Method for recycling treated ladle refining waste residues

A ladle refining and recycling technology, applied in recycling technology, chemical instruments and methods, and improvement of process efficiency, can solve problems such as difficulty in taking into account large quantities and low-cost processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

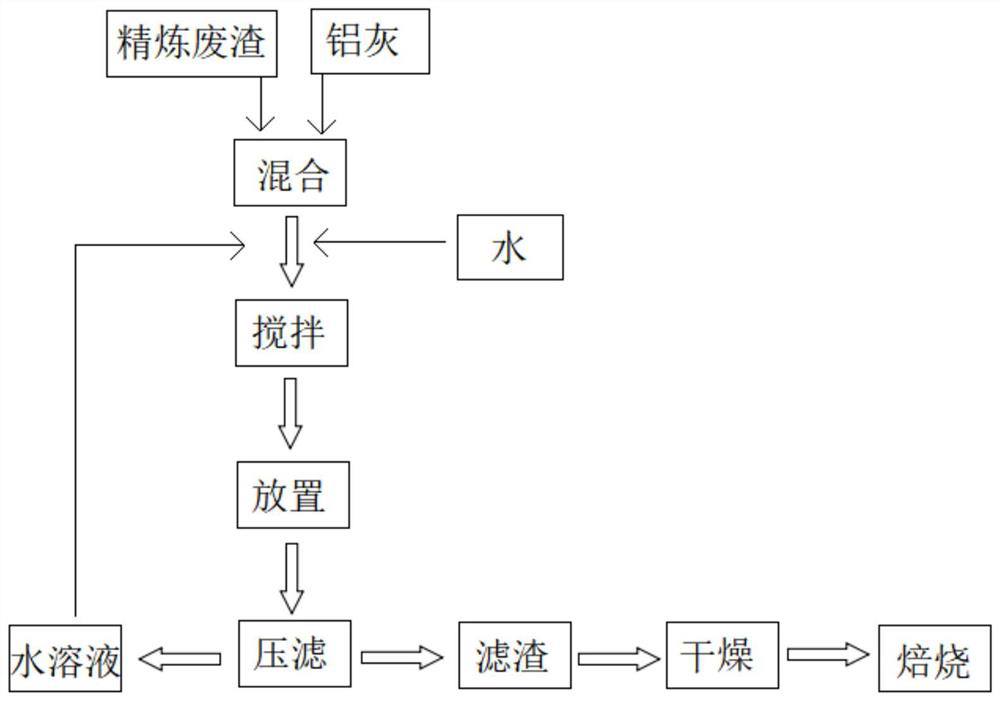

[0032] Such as figure 1 As shown, a method for recycling ladle refining waste slag in this embodiment after treatment includes the following steps:

[0033] S1: Mixing solid waste: mixing ladle refining waste slag and secondary aluminum ash in a certain proportion, so that N / S=1~2 in the mixed mixture, wherein ladle refining waste slag includes the following components in mass percentage: 40%~55% %CaO, 8%~20%SiO 2 ,8%~30%Al 2 o 3 , 0.5%≤(FeO+MnO), 0.3%~1.2% S and a small amount of other components. Secondary aluminum ash includes the following components in mass percentage: 50% to 60% Al 2 o 3 , 1% to 10% Al, 5% to 30% AlN, 3% to 6% SiO 2 , 1%≤(FeO+MnO), 2%~3%MgO, 1%~3%Na 2 O and a small amount of other ingredients.

[0034] S2: Water immersion of the mixture: mix and stir the above mixture and water according to the ratio of 1:2 to 1:3, and leach at room temperature. Specifically, in this embodiment, put the mixture in the leaching tank, Add water, stir for 20min to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com