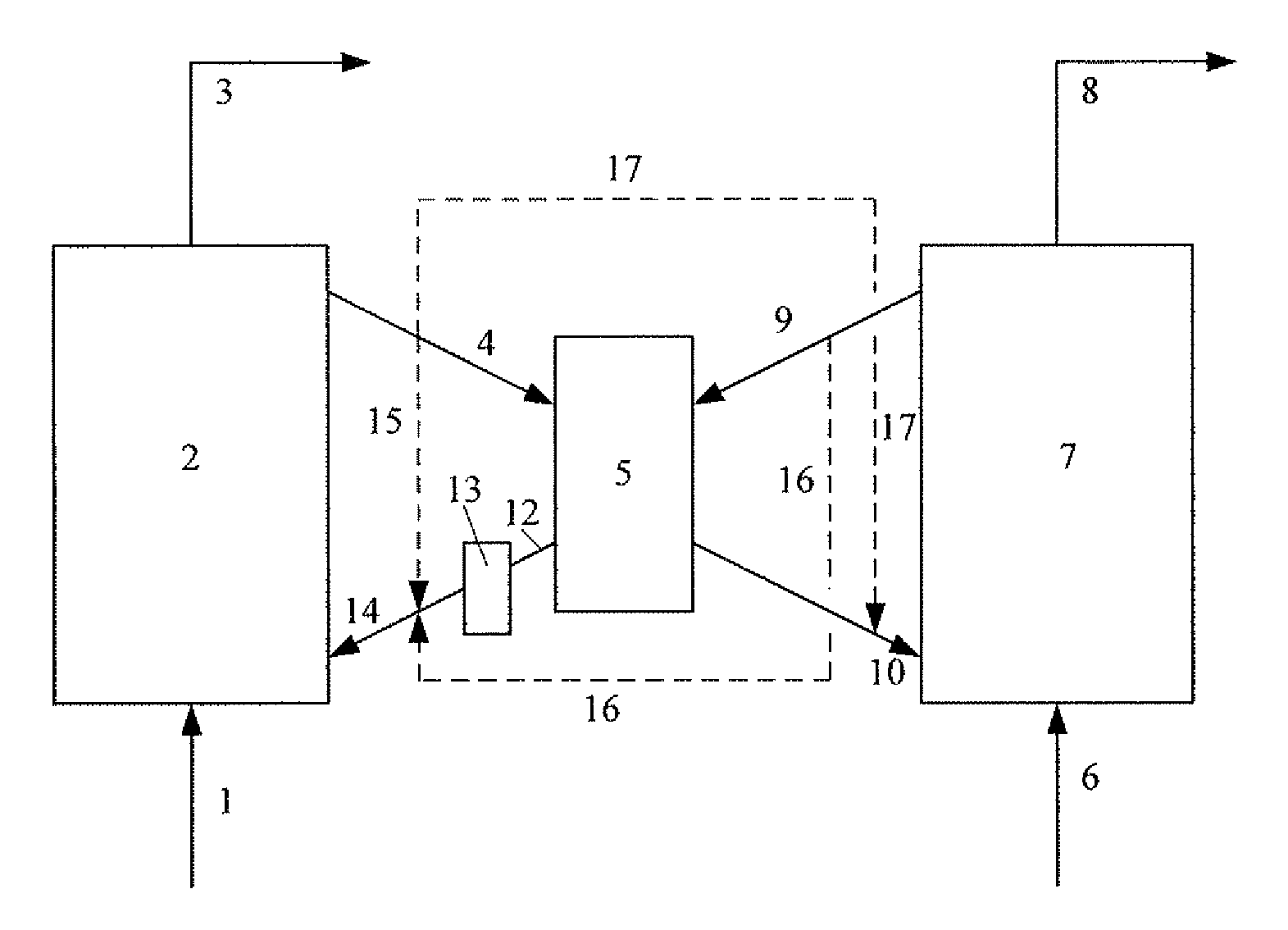

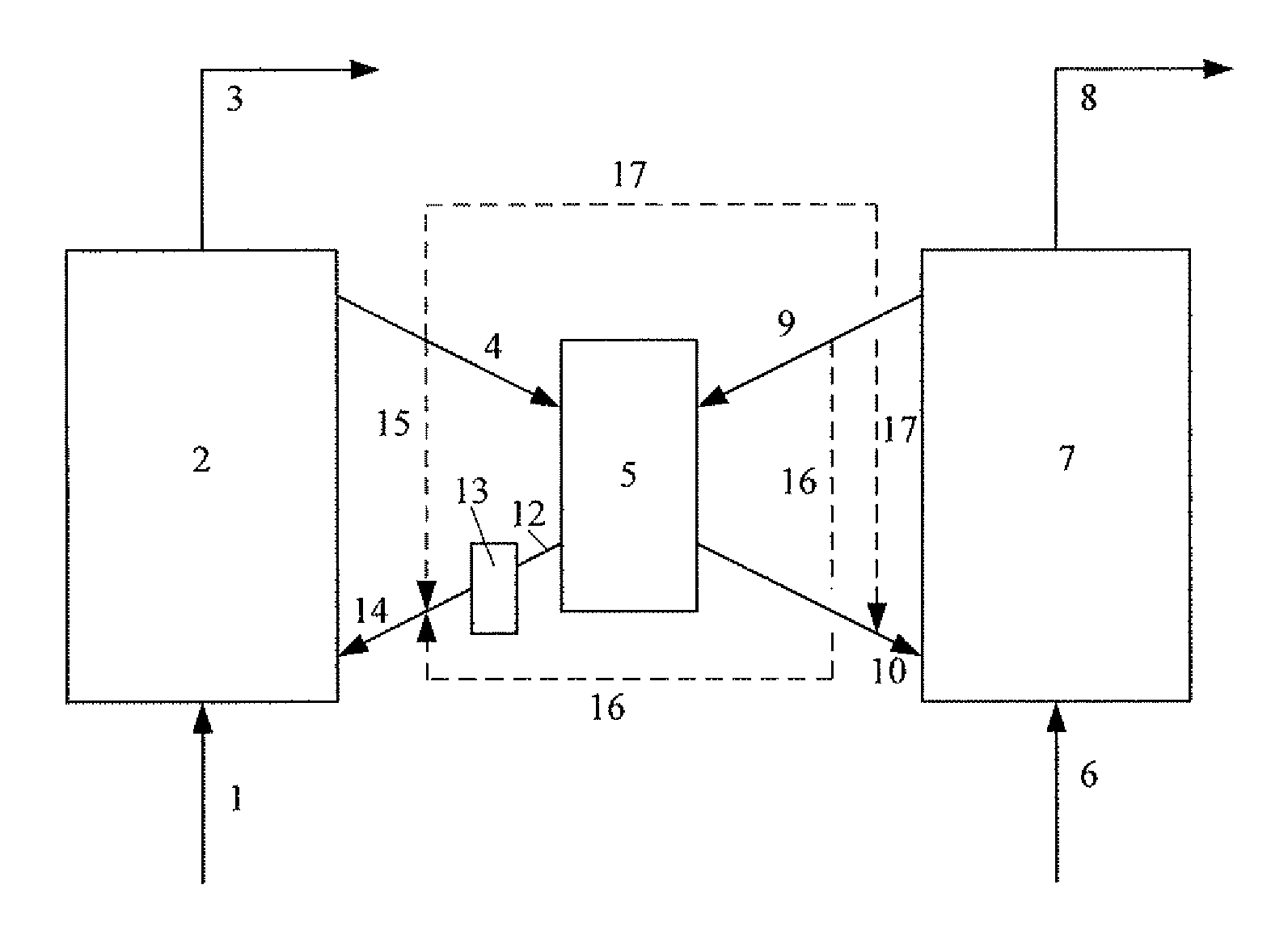

A process for combining the catalytic conversion of organic oxygenates and the catalytic conversion of hydrocarbons: an organic oxygenate feedstock is contacted with a Y-zeolite containing catalyst to produce a reaction stream, and a coked catalyst and a product stream are obtained after separating the reaction stream; a hydrocarbon feedstock is contacted with a Y-zeolite containing catalyst to produce a reaction stream, a spent catalyst and a reaction oil vapor are obtained after separating the reaction stream, and the reaction oil vapor is further separated to give the products such as gas, gasoline and the like; a part or all of the coked catalyst and a part or all of the spent catalyst enter the regenerator for the coke-burning regeneration, and the regenerated catalyst is divided into two portions, wherein one portion returns to be contacted with the hydrocarbon feedstock, and the other portion, after cooling, returns to be contacted with the organic oxygenate feedstock. This process not only reasonably utilizes the excessive thermal energy of the hydrocarbon conversion, but also solves the problem of heat supply for the conversion of the organic oxygenate, thus ensuring the continuous catalytic conversion of the organic oxygenate.

Owner:CHINA PETROCHEMICAL CORP +1

Method for preparing manganese sulfide coproduced with strontium sulfate and ammonium sulfide by using manganese-containing waste liquor produced during production of hydroquinone

InactiveCN102115187AReduce pollutionSimple processAmmonium sulfides/polysulfidesCalcium/strontium/barium sulfatesSocial benefitsAmmonium sulfide

The invention relates the technical filed of utilization of manganese-containing waste liquor produced during production of hydroquinone, in particular to a method for preparing manganese sulfide coproduced with strontium sulfate and ammonium sulfide by using the manganese-containing waste liquor produced during the production of hydroquinone. The method mainly comprises the following steps of: performing suction filtration on the waste liquor produced by hydroquinone by using a suction filter machine to obtain filtrate, distilling and filtering the filtrate, and performing deep processing on a filter cake to obtain a manganese sulfide product; and distilling the filtrate under a reduced pressure and performing further deep processing on the filtrate respectively to obtain a strontium sulfate product and an ammonium sulfide product respectively. By adopting the method, the waste liquor can be treated completely, environmental pollution caused by waste liquor is relieved, valuable manganese sulfide, strontium sulfate and ammonium sulfide products can be prepared, remarkable social benefit and economic benefit are achieved, and process and production equipment are simple. The method is a relatively practical treatment and utilization method.

Owner:何云

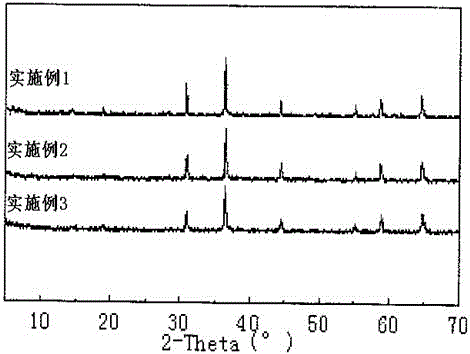

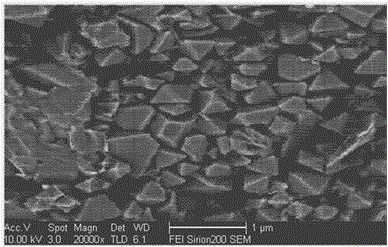

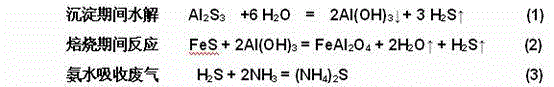

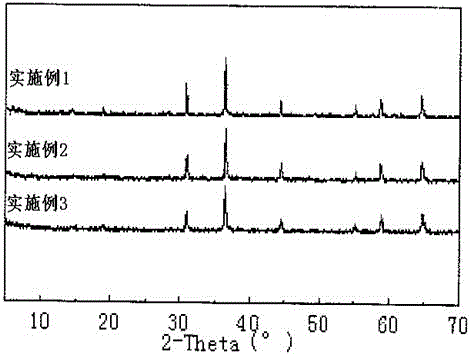

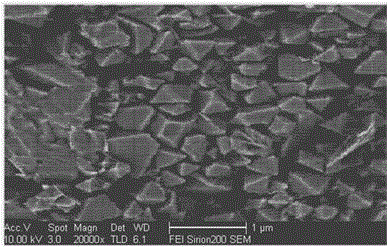

Sub-micron hercynite, as well as preparation method and application thereof

The invention relates to sub-micron hercynite. The sub-micron hercynite is characterized in that the grain diameter is below 1.0micron, the hercynite is added into materials for synthesizing a hercynite flame-retardant raw material by a sintering process to serve as seed crystal, and the sintering temperature can be reduced. The invention further provides a method for preparing the sub-micron hercynite. The method comprises the following steps: respectively preparing a ferrous sulfate solution and an aluminum sulfate solution; sequentially adding the ferrous sulfate solution and the aluminum sulfate solution into a reactor, mixing, adding an ammonium sulfide solution into the mixed solution, and filtering after mixed precipitation is generated; carrying out vacuum drying and roasting on a filter cake to obtain the sub-micron hercynite; and distillating, concentrating and crystallizing the filtrate to obtain ammonium sulfate.

Owner:SHANDONG UNIV OF TECH

Petroleum hydrocarbon binder with reduced polycyclic aromatic hydrocarbon content

InactiveUS7393449B1Cyanogen compoundsLiquid hydrocarbon mixture productionPolycyclic aromatic hydrocarbonBituminous materials

A binder pitch material includes a petroleum pitch and asphalt fraction obtained from petroleum crude oil and has a significantly lower polycyclic aromatic hydrocarbon composition than a coal tar pitch having a like softening point. The pitch material is useful as a binder material for various applications such as clay pigeons.

Owner:MARATHON PETROLEUM

Method for co-production of manganese sulfide, magnesium sulfate and ammonium sulfide from manganese-containing waste liquid generated during hydroquinone production

InactiveCN102115178AReduce pollutionSimple processAmmonium sulfides/polysulfidesWater/sewage treatmentAmmonium sulfideManganese sulfide

The invention relates to the technical field of utilization of manganese-containing waste liquid generated during the production of hydroquinone, in particular to a method for co-production of manganese sulfide, magnesium sulfate and ammonium sulfide from manganese-containing waste liquid generated during the hydroquinone production. The method mainly comprises the following steps: firstly the waste liquid generated during the hydroquinone production is filtered by a filtering machine to produce a filtrate, the filtrate is distilled and filtered to produce a filter cake and a filtrate, and the filter cake is deep-processed to obtain a manganese sulfide product; and the filtrate is further distilled under a reduced pressure and then deep-processed to obtain a magnesium sulfate product and an ammonium sulfide product respectively. The method can not only completely eliminate the waste liquid to reduce the environmental pollution due to the waste liquid but also provide the valuable products of manganese sulfide, magnesium sulfate and ammonium sulfide. The method not only has significant social and economic benefits but also simplifies the production process and the production equipment, and is a relatively practical method for treatment and utilization.

Owner:何云

A kind of method utilizing titanium white waste acid to prepare precipitated barium sulfate

ActiveCN107720801BReduce cost pressureReduce pressure on environmental protectionAmmonium sulfides/polysulfidesCalcium/strontium/barium sulfatesFerric hydroxideSodium sulfate

The invention discloses a method for preparing precipitated barium sulfate by utilizing titanium white waste acid, belonging to the technical field of comprehensive utilization of titanium white wasteacid and preparation of barium sulfate. The method comprises the following steps of adding ammonium hydroxide to neutralize with titanium white waste acid firstly, then generating ammonium sulfate, and controlling a systemic pH to separate out photodegredation sediment; then adding the ammonium hydroxide continuously, and controlling the pH to separate out ferrous hydroxide sediment; then addinghydrogen peroxide in proportion, oxidating residual Fe2<+> into Fe3<+>, and adjusting the pH to separate out ferric hydroxide sediment; condensing an ammonium sulfate solution, then replacing a mirabilite solution in a traditional precipitated barium sulfate production process, enabling the ammonium sulfate solution to generate replacement reaction with a barium sulfide solution, and washing, drying and smashing to prepare a precipitated barium sulfate product. According to the method, after neutralizing the titanium white waste acid with the ammonium hydroxide and performing purification andimpurity removal, a traditional sodium sulfate solution is replaced for producing the precipitated barium sulfate, meanwhile, recycled photodegredation sediment can be further used for titanium dioxide production, not only are resources saved, but also waste can be recycled, and the waste acid treatment costs of titanium dioxide plants and environment protection pressure are reduced.

Owner:ANHUI JXTB GRP

Ammonium sulfide solution and processing process thereof

InactiveCN101337682AImprove stabilityImprove securityAmmonium sulfides/polysulfidesAmmonium sulfideNuclear chemistry

The invention relates to the chemical engineering field, in particular to an ammonium sulfide solution and a production process thereof. The content of ammonium sulfide in the ammonium sulfide solution is 10 percent to 45 percent. The ammonium sulfide solution and the production process have the advantages of strong stability and unchanged concentration and is deposit-free, and the color of the ammonium sulfide solution cannot be changed within a year.

Owner:TIANJIN DAGANG YIZHONG CHEM FACTORY

Method for preparing co-product of manganese sulfide and ammonium sulfate as well as ammonium sulfide by manganese-containing waste liquid obtained by producing hydroquinone

InactiveCN102115184AReduce pollutionSimple processAmmonium sulfides/polysulfidesWater/sewage treatmentDistillationAmmonium sulfide

The invention relates to the technical field of the utilization of manganese-containing waste liquid obtained by producing hydroquinone, in particular to a method for preparing co-product of manganese sulfide and ammonium sulfate as well as ammonium sulfide by manganese-containing waste liquid obtained by producing hydroquinone. The method mainly comprises the steps of: firstly, leaching the manganese-containing waste liquid obtained by producing hydroquinone by a leaching machine, and obtaining filtrate for distilling and filtering; carrying out deep processing on a filter cake, and obtaining the manganese sulfide product; and then carrying out reduced pressure distillation on the filtrate, respectively carrying out further deep processing, and obtaining the ammonium sulfate and the ammonium sulfide. The method leads the waste liquid to be cleanly removed so as to reduce the pollution of the waste liquid for the environment, and can be used for preparing the valuable manganese sulfide, ammonium sulfate and ammonium sulfide, thus not only being remarkable in social benefit and economic benefit, but also being simple in technique and production equipment; therefore, the invention is a more practical processing and utilizing method.

Owner:何云

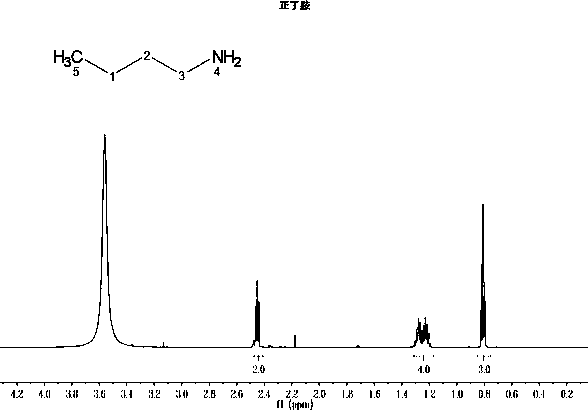

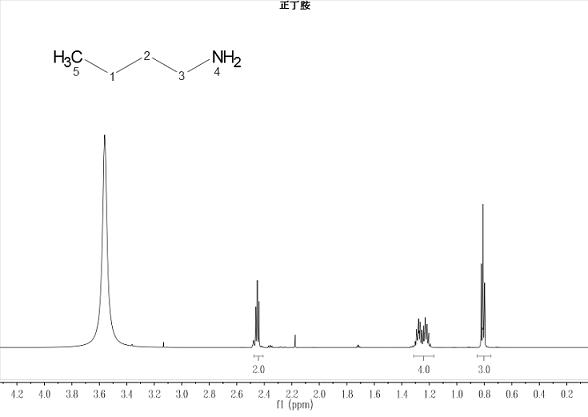

NBPT hazardous waste harmless treatment method

ActiveCN111515215AAchieve the effect of full resource recovery and harmless treatmentSimple methodAmino compound purification/separationAmmonium sulfides/polysulfidesAmmonium sulphideSulfide

The invention relates to an NBPT hazardous waste harmless treatment method. The NBPT hazardous waste harmless treatment method comprises the following steps that firstly, a degradation transforming agent is added in a reaction kettle, NBPT hazardous waste is added, stirring and heating are conducted, ammonia and distilled condensate liquid are obtained, an absorption tower is inflated with the ammonia for water absorption, the distilled condensate liquid is transferred into a normal-pressure rectifying tower, the reaction kettle is subjected to stirring cooling to 25 DEG C-30 DEG C, the distilled condensate liquid is refined at the temperature lower than the n-butylamine boiling point, tower roof extracted liquid is n-butylamine, and tower bottom kettle liquid serves as the degradation transforming agent to return into the reaction kettle; and secondly, a desulfuration transforming agent is added into the reaction kettle with 10 kg / min, the stirring reaction is conducted at 35-55 DEG Cfor 1-2 h, hydrogen sulfide is obtained and led into an ammonium hydroxide absorption tower for chemical absorption, an ammonium sulfide solution with the concentration being 16-20% is obtained, theammonium sulfide solution is subjected to centrifugal separation, filter liquor and filter residue calcium superphosphate are obtained, and the filter liquor serves as the desulfuration transforming agent to return into the reaction kettle. The NBPT hazardous waste harmless treatment method is free of three-waste emission and can reach all resource recycling.

Owner:甘肃金创绿丰环境技术有限公司 +1

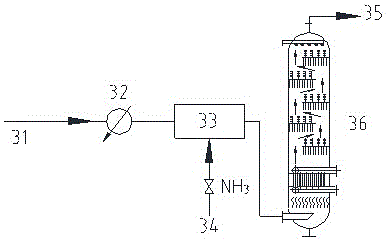

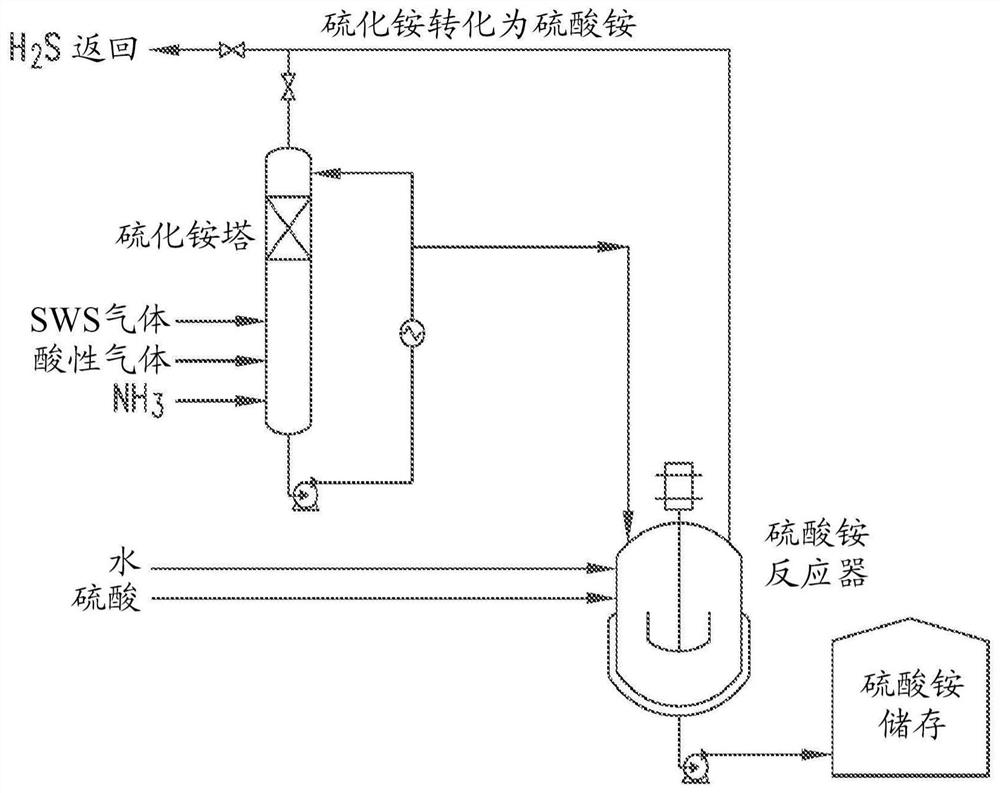

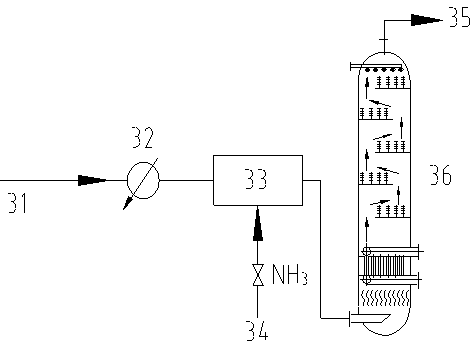

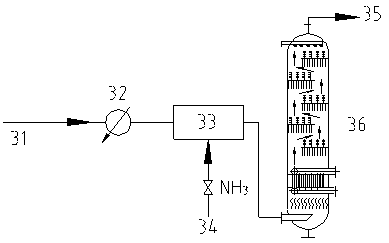

Hydrogen sulphide-containing gas treatment method and device

ActiveCN106345255AIncrease the attachment areaPromote sheddingAmmonium sulfides/polysulfidesDispersed particle separationGas phaseChemistry

The invention discloses a hydrogen sulphide-containing gas treatment device. The device comprises a cooler, a mixer and a crystallization tower; a hydrogen sulphide-containing gas feeding pipeline is connected with an inlet of the cooler; an outlet of the cooler is connected with an inlet of the mixer; the inlet of the mixer is also connected with the hydrogen sulphide-containing gas feeding pipeline; an outlet of the mixer is connected with an inlet of the crystallization tower. The invention also discloses a hydrogen sulphide-containing gas treatment method. According to the hydrogen sulphide-containing gas treatment method and the hydrogen sulphide-containing gas treatment device, the hydrogen sulphide is separated from a hydrogen sulphide-containing gas and simultaneously an ammonium hydrogen sulphide product is obtained by utilizing the characteristic that ammonia gas and hydrogen sulphide perform gas phase reaction to generate ammonium hydrogen sulphide; the method is simple in process and low in energy consumption, is particularly suitable for separating acid gas of a refinery plant; the used crystallization tower has the advantages that crystal substances fall easily, the surface on which the crystal substances can be attached is large and the like.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for preparing manganese sulfide coproduced with potassium sulfate and ammonium sulfide coproduced with manganese sulfide by using manganese-containing waste liquor produced during production of hydroquinone

InactiveCN102115180AReduce pollutionSimple processAmmonium sulfides/polysulfidesSulfate/bisulfate preparationSocial benefitsAmmonium sulfide

The invention relates the technical filed of utilization of manganese-containing waste liquor produced during production of hydroquinone, in particular to a method for preparing manganese sulfide coproduced with potassium sulfate and ammonium sulfide by using the manganese-containing waste liquor produced during the production of hydroquinone. The method mainly comprises the following steps of: performing suction filtration on the waste liquor produced by hydroquinone by using a suction filter machine to obtain filtrate, distilling and filtering the filtrate, and performing deep processing on a filter cake to obtain a manganese sulfide product; and distilling the filtrate under a reduced pressure and performing further deep processing on the filtrate respectively to obtain a potassium sulfate product and an ammonium sulfide product respectively. By adopting the method, the waste liquor can be treated completely, environmental pollution caused by waste liquor is relieved, valuable manganese sulfide, potassium sulfate product and ammonium sulfide products can be prepared, remarkable social benefit and economic benefit are achieved, and process and production equipment are simple. The method is a relatively practical treatment and utilization method.

Owner:何云

Method for preparing manganese sulfide coproduced with lithium sulfate and ammonium sulfide by using manganese-containing waste liquor produced during production of hydroquinone

InactiveCN102115188AReduce pollutionSimple processAmmonium sulfides/polysulfidesWater/sewage treatmentSocial benefitsLithium sulphate

The invention relates the technical filed of utilization of manganese-containing waste liquor produced during production of hydroquinone, in particular to a method for preparing manganese sulfide coproduced with lithium sulfate and ammonium sulfide by using the manganese-containing waste liquor produced during production of hydroquinone. The method mainly comprises the following steps of: performing suction filtration on the waste liquor produced by the hydroquinone by using a suction filter machine to obtain filtrate, distilling and filtering the filtrate, and performing deep processing on a filter cake to obtain a manganese sulfide product; and distilling the filtrate under a reduced pressure and performing further deep processing on the filtrate respectively to obtain a lithium sulfate product and an ammonium sulfide product respectively. By adopting the method, the waste liquor can be treated completely, environmental pollution caused by waste liquor is relieved, valuable manganese sulfide, lithium sulfate and ammonium sulfide products can be prepared, remarkable social benefit and economic benefit are achieved, and process and production equipment are simple. The method is a relatively practical treatment and utilization method.

Owner:何云

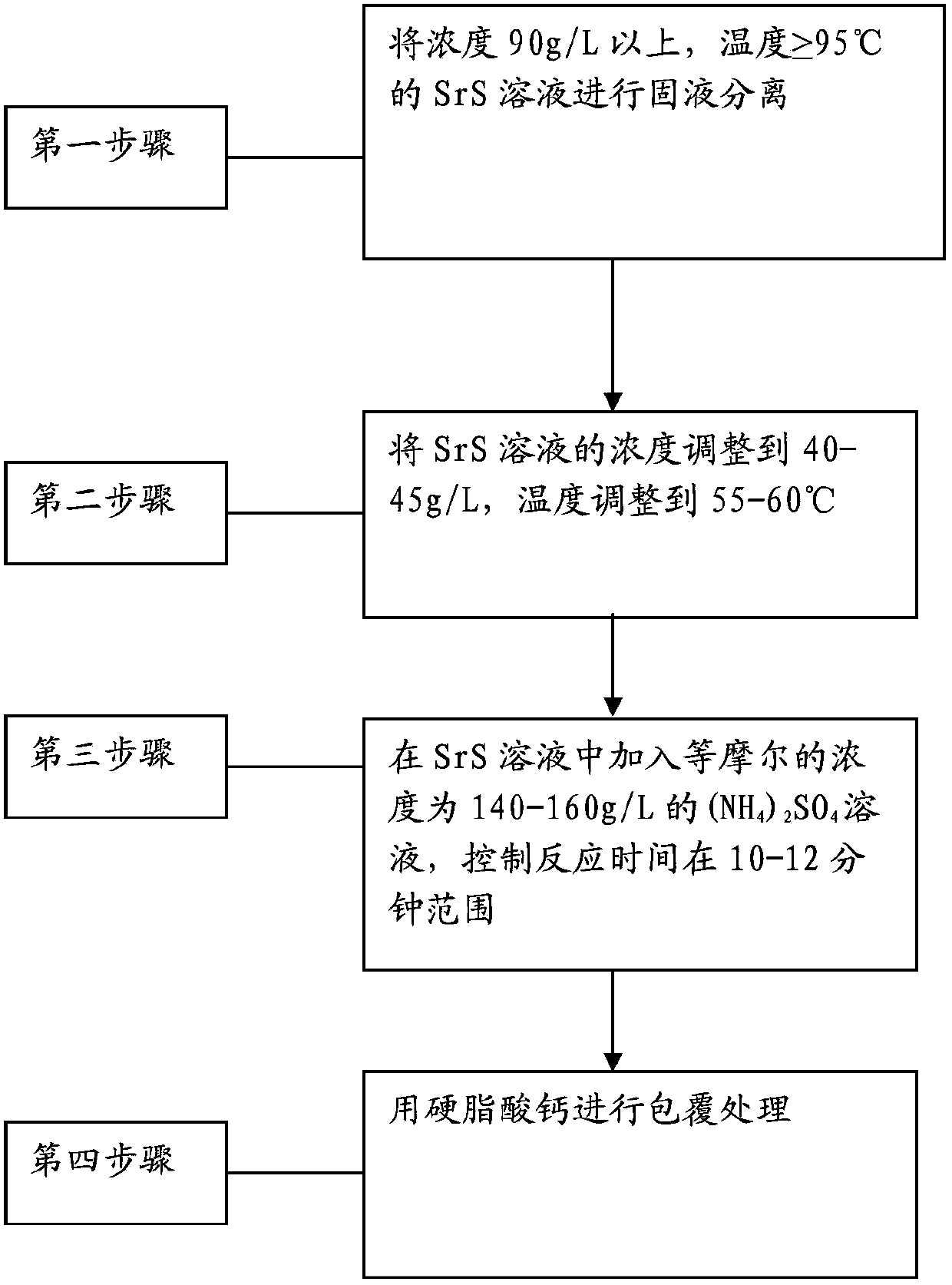

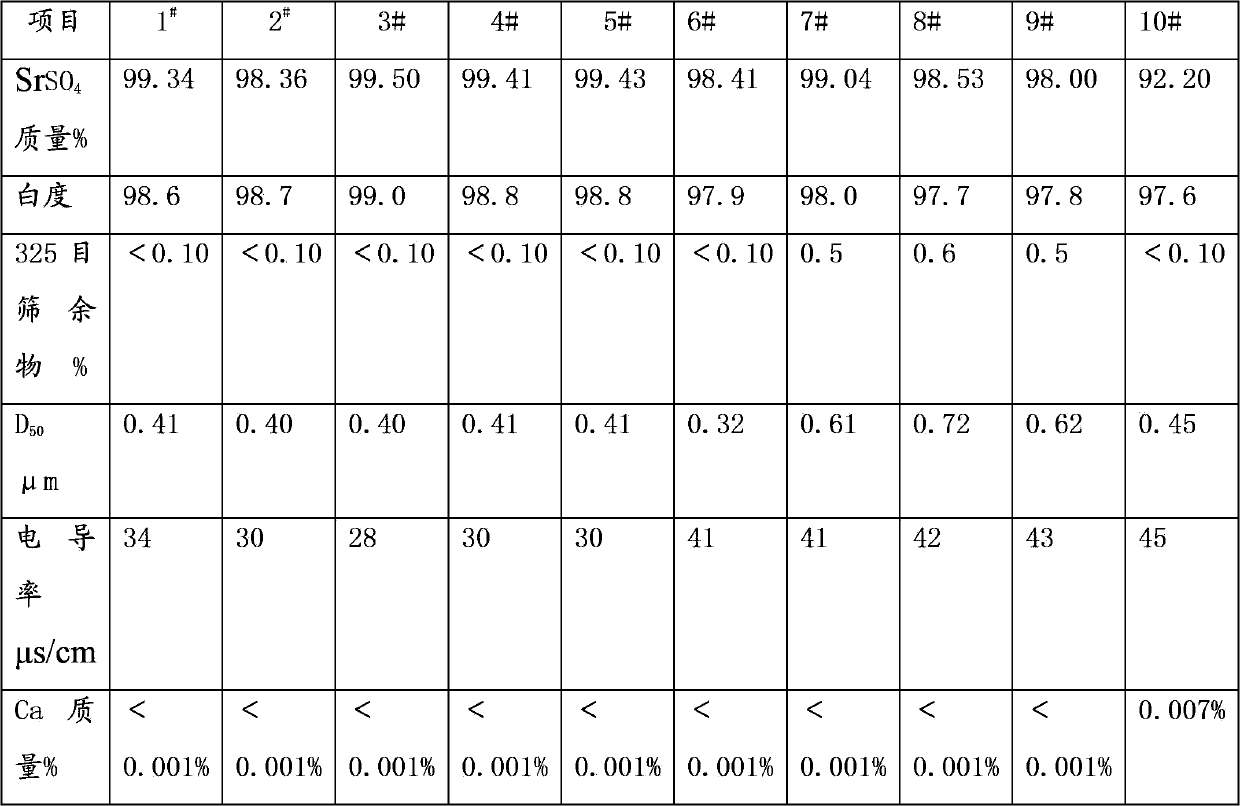

Sub-micron spherical strontium sulfate, and preparation and application thereof

InactiveCN102675922BHigh purityImprove performanceAmmonium sulfides/polysulfidesCalcium/strontium/barium sulfatesDispersityPrinted circuit board

The invention relates to a sub-micron spherical strontium sulfate, and preparation and application thereof. The method comprises the following steps: 1. carrying out solid-liquid separation on an SrS solution of which the concentration is higher than 90 g / L and the temperature is greater than or equal to 95 DEG C; 2. regulating the concentration of the SrS solution obtained in the step 1 to 40-45 g / L, and regulating the temperature to 55-60 DEG C (preferably 57 DEG C); 3. while stirring, adding equal mol of (NH4)2SO4 solution (the concentration is 140-160 g / L, preferably 150 g / L) into the SrS solution obtained in the step 2, controlling the reaction time within the range of 10-12 minutes, and filtering to obtain a filter cake; and 4. coating calcium stearate, which accounts for 0.8-1.5 wt% of the SrSO4, on the filter cake at 90-95 DEG C, thereby obtaining the sub-micron spherical strontium sulfate product. The invention overcomes the defect that the existing strontium sulfate has high electric conductivity and can not be used in a PCB (printed circuit board) paper substrate as a filler. The sub-micron spherical strontium sulfate has the advantages high purity and favorable whiteness, has lower electric conductivity through the treatment of the coating agent, improves the dispersity in the organic system, and satisfies the application as a filler in a paper PCB.

Owner:GUIZHOU REDSTAR DEVING

A method for harmless treatment of n-butylthiophosphoric triamide hazardous waste

ActiveCN111515215BAchieve the effect of full resource recovery and harmless treatmentSimple methodAmino compound purification/separationAmmonium sulfides/polysulfidesThio-Distillation

Owner:甘肃金创绿丰环境技术有限公司 +1

A kind of submicron iron-aluminum spinel and its preparation method and application

InactiveCN104311074BImprove stabilityAmmonium sulfides/polysulfidesAluminium sulfateAmmonium sulfide

The invention relates to sub-micron hercynite. The sub-micron hercynite is characterized in that the grain diameter is below 1.0micron, the hercynite is added into materials for synthesizing a hercynite flame-retardant raw material by a sintering process to serve as seed crystal, and the sintering temperature can be reduced. The invention further provides a method for preparing the sub-micron hercynite. The method comprises the following steps: respectively preparing a ferrous sulfate solution and an aluminum sulfate solution; sequentially adding the ferrous sulfate solution and the aluminum sulfate solution into a reactor, mixing, adding an ammonium sulfide solution into the mixed solution, and filtering after mixed precipitation is generated; carrying out vacuum drying and roasting on a filter cake to obtain the sub-micron hercynite; and distillating, concentrating and crystallizing the filtrate to obtain ammonium sulfate.

Owner:SHANDONG UNIV OF TECH

A cleaning pretreatment method for low-grade complex nickel-molybdenum ore

ActiveCN108517408BReduce contentEasy to cleanZinc halidesAmmonium sulfides/polysulfidesPretreatment methodAmmonium sulfide

The invention provides a low-grade complex nickel-molybdenum ore cleaning pretreatment method. Nickel-molybdenum ores, a chlorinating agent and water are uniformly mixed at the specific proportions and then subjected to pelleting, material balls after being pelleted are directly placed in a volatilization furnace without being dried, and chlorination volatilization and smelting are conducted undera specific warming mechanism. Products such as molybdenum chloride, zinc chloride, arsenic chloride, nickel chloride, ammonium sulfide and ammonium sulfate in the smoke generated by volatilization are recycled respectively in a smoke collection device. The method can treat various kinds of low-grade and complex nickel-molybdenum ores, molybdenum, zinc, nickel and other valuable components in thenickel-molybdenum ores can be separated in a one-step mode, sulphur can be recycled in the forms of ammonium sulfide, ammonium sulfate and the like, and emission of low-concentration SO2 is avoided. Meanwhile, harmful components such as concomitant arsenic in the nickel-molybdenum ores can be deeply volatilized and removed, and the volatile residue obtained through volatilization is harmless to the environment. Compared with an existing nickel-molybdenum ore treatment method, the method has the advantages that the energy consumption is low, the efficiency is high, and the clean and environment-friendly effects are achieved.

Owner:CENT SOUTH UNIV

Crystallization column and crystallization method

ActiveUS10384148B2Simple structureLow costAmmonium sulfides/polysulfidesDispersed particle separationEngineeringTower

A crystallization column and a crystallization method. The crystallization column comprises an upper head (1), a tower body (2) and a lower head (3), wherein a crystallization section (11) is provided with a tray (14); and the tray (14) comprises a tray plate (15) and a plurality of lower crystallization members (17). The top end of the lower crystallization member (17) can form a movable connection with the tray plate (15), so that the two adjacent lower crystallizing members (17) are capable of oscillating collisions. The tray (14) may also comprise a plurality of upper crystallization members (21) extending upwardly from the upper surface of the tray plate (15).

Owner:CHINA PETROCHEMICAL CORP +1

Ammonium sulfide solution and production process thereof

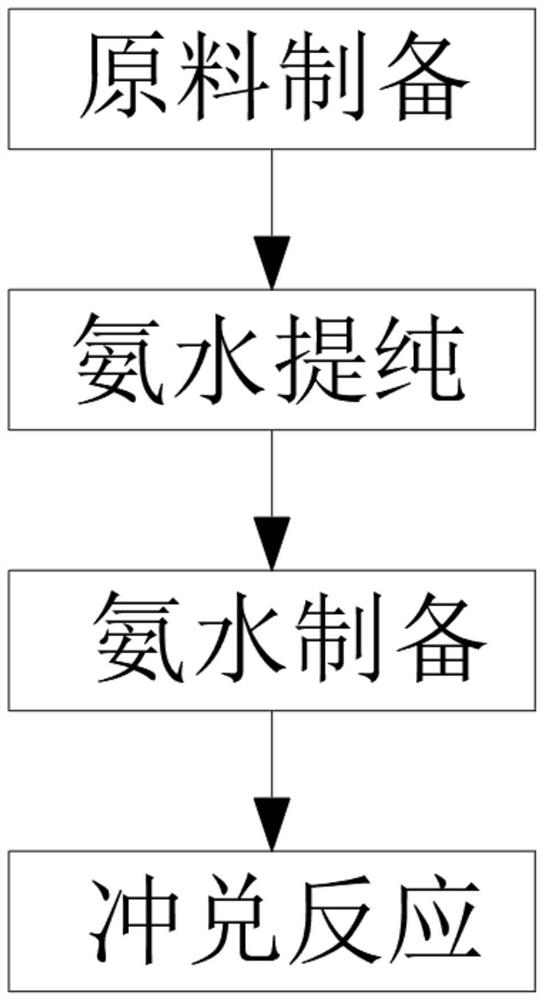

InactiveCN112194152AReduce volatilityImprove concentration accuracyAmmonium sulfides/polysulfidesAmmonium sulphideSulfidation

The invention relates to the technical field of sodium sulfide solution preparation, in particular to an ammonium sulfide solution and a production process thereof. The ammonium sulfide solution is composed of water and ammonium sulfide, the content of ammonium sulfide in the ammonium sulfide solution ranges from 15% to 40%, and the ammonium sulfide solution is stored in a storage tank in a sealedmode. The solution has the beneficial effects that production is carried out in a mode of preparing the ammonia water on site, so that volatilization of the ammonia water in the storage process is greatly reduced, the concentration precision of the ammonia water is improved, errors are reduced, the concentration error of the produced sodium sulfide is reduced, meanwhile, the reaction efficiency and solubility are improved by utilizing the gas storage tank and controlling the temperature, gas leakage caused in the dissolving process is avoided, so that the production safety and stability are improved, and compared with the traditional technology, the process is more stable and safer in production and higher in precision.

Owner:吉安天卓选矿药剂有限公司

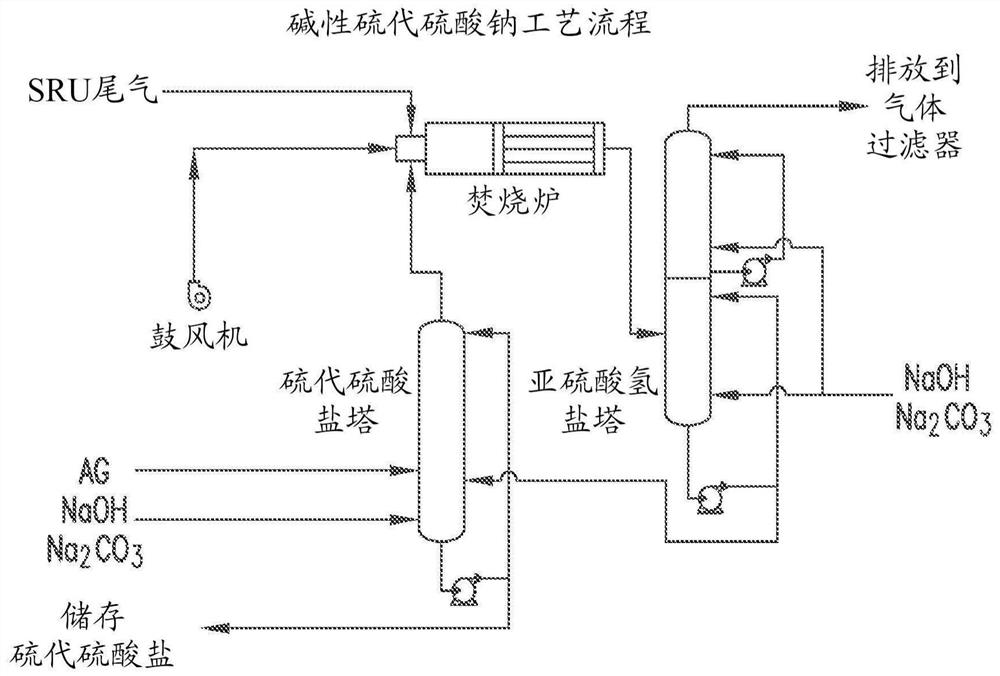

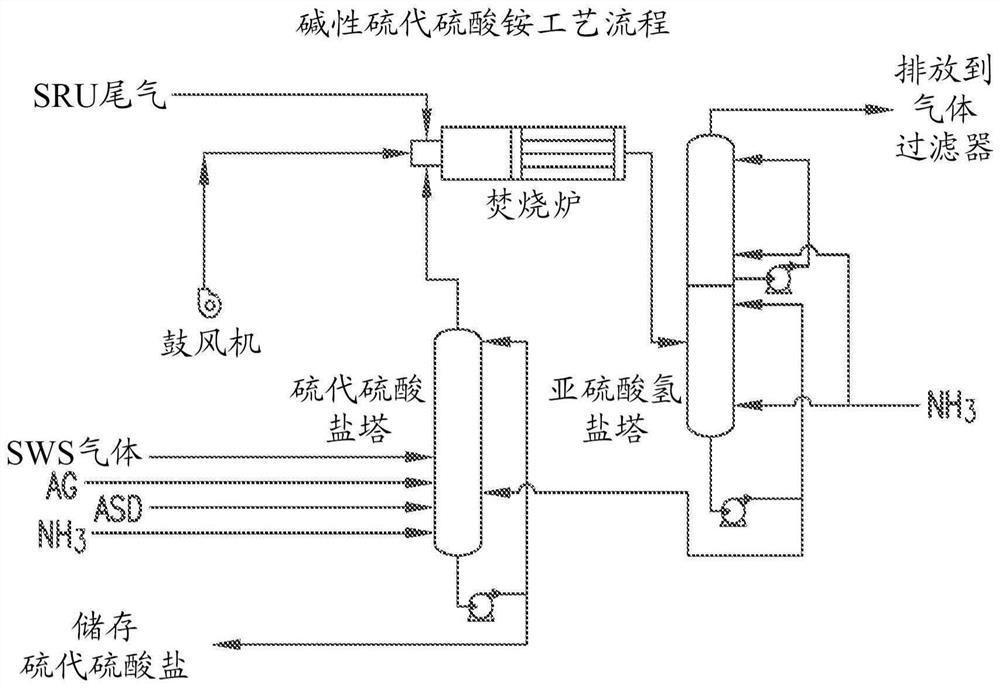

Product produced from off-gas stream containing H2S, SO2 and/or NH3

PendingCN114364632AThe result is obviousCalcareous fertilisersMagnesium fertilisersGas liquid chromatographicSulfuryl

Owner:TESSENDERLO CHEM

Method and device for treating gas containing hydrogen sulfide

ActiveCN106345254BIncrease the attachment areaEasy to peel offAmmonium sulfides/polysulfidesDispersed particle separationGas phaseAcid gas

The invention discloses a device for treating hydrogen sulfide-containing gas. The device comprises a cooler, a mixer and a crystallizing tower, wherein a hydrogen sulfide-containing gas feeding pipeline is connected with the inlet of the cooler; the outlet of the cooler is connected with the inlet of the mixer; the inlet of the mixer is connected with an ammonia gas feeding pipeline; the outlet of the mixer is connected with the gas inlet of the crystallizing tower. The invention further discloses a method for treating the hydrogen sulfide-containing gas. According to the method and the device for treating the hydrogen sulfide-containing gas, separation of hydrogen sulfide from the hydrogen sulfide-containing gas is realized based on the characteristic that ammonia gas and hydrogen sulfide generate gas-phase reaction to produce sulfur ammonium hydrogen, and a sulfur ammonium hydrogen product is obtained; the method is simple in process, low in energy consumption, and particularly applicable to separation of refinery acid gas; the crystallizing tower has the advantages of easiness in falling of crystal substances, large surface area of attachable crystal substances and the like.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation method of sulfur positive electrode composite material based on high-energy density type graphene

InactiveCN114506845AMeet the requirements of industrializationAmmonium sulfides/polysulfidesCarbon compoundsHigh energySodium nitrate

The invention discloses a preparation method of a sulfur positive electrode composite material based on high-energy density type graphene, which comprises the following steps: adding graphite powder, sodium nitrate and potassium permanganate into concentrated sulfuric acid, and stirring to slowly heat; after the solution is reacted and heated, adding deionized water and a reducing agent, filtering and drying to obtain graphite oxide; the preparation method comprises the following steps: performing ultrasonic treatment on graphite oxide to obtain a dispersion liquid A, heating to 80-90 DEG C, adding hydrazine hydrate, filtering, washing and drying to obtain graphene oxide; adding water into graphene oxide, and performing ultrasonic treatment to obtain dispersion liquid B; adding water into inorganic sulfide, stirring and dissolving to obtain a sulfur solution C; and mixing the dispersion liquid B and the sulfur solution C until the reaction is complete, adding dilute acid to adjust the solution to be acidic, filtering and drying to obtain the graphene / sulfur positive electrode composite material, the capacity is 1186 mAh.g <-1 > under the charging condition of 0.1 DEG C, the coulombic efficiency is 96% after 200 times of circulation, the capacity is 997 mAh.g <-1 > under the charging condition of 1 DEG C, and the capacity is 578 mAh.g <-1 > after 1000 times of circulation.

Owner:绿宸新能源科技苏州有限公司

Low-grade complex nickel-molybdenum ore cleaning pretreatment method

ActiveCN108517408AGood for volatilizationVolatile atmosphere is goodZinc halidesAmmonium sulfides/polysulfidesPretreatment methodAmmonium sulfide

The invention provides a low-grade complex nickel-molybdenum ore cleaning pretreatment method. Nickel-molybdenum ores, a chlorinating agent and water are uniformly mixed at the specific proportions and then subjected to pelleting, material balls after being pelleted are directly placed in a volatilization furnace without being dried, and chlorination volatilization and smelting are conducted undera specific warming mechanism. Products such as molybdenum chloride, zinc chloride, arsenic chloride, nickel chloride, ammonium sulfide and ammonium sulfate in the smoke generated by volatilization are recycled respectively in a smoke collection device. The method can treat various kinds of low-grade and complex nickel-molybdenum ores, molybdenum, zinc, nickel and other valuable components in thenickel-molybdenum ores can be separated in a one-step mode, sulphur can be recycled in the forms of ammonium sulfide, ammonium sulfate and the like, and emission of low-concentration SO2 is avoided. Meanwhile, harmful components such as concomitant arsenic in the nickel-molybdenum ores can be deeply volatilized and removed, and the volatile residue obtained through volatilization is harmless to the environment. Compared with an existing nickel-molybdenum ore treatment method, the method has the advantages that the energy consumption is low, the efficiency is high, and the clean and environment-friendly effects are achieved.

Owner:CENT SOUTH UNIV

A kind of treatment method and device of hydrogen sulfide-containing gas

ActiveCN106345255BIncrease the attachment areaPromote sheddingAmmonium sulfides/polysulfidesDispersed particle separationGas phaseAcid gas

Owner:CHINA PETROLEUM & CHEM CORP +1

Process and reactor system for the preparation of an olefinic product

InactiveUS9120069B2Ammonium sulfides/polysulfidesHydrocarbon from oxygen organic compoundsReactor systemAlkene

A process and a reactor system for the preparation of an olefinic product by reacting an oxygenate feedstock in the presence of an oxygenate conversion catalyst within a reactor system under oxygenate-to-olefin conversion conditions, to obtain the olefinic product, wherein the reactor system has a contact surface coming in contact with oxygenates and wherein at least part of the contact surface is an material of the formula MX wherein: M is a metal and X is C, or M is a metal or Si and X is N.

Owner:SHELL OIL CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com