Sub-micron spherical strontium sulfate, and preparation and application thereof

A sub-micron strontium sulfate technology, applied in the direction of calcium/strontium/barium sulfate, fibrous filler, ammonium sulfide/polysulfide, etc., can solve the problem of high conductivity of strontium sulfate and avoid the increase of conductivity , Low impurity ions, high purity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

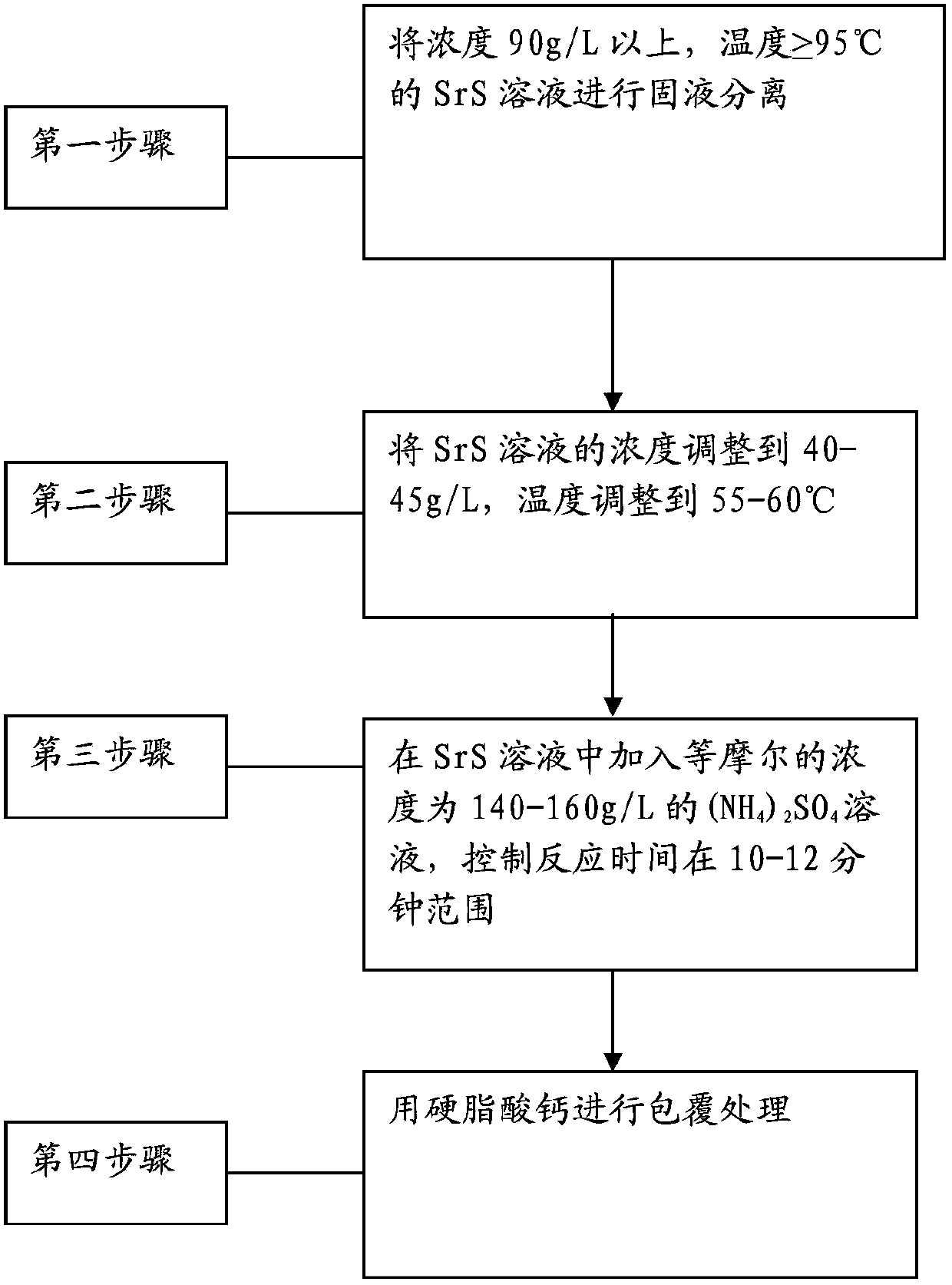

[0034] A preparation method of submicron spherical strontium sulfate, the method comprises the following steps: the first step, the SrS solution with a concentration above 90g / L and a temperature ≥ 95°C is subjected to solid-liquid separation; the second step is the first step The concentration of the obtained SrS solution is adjusted to 40-45g / L, and the temperature is adjusted to 55-60°C (preferably 57°C); in the third step, under stirring, add an equimolar concentration of 140-160g to the SrS solution obtained in the second step / L (preferably 150g / L) (NH 4 ) 2 SO 4 Solution, control the reaction time in the range of 10-12 minutes, and then filter to obtain the filter cake; the fourth step, at a temperature of 90-95 ° C, use SrSO 4 In terms of weight, the obtained filter cake is coated with calcium stearate according to the proportion of 0.8-1.5% by weight to obtain a submicron spherical strontium sulfate product.

[0035] A kind of submicron spherical strontium sulfate ...

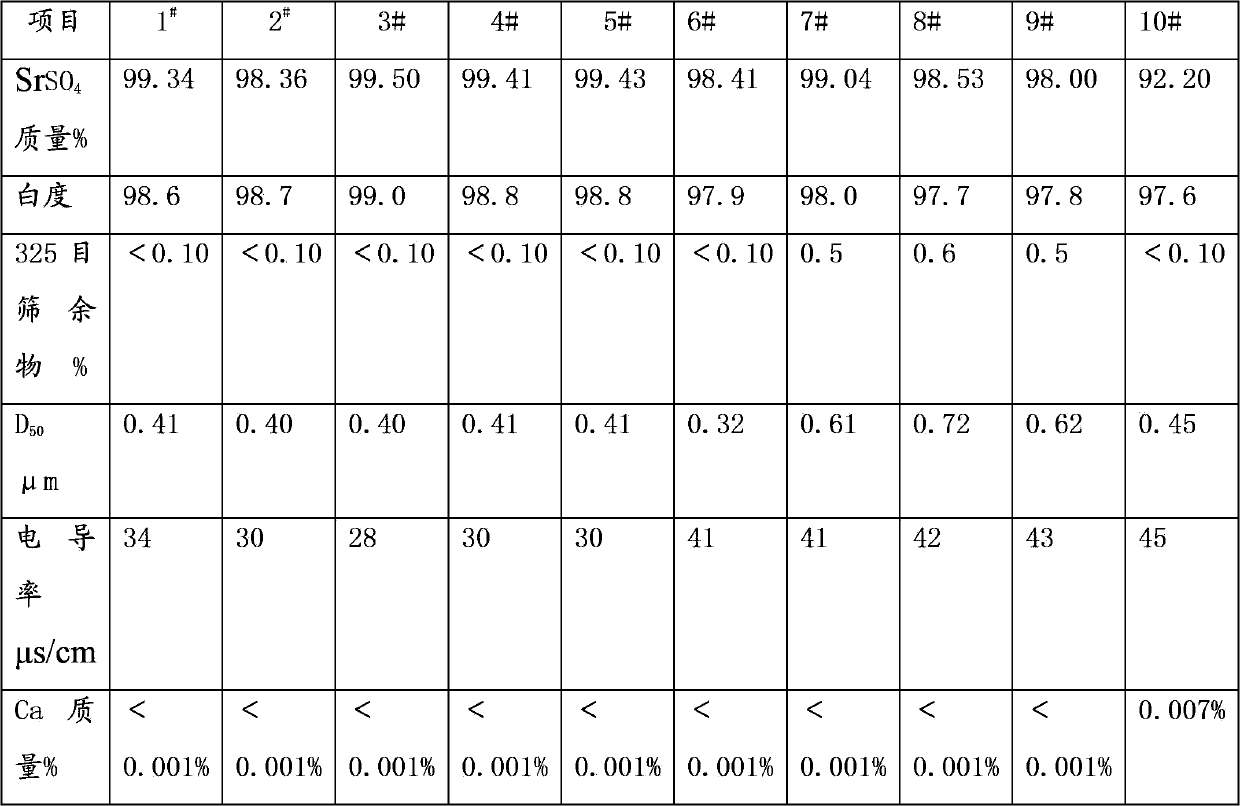

Embodiment 1

[0051] The concentration of the SrS solution was controlled at 90g / L, and the temperature of the solution was controlled at 95°C, then pressed and filtered, and the obtained clear filtrate was diluted with water to a SrS concentration of 40g / L. The SrS solution with a concentration of 40g / L was heated to 55°C, then placed in a synthesis reaction pot, the stirring speed was controlled at 30rpm, and an equimolar concentration of 140g / L (NH 4 ) 2 SO 4 solution, control the reaction time in the range of 10 minutes, then squeeze and filter, and the filtrate is recovered (NH 4 ) 2 S.

[0052] According to the ratio of material to water 1:5, use deionized water to beat the filtered cake into slurry, heat up and control the temperature of the slurry at 60°C, then adjust the pH value of the slurry to 1.5 with a sulfuric acid solution with a mass concentration of 98%, and then , stirred and washed for 1.5 hours, pressed and filtered to obtain a filter cake.

[0053] According to th...

Embodiment 2

[0056] The concentration of the SrS solution was controlled at 97g / L, and the temperature of the solution was controlled at 99°C, and then press-filtered, and the obtained clear filtrate was diluted with water to a SrS concentration of 45g / L. The SrS solution with a concentration of 45g / L was heated to 60°C, then placed in a synthesis reaction pot, the stirring speed was controlled at 35rpm, and an equimolar concentration of 160g / L (NH 4 ) 2 SO 4 solution, control the reaction time in the range of 12 minutes, then squeeze and filter, and the filtrate is recovered (NH 4 ) 2 S.

[0057] According to the ratio of material to water 1:5, use deionized water to beat the filtered cake into slurry, heat up and control the temperature of the slurry at 70°C, then adjust the pH of the slurry to 2.0 with a sulfuric acid solution with a mass concentration of 98%, and then , stirred and washed for 2.5 hours, pressed and filtered to obtain a filter cake.

[0058] According to the materi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| whiteness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com