Method and device for treating gas containing hydrogen sulfide

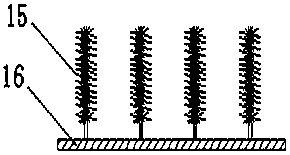

A hydrogen sulfide and gas technology, applied in chemical instruments and methods, separation methods, ammonium sulfide/polysulfide, etc., can solve the problems of expensive desulfurization catalysts, solid waste generation, low purity of sulfur products, etc., and achieve increased crystal adhesion. Area, reduce energy consumption, the effect of large surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

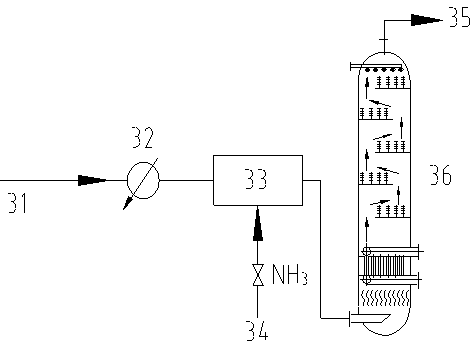

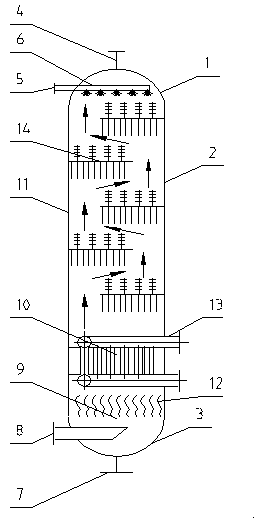

[0057] use as figure 1 The shown treatment method and device use acid gas as raw material for treatment. CO in acid gas 2 The volume fraction is 94%, H 2 The volume fraction of S is 5%, and the volume fraction of hydrocarbons is 1%. In embodiment 1, crystallization tower structure is as figure 2 shown. The acid gas is first cooled by 20°C through the cooler, and then mixed evenly with ammonia gas in the mixer. The feed molar ratio of acid gas and ammonia gas is 2:3. The mixed stream enters the crystallization tower to obtain gas phase stream and ammonium hydrogen sulfide crystallization. The ammonium hydrosulfide crystals are deposited on the crystallization column in the crystallization tower. The results of material analysis are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com