A kind of submicron iron-aluminum spinel and its preparation method and application

A Fe-Al spinel, sub-micron technology, applied in the field of refractory materials, can solve the problem of high energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

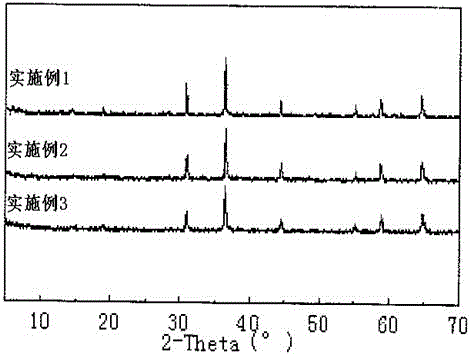

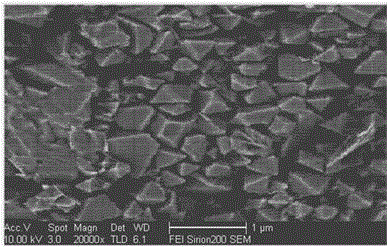

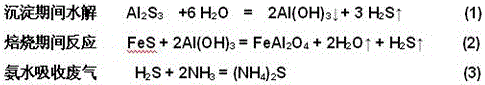

Embodiment 1

[0015] Prepare 8wt% ferrous sulfate solution and 45wt% aluminum sulfate solution respectively, these two kinds of solutions add reactor successively, add the ammonium sulfide solution that concentration is 5wt% in mixed solution; The mol ratio of three kinds of reactants is: Fe : Al: S = 1:2.03: 4.15. Filtrate, put the filter cake in a vacuum furnace, evacuate to a vacuum degree of 0.08MPa, raise the temperature to 150°C in 1 hour, then rise to 900°C in 1.5 hours and keep the temperature at a constant temperature for 3 hours, and naturally cool down to 160°C while maintaining the vacuum condition , took out the roasted sample, and measured its X-ray diffraction spectrum as shown in figure 1 ;From figure 1 It can be seen that the prepared sample belongs to spinel with higher purity; the scanning electron microscope image of the sample is shown in figure 2 ,From figure 2 It can be seen that the particle diameters are basically in the submicron range of 0.1-0.9 microns; the ...

Embodiment 2

[0017] Prepare 23wt% ferrous sulfate solution and 28wt% aluminum sulfate solution respectively, these two kinds of solutions add reactor successively, add the ammonium sulfide solution that concentration is 12wt% in mixed solution; The mol ratio of three kinds of reactants is: Fe : Al: S =1: 2.20: 4.50. Filtrate, put the filter cake in a vacuum furnace, evacuate to a vacuum degree of 0.09MPa, heat up to 150°C in 2 hours, then rise to 1000°C in 2.5 hours and keep the temperature for 2 hours, and cool down naturally to 160°C while maintaining the vacuum condition , took out the roasted sample, and measured its X-ray diffraction spectrum as shown in figure 1 ;From figure 1 It can be seen that the prepared sample belongs to spinel with high purity; from the scanning electron microscope image of the sample (figure omitted), it can be seen that the particle diameter is basically in the submicron range of 0.1-0.9 microns; the filtrate is evaporated and concentrated, cooled and cryst...

Embodiment 3

[0019] Prepare 38wt% ferrous sulfate solution and 10wt% aluminum sulfate solution respectively, these two kinds of solutions add reactor successively, add the ammonium sulfide solution that concentration is 20wt% in mixed solution; The mol ratio of three kinds of reactants is: Fe : Al: S =1: 2.16: 4.34. Filtrate, put the filter cake in a vacuum furnace, evacuate to a vacuum degree of 0.09MPa, raise the temperature to 150°C in 1.5 hours, then rise to 900°C in 4 hours and keep the temperature at a constant temperature for 3 hours, and naturally cool down to 160°C while maintaining the vacuum condition Left and right, take out the roasted sample, measure its X-ray diffraction spectrum and see figure 1 ;From figure 1 It can be seen that the prepared sample belongs to iron-aluminum spinel with high purity; from the scanning electron microscope image of the sample (figure omitted), it can be seen that the particle diameter is basically in the submicron range of 0.1-0.9 microns; the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com