A method for harmless treatment of n-butylthiophosphoric triamide hazardous waste

A technology for n-butyl thiophosphoric triamide and hazardous waste, which is applied in chemical instruments and methods, ammonium sulfide/polysulfide, amino compound purification/separation, etc., to achieve the effect of simple and easy implementation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Example 1 A method for harmless treatment of n-butylthiophosphoric triamide hazardous waste, comprising the following steps:

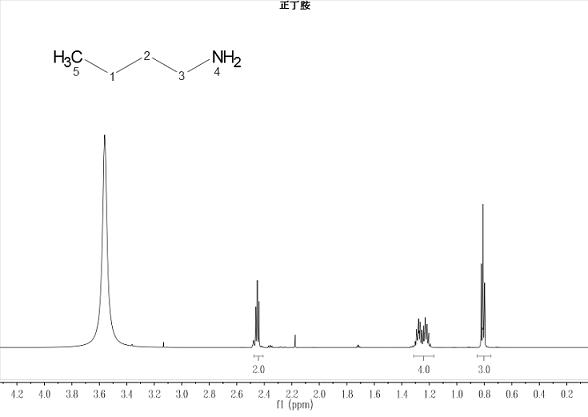

[0020] (1) Add 210kg of quicklime solution with a mass concentration of 40% into the reactor, add 100kg of n-butylthiophosphoric triamide hazardous waste (NBPTHW), stir and heat to 40~45°C, and keep it warm for 1 hour; then heat up to 85~95°C, keep warm for 3 hours until no distillation condensate overflows, and obtain 20kg ammonia gas and 48kg distillation condensate respectively. The ammonia gas is passed into the absorption tower to be absorbed by water, and the mass concentration of the absorbed ammonia water is adjusted to 8-10%, which is used in the subsequent process to absorb hydrogen sulfide; the distillation condensate is n-butylamine aqueous solution.

[0021] The distillation condensate is transferred to the atmospheric distillation column. At this time, the reaction kettle is stirred and cooled to 25°C~30°C; the distillation condens...

Embodiment 2

[0023] Example 2 A method for the harmless treatment of n-butylthiophosphoric triamide hazardous waste, comprising the following steps:

[0024] (1) Add 240kg of quicklime solution with a mass concentration of 35% into the reactor, add 100kg of n-butylthiophosphoric triamide hazardous waste (NBPTHW), stir and heat to 40~45°C, and keep it warm for 1 hour; then heat up to 85~95°C, keep warm for 3 hours until no distillation condensate overflows, and obtain 20kg ammonia gas and 48kg distillation condensate respectively. The ammonia gas is passed into the absorption tower to be absorbed by water, and the mass concentration of the absorbed ammonia water is adjusted to 8-10%, which is used in the subsequent process to absorb hydrogen sulfide; the distillation condensate is n-butylamine aqueous solution.

[0025] The distillation condensate is transferred to the atmospheric distillation column. At this time, the reaction kettle is stirred and cooled to 25°C~30°C; the distillation con...

Embodiment 3

[0027] Example 3 A method for the harmless treatment of n-butylthiophosphoric triamide hazardous waste, comprising the following steps:

[0028] (1) Add 296kg of slaked lime solution with a mass concentration of 30% into the reactor, add 100kg of n-butylthiophosphoric triamide hazardous waste (NBPTHW), stir and heat to 40~45°C, and keep it warm for 1 hour; then heat up to 85~95°C, keep warm for 3 hours until no distillation condensate overflows, and obtain 20kg ammonia gas and 48kg distillation condensate respectively. The ammonia gas is passed into the absorption tower to be absorbed by water, and the mass concentration of the absorbed ammonia water is adjusted to 8-10%, which is used in the subsequent process to absorb hydrogen sulfide; the distillation condensate is n-butylamine aqueous solution.

[0029] The distillation condensate is transferred to the atmospheric distillation column. At this time, the reaction kettle is stirred and cooled to 25°C~30°C; the distillation c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com