Ammonium sulfide solution and production process thereof

A production process and technology for ammonium sulfide, applied in the field of sodium sulfide solution preparation, can solve the problems of improving the production safety of ammonium sulfide production concentration, difficult to control the concentration of ammonium sulfide solution, high production risk, etc., so as to improve reaction efficiency and solubility , Improve production safety and stability, the effect of stable and safe production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] An ammonium sulfide solution comprises ammonium sulfide solution. The ammonium sulfide solution is composed of water and ammonium sulfide. The content of ammonium sulfide in the ammonium sulfide solution is 25%. The ammonium sulfide solution is sealed and stored in a storage tank.

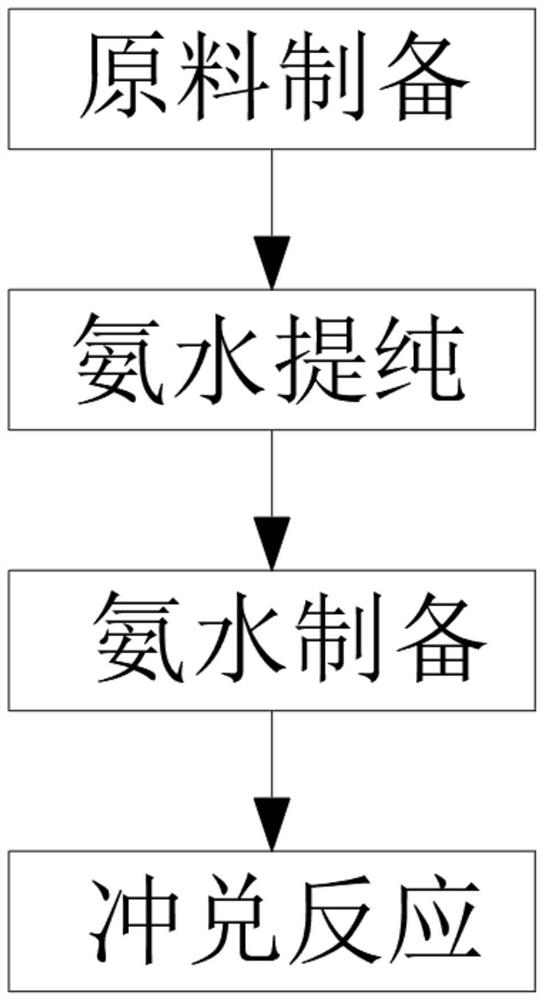

[0023] A kind of production technique of ammonium sulfide solution, this production technique comprises the following steps:

[0024] Step 1: raw material preparation, the preparation raw material of ammonium sulfide solution is sodium sulfide and sulfuric acid, measure the sodium sulfide solid of 5 parts per unit mass and 100ml concentration be the sulfuric acid solution of 30%, the sodium sulfide solid and sulfuric acid solution that measure are put into In the reaction tank, the sodium sulfide solid and the sulfuric acid solution are distributed into the reaction tank. The sulfuric acid solution is first put into the reaction tank and then the sodium sulfide solid is poured into the reacti...

Embodiment 2

[0029] An ammonium sulfide solution comprises ammonium sulfide solution. The ammonium sulfide solution is composed of water and ammonium sulfide. The content of ammonium sulfide in the ammonium sulfide solution is 30%. The ammonium sulfide solution is sealed and stored in a storage tank.

[0030] A kind of production technique of ammonium sulfide solution, this production technique comprises the following steps:

[0031] Step 1: raw material preparation, the preparation raw material of ammonium sulfide solution is sodium sulfide and sulfuric acid, measure the sodium sulfide solid of 8 parts of unit mass and 100ml concentration be the sulfuric acid solution of 40%, put the sodium sulfide solid and sulfuric acid solution that measure into In the reaction tank, the sodium sulfide solid and the sulfuric acid solution are distributed into the reaction tank. The sulfuric acid solution is first put into the reaction tank and then the sodium sulfide solid is poured into the reaction ta...

Embodiment 3

[0036] An ammonium sulfide solution comprises ammonium sulfide solution. The ammonium sulfide solution is composed of water and ammonium sulfide. The content of ammonium sulfide in the ammonium sulfide solution is 40%. The ammonium sulfide solution is sealed and stored in a storage tank.

[0037] A kind of production technique of ammonium sulfide solution, this production technique comprises the following steps:

[0038] Step 1: raw material preparation, the preparation raw material of ammonium sulfide solution is sodium sulfide and sulfuric acid, measure the sodium sulfide solid of 10 parts per unit mass and 100ml concentration be the sulfuric acid solution of 50%, the sodium sulfide solid and sulfuric acid solution that measure are put into In the reaction tank, the sodium sulfide solid and the sulfuric acid solution are distributed into the reaction tank. The sulfuric acid solution is first put into the reaction tank and then the sodium sulfide solid is poured into the react...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com